Introduction: Navigating the Global Market for machining tolerances

In the competitive landscape of international manufacturing, sourcing high-quality machining tolerances can pose significant challenges for B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. The precision required in machining tolerances directly impacts product performance, assembly compatibility, and overall operational efficiency. This guide serves as a comprehensive resource, detailing the various types of machining tolerances, their applications across different industries, and essential supplier vetting criteria.

By delving into the intricacies of machining tolerances, including calculation methods and industry standards, this guide equips buyers with the knowledge needed to make informed decisions. It explores the implications of tolerances on cost, quality, and lead times, helping businesses navigate the complexities of global sourcing effectively. Additionally, the guide provides actionable insights on how to optimize tolerance specifications to enhance product quality while managing costs.

Whether you are a manufacturer in Brazil seeking reliable suppliers in Europe or a procurement manager in Vietnam looking to understand the nuances of tolerances in CNC machining, this guide empowers you to streamline your purchasing process. By leveraging the information within, B2B buyers can enhance their competitive edge, ensuring that they not only meet market demands but also exceed customer expectations.

Understanding machining tolerances Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bilateral Tolerance | Allows variation in both directions from a nominal size | General manufacturing, automotive | Pros: Flexibility in production; Cons: Can lead to ambiguity in fit. |

| Unilateral Tolerance | Variation allowed only in one direction | Aerospace, precision instruments | Pros: Greater control over critical dimensions; Cons: Limited flexibility may increase costs. |

| Geometric Dimensioning | Uses symbols to define tolerance conditions | Complex assemblies, high-precision parts | Pros: Enhanced clarity and accuracy; Cons: Requires specialized knowledge to interpret. |

| Maximum Material Condition | Focuses on the maximum size to ensure fit | Assembly operations, structural components | Pros: Guarantees compatibility; Cons: May limit manufacturing options. |

| Least Material Condition | Focuses on the minimum size for functionality | Electrical components, fittings | Pros: Allows for greater assembly tolerance; Cons: Risk of reduced strength in critical parts. |

What are the Characteristics of Bilateral Tolerance and Its Suitability for B2B Buyers?

Bilateral tolerance permits deviations in both positive and negative directions from a specified nominal dimension. This flexibility makes it suitable for a wide range of applications, particularly in general manufacturing and the automotive sector, where parts may need to fit together without exacting precision. B2B buyers should consider the balance between flexibility and the potential for fit issues, as ambiguous tolerances can lead to discrepancies during assembly.

How Does Unilateral Tolerance Offer Precision in Manufacturing?

Unilateral tolerance allows variation in only one direction, providing precise control over critical dimensions. This type of tolerance is commonly used in aerospace and precision instruments, where exact measurements are crucial for safety and performance. Buyers must weigh the benefits of enhanced accuracy against the limitations in flexibility, which may necessitate additional costs for adjustments or secondary operations.

Why Choose Geometric Dimensioning for Complex Assemblies?

Geometric Dimensioning and Tolerancing (GD&T) employs a system of symbols to define the allowable variations in part dimensions. This method is particularly beneficial for complex assemblies and high-precision components, as it enhances clarity and reduces the risk of misinterpretation. However, B2B buyers should ensure their teams are familiar with GD&T principles to avoid costly errors during the manufacturing process.

What is the Importance of Maximum Material Condition in Ensuring Fit?

Maximum Material Condition (MMC) specifies the maximum size of a part feature, ensuring that components fit together correctly during assembly. This approach is vital in assembly operations and structural components, where compatibility is essential. Buyers should consider MMC when designing parts to ensure they meet assembly requirements, though it may constrain manufacturing processes and options.

How Does Least Material Condition Facilitate Functional Assembly?

Least Material Condition (LMC) focuses on ensuring that a part maintains functionality with the least amount of material. This type of tolerance is particularly relevant in electrical components and fittings, where parts must connect effectively. B2B buyers should be aware that while LMC allows for greater assembly tolerance, it may compromise the structural integrity of parts, making it critical to assess the application thoroughly.

Key Industrial Applications of machining tolerances

| Industry/Sector | Specific Application of Machining Tolerances | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision components for aircraft engines | Enhanced safety and reliability of flight systems | Supplier certifications (ISO 9001, AS9100), material traceability, and advanced machining capabilities |

| Automotive | Engine and transmission parts | Improved performance and fuel efficiency | Compliance with industry standards, ability to produce complex geometries, and quick turnaround times |

| Medical Devices | Surgical instruments and implants | Increased patient safety and device performance | Regulatory compliance (FDA, ISO 13485), precision machining capabilities, and biocompatible materials |

| Electronics | Enclosures and connectors for devices | Optimal performance and longevity of products | Material selection, precision tolerances, and compatibility with electronic components |

| Renewable Energy | Components for wind turbines and solar panels | Efficiency improvements and reduced operational costs | Expertise in large-scale machining, material durability, and adherence to environmental standards |

How Are Machining Tolerances Applied in Aerospace Manufacturing?

In the aerospace sector, machining tolerances are critical for manufacturing precision components such as engine parts and structural elements. The stringent tolerances ensure that every part fits perfectly, which is vital for the safety and efficiency of flight operations. Buyers must prioritize suppliers with certifications like ISO 9001 and AS9100, which guarantee adherence to strict quality standards. Furthermore, material traceability is essential to ensure that all components meet the required specifications for safety and performance.

What Role Do Machining Tolerances Play in Automotive Parts Production?

Machining tolerances in the automotive industry are essential for producing engine and transmission components that require high precision to enhance vehicle performance and fuel efficiency. Tighter tolerances can lead to better fitting parts, resulting in lower emissions and improved fuel consumption. Buyers should consider suppliers who can demonstrate compliance with industry standards, such as IATF 16949, and who possess advanced machining capabilities to produce complex geometries efficiently.

Why Are Machining Tolerances Important for Medical Device Manufacturing?

In the medical devices sector, machining tolerances are paramount for producing surgical instruments and implants that must operate reliably within the human body. The precision in machining ensures that these devices meet stringent regulatory requirements while enhancing patient safety. Buyers from this industry should focus on suppliers that comply with FDA regulations and ISO 13485 standards, ensuring that the products are manufactured in a controlled environment with high-quality materials suitable for medical applications.

How Do Machining Tolerances Affect Electronics Manufacturing?

For the electronics industry, machining tolerances are crucial for creating enclosures and connectors that ensure optimal performance and longevity of devices. These components often require precise dimensions to accommodate sensitive electronic parts without compromising functionality. Buyers should evaluate sourcing partners based on their ability to maintain high precision in machining, select appropriate materials, and ensure compatibility with other electronic components, which can significantly impact the overall product performance.

What Are the Benefits of Machining Tolerances in Renewable Energy Applications?

Machining tolerances are vital in the renewable energy sector, particularly for components used in wind turbines and solar panels. High precision in these parts leads to improved efficiency and reduced operational costs, which are critical for maximizing energy output. Buyers should seek suppliers with expertise in large-scale machining and a strong understanding of material durability, as these factors directly influence the longevity and reliability of renewable energy systems. Additionally, adherence to environmental standards can enhance the sustainability of the manufacturing process.

3 Common User Pain Points for ‘machining tolerances’ & Their Solutions

Scenario 1: Struggling with Overly Tight Tolerances

The Problem: Many B2B buyers, particularly those in high-precision industries like aerospace or medical device manufacturing, often impose excessively tight tolerances on their components. This can lead to increased production costs as parts may require additional machining processes like grinding or electrical discharge machining (EDM). The result is longer lead times, wasted materials, and potential quality issues, as parts that don’t meet these stringent standards may be rejected, leading to frustration and increased operational costs.

The Solution: To avoid the pitfalls of overly tight tolerances, buyers should engage in thorough collaboration with their manufacturing partners. Begin by understanding the functionality of each component and consider applying a tolerancing strategy that balances quality with cost-effectiveness. Instead of defaulting to the most stringent tolerances, utilize tools such as Geometric Dimensioning and Tolerancing (GD&T) to define necessary tolerances based on the assembly context. This approach allows for some flexibility and can significantly reduce machining costs while maintaining the required performance of the finished product. Additionally, working with suppliers who can offer advanced manufacturing capabilities can help in achieving desired tolerances without unnecessary processes.

Scenario 2: Inconsistent Tolerances Leading to Assembly Issues

The Problem: Inconsistent tolerances between different parts from multiple suppliers can create significant challenges during the assembly phase. For example, if a company sources components from various manufacturers who interpret tolerances differently, it may lead to compatibility issues, resulting in assembly failures and increased rework. This not only affects the production timeline but also can compromise the overall quality of the final product.

The Solution: To mitigate these risks, buyers should standardize their tolerance requirements across all suppliers. Establishing a clear and consistent set of specifications, such as a detailed engineering drawing with well-defined tolerances using GD&T, ensures that all suppliers understand the exact requirements. Furthermore, conducting regular audits and quality checks on parts received from different suppliers can help catch discrepancies early in the process. Investing in a collaborative relationship with suppliers, including providing them with feedback and sharing best practices, can also enhance their understanding of your specific needs and improve the consistency of parts produced.

Scenario 3: Lack of Understanding of Machining Tolerances

The Problem: Many buyers, particularly those new to the machining industry or from sectors less focused on precision engineering, struggle to understand the concept of machining tolerances. This lack of knowledge can lead to miscommunications with suppliers, resulting in parts that do not meet specifications or that incur unnecessary costs due to poorly defined requirements. Such challenges can lead to project delays and increased frustration, impacting overall productivity.

The Solution: Buyers should invest time in educating themselves about machining tolerances and their implications for manufacturing processes. This can be achieved through workshops, online courses, or engaging with industry experts. Additionally, when submitting requests for quotes or orders, buyers should provide detailed specifications, including desired tolerances, material types, and functional requirements. Working closely with engineers or technical staff within their organization to develop a clear understanding of how tolerances affect product performance will also help. Engaging suppliers in discussions about tolerance requirements can further clarify expectations, ensuring that both parties are aligned on project goals and reducing the likelihood of misunderstandings.

Strategic Material Selection Guide for machining tolerances

What Are the Key Properties of Common Materials Used in Machining Tolerances?

When selecting materials for machining tolerances, it’s crucial to consider their properties that directly influence product performance. Here, we analyze four common materials: Aluminum, Steel, Stainless Steel, and Plastics, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Aluminum Perform in Machining Tolerances?

Aluminum is known for its lightweight and excellent machinability, making it a popular choice in various industries. Its temperature rating is typically around 150°C, and it offers good corrosion resistance, particularly when anodized.

Pros: Aluminum is durable yet lightweight, reducing shipping costs and improving energy efficiency in applications like aerospace and automotive. Its lower manufacturing complexity compared to metals like steel allows for faster production times.

Cons: While generally cost-effective, aluminum can be more expensive than some plastics. It also has lower tensile strength compared to steel, which may limit its use in high-stress applications.

Impact on Application: Aluminum is compatible with various media, including water and air, but may not be suitable for harsh chemicals without proper coatings.

Considerations for International Buyers: Compliance with standards like ASTM and EN is essential, especially in regions like Europe and North America. Buyers from Africa and South America should also consider local availability and import tariffs.

What Advantages Does Steel Offer for Machining Tolerances?

Steel is renowned for its strength and versatility. With a temperature rating that can exceed 300°C, it is suitable for high-stress applications. Steel also exhibits excellent wear resistance, making it ideal for components subjected to friction.

Pros: Steel’s durability and strength make it suitable for heavy machinery and structural applications. Its relatively low cost and wide availability make it a go-to material for many manufacturers.

Cons: Steel is heavier than aluminum and can be prone to corrosion if not properly treated. Machining steel can also be more complex, requiring specialized tools and processes.

Impact on Application: Steel is compatible with various media, including oils and fuels, making it suitable for automotive and industrial applications.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM or DIN, especially in Europe and the Middle East. Understanding local market conditions can also help mitigate supply chain risks.

Why Choose Stainless Steel for Machining Tolerances?

Stainless steel is celebrated for its corrosion resistance and aesthetic appeal. It can withstand temperatures up to 600°C and is often used in food processing and medical applications due to its hygienic properties.

Pros: The durability and corrosion resistance of stainless steel make it ideal for harsh environments. Its aesthetic finish is also a plus for consumer-facing products.

Cons: Stainless steel is generally more expensive than both aluminum and regular steel. Its machining process can be more challenging, requiring advanced tooling and techniques.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances, making it highly versatile.

Considerations for International Buyers: Compliance with standards like JIS in Japan or ASTM in the U.S. is crucial. Buyers should also be aware of local sourcing options to reduce costs.

What Role Do Plastics Play in Machining Tolerances?

Plastics, such as polycarbonate and nylon, offer unique advantages in specific applications. They can withstand temperatures up to 100°C and are often used in electrical and consumer goods.

Pros: Plastics are lightweight, cost-effective, and resistant to corrosion. They are also easier to machine than metals, allowing for complex geometries.

Cons: While suitable for many applications, plastics can be less durable than metals and may not withstand high temperatures or mechanical stresses.

Impact on Application: Plastics are compatible with various media, but their chemical resistance varies, so careful selection is necessary.

Considerations for International Buyers: Understanding local regulations regarding plastic materials is essential, especially in Europe, where restrictions on certain plastics are stricter.

Summary Table of Material Selection for Machining Tolerances

| Material | Typical Use Case for machining tolerances | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and excellent machinability | Lower tensile strength than steel | Medium |

| Steel | Heavy machinery, structural components | High strength and durability | Prone to corrosion without treatment | Low |

| Stainless Steel | Food processing, medical devices | Corrosion resistance and hygiene | Higher cost and complex machining | High |

| Plastics | Electrical housings, consumer goods | Lightweight and cost-effective | Less durable than metals | Low |

This analysis provides valuable insights for international B2B buyers, enabling informed decisions based on material properties, application suitability, and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for machining tolerances

What Are the Main Stages of Manufacturing Processes for Machining Tolerances?

Manufacturing processes for achieving precise machining tolerances involve several critical stages. Each stage is designed to ensure that the final product meets the specified tolerances and quality standards.

Material Preparation: How Is Raw Material Selected and Processed?

The first step in manufacturing is selecting the appropriate raw material, which can significantly influence the final machining tolerances. Common materials include metals like aluminum, steel, and titanium, as well as plastics. The chosen material should have properties that align with the intended application, such as strength, weight, and machinability.

Once selected, the material undergoes preparation, which may involve cutting it to size, heat treating to enhance properties, or surface finishing to remove imperfections. Proper material preparation is crucial as it lays the foundation for achieving tighter tolerances.

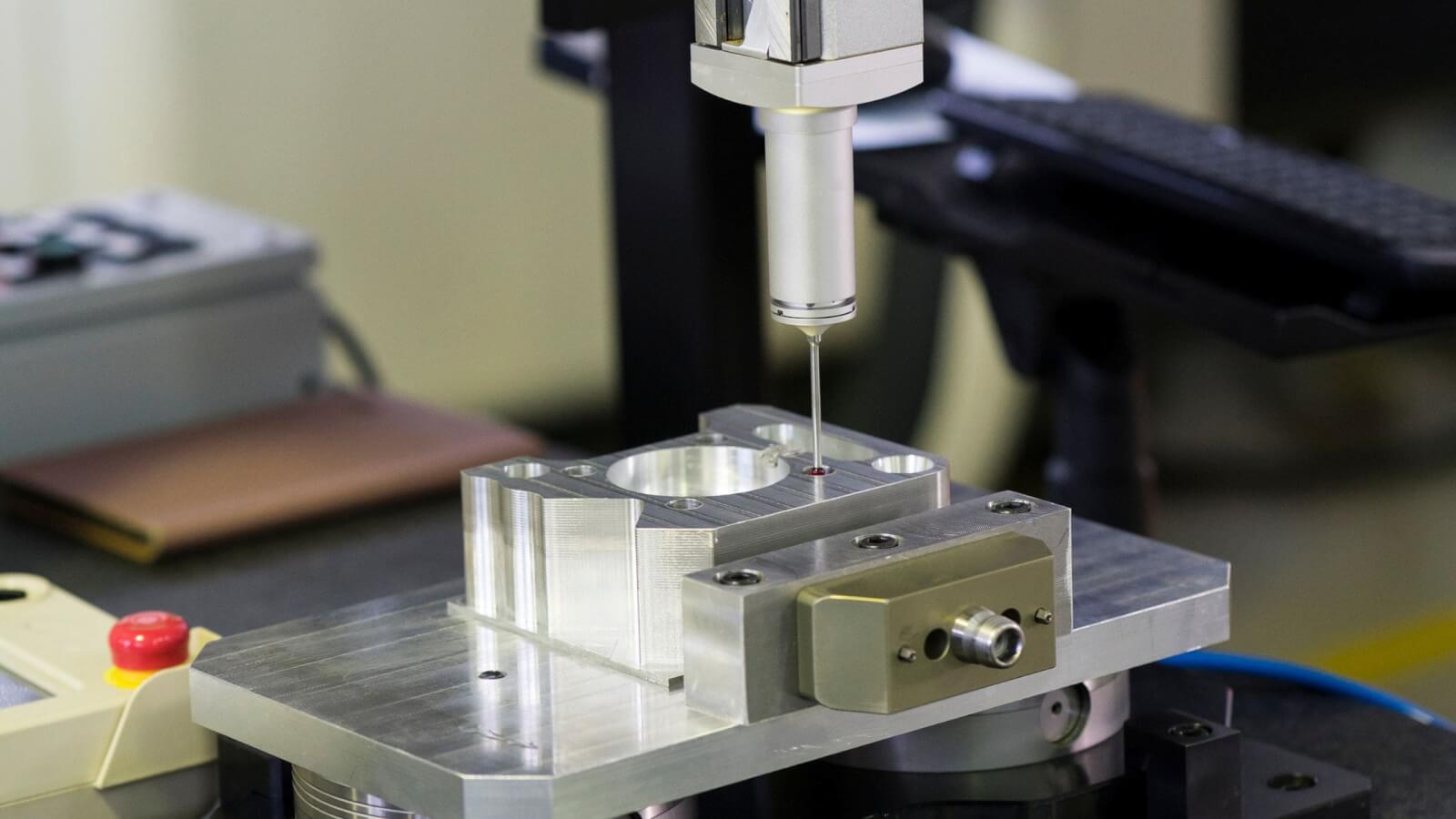

Forming: What Techniques Are Used to Shape Components?

The forming stage involves shaping the prepared material into the desired geometry. Techniques include:

-

CNC Machining: Computer Numerical Control (CNC) machining is widely used for its precision. It allows for automated cutting, drilling, and milling operations that maintain tight tolerances.

-

Turning: This technique is used for cylindrical parts, where material is rotated against a cutting tool to achieve precise dimensions.

-

Milling: In milling, a rotating tool removes material from a stationary workpiece, allowing for complex shapes and features.

Each of these techniques can achieve different levels of precision, and understanding their capabilities is essential for B2B buyers looking to meet specific tolerances.

Assembly: How Is Precision Maintained During Assembly?

After forming, components are assembled. This stage is critical as it can affect the overall functionality and tolerances of the final product. Proper alignment and fitting of parts are paramount. Techniques such as:

-

Interference Fit: Ensuring parts fit tightly together without gaps to maintain alignment and performance.

-

Clearance Fit: Allowing slight gaps for ease of assembly while still ensuring the parts function together as intended.

Buyers should ensure that suppliers have established processes for maintaining tolerances during assembly, as this can be a significant source of error.

Finishing: What Final Touches Ensure Quality and Tolerance?

The finishing stage involves processes that enhance the surface quality and overall precision of the part. Techniques include:

-

Grinding: This process provides high precision and smooth surfaces, essential for parts requiring tight tolerances.

-

Electropolishing: Often used for stainless steel, this process improves corrosion resistance and surface finish.

Finishing operations can significantly impact the final dimensions of the part, so it’s crucial for buyers to specify their requirements clearly.

What Are the Key Quality Control Measures for Machining Tolerances?

Quality control (QC) is an integral part of the manufacturing process, ensuring that all parts meet the required specifications. The following are standard QC practices relevant to machining tolerances.

Which International Standards Should B2B Buyers Consider?

For international B2B transactions, adherence to recognized quality standards is vital. The following standards are commonly applicable:

-

ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent quality in manufacturing processes.

-

ISO 2768: Pertaining specifically to general tolerances, this standard provides guidelines on how to specify tolerances in engineering drawings.

-

Industry-Specific Standards: Depending on the sector, additional standards may apply, such as CE marking for safety in Europe or API standards for the oil and gas industry.

Understanding these standards helps buyers verify that suppliers comply with best practices in quality management.

What Are the QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are established throughout the manufacturing process to catch defects early. Key checkpoints include:

-

Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify deviations from tolerances in real-time.

-

Final Quality Control (FQC): The final inspection ensures that all products meet the agreed-upon specifications before shipping.

Buyers should inquire about these QC checkpoints when assessing potential suppliers.

What Common Testing Methods Are Used to Verify Tolerances?

Several testing methods can be employed to verify machining tolerances:

-

Dimensional Inspection: Using calipers, micrometers, and coordinate measuring machines (CMM) to measure physical dimensions against specifications.

-

Functional Testing: Ascertaining whether the part performs as intended in its application, which indirectly verifies tolerances.

-

Non-Destructive Testing (NDT): Techniques like ultrasonic and radiographic testing can reveal internal defects without damaging the part.

By understanding these methods, buyers can better assess the reliability of their suppliers’ quality assurance processes.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, verifying the quality control processes of suppliers is crucial for ensuring consistent product quality. Here are some effective strategies:

What Role Do Audits and Reports Play in Supplier Verification?

Conducting audits of potential suppliers can provide insights into their quality management practices. Audits can be performed by the buyer or by third-party organizations. Key aspects to examine include:

-

Documented Procedures: Ensure that the supplier has documented quality control procedures and standards.

-

Training and Competence: Assess whether the supplier’s staff is adequately trained in quality assurance practices.

-

Traceability: Verify that the supplier can trace materials and processes used in production.

Requesting detailed quality reports from suppliers can also provide transparency into their quality control measures.

How Important Are Third-Party Inspections for Quality Assurance?

Third-party inspections can serve as an independent verification of a supplier’s quality control processes. Engaging a reputable inspection agency can help ensure that products meet international standards and specifications. This is particularly important for buyers from regions like Africa and South America, where local quality assurance practices may vary.

What Nuances Should International B2B Buyers Be Aware Of?

International buyers must navigate various nuances that can affect quality assurance:

-

Cultural Differences: Understanding the local manufacturing culture can help buyers communicate their quality expectations effectively.

-

Regulatory Compliance: Different regions have varying regulatory requirements, which can impact production and quality standards.

-

Logistical Considerations: Shipping and handling can introduce variances in product quality; thus, ensuring that suppliers have robust packaging and transport protocols is essential.

By being aware of these factors, B2B buyers can make more informed decisions when selecting suppliers for machining tolerances.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘machining tolerances’

Introduction

Navigating the complexities of machining tolerances is essential for international B2B buyers aiming to procure high-quality components. This guide provides a step-by-step checklist to help you establish clear specifications, assess supplier capabilities, and ensure that the parts you order meet your precise requirements.

Step 1: Define Your Technical Specifications

Begin by clearly defining the technical specifications of the components you need. This includes dimensions, tolerances, and material requirements, which will serve as the foundation for your procurement process.

– What to consider: Specify the basic and actual sizes, limits, and deviations to ensure clarity in your expectations.

– Why it matters: Well-defined specifications reduce the risk of miscommunication and ensure that suppliers understand your quality standards.

Step 2: Research Industry Standards

Familiarize yourself with the relevant industry standards for machining tolerances, such as ASME Y14.5 for Geometric Dimensioning and Tolerancing (GD&T). Understanding these standards will help you articulate your requirements more effectively.

– Key areas: Focus on standardized tolerances applicable to your specific industry and how they impact the functionality of the parts.

– Importance: Adhering to industry standards can enhance compatibility and interchangeability of parts, which is crucial for assembly processes.

Step 3: Evaluate Potential Suppliers

Before making a decision, it’s vital to thoroughly evaluate potential suppliers. Look for established companies with a proven track record in CNC machining and tolerancing.

– What to check: Request case studies, references from previous clients, and detailed company profiles.

– Why this is essential: A supplier’s history can provide insights into their reliability and quality of work, reducing the risk of costly errors down the line.

Step 4: Request Sample Parts

Once you have shortlisted suppliers, request sample parts that meet your specified tolerances. This step allows you to assess the quality and precision of their machining capabilities firsthand.

– What to observe: Examine the samples for adherence to your tolerances, surface finish, and overall quality.

– Benefits: Sampling gives you a tangible basis for comparison between suppliers, ensuring you choose the best fit for your needs.

Step 5: Verify Supplier Certifications

Ensure that your chosen suppliers have the necessary certifications, such as ISO 9001, which indicates a commitment to quality management systems.

– Why to verify: Certifications not only reflect a supplier’s adherence to quality standards but also their ability to consistently meet customer expectations.

– What to look for: Request copies of their certifications and check their validity, especially if you are sourcing from different regions, as standards may vary.

Step 6: Negotiate Terms and Conditions

Engage in negotiations with potential suppliers to finalize terms and conditions, including pricing, lead times, and after-sales support.

– What to clarify: Ensure that both parties understand the implications of tolerance levels on pricing and delivery schedules.

– Importance of negotiation: Clear agreements prevent misunderstandings and establish a solid foundation for your business relationship.

Step 7: Establish a Quality Control Process

After placing orders, implement a quality control process to monitor the received parts against the specified tolerances.

– What to include: Define inspection methods and acceptance criteria, and consider third-party inspection if necessary.

– Why it’s crucial: Ongoing quality assurance ensures that the parts you receive meet your specifications and reduces the risk of assembly issues or product failures.

Following this checklist will help you procure machining tolerances effectively, ensuring quality and consistency in your manufacturing processes.

Comprehensive Cost and Pricing Analysis for machining tolerances Sourcing

What Are the Key Cost Components in Machining Tolerances Sourcing?

Understanding the cost structure of machining tolerances is essential for B2B buyers aiming to optimize their procurement strategies. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

- Materials: The choice of materials significantly affects the overall cost. High-quality metals or plastics may come at a premium but can improve durability and performance.

- Labor: Skilled labor is necessary for precision machining, and labor costs can vary by region. Countries with a robust engineering workforce may present higher labor costs but offer superior quality.

- Manufacturing Overhead: This encompasses expenses related to equipment maintenance, facility operations, and administrative costs. Efficient manufacturing processes can help reduce overhead.

- Tooling: The initial investment in tooling can be substantial, especially for custom parts. However, the right tooling can enhance production efficiency and reduce long-term costs.

- Quality Control: Investing in rigorous QC processes ensures that tolerances are met, reducing the risk of defects. This can include both in-process inspections and final product testing.

- Logistics: Transportation and handling costs can add up, especially for international shipments. Understanding Incoterms and local regulations is crucial for managing these costs.

- Margin: Suppliers will typically include a profit margin in their pricing, which can vary based on market demand and competition.

How Do Price Influencers Affect Machining Tolerances?

Several factors can influence pricing in machining tolerances, impacting the overall cost for buyers.

- Volume/MOQ: Higher order volumes often lead to lower per-unit costs due to economies of scale. Negotiating minimum order quantities (MOQs) can also yield better pricing.

- Specifications and Customization: Custom parts with specific tolerances and features typically command higher prices. Standardized parts may be more cost-effective.

- Materials: The type and quality of materials used directly impact pricing. Buyers should balance material costs with performance requirements.

- Quality and Certifications: Parts that require specific certifications or meet high-quality standards may incur additional costs. Buyers should assess whether these certifications are necessary for their applications.

- Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more but offer greater assurance of quality and service.

- Incoterms: The chosen Incoterms can affect the total landed cost. Understanding the responsibilities of buyers and sellers in international trade can help manage expenses.

What Are the Best Tips for Buyers Negotiating Machining Tolerances?

When negotiating prices for machining tolerances, B2B buyers should consider several strategies to achieve cost efficiency.

- Negotiation: Always be prepared to negotiate. Understanding the supplier’s cost structure can provide leverage in discussions. Don’t hesitate to ask for discounts based on volume or long-term partnerships.

- Cost-Efficiency: Evaluate the total cost of ownership rather than just the upfront price. This includes maintenance, potential rework, and the product’s lifespan.

- Total Cost of Ownership: Incorporate all costs associated with the product, including shipping, duties, and storage. This holistic view will provide a clearer picture of the true expense.

- Pricing Nuances for International Buyers: For buyers from regions such as Africa, South America, the Middle East, and Europe, being aware of currency fluctuations, import tariffs, and local market conditions is critical. This knowledge can aid in making informed purchasing decisions.

- Disclaimer for Indicative Prices: Always approach pricing with an understanding that costs can vary based on changing market conditions, supplier capabilities, and specific project requirements. Therefore, it’s advisable to request formal quotes tailored to your needs.

By thoroughly analyzing these components and employing strategic negotiation techniques, B2B buyers can enhance their sourcing outcomes for machining tolerances, ensuring they achieve the best possible value for their investments.

Alternatives Analysis: Comparing machining tolerances With Other Solutions

When evaluating manufacturing processes, it’s crucial to consider various alternatives to machining tolerances, particularly as industries increasingly demand precision and efficiency. While traditional machining tolerances are a staple in manufacturing for ensuring part accuracy, there are several alternative solutions that can also meet similar goals. This analysis compares machining tolerances with additive manufacturing and injection molding, both of which offer distinct advantages and challenges.

| Comparison Aspect | Machining Tolerances | Additive Manufacturing | Injection Molding |

|---|---|---|---|

| Performance | High precision (±0.005 in.) | Moderate precision (±0.1 mm) | High precision (±0.05 mm) |

| Cost | Higher setup costs | Lower initial costs, but variable | High initial tooling costs |

| Ease of Implementation | Requires skilled labor | User-friendly design software | Complex mold design needed |

| Maintenance | Regular tool maintenance | Minimal maintenance | Mold maintenance required |

| Best Use Case | Custom, high-precision parts | Rapid prototyping, complex geometries | Mass production, simple geometries |

How Does Additive Manufacturing Compare to Machining Tolerances?

Additive manufacturing (AM), often referred to as 3D printing, allows for the creation of parts layer by layer. This method excels in producing intricate designs that would be challenging or impossible to achieve with traditional machining. The initial setup costs are typically lower than machining, making it a cost-effective solution for small production runs or prototypes. However, the precision of AM is generally lower than that of machining, which may not meet the stringent requirements of certain industries. Additionally, AM is easier to implement, as it often requires less specialized labor. On the downside, the material options are limited compared to traditional machining, which can restrict its application in some sectors.

What Advantages Does Injection Molding Offer Over Traditional Machining?

Injection molding is a highly efficient process for mass production of parts, particularly for simple geometries. It allows for high precision similar to machining tolerances, with the ability to produce thousands of identical parts quickly. While the initial tooling costs can be significant, the cost per unit decreases drastically with higher production volumes. Injection molding is also relatively easy to implement once molds are created, and it requires less ongoing maintenance than machining. However, the complexity of mold design can be a barrier to entry, and it is less suitable for custom or low-volume production runs.

Conclusion: Which Solution is Right for Your Needs?

Choosing the right manufacturing solution depends on specific business needs, production volumes, and the desired precision of the final product. For businesses requiring high precision and customization, machining tolerances remain the gold standard. However, if rapid prototyping and complex designs are priorities, additive manufacturing may be the better choice. Conversely, for high-volume production of simpler parts, injection molding is the most cost-effective and efficient method. B2B buyers should evaluate their unique requirements, including budget constraints, production speed, and quality standards, to determine the best solution for their applications.

Essential Technical Properties and Trade Terminology for machining tolerances

What Are the Key Technical Properties Relevant to Machining Tolerances?

Understanding the technical properties associated with machining tolerances is crucial for B2B buyers looking to optimize their manufacturing processes. Here are several essential specifications that play a pivotal role in ensuring quality and efficiency:

1. Tolerance

Tolerance refers to the allowable deviation from a specified dimension. It is expressed as a range (e.g., ±0.01 mm), indicating the maximum and minimum limits within which a part must fall to be considered acceptable. In B2B contexts, tighter tolerances are essential for high-precision applications, ensuring that parts fit together correctly and function effectively.

2. Material Grade

The material grade specifies the type of material used in manufacturing a part, which directly impacts its strength, durability, and machinability. Different grades of metals, plastics, and composites offer varying properties suitable for specific applications. Understanding material grades helps buyers select the right materials that align with their product specifications and performance requirements.

3. Surface Finish

Surface finish refers to the texture and smoothness of a machined part’s surface, often specified by a roughness average (Ra) value. A finer surface finish can enhance aesthetic appeal and improve the functionality of parts, particularly in applications involving friction. B2B buyers must consider surface finish to ensure parts meet both functional and aesthetic requirements.

4. Geometric Dimensioning and Tolerancing (GD&T)

GD&T is a system for defining and communicating engineering tolerances. It provides a clear framework for specifying relationships between part features, which is critical for ensuring compatibility in assembly. For B2B buyers, familiarity with GD&T can facilitate better communication with manufacturers and reduce the likelihood of errors in production.

5. Maximum Material Condition (MMC)

MMC is a concept used in tolerancing that specifies the condition where a feature contains the maximum amount of material. This is particularly relevant in assembly situations, as it ensures that parts will fit together correctly even in the worst-case scenario. B2B buyers should understand MMC to optimize part design for assembly efficiency.

6. Minimum Order Quantity (MOQ)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This specification is critical for B2B buyers when considering inventory management and cost control. Understanding MOQs can help businesses plan their purchases more effectively, balancing the need for sufficient stock against budget constraints.

Which Common Trade Terms Should B2B Buyers Know?

Familiarity with industry jargon can enhance communication and streamline procurement processes. Here are several common terms that every B2B buyer should understand:

1. Original Equipment Manufacturer (OEM)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the role of OEMs is vital for buyers who are looking for reliable suppliers for specific components that will be integrated into their own products.

2. Request for Quotation (RFQ)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. It is a key step in the procurement process, allowing buyers to gather competitive bids and make informed purchasing decisions. Crafting a clear RFQ can significantly impact the quality of responses received.

3. Incoterms

Incoterms (International Commercial Terms) are a series of pre-defined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and manage risks during international transactions.

4. Lead Time

Lead time is the period between the initiation of an order and its completion. Understanding lead times is essential for B2B buyers to effectively manage production schedules and inventory levels. Longer lead times can impact project timelines, making it critical to factor this into planning.

5. Bill of Materials (BOM)

A BOM is a comprehensive list detailing all components and materials required to manufacture a product. For B2B buyers, having an accurate BOM is crucial for cost estimation and ensuring that all necessary parts are sourced efficiently.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, optimize their manufacturing processes, and enhance the quality of their final products.

Navigating Market Dynamics and Sourcing Trends in the machining tolerances Sector

What Are the Global Drivers Shaping the Machining Tolerances Market?

The machining tolerances market is experiencing significant growth, driven by advancements in manufacturing technologies, increasing demand for precision components, and the global push for efficiency. Key trends include the adoption of CNC machining, which allows for tighter tolerances and higher accuracy in production processes. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly focused on sourcing suppliers that can deliver consistent quality at competitive prices.

Emerging technologies like additive manufacturing and automation are also transforming the landscape, allowing manufacturers to produce parts with complex geometries while maintaining strict tolerance requirements. Furthermore, the integration of Industry 4.0 principles—such as data analytics and IoT—into machining processes is enhancing supply chain transparency and efficiency. Buyers are now prioritizing suppliers who leverage these technologies to ensure timely delivery and quality assurance.

How Can B2B Buyers Navigate Sourcing Trends in Machining Tolerances?

B2B buyers must be vigilant about understanding the varying standards and tolerances offered by different suppliers. As the market evolves, the demand for standardized tolerances, such as those defined by Geometric Dimensioning and Tolerancing (GD&T), is becoming crucial. This standardization helps in minimizing discrepancies during production and assembly, ultimately reducing costs associated with rework and waste.

Moreover, as global trade continues to expand, buyers are encouraged to consider suppliers that offer flexible sourcing options, enabling them to respond swiftly to market changes. This adaptability is particularly important for buyers in developing regions, where market dynamics may shift rapidly due to economic or political factors.

What Role Does Sustainability Play in Sourcing Machining Tolerances?

Sustainability has become a critical factor in sourcing decisions for B2B buyers in the machining tolerances sector. The environmental impact of machining processes—such as waste generation, energy consumption, and resource depletion—necessitates a shift toward more sustainable practices. Buyers should seek out suppliers who employ eco-friendly machining techniques and utilize renewable energy sources.

Ethical sourcing is equally important. Buyers must ensure that their supply chains are transparent and that materials used in production are sourced responsibly. Certifications such as ISO 14001 for environmental management systems and materials that are recyclable or biodegradable can enhance a supplier’s appeal. By prioritizing these factors, buyers can not only meet regulatory requirements but also align with the growing consumer demand for sustainable products.

How Has the Machining Tolerances Industry Evolved Over Time?

The concept of machining tolerances has evolved significantly since its inception, rooted in the need for precision in manufacturing. Initially focused on ensuring component interchangeability, the industry has expanded to accommodate more complex geometries and tighter tolerances. The introduction of CNC machining revolutionized the sector, enabling manufacturers to achieve previously unattainable levels of accuracy.

As global competition intensified, the need for standardized tolerances emerged, paving the way for frameworks like GD&T. This evolution reflects a broader trend in manufacturing toward quality assurance and operational efficiency, fundamentally changing how businesses approach production and sourcing in the machining tolerances sector. As the industry continues to advance, understanding these historical developments will be crucial for B2B buyers looking to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of machining tolerances

-

How do I determine the appropriate machining tolerances for my project?

To determine the right machining tolerances, start by analyzing the functional requirements of your part and how it interacts with other components. Consider the material, the manufacturing process, and any industry standards applicable to your project. Consult with your supplier to understand their capabilities and the tolerances they can achieve reliably. Establishing a balance between precision and cost is crucial, as overly stringent tolerances can lead to increased production costs and longer lead times. -

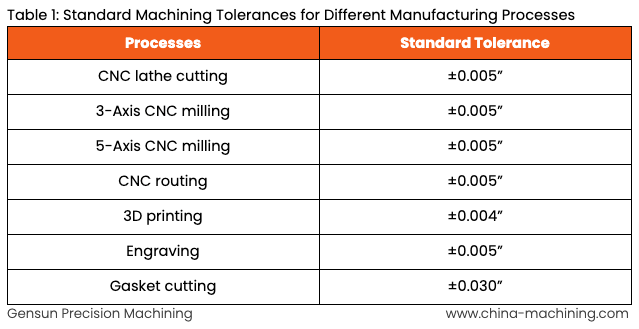

What are the standard machining tolerances for CNC machining?

Standard machining tolerances for CNC machining typically range from ±0.005 inches (±0.13 mm) for general applications to ±0.0005 inches (±0.0127 mm) for high-precision parts. However, these tolerances can vary based on the complexity of the part, material used, and specific machining processes. Always clarify these tolerances with your supplier to ensure they align with your project requirements. Understanding these standards can help you choose the right supplier and avoid costly rework. -

What factors should I consider when selecting a supplier for machining tolerances?

When selecting a supplier, consider their experience and expertise in your specific industry. Evaluate their production capabilities, including the range of tolerances they can achieve. Additionally, assess their quality assurance processes and certifications, such as ISO standards. It’s also beneficial to look at customer reviews and case studies to gauge their reliability. Finally, ensure they can accommodate your supply chain needs, including lead times and logistics support. -

How can I customize machining tolerances for my specific needs?

Customizing machining tolerances requires clear communication with your supplier regarding your project specifications. Discuss your functional requirements, desired performance outcomes, and any constraints related to cost and lead time. Many suppliers offer flexibility in tolerances based on the design and manufacturing process. Be prepared to provide detailed drawings and specifications to facilitate accurate quoting and production. Collaborating early in the design phase can help optimize tolerances and reduce potential issues. -

What are the minimum order quantities (MOQs) for machining tolerances?

Minimum order quantities (MOQs) for machining services can vary widely among suppliers and depend on factors such as the complexity of the part, material type, and production methods. Some suppliers may have low MOQs for prototype runs, while others may require larger quantities for cost-effective production. It’s essential to discuss your specific needs with potential suppliers to understand their MOQ policies and how they can accommodate smaller or larger orders. -

What payment terms should I expect when sourcing machining tolerances internationally?

Payment terms for international machining services can vary based on the supplier’s policies and your negotiation. Common terms include upfront payments, payment upon delivery, or a combination of both. It’s advisable to establish clear payment terms in your contract, including currency and payment method (e.g., wire transfer, credit card). Consider using escrow services for large orders to protect both parties. Always ensure that the payment terms align with your cash flow requirements and project timelines. -

How do quality assurance processes impact machining tolerances?

Quality assurance (QA) processes are critical in maintaining machining tolerances. Suppliers should implement systematic QA procedures, including inspections and testing at various stages of production. This ensures that parts meet the specified tolerances and functional requirements. Ask potential suppliers about their QA certifications, such as ISO 9001, and their specific methodologies for measuring and verifying tolerances. A robust QA process can significantly reduce the risk of defects and enhance overall product reliability. -

What logistics considerations should I be aware of when sourcing machining tolerances internationally?

When sourcing machining tolerances internationally, logistics considerations include shipping methods, customs regulations, and delivery timelines. Understand the shipping options available, such as air freight for faster delivery or sea freight for cost savings. Be aware of customs duties and import regulations in your country, as these can impact overall costs. Collaborate with your supplier to ensure they can provide the necessary documentation for smooth customs clearance. Planning logistics early can help avoid delays and additional expenses.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Machining Tolerances Manufacturers & Suppliers List

1. Protolabs – CNC Machining Services

Domain: protolabs.com

Registered: 2006 (19 years)

Introduction: Protolabs offers CNC machining services with standard prototype and production machining tolerances of +/- 0.005 in. (0.13mm). For greater accuracy, they provide precision machining tolerances of +/- 0.002 in. (0.051mm) and can hold +/- 0.0005 in. (0.0127mm) on reamed holes, and +/- 0.002 in. (0.051mm) on feature locations if machined on the same side of the part. The company emphasizes the import…

2. American Micro Inc – Precision Machining Tolerances

Domain: americanmicroinc.com

Registered: 2001 (24 years)

Introduction: Machining tolerances define the total amount of dimensional variation allowed from a specified value, ensuring components function properly within assemblies. Key aspects include: 1. Tolerance specifications: Upper and lower limits, allowable deviation notation, and standalone variance values. 2. Tolerance bands: Tight tolerance bands require more precise manufacturing, while loose bands allow for…

3. Precision CNC Machined 6061 Aluminum Part

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Part material: 6061 aluminum; Part dimensions: approximately 60mm x 20mm x 5mm; Standard tolerance: ±0.005″; Other mentioned tolerances: ±0.002″, ±0.0005 / -0.0000″; Manufacturing method: CNC machining with 1/8″ endmill; Design consideration: snug fit between interfacing moving parts.

4. IMC Intertech – Precision Machining Solutions

Domain: imcintertech.com

Registered: 2003 (22 years)

Introduction: Tightest possible machining tolerances as small as 1 micron (0.00004 in). Standard machining tolerances range from ± 0.005″ down to ± 0.002″ (± 0.127 mm down to ± 0.050 mm). Smallest micro machining tolerances range from ± 0.002″ down to ± 0.0004″ (± 0.050 mm down to ± 0.010 mm). Smallest micro EDM tolerances range from ± 0.001″ down to ± 0.0004″ (± 0.025 mm down to ± 0.010 mm). Smallest femtoseco…

5. Avanti Engineering – CNC Machining Services

Domain: avantiengineering.com

Registered: 2000 (25 years)

Introduction: Avanti Engineering specializes in CNC machining with tight tolerances, typically around ±0.001 inches. They are ISO 9001:2015 certified and implement a C=0 sampling plan along with various quality assurance measures. The company offers a range of machining services including CNC machining, CNC turning & milling, custom machining, high-volume machining, multi-spindle screw machining, and Swiss CNC …

6. HPPI – Precision Machining Tolerances

Domain: hppi.com

Registered: 1997 (28 years)

Introduction: Machining tolerances refer to the permissible range of variation in dimensions that ensure a part fits and functions correctly. CNC machines can achieve an accuracy of ± 0.0025mm, with 0.02mm being a common standard. Types of tolerances include standard tolerances, limit tolerances (specifying minimum and maximum dimensions), unilateral tolerances (applied in one direction), and bilateral toleranc…

Strategic Sourcing Conclusion and Outlook for machining tolerances

In the ever-evolving landscape of global manufacturing, understanding and effectively managing machining tolerances is crucial for international B2B buyers. By prioritizing strategic sourcing, businesses can ensure they select suppliers capable of delivering precise tolerances that align with their product specifications. This focus not only enhances part quality and reduces costs but also mitigates the risks associated with misalignment during assembly.

As you navigate the complexities of machining tolerances, consider leveraging advanced manufacturing techniques like CNC machining, which offer tighter tolerances and greater accuracy. Furthermore, adopting standardized tolerancing practices, such as Geometric Dimensioning and Tolerancing (GD&T), can streamline your design processes and improve compatibility across components.

Looking ahead, the demand for high-precision parts will continue to grow, particularly in regions like Africa, South America, the Middle East, and Europe. By embracing innovation and investing in strategic sourcing partnerships, you can position your business at the forefront of this trend. Take action today by assessing your current machining tolerance requirements and exploring potential suppliers who can meet your evolving needs. Your commitment to quality will not only enhance your product offerings but also strengthen your competitive edge in the global market.