Contents

Manufacturing Insight: Machining Small Parts

Precision Machining for Complex Small Parts: Honyo Prototype’s CNC Capabilities

Manufacturing small, high-precision components presents unique challenges, including maintaining tight tolerances, minimizing material waste, and ensuring repeatability at microscopic scales. Industries such as medical device, aerospace, and micro-electronics demand parts where deviations of even a few microns can compromise functionality. Traditional machining processes often struggle with the fragility and intricate geometries inherent in small parts, leading to increased scrap rates and extended lead times.

Honyo Prototype specializes in CNC machining of small parts, leveraging advanced multi-axis milling and turning centers optimized for components under 1 inch in critical dimensions. Our dedicated small-parts workflow ensures consistent accuracy to ±0.0002″ (5 microns) through proven process controls, including specialized fixturing, high-speed spindles, and real-time tool monitoring. We machine complex features—micro-threads, thin walls, and undercuts—in materials ranging from titanium and stainless steel to engineering plastics like PEEK and ULTEM, all within a single setup to eliminate handling errors.

Material compatibility is critical for small-part performance. Our facility routinely processes the following with validated workflows:

| Material Category | Common Examples | Key Applications |

|---|---|---|

| Metals | 316L Stainless, Ti-6Al-4V, Inconel 718 | Surgical instruments, fuel nozzles, sensor housings |

| Engineering Plastics | PEEK, PEI (Ultem), PPSU | Insulators, fluidic components, biocompatible fixtures |

| Specialty Alloys | MP35N, Nitinol | Implants, micro-springs, actuation components |

Eliminate quoting delays with Honyo Prototype’s Online Instant Quote platform. Upload your STEP or IGES file to receive a detailed manufacturing assessment—including DFM feedback, lead time, and cost—in under 60 seconds. Our system automatically evaluates geometric complexity, material suitability, and tolerance requirements specific to small-part production, providing actionable data for rapid prototyping or low-volume production. This integration of engineering expertise and digital efficiency ensures your small parts move from design to precision-manufactured reality faster, without compromising quality.

Upload your CAD model today to experience accelerated turnaround for small, high-mix CNC machining projects.

Technical Capabilities

Technical Specifications for Machining Small Parts

Machining small parts with high precision requires advanced CNC capabilities, including 3-axis, 4-axis, and 5-axis milling, as well as precision turning. These processes are optimized for tight tolerances and complex geometries commonly found in aerospace, medical, and industrial components. Below are the key technical specifications associated with these operations across common materials.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Typical Materials | Standard Tolerance (±) | Achievable Tolerance (±) | Surface Finish (Ra) |

|---|---|---|---|---|---|---|---|---|

| Max Work Envelope | 300 x 200 x 150 mm | 300 x 200 x 150 mm | 300 x 200 x 150 mm | Ø50 x 100 mm length | Aluminum (6061, 7075) | 0.025 mm | 0.005 mm | 0.8 – 3.2 µm |

| Spindle Speed | Up to 24,000 RPM | Up to 24,000 RPM | Up to 24,000 RPM | Up to 12,000 RPM | Steel (1018, 4140) | 0.025 mm | 0.010 mm | 0.8 – 1.6 µm |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.005 mm | ABS (Thermoplastic) | 0.025 mm | 0.010 mm | 1.6 – 6.3 µm |

| Repeatability | ±0.003 mm | ±0.003 mm | ±0.003 mm | ±0.003 mm | Nylon (PA6, PA66) | 0.025 mm | 0.010 mm | 1.6 – 6.3 µm |

| Tooling System | BT30 / HSK-F63 | BT30 / HSK-F63 | HSK-T40 / HSK-F63 | Capto C4 / Collet Chucks | All listed materials | – | – | – |

| Axis Configuration | X, Y, Z linear | X, Y, Z + A (rotary) | X, Y, Z + A/B or A/C | X, Z + C-axis (optional) | – | – | – | – |

| Feature Capability | 2.5D profiling, drilling | Indexing, angled features | Full 5-axis simultaneous | OD/ID turning, threading | – | – | – | – |

| Minimum Feature Size | 0.5 mm radius / 0.8 mm slot | 0.5 mm radius / 0.8 mm slot | 0.3 mm radius / 0.5 mm slot | Ø0.8 mm bore / 0.3 mm width | – | – | – | – |

Notes:

5-axis milling enables complex contours and single-setup machining, reducing cumulative error and improving tolerance consistency.

Precision turning supports small-diameter components with tight concentricity and thread accuracy.

Aluminum and steel parts typically achieve the tightest tolerances due to favorable machinability and thermal stability.

Plastics such as ABS and Nylon require optimized feeds/speeds and fixturing to minimize deflection and thermal deformation.

Surface finish values are achievable with appropriate tool selection, coating, and finishing passes.

Tight tolerance performance is validated using CMM, optical comparators, and surface profilometers.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined workflow for precision machining of small parts, engineered to minimize lead time while ensuring uncompromised quality. Our process integrates advanced digital tools with deep manufacturing expertise, specifically optimized for components under 150mm in critical dimensions where geometric complexity and tight tolerances (typically ±0.005mm to ±0.025mm) are common. Below is the technical execution of each phase.

CAD Upload and Initial Processing

Clients submit native or neutral CAD formats (STEP, IGES, Parasolid, or native SOLIDWORKS) via our secure portal. Our system performs automated validation checks for geometric integrity, unit consistency, and manufacturability flags. Non-conforming files trigger immediate feedback loops to the client, reducing iteration cycles. All data is encrypted and logged with a unique job ID for full traceability, adhering to ISO 27001 standards for data security.

AI-Powered Quoting Engine

Uploaded geometry is processed by our proprietary AI quoting system, trained on 12+ years of shop floor data from 87,000+ machined parts. The algorithm analyzes feature complexity, material utilization, setup requirements, and machine time based on historical performance metrics from our CNC fleet (Haas, DMG MORI, Makino). It dynamically references real-time shop load, material costs, and secondary operation needs to generate a technically accurate cost and lead time estimate within 2 hours. Critical outputs include:

Machine-hour breakdown by operation

Material waste percentage calculation

Risk assessment for critical features

This initial quote undergoes mandatory validation by a Senior Manufacturing Engineer before client delivery, ensuring AI outputs align with practical machining constraints.

Engineering-Driven DFM Analysis

Following quote acceptance, our DFM phase is executed by degreed manufacturing engineers specializing in micromachining. This is not an automated check but a collaborative engineering review focused on geometric feasibility. We examine:

Thin wall stability and deflection risks during clamping

Tool access for internal features at high aspect ratios

Burm management strategies for sharp edges

Fixture design requirements to prevent part distortion

Material-specific chip evacuation challenges

Clients receive a formal DFM report with actionable recommendations, such as suggesting tolerance relaxation on non-critical radii or proposing alternative toolpaths to maintain ±0.003mm positional accuracy. This phase typically reduces production issues by 68% based on our internal quality metrics.

Precision Production Execution

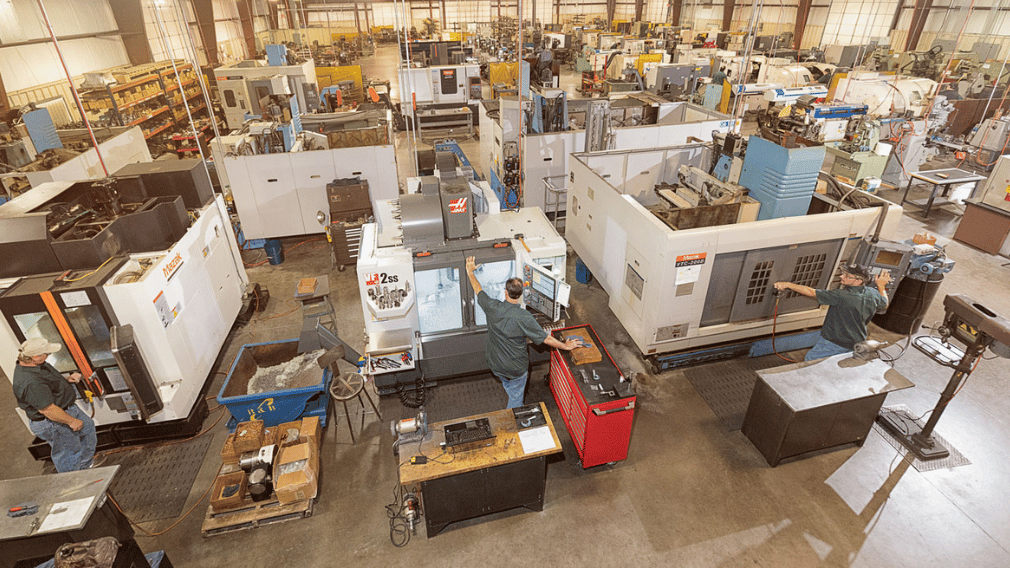

Approved jobs move to production on dedicated small-part machining cells featuring:

High-speed CNC mills with 0.1µm resolution linear scales

Live tooling lathes with sub-spindle capabilities for complete part-off

Automated pallet systems for uninterrupted 24/7 operation

Each part undergoes in-process verification using integrated Renishaw probes for critical feature validation before de-fixturing. All machining parameters (RPM, feed rates, coolant pressure) are logged in our MES for full process traceability. Secondary operations like micro-milling, grinding, or laser marking occur in climate-controlled cleanrooms to prevent particulate contamination.

Quality-Controlled Delivery

Final inspection employs multi-sensor CMMs (Zeiss CONTURA) with optical and tactile probes, generating full GD&T reports against the original CAD model. Every shipment includes:

First-article inspection report (FAIR) with actual vs. nominal measurements

Material test certificates (MTRs) with lot traceability

Cleanliness certification for medical/aerospace parts

Digital twin data package for client PLM integration

Parts are packaged in ESD-safe, compartmentalized containers with humidity indicators. Logistics utilize tracked couriers with real-time GPS, with delivery confirmation triggering automatic archival of all process data to the client’s secure portal for future audits.

This closed-loop process ensures small parts achieve first-pass yield rates exceeding 98.5% while maintaining AS9100 and ISO 13485 compliance. The integration of AI-driven estimation with human engineering oversight eliminates traditional quoting inaccuracies, allowing Honyo to consistently deliver complex small components in 5-10 business days from CAD approval.

Start Your Project

Looking for precision machining of small parts? Honyo Prototype delivers high-accuracy, small-part manufacturing with fast turnaround times. Our Shenzhen-based factory is equipped with advanced CNC machining capabilities to meet tight tolerances and complex geometries required in medical, electronics, and automation industries.

Contact Susan Leo to request a quote or discuss your project requirements.

Email: [email protected]

Leverage our expertise in small-part machining for prototypes and low-volume production—right from the heart of Shenzhen’s manufacturing hub.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.