Contents

Manufacturing Insight: Machining Products

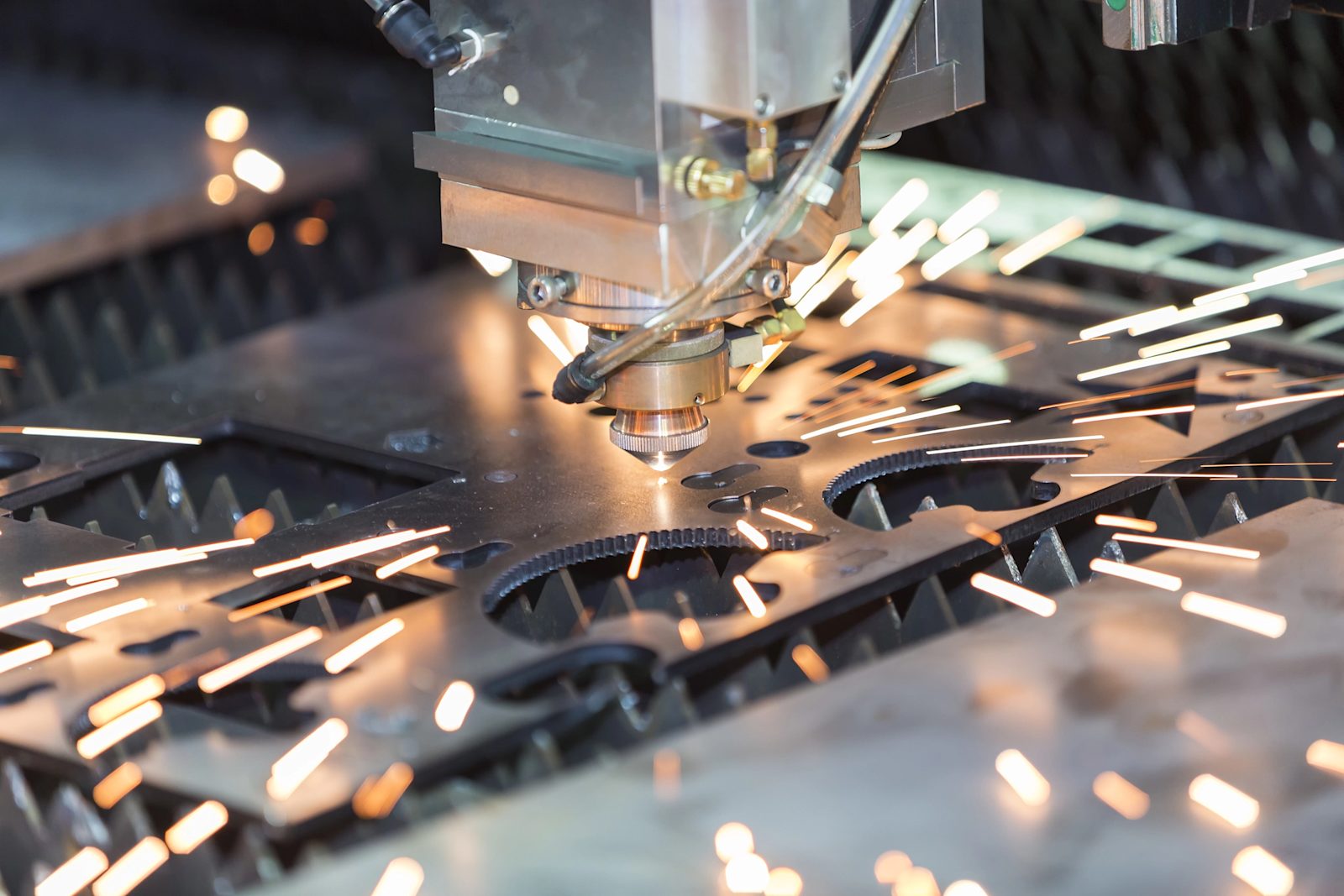

Precision Machined Components Engineered for Your Success

At Honyo Prototype, we transform complex design challenges into high-integrity machined components through advanced CNC machining capabilities. Our multi-axis milling and turning centers deliver micron-level accuracy across aluminum, stainless steel, titanium, engineering plastics, and exotic alloys, ensuring every part meets stringent aerospace, medical, and industrial specifications. With ISO 9001-certified processes and in-house metrology validation, we consistently achieve tight tolerances down to ±0.0002″ while maintaining repeatability for both rapid prototypes and low-to-mid volume production runs.

Central to our customer experience is the Honyo Online Instant Quote platform—a proprietary system that eliminates traditional quoting delays. Simply upload your 3D CAD file, specify materials and quantities, and receive a detailed manufacturing assessment with lead time and cost breakdown within minutes. This streamlined procurement tool empowers engineering teams to accelerate project timelines without compromising on technical rigor or supply chain transparency.

Request your quote today and experience how Honyo’s CNC machining expertise and digital workflow integration solve your most demanding precision manufacturing requirements.

Technical Capabilities

Technical Specifications for Machining Products

Honyo Prototype offers precision machining services specializing in 3-axis, 4-axis, and 5-axis CNC milling, as well as CNC turning, designed to meet tight tolerance requirements across a range of engineering materials including aluminum, steel, ABS, and nylon. Our capabilities support high-accuracy prototyping and low-to-mid volume production for demanding industrial, aerospace, medical, and automotive applications.

| Specification Category | Details |

|---|---|

| Machining Processes | 3-Axis CNC Milling, 4-Axis CNC Milling (indexed/rotary), 5-Axis CNC Milling (simultaneous multi-axis), CNC Turning (including mill-turn with live tooling) |

| Tolerance Capability | Standard: ±0.005 mm (±0.0002″) Tight Tolerance: ±0.0025 mm (±0.0001″) achievable with process control and inspection validation |

| Surface Finish | Typical: Ra 1.6 μm (63 μin) As Fine As: Ra 0.4 μm (16 μin) with polishing or fine tool paths |

| Maximum Work Envelope | Milling: 1000 mm × 600 mm × 500 mm (X×Y×Z) Turning: Max. Diameter: 300 mm, Max. Length: 500 mm |

| Materials Supported | Aluminum: 6061-T6, 7075-T6, 2024, 5052 Steel: 1018, 4140, 4340, Stainless Steel (303, 304, 316) Engineering Plastics: ABS (natural/colored), Nylon (PA6, PA66), Delrin (POM), PEEK (on request) |

| Tooling & Control Systems | High-precision carbide and PCD tooling; Fanuc, Siemens, and Heidenhain CNC controls; in-process probing and tool length measurement |

| Inspection & Quality | First article inspection (FAI) available; CMM, optical comparators, micrometers, and height gauges used for GD&T validation; ISO 2768 or custom drawing specifications followed |

| Lead Time | Prototype: 5–7 business days Production: 10–15 business days (volume dependent) |

| Secondary Operations | Deburring, anodizing (Type II & III), plating, powder coating, laser marking, passivation, heat treatment coordination |

All machined components are produced under controlled conditions with full traceability, ensuring compliance with technical drawings and customer-specific quality requirements. Multi-axis capabilities enable complex geometries with reduced setup, improving accuracy and repeatability for high-integrity parts.

From CAD to Part: The Process

At Honyo Prototype, our machining process is engineered for precision, speed, and client transparency. We execute a structured workflow from initial design submission through final delivery, minimizing risk and maximizing manufacturability. Below is our standard operational sequence for CNC machining projects.

CAD Upload and Initial Processing

Clients initiate the process by uploading native or neutral format CAD files (STEP, IGES, Parasolid, SLDPRT) via our secure customer portal. Our system performs an immediate format validation and geometry integrity check. This step confirms file compatibility with our CAM systems and identifies obvious topological errors such as non-manifold edges or missing surfaces. Clients receive instant notification of upload success or required file corrections, ensuring no project delay at the intake stage.

AI-Powered Quoting with Engineering Validation

Uploaded designs enter our proprietary AI quoting engine, which analyzes geometric complexity, feature density, material requirements, and tolerance specifications. The AI cross-references real-time data on machine availability, material costs, and historical production metrics to generate a preliminary cost and timeline estimate within 2 hours. Crucially, this AI output is never final. A dedicated Manufacturing Engineer reviews the AI assessment, validating feasibility against our CNC capabilities (3-axis to 5-axis milling, turning, mill-turn) and applying domain expertise to refine the quote. This dual-layer approach ensures quotes are both data-driven and technically sound, typically finalized within 24 business hours.

Engineering-Led DFM Analysis

Upon quote acceptance, our team conducts a rigorous Design for Manufacturability (DFM) review. This is not an automated checklist but an engineer-to-engineer collaboration. We identify potential production hurdles such as inadequate tool access, problematic wall thicknesses, or non-optimal tolerance stacking. Common findings and resolutions follow this pattern:

| Common DFM Issue | Honyo’s Resolution Approach |

|---|---|

| Internal radii smaller than standard tooling | Propose radius adjustment or specialty tooling with cost/time impact disclosure |

| Thin walls prone to chatter/vibration | Recommend thickness modification or adaptive machining strategy |

| Over-specified surface finishes on non-critical areas | Suggest relaxed finish standards to reduce cycle time |

| Unmachinable undercuts | Propose design modification or multi-setup solution |

Clients receive a detailed DFM report with annotated visuals and actionable recommendations. We require client sign-off on any design changes before proceeding, ensuring alignment on final specifications.

Precision Production Execution

Approved designs move to production on our certified CNC equipment (Haas, DMG MORI, Makino). Each job follows a controlled sequence: material procurement with full certification traceability, first-article inspection using calibrated CMMs and optical comparators, and in-process gauging for critical dimensions. Our MES (Manufacturing Execution System) provides clients real-time visibility into job status, including machine start/completion times and quality checkpoint results. All machined parts undergo final inspection against the original CAD model using 3D scanning where required, with full inspection reports delivered digitally.

Logistics and On-Time Delivery

Completed orders are packaged per client specifications (ESD-safe, custom crating) and processed through our integrated logistics platform. We provide automated shipping notifications with tracking and coordinate customs documentation for international deliveries. Every shipment includes a digital package with as-built inspection reports, material certifications, and process documentation. Our standard lead time for machined prototypes is 5-7 business days from DFM approval, with expedited options available. We maintain a 98.7% on-time delivery rate for machined components based on 2023 performance data.

This integrated process ensures technical rigor at every phase while maintaining the agility required for prototype and low-volume production. By embedding engineering oversight within each step—notably in quote validation and DFM—we prevent downstream issues that cause delays in conventional workflows. Clients receive certified, ready-to-use components with full documentation transparency from upload to delivery.

Start Your Project

Explore our precision machining products engineered for high performance and reliability. Manufactured at our state-of-the-art facility in Shenzhen, each component is produced to meet strict quality standards with fast turnaround times.

For inquiries or custom project discussions, contact Susan Leo at [email protected] to receive expert support tailored to your manufacturing needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.