Contents

Manufacturing Insight: Machining Peek

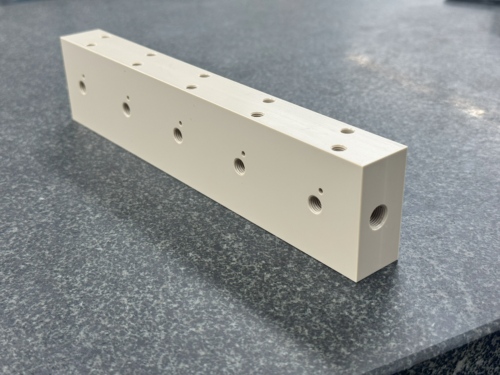

Precision PEEK Machining: Where Material Science Meets Manufacturing Excellence

Machining polyether ether ketone (PEEK) presents unique challenges due to its high-performance thermoplastic properties, including exceptional thermal stability, chemical resistance, and mechanical strength. However, its low thermal conductivity and tendency toward dimensional creep under heat demand specialized CNC expertise to avoid part distortion, surface degradation, or compromised tolerances. At Honyo Prototype, we leverage decades of polymer-specific machining experience to transform PEEK into mission-critical components for aerospace, medical, and semiconductor applications where failure is not an option.

Our dedicated CNC machining services for PEEK integrate optimized toolpath strategies, precision-controlled coolant systems, and custom fixture designs to maintain strict geometric tolerances (±0.005 mm) and surface finishes (Ra 0.8 µm). We prioritize material integrity through rigorous thermal management protocols, ensuring minimal residual stress and consistent part performance in demanding operational environments. Every PEEK component undergoes stringent in-process inspection against ASTM D6266 standards, with full traceability from raw stock to final shipment.

For engineering teams requiring rapid validation of PEEK designs, our Online Instant Quote platform delivers detailed manufacturability feedback and lead-time estimates within hours—not days. Simply upload your STEP or IGES file to receive a transparent cost breakdown, material certification options, and DFM insights tailored to PEEK’s unique machining requirements. Accelerate your high-performance prototype development with Honyo’s precision-engineered solutions.

| Key PEEK Machining Capability | Honyo Standard | Industry Typical |

|---|---|---|

| Tolerance Control (mm) | ±0.005 | ±0.025 |

| Surface Finish (Ra, µm) | 0.8 | 3.2 |

| Lead Time (Prototype) | 5–7 days | 10–14 days |

| Material Certification | ASTM D6266 | Basic Compliance |

Technical Capabilities

Machining PEEK (Polyether Ether Ketone) requires specific technical considerations due to its high-performance thermoplastic properties, including excellent thermal stability, chemical resistance, and mechanical strength. When processing PEEK using 3/4/5-axis milling or turning operations, tight tolerance capabilities are achievable with proper toolpath strategies, fixturing, and thermal management. Below are the technical specifications and comparative insights when machining PEEK versus other commonly machined materials such as Aluminum, Steel, ABS, and Nylon in precision CNC environments.

| Parameter | PEEK | Aluminum (6061-T6) | Steel (AISI 4140) | ABS | Nylon (PA6/PA66) |

|---|---|---|---|---|---|

| Typical Tolerance Range | ±0.025 mm (±0.001″) | ±0.025 mm (±0.001″) | ±0.0125 mm (±0.0005″) | ±0.05 mm (±0.002″) | ±0.05 mm (±0.002″) |

| Recommended Cutting Speed (Milling) | 40–80 m/min (130–260 sfm) | 300–500 m/min (1000–1600 sfm) | 90–150 m/min (300–500 sfm) | 150–250 m/min (500–800 sfm) | 100–200 m/min (300–650 sfm) |

| Feed Rate (per tooth) | 0.05–0.10 mm/tooth | 0.10–0.25 mm/tooth | 0.05–0.15 mm/tooth | 0.10–0.20 mm/tooth | 0.08–0.15 mm/tooth |

| Spindle Speed (Turning) | 1000–2500 RPM | 1500–3000 RPM | 600–1200 RPM | 1200–2000 RPM | 1000–1800 RPM |

| Tool Material | Carbide, Polycrystalline Diamond (PCD) | Carbide, High-Speed Steel (HSS) | Carbide, Cermet | Carbide, HSS | Carbide, HSS |

| Coolant Use | Minimal or air blow (avoid thermal shock) | Flood coolant recommended | Flood coolant required | Air blow or minimal coolant | Air blow preferred (hygroscopic) |

| Clamping Force | Low to moderate (avoid part deformation) | Moderate | High | Low | Low to moderate |

| Thermal Sensitivity | High (glass transition ~143°C) | Moderate | Low | High (softens ~100°C) | High (softens ~80°C) |

| Chatter Sensitivity | Moderate (requires rigid setup) | Low (good damping) | Low | High (low stiffness) | High (low stiffness) |

| Surface Finish (Typical Ra) | 0.8–1.6 µm | 0.4–0.8 µm | 0.2–0.8 µm | 1.6–3.2 µm | 1.6–3.2 µm |

| Moisture Absorption | <0.5% at saturation | Negligible | Negligible | 0.2–0.4% | 2.5–3.5% (requires drying) |

| Applications | Aerospace, Medical, Semiconductor | Automotive, Consumer, Structural | Industrial, Tooling, Defense | Prototypes, Housings | Gears, Wear Parts, Insulators |

Notes on Machining PEEK in Multi-Axis CNC:

3/4/5-axis milling of PEEK benefits from high-precision motion control and reduced setup次数, enabling complex geometries common in medical and aerospace components. Due to PEEK’s low thermal conductivity, heat concentration at the cutting edge is a concern, necessitating sharp tools and consistent chip evacuation. Use of climb milling and low radial engagement strategies helps manage heat and maintain dimensional stability.

In turning operations, PEEK requires stable workholding and fine nose radius tools to achieve tight tolerances and smooth finishes. Unlike metals, PEEK does not conduct heat well, so excessive speed or feed can lead to localized melting or dimensional inaccuracy.

Compared to Aluminum and Steel, PEEK has lower stiffness and higher thermal expansion, which must be accounted for in fixture design and process planning. ABS and Nylon are easier to machine but lack the thermal and mechanical performance of PEEK, making them less suitable for high-stress, high-temperature environments.

For tight tolerance work across all materials, environmental control (temperature and humidity) is critical—especially for hygroscopic materials like Nylon and PEEK, which should be machined soon after drying to prevent moisture-related dimensional shifts.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined workflow for PEEK (Polyether Ether Ketone) machining projects, leveraging material-specific expertise to ensure precision and reliability. This process integrates advanced digital tools with deep manufacturing knowledge, critical for handling PEEK’s unique thermal and mechanical properties. Below is the detailed sequence:

CAD File Upload and Initial Assessment

Clients initiate the process by uploading native CAD files (STEP, IGES, or Parasolid formats preferred) via our secure portal. Our system performs immediate validation checks for geometric integrity, unit consistency (exclusively metric for PEEK), and minimum feature resolution. PEEK-specific considerations begin here, such as verifying wall thicknesses against minimum recommendations (typically ≥0.5 mm for structural stability during high-temperature machining) and identifying potential thermal distortion risks in thin-walled features.

AI-Powered Quoting with Material Intelligence

Our proprietary AI quoting engine analyzes the validated CAD geometry while incorporating PEEK-specific parameters. Unlike generic quoting systems, it references a curated database of historical PEEK machining data, including:

Thermal expansion coefficients (13–43 × 10⁻⁶ /°C depending on grade)

Optimal cutting speeds (50–150 m/min) and feed rates to prevent melting

Specialized tooling requirements (carbide or diamond-coated tools essential)

Coolant compatibility constraints (air cooling or specialized oils only; water-based coolants prohibited)

The AI generates a preliminary quote within 2 business hours, highlighting potential cost drivers unique to PEEK such as extended cycle times for stress-relief annealing cycles or secondary operations for critical tolerances.

Material-Centric DFM Analysis

A senior manufacturing engineer conducts a formal Design for Manufacturability review focused explicitly on PEEK’s challenges. This phase addresses:

| DFM Factor | Standard Plastics | PEEK-Specific Requirement at Honyo |

|---|---|---|

| Wall Thickness | ≥0.8 mm | ≥1.0 mm (to resist thermal warpage) |

| Hole Aspect Ratio | ≤10:1 | ≤6:1 (prevents tool deflection in high-strength material) |

| Tolerance Control | ±0.1 mm typical | ±0.025 mm requires post-machining stress relief |

| Surface Finish | As-machined | Critical surfaces require diamond polishing to prevent microcracks |

We provide clients with a collaborative DFM report detailing actionable modifications, such as adding draft angles to mitigate shrinkage effects or recommending strategic support features to counteract PEEK’s high clamping force requirements. Client approval is mandatory before proceeding.

Controlled Production Execution

PEEK machining occurs in our temperature-stabilized cleanroom environment (22±1°C). Key production protocols include:

Machines undergo pre-production thermal calibration cycles to compensate for PEEK’s sensitivity to ambient fluctuations. All operations use dedicated toolpaths with reduced spindle loads (max 60% capacity) to prevent localized heating beyond PEEK’s glass transition temperature (143°C). Critical components undergo in-process CMM verification after roughing and semi-finishing stages to detect thermal drift. Stress-relief annealing at 180–200°C for 2–4 hours occurs between machining stages for parts with tolerances tighter than ±0.05 mm, followed by controlled cooling at 10°C/hour.

Certified Delivery and Traceability

Final inspection includes full CMM reporting against client-specified GD&T, material certification traceable to raw stock batch numbers, and surface roughness validation (Ra ≤0.8 µm for critical surfaces). All PEEK components ship with:

ISO 13485-compliant documentation package

Thermal history log from machining through annealing

Certificate of Conformance with dimensional variance analysis

Handling instructions for PEEK’s moisture sensitivity (parts stored in vacuum-sealed containers with desiccant)

Delivery timelines include mandatory 48-hour post-machining stabilization at controlled temperature before final measurement, ensuring dimensional stability meets aerospace and medical industry requirements.

Start Your Project

Looking to machine high-performance PEEK components with precision and speed? Partner with Honyo Prototype for expert machining services from our Shenzhen-based factory.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a fast, competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.