Contents

Manufacturing Insight: Machining Parts Chemical Industry

Precision CNC Machining for Chemical Processing Applications

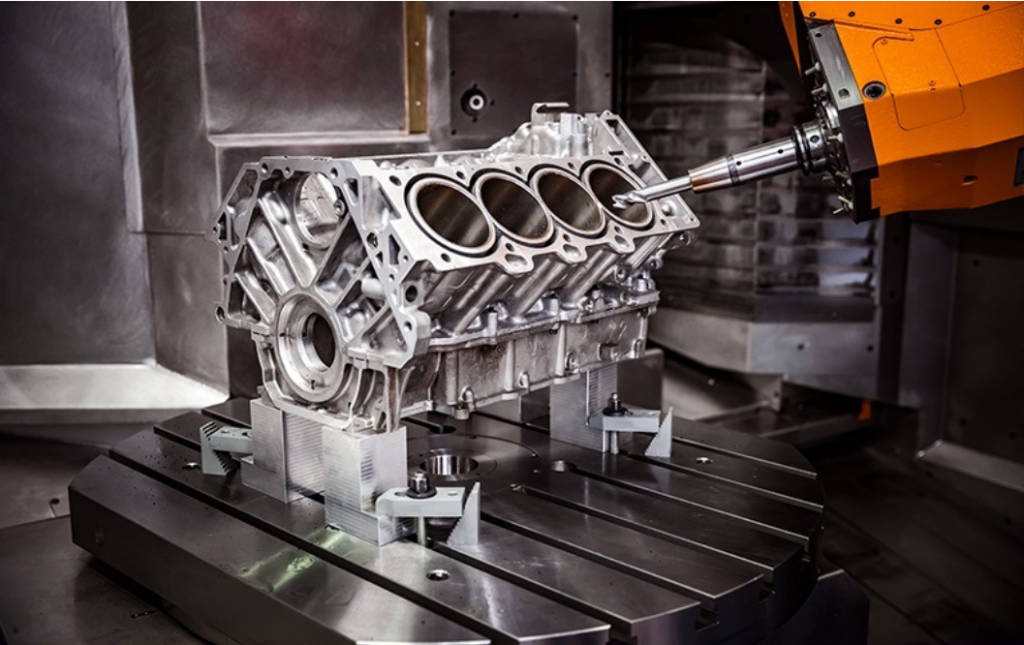

Chemical industry operations demand components engineered to withstand extreme conditions including corrosive media, high pressures, and elevated temperatures. Standard machining solutions often fail under these stresses, leading to premature part degradation, unplanned downtime, and safety risks. Honyo Prototype addresses these critical challenges through specialized CNC machining services designed explicitly for chemical processing environments. Our expertise spans complex geometries in highly resistant materials such as Hastelloy, Inconel, titanium, PTFE, and specialized alloys, ensuring long-term reliability in reactors, valves, pumps, and fluid handling systems.

Leveraging advanced multi-axis CNC milling and turning centers, we achieve tight tolerances down to ±0.0002 inches while maintaining strict material integrity. Every component undergoes rigorous in-process inspection and final validation per AS9100 and ISO 9001 standards, with full material traceability and certification documentation provided. This disciplined approach guarantees compatibility with aggressive chemicals like sulfuric acid, chlorine, and caustic solutions, directly supporting your facility’s operational safety and regulatory compliance.

Accelerate your prototyping and production timelines with Honyo Prototype’s Online Instant Quote system. Upload your CAD files to receive a detailed, no-obligation quotation within hours—not days—including manufacturability feedback and lead time estimates. This digital workflow eliminates procurement delays while ensuring your chemical-grade components meet exacting performance specifications from initial design through delivery.

Technical Capabilities

Technical Specifications for Machined Components in the Chemical Industry

Machined parts used in the chemical industry require high precision, tight tolerances, and compatibility with corrosive environments. These components are typically manufactured using 3-axis, 4-axis, and 5-axis CNC milling as well as CNC turning operations to achieve complex geometries and fine surface finishes. Below are the technical specifications relevant to these processes and materials.

| Parameter | Specification |

|---|---|

| Machining Processes | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (including live tooling for mill-turn operations) |

| Tolerance Capability | ±0.005 mm (±0.0002″) for critical dimensions; up to ±0.0125 mm (±0.0005″) for standard features |

| Surface Finish (Typical) | Ra 0.8 µm (32 µin) to Ra 3.2 µm (125 µin); polished finishes available upon request |

| Positional Accuracy | ±0.005 mm (±0.0002″) with advanced CNC controls and in-process probing |

| Feature Complexity | Capable of internal channels, undercuts, compound angles, and asymmetric geometries via multi-axis machining |

| Materials – Metals | Aluminum (6061-T6, 7075-T6), Stainless Steel (304, 316/L, 17-4 PH), Titanium (Grade 2, 5), Hastelloy, Inconel |

| Materials – Plastics | ABS (impact-resistant, moderate chemical resistance), Nylon (6, 6/6 – high wear and chemical resistance), PEEK, PTFE, PVC |

| Material Selection Criteria | Corrosion resistance, thermal stability, mechanical strength, and compatibility with chemical exposure (acids, bases, solvents) |

| Secondary Operations | Passivation (stainless steel), anodizing (aluminum), stress relieving, precision cleaning, metrology inspection (CMM, optical comparators) |

| Quality Standards | ISO 9001, AS9100 (if applicable), full traceability, first-article inspection (FAI), PPAP documentation available |

| Typical Applications | Valve bodies, pump housings, reactor components, fittings, seals, sensor mounts, and fluid handling manifolds |

Components are routinely validated for dimensional accuracy and material integrity to ensure performance in aggressive chemical environments. Multi-axis machining enables reduced setup次数 and improved geometric consistency, especially for complex parts requiring high repeatability and tight tolerance control.

From CAD to Part: The Process

Honyo Prototype Chemical Industry Machining Process Overview

Honyo Prototype delivers precision-machined components for the chemical industry through a rigorously controlled workflow designed to address extreme material compatibility, corrosion resistance, and regulatory compliance requirements. Our process ensures parts withstand aggressive chemical exposure, high pressures, and stringent purity standards.

CAD Upload

Customers submit 3D CAD models with explicit material specifications (e.g., Hastelloy C-276, PTFE-lined alloys, or duplex stainless steels) and chemical exposure parameters. We require full documentation of operational conditions—including chemical concentrations, temperatures, and pressure cycles—to validate material suitability against NACE MR0175/ISO 15156 standards. Non-conforming submissions trigger immediate technical consultation to prevent downstream failures.

AI-Powered Quoting

Our proprietary AI engine analyzes CAD geometry against chemical industry-specific databases, cross-referencing material reactivity charts (e.g., Perry’s Chemical Engineers’ Handbook), corrosion rates, and ASME BPE surface finish requirements. The quote includes:

Material certification costs (e.g., EN 10204 3.1/3.2 for traceable heat numbers)

Specialized machining protocols for hazardous materials (e.g., acid-resistant tooling, non-contaminating coolants)

Estimated lead time incorporating mandatory NDT validation steps

Quotes are generated within 4 business hours, with technical deviations flagged for customer review.

DFM for Chemical Applications

Design for Manufacturability reviews focus exclusively on chemical process integrity. Key assessments include:

Elimination of crevice corrosion risks via seamless transitions and radiused corners per ASME BPE-2022

Validation of surface roughness (Ra ≤ 0.8 µm for high-purity fluid paths)

Verification of weld accessibility for post-machining passivation (ASTM A967)

Stress concentration analysis for cyclic pressure loads (using ISO 16528)

We provide annotated DFM reports with actionable redesign recommendations, often reducing total cost by 15–30% through geometry optimization for chemical resilience.

Production Execution

Machining occurs in dedicated ISO Class 8 cleanrooms with segregated tooling for reactive alloys. Critical controls include:

In-process ICP-MS testing of material batches to confirm elemental composition

Cryogenic cooling for nickel-based superalloys to prevent work hardening

Electrochemical polishing for electropolished finishes (ASTM B912)

Helium leak testing at 1.5x design pressure for containment-critical parts

All operations adhere to IATF 16949 and ISO 13485 frameworks, with real-time SPC monitoring of dimensional tolerances (±0.005 mm typical).

Delivery and Compliance Documentation

Shipments include:

Full material traceability dossiers (mill test reports, heat treatment records)

NDT certificates (dye penetrant, X-ray for welds per ASME Section V)

Surface cleanliness validation (particulate counts per SEMI F57)

FAT reports with pressure/leak test videos

Parts are packaged in VCI-certified containers with inert gas purging to prevent pre-installation corrosion. Standard lead time is 12–18 days from CAD approval, with expedited 7-day options for critical spares.

This end-to-end process ensures chemical industry components meet API 607/641 fire safety standards and FDA 21 CFR compliance, minimizing operational risk in high-hazard environments. All deliverables undergo final cross-functional review by our chemical engineering and quality assurance teams prior to shipment.

Start Your Project

Looking for precision-machined parts tailored for the chemical industry? Honyo Prototype delivers high-performance components engineered to withstand demanding chemical environments. Our manufacturing facility in Shenzhen utilizes advanced CNC machining and material expertise to ensure reliability, tight tolerances, and corrosion resistance.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Leverage our in-house capabilities and rapid turnaround for prototypes and production runs. Trusted quality. Made in Shenzhen.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.