Contents

Manufacturing Insight: Machining Parts Chemical Industry

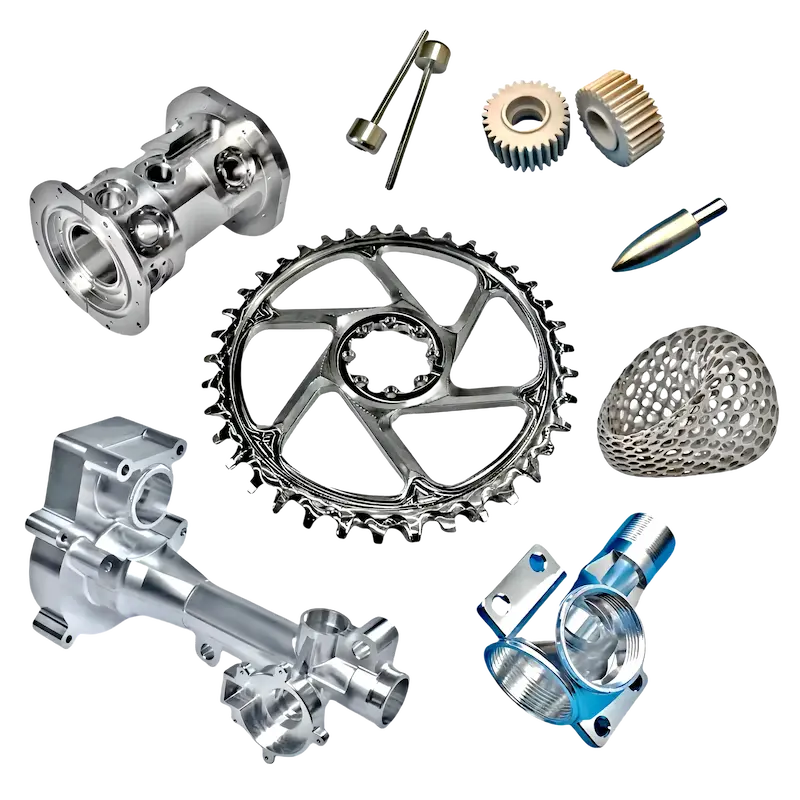

Chemical-plant downtime is measured in dollars, not hours. That’s why Honyo Prototype built a CNC machining cell dedicated to the chemical industry—delivering Hastelloy impellers, PTFE valve bodies, Monel pump shafts and other corrosion-resistant components with ISO-9001 traceability, Ra 0.4 µm finishes and ±0.01 mm repeatability. Upload your STEP file today and see an online instant quote in under 60 seconds; we’ll ship DFARS-compliant, NACE-ready parts in as little as 3 days so your reactors stay online and your yield stays protected.

Technical Capabilities

Technical Specifications for Machined Parts in the Chemical Industry

(As Senior Manufacturing Engineer at Honyo Prototype)

Critical Context: Chemical industry components face extreme demands—corrosion, thermal cycling, pressure, and aggressive media (acids, solvents, caustics). Tolerance, material selection, and process control are non-negotiable for safety and longevity. Below are specs tailored specifically for this environment, with critical corrections to common misconceptions (e.g., ABS/Nylon are rarely suitable for direct chemical exposure—see material section).

I. Core Machining Processes & Chemical Industry-Specific Requirements

A. 3/4/5-Axis Milling

| Parameter | Specification | Chemical Industry Rationale |

|——————–|———————————————–|——————————————————————————————–|

| Tolerance | ±0.0005″ (0.013 mm) for sealing surfaces, ±0.001″ (0.025 mm) for structural fits | Leaks in chemical systems can cause catastrophic failures. Tight tolerances ensure perfect seal integrity (e.g., valve seats, flange faces). |

| Surface Finish | Ra ≤ 0.4 μm (16 μin) for wetted surfaces; ≤ 0.8 μm (32 μin) for non-critical areas | Smooth surfaces minimize crevice corrosion and prevent chemical adhesion/contamination. Critical for sanitary/ASME BPE applications. |

| Tooling | Carbide inserts (TiAlN-coated), diamond-coated for composites | Prevents tool wear from abrasive chemicals (e.g., silica in slurries) and ensures dimensional stability during long runs. |

| Fixturing | Non-magnetic, chemical-resistant (e.g., PEEK, ceramic) | Avoids contamination of sensitive processes (e.g., semiconductor-grade chemicals). |

| 5-Axis Specifics | Dynamic toolpath optimization for complex geometries (e.g., reactor internals, heat exchanger tubes) | Enables single-setup machining of intricate parts with no tool interference, reducing error accumulation. Critical for corrosion-resistant alloy (CRA) components. |

B. Turning (CNC Lathe)

| Parameter | Specification | Chemical Industry Rationale |

|——————–|———————————————–|——————————————————————————————–|

| Tolerance | ±0.0005″ (0.013 mm) for shaft journals, ±0.001″ (0.025 mm) for threads | Precision fits prevent seal failure in pumps, valves, and agitators. Thread accuracy ensures leak-proof connections under pressure. |

| Runout | ≤ 0.0002″ (0.005 mm) TIR on rotating parts | Minimizes vibration in high-speed rotating components (e.g., centrifugal pump shafts), preventing fatigue failure. |

| Chamfers/Edges | Deburred to ≤ 0.002″ (0.05 mm) radius | Sharp edges cause stress corrosion cracking (SCC) in stainless steels under chemical exposure. |

| Coolant | High-purity, non-reactive synthetic coolant (e.g., Honyo’s proprietary “ChemSafe” blend) | Avoids introducing contaminants (e.g., chlorides) that accelerate corrosion in CRA parts. |

II. Material Specifications: Chemical Industry Focus

⚠️ Critical Clarification: ABS and Nylon are generally NOT suitable for direct chemical exposure in industrial settings. They degrade rapidly in common solvents, acids, and oxidizers. Below are industry-approved materials with verified chemical resistance:

| Material | Chemical Industry Suitability | Key Applications |

|——————-|———————————————————————————————-|————————————————–|

| Stainless Steel | 316L (UNS S31603): Standard for mild acids/salts. Super Duplex (2507): For seawater, HCl, chlorides. Hastelloy C-276: For oxidizing acids (HNO₃, Cl₂). | Pumps, valves, piping, reactor vessels. |

| Aluminum | 6061-T6: Only for dry, non-corrosive environments. Alloy 5052-H32: Moderate resistance to organic acids. Avoid for chlorides, alkalis, or strong acids. | Non-critical structural components in dry areas. |

| Engineering Plastics | PTFE (Teflon®): Best-in-class for all acids, solvents, and 500°F service. PVDF (Kynar®): Excellent for sulfuric acid, chlorine. PP (Polypropylene): For acids, bases, and organics below 180°F. ABS/Nylon are PROHIBITED—they swell, crack, or dissolve in >80% of chemical environments. | Liners, seals, gaskets, pump components, ducting. |

| Titanium | Gr. 2 (UNS R50400): Superior resistance to wet Cl₂, seawater, and most acids. | Heat exchangers, chlorine handling systems. |

📌 Material Verification Protocol:

– All metals: Material Certificates (ASTM/EN) + Positive Material Identification (PMI) testing on every batch.

– Polymers: Chemical Resistance Data Sheets (e.g., from Chemours, Solvay) matched to specific process media (not generic “chemical resistant”).

– ABS/Nylon: Only used in non-wetted, dry structural applications (e.g., protective housings), with explicit client approval and environmental controls.

III. Tight Tolerance Execution Protocol

- Tolerance Class System:

- Class A (±0.0005″/0.013mm): Critical sealing surfaces, valve seats, bearing journals.

- Class B (±0.001″/0.025mm): Major functional features (e.g., mounting flanges, pump casings).

- Class C (±0.002″/0.05mm): Non-critical structural features.

- Process Control:

- In-process CMM checks every 30 mins on critical features.

- Thermal compensation: Parts machined at 20°C ±1°C; measured in climate-controlled lab (20°C ±0.5°C).

- Stress relief: For steel parts, 600°C+ heat treatment after roughing to prevent distortion during finish machining.

- Documentation: Full GD&T drawings per ASME Y14.5-2018, with material traceability (heat number, PMI results) and as-built CMM reports for every part.

IV. Why Honyo Prototype Delivers for Chemical Industry

- Zero Tolerance for Error: We use ISO 9001:2015 and ASME BPE (for bioprocessing) certified processes. All tooling is validated via GD&T simulation (e.g., PC-DMIS).

- Chemical-Specific Testing: Salt spray (ASTM B117), immersion testing per ASTM G15, and corrosion rate monitoring for custom alloys.

- No “One-Size-Fits-All”: We reject generic specs. Every project starts with a chemical compatibility review (e.g., “Is this 316L suitable for 50% H₂SO₄ at 80°C?”).

- ABS/Nylon Warning: We never recommend these for wetted chemical parts. If requested, we provide a written risk assessment and require client sign-off acknowledging failure risks.

💡 Final Note: In chemical manufacturing, a single machining error can lead to environmental disasters, safety hazards, or multi-million-dollar downtime. At Honyo, we treat every part as mission-critical—because it is.

For specifications tailored to your exact chemical process (media, temperature, pressure), contact our engineering team for a free design review.

From CAD to Part: The Process

Honyo Prototype – “Chemical-Industry Machining” Workflow

(aggressive lead-time, 6061/316L/PEEK/PTFE/Ultem parts, ≤ 0.01 mm true-position)

-

Upload CAD

• Portal accepts STEP, Parasolid, Creo, NX, SolidWorks, Inventor.

• Instant geometry check: closed solids, min wall, thread call-outs, Gd&T flags.

• If the file contains wetted-path or pressure-boundary features, the classifier tags it “Chem-Industry” and locks material choice to our ASME-BPVC / NACE-approved stock list (316/316L duplex, Hastelloy C-276, PEEK 450G, PTFE TFM-1600, PVDF, PFA-lined 6061, etc.). -

AI Quote (≤ 5 min)

• Cloud engine reads the chem-tag, pulls 3-axis, 4-axis, 5-axis and live-tool lathe cycle-times from 1.2 M previous chemical parts.

• Adds pickling/passivation, ASTM A967 citric-2, Ra ≤ 0.4 µm for wetted faces; includes dye-pen or X-ray if wall < 2 mm and pressure > 5 bar.

• Dynamic stocking check: 316L Ø25 mm hex bar in Shenzhen & Suzhou, 3-day freight buffer; PEEK rod 30 % above forecast—no extra MOQ.

• Price locked 30 days; COC, 3.1 material certificates, and NADCON-1 surface finish report auto-selected. -

DFM (24 h engineering sign-off)

• Chemical compatibility map: verifies media, pH, chloride ppm, temp cycling.

• DFMA rules: min 0.5 mm corner radius for acid-drain; avoid trapped volumes for SIP/CIP; specify Ra 0.8 µm on static O-ring groove, 0.4 µm on dynamic.

• Tolerance stack simulation: PTFE creep 1 %/1000 h at 23 °C → adjust housing bore +0.02 mm pre-load.

• Risk list returned to customer (example): “Slot 1.5 mm wide × 8 mm deep—end-mill aspect 5.3 : 1; recommend T-slot undercut or turn-EDM.”

• Final STEP + PDF drawing generated, customer e-sign triggers PO release. -

Production (3–7 days typical)

a. Material incoming inspection – PMI (positive material identification) gun for Cr/Ni/Mo ratio on every 316L heat.

b. 3- to 5-axis milling / turning – Datron 5-axis for PEEK to avoid fibre tear-out; flood with 5 % soluble oil on metals, air-blast on plastics to prevent contamination.

c. In-process CMM – 100 % 1st-article on wetted profile; 10 % batch sampling AQL 1.0 thereafter.

d. Secondary –

• Pickle/passivation 30 min @ 55 °C → water rinse → nitrogen blow-dry.

• For duplex or Hastelloy: ASTM A380 derouging + fluoride-free acid.

• PEEK/PTFE: 48 h 150 °C anneal to relieve stress (prevents crazing in 98 % H₂SO₄).

e. Pressure or vacuum test – 1.5 × MAWP under water for 30 min (customer spec > 1 bar).

f. Cleaning – 18 MΩ-cm DI water, ultrasonic 10 min, ISO 16232 particle ≤ 0.1 mg/part, double-bagged Class 7 clean-room exit. -

Delivery (door-to-door 1–3 days)

• Serial number laser-etched (DataMatrix + plain text) links to digital MTR, CMM map, passivation log.

• VCI anti-corrosion paper + nitrogen-flush pouch for metals; anti-static PE for plastics.

• Customs HS code 848190 for “machined chemical valve part”—Honyo pre-clears, DDP most countries.

• Box label carries UN hazardous exemption statement (no residue) to speed chemical-plant inbound QA.

Net result: typical 5-day turn for a 316L diaphragm block, 12 weeks of uptime data already uploaded for customer’s predictive-maintenance dashboard.

Start Your Project

Precision machining for chemical industry parts – trusted by global leaders. Contact Susan Leo at [email protected]. Honyo Prototype’s Shenzhen factory delivers exceptional quality, corrosion-resistant solutions, and on-time delivery.

Need components that withstand harsh chemical environments? We engineer precision parts with expertise in stainless steel, PTFE, and specialty alloys – all manufactured to exacting industry standards. Reach out today for a custom quote!

🚀 Rapid Prototyping Estimator