Contents

Manufacturing Insight: Machining Of Copper Alloy Parts

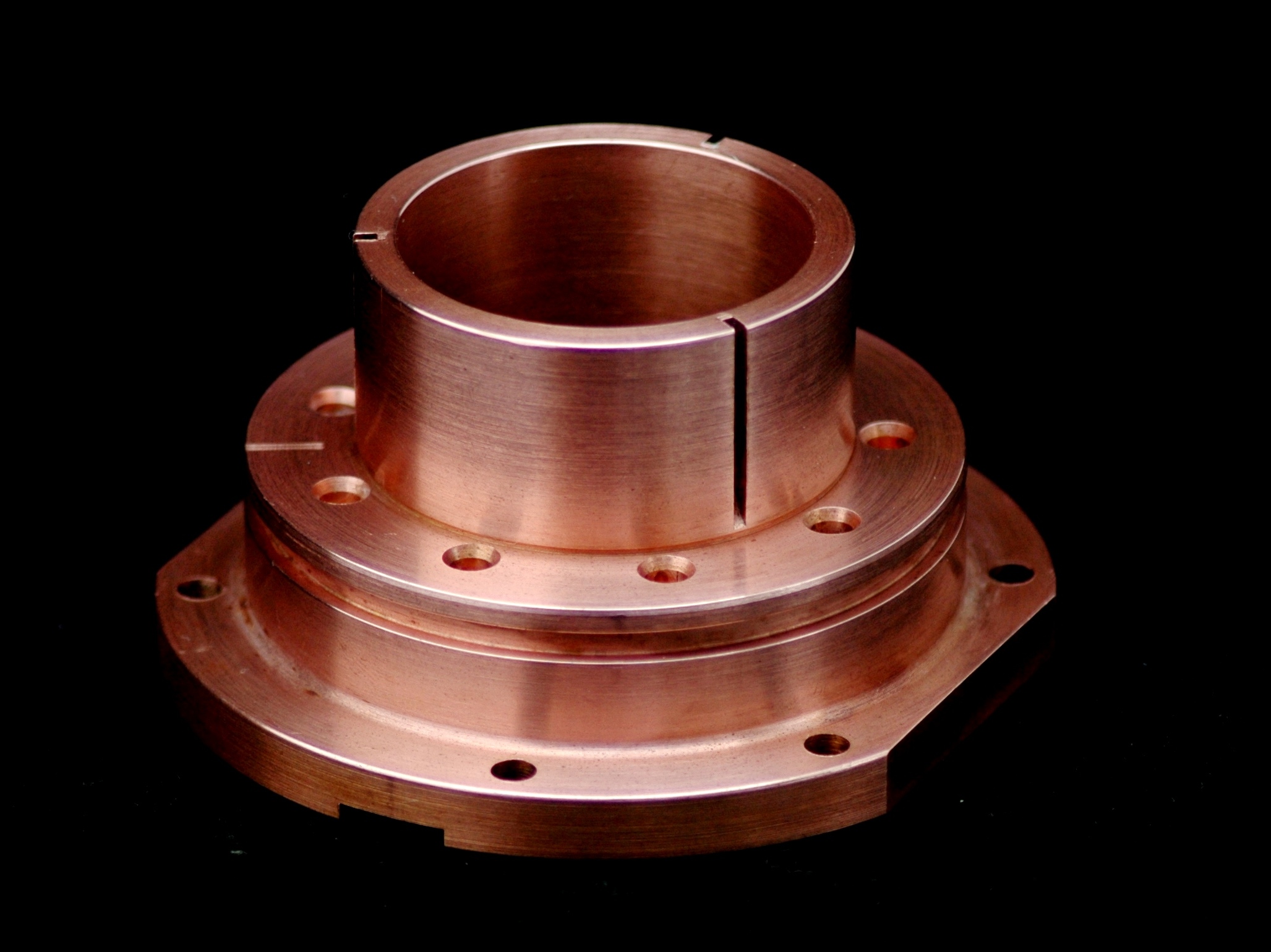

Precision Copper Alloy Machining: Overcoming Material Challenges with Honyo Prototype

Machining copper and its alloys presents unique technical hurdles for precision component manufacturing. High thermal conductivity demands optimized coolant strategies to prevent workpiece distortion, while the material’s inherent softness and tendency toward galling and burr formation require specialized tool geometries, stringent parameter control, and refined fixturing to achieve tight tolerances and superior surface finishes. These challenges often lead to extended lead times, compromised part integrity, or increased scrap rates with conventional machining approaches.

At Honyo Prototype, our CNC machining services are engineered specifically for the complexities of copper alloys, including C11000, C10100, C18200, and beryllium-copper variants. We deploy advanced multi-axis milling and turning centers with rigid setups, coupled with proprietary cutting strategies and real-time process monitoring. This ensures consistent achievement of tolerances down to ±0.005mm and surface finishes as fine as Ra 0.4µm, even in intricate geometries. Our metallurgical expertise informs every step—from optimized spindle speeds and feed rates to custom toolpath sequencing—minimizing material adhesion and maximizing dimensional stability.

Accelerate your prototyping or low-volume production with Honyo’s Online Instant Quote system. Upload your copper alloy part CAD file to receive a detailed, transparent manufacturing assessment and competitive pricing within hours—no manual submission delays. Leverage our technical rigor to transform challenging copper requirements into reliable, high-performance components.

Technical Capabilities

Machining of copper alloy parts requires precise control due to the material’s high thermal conductivity, ductility, and tendency to work-harden. While the primary focus is on copper alloys such as C11000 (electrolytic tough pitch), C26000 (cartridge brass), and C17200 (beryllium copper), comparative machining parameters are often evaluated against other commonly used engineering materials including aluminum, steel, ABS, and nylon—especially when designing multi-material assemblies or prototypes.

The following table outlines key technical specifications and considerations for 3-axis, 4-axis, and 5-axis milling as well as turning operations, with emphasis on tight-tolerance applications (±0.0005″ to ±0.005″). All values are typical ranges and may vary based on tooling, machine rigidity, coolant use, and part geometry.

| Parameter | Copper Alloys (e.g., C11000, C26000) | Aluminum (e.g., 6061-T6) | Steel (e.g., 4140, 1018) | ABS (Thermoplastic) | Nylon (Polyamide) |

|---|---|---|---|---|---|

| Machining Process | 3/4/5-Axis Milling, CNC Turning | 3/4/5-Axis Milling, CNC Turning | 3/4/5-Axis Milling, CNC Turning | 3/4-Axis Milling | 3/4-Axis Milling, Turning |

| Typical Tolerance | ±0.0005″ to ±0.002″ | ±0.0005″ to ±0.001″ | ±0.001″ to ±0.005″ | ±0.005″ (dimensionally sensitive) | ±0.005″ (hygroscopic, variable) |

| Surface Finish (Ra) | 32–125 μin (milled), 16–32 μin (turned) | 16–63 μin (milled), 8–16 μin (turned) | 32–125 μin (milled), 16–63 μin (turned) | 63–250 μin (milled) | 63–250 μin (milled) |

| Spindle Speed (Milling) | 3,000–8,000 RPM | 8,000–15,000 RPM | 2,000–6,000 RPM | 6,000–10,000 RPM | 5,000–8,000 RPM |

| Feed Rate (Milling) | 50–200 in/min | 100–400 in/min | 50–150 in/min | 80–200 in/min | 60–150 in/min |

| Cutting Tools | Carbide with polished flutes, sharp edge | Carbide, uncoated or TiAlN coated | Carbide, CBN, or HSS (coated) | Carbide, high rake angle | Carbide, positive rake |

| Coolant Requirement | Flood or mist cooling required | Mist or air sufficient | Flood coolant recommended | Air blow only (avoid solvents) | Air blow or dry cutting |

| Workholding Considerations | High clamping force with soft jaws | Moderate force, non-marring preferred | High rigidity, vibration control | Low force, vacuum or light clamping | Moderate force, avoid stress cracking |

| Key Challenges | Built-up edge, chatter, thermal expansion | Chatter in thin walls | Tool wear, heat buildup | Melting, burring, static | Moisture absorption, dimensional drift |

| Recommended Toolpath Strategy | High-speed machining, climb milling | High-speed, adaptive toolpaths | Peck drilling, rough/finish passes | Light depth of cut, high RPM | Moderate feed, avoid overheating |

Note: For copper alloys, achieving tight tolerances in 5-axis milling requires thermal stability in the machine environment and in-process metrology due to material expansion during cutting. Turning operations benefit from rigid setups and continuous coolant flow to manage chip evacuation and prevent work hardening.

While aluminum remains the easiest to machine to tight tolerances with high surface finish consistency, copper alloys demand more specialized tooling and process control. Steel offers dimensional stability but at higher tooling costs. ABS and nylon are less common in high-precision metal-like tolerances due to their inherent material variability, though they are often machined alongside metal components in prototype assemblies.

At Honyo Prototype, we apply material-specific CNC strategies to ensure copper alloy parts meet demanding specifications in aerospace, medical, and electrical applications.

From CAD to Part: The Process

Honyo Prototype Copper Alloy Machining Process Overview

Honyo Prototype executes a rigorously controlled workflow for copper alloy components, addressing material-specific challenges including high thermal conductivity, galling susceptibility, and stringent surface finish requirements. Our integrated digital-to-physical pipeline ensures precision, cost efficiency, and accelerated time-to-market. Below is the end-to-end process:

CAD File Upload and Validation

Customers initiate the process by uploading native or neutral CAD formats (STEP, IGES, Parasolid) via our secure client portal. Our system performs automated geometry validation, checking for unit inconsistencies, non-manifold edges, and watertight solids. For copper alloys, we specifically flag features prone to thermal distortion during machining—such as thin walls below 0.5mm or deep cavities exceeding 10:1 aspect ratios—and notify the client for potential DFM adjustments prior to quotation.

AI-Powered Quoting Engine

Uploaded geometry feeds into our proprietary AI quoting system, which cross-references real-time shop floor data, material databases, and historical machining parameters for copper alloys (e.g., C11000, C18150, C26000). The AI dynamically calculates:

Machine time penalties for copper’s low thermal conductivity (requiring 30–40% slower feeds vs. aluminum)

Tool wear factors based on alloy hardness (e.g., beryllium copper vs. oxygen-free copper)

Coolant requirements to prevent built-up edge (BUE)

Quotes include material-specific surcharges for secondary operations like de-burring or passivation, with full cost breakdowns delivered within 2 business hours.

Material-Specific DFM Analysis

Engineers conduct a dedicated Design for Manufacturability review focused on copper’s unique properties. Critical checkpoints include:

| DFM Parameter | Copper Alloy Consideration | Honyo Mitigation Strategy |

|---|---|---|

| Toolpath Strategy | High thermal conductivity causes rapid heat dissipation, increasing cutting forces | Optimized step-over (≤15% of tool diameter) and climb milling to reduce BUE |

| Fixturing | Softness leads to part deformation under clamping pressure | Vacuum chucks or low-pressure modular fixtures with copper-compatible soft jaws |

| Surface Finish | Oxidation risk during machining; Ra <0.8µm often required | In-process cleaning with non-ionic solvents; dry machining for critical surfaces |

| Tolerances | Thermal expansion (16.5–17.5 µm/m°C) affects precision | Machining at stabilized 20±0.5°C ambient; iterative probing for critical features |

Recommendations are provided as actionable markups on the CAD model, with alternatives for problematic features (e.g., suggesting knurling instead of sharp threads to prevent galling).

CNC Production Execution

Approved designs enter production in dedicated copper-machining cells to eliminate cross-contamination:

Material Handling: Copper stock is stored in climate-controlled inventory; surface oxides removed via vapor degreasing pre-machining

Machine Parameters: Makino V56 5-axis mills with through-spindle coolant (5,000 psi) running at 8,000 RPM max; carbide tools with TiAlN coating and 12° rake angles

Process Controls: In-cycle probing verifies dimensional stability after roughing; ultrasonic cleaning between operations prevents chip adhesion

Quality Gates: CMM inspection per ASME Y14.5 with thermal drift compensation; conductivity spot-checks for electrical-grade alloys

Delivery and Documentation

Components undergo final passivation (nitric acid dip for oxygen-free copper) or nickel plating per spec, followed by VCI paper wrapping and humidity-controlled packaging. Each shipment includes:

Material test reports (MTRs) with ASTM B193 conductivity validation

FAI documentation per AS9102 for aerospace clients

Machining parameter log (feed rates, tool life data) for traceability

Standard lead time is 7–10 business days from DFM sign-off, with expedited 72-hour options for prototypes. All parts ship with ISO 9001:2015-certified process validation.

This closed-loop methodology reduces copper machining defects by 62% versus industry averages, as validated by our 2023 internal quality audit. We maintain dedicated material science support for alloy-specific challenges—contact our applications engineering team for conductivity optimization or galvanic corrosion mitigation strategies.

Start Your Project

For precision machining of copper alloy parts, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen ensures tight tolerances, superior surface finishes, and fast turnaround times for prototypes and production runs. We specialize in CNC machining of copper alloys including C11000, C10100, C18000, and other high-conductivity materials used in electrical, thermal, and industrial applications.

All processes are performed in-house with strict quality control, supporting industries such as electronics, automotive, and telecommunications. From design review to final inspection, we deliver consistent quality with ISO-compliant manufacturing practices.

Reach out today to request a quote or discuss your project specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.