Contents

Manufacturing Insight: Machining Molds

Precision Machined Molds: Accelerating Your Path from Concept to Production

At Honyo Prototype, we recognize that the foundation of successful injection-molded parts lies in the quality and speed of mold development. Traditional mold manufacturing often introduces critical delays in product validation and time-to-market, creating bottlenecks for engineering teams under aggressive development schedules. Our integrated Rapid Tooling and Injection Molding services directly address this challenge, leveraging advanced CNC machining capabilities to deliver production-ready molds faster without compromising on precision or durability.

We specialize in fabricating high-integrity aluminum and steel molds optimized for low-to-mid volume production runs, functional prototyping, and first-article validation. Utilizing multi-axis milling, wire EDM, and stringent quality control protocols, our molds consistently achieve tight tolerances (±0.005 mm) and superior surface finishes, ensuring your parts meet exact specifications from the initial production cycle. This rapid tooling approach bridges the gap between prototyping and full-scale manufacturing, enabling design verification, material testing, and market testing weeks ahead of conventional timelines.

The efficiency of our process is further amplified by Honyo’s Online Instant Quote platform. Engineering teams can now bypass lengthy RFQ cycles: simply upload your 3D CAD model, specify material and volume requirements, and receive a detailed, transparent cost estimate within minutes—not days. This immediacy empowers faster decision-making and project initiation, eliminating a common friction point in the sourcing workflow.

Rapid Tooling Timeline Comparison

| Process Stage | Traditional Lead Time | Honyo Prototype Lead Time |

|---|---|---|

| Mold Design & Quoting | 5-10 Business Days | < 24 Hours (via Online Instant Quote) |

| Mold Fabrication | 4-8 Weeks | 1-3 Weeks |

| First Article Delivery | 6-12 Weeks | 2-5 Weeks |

By combining technical expertise in precision mold machining with digital procurement innovation, Honyo Prototype delivers a streamlined pathway for manufacturers to de-risk product launches and accelerate commercialization. Request your instant quote today to experience how our rapid tooling solutions can transform your development cycle.

Technical Capabilities

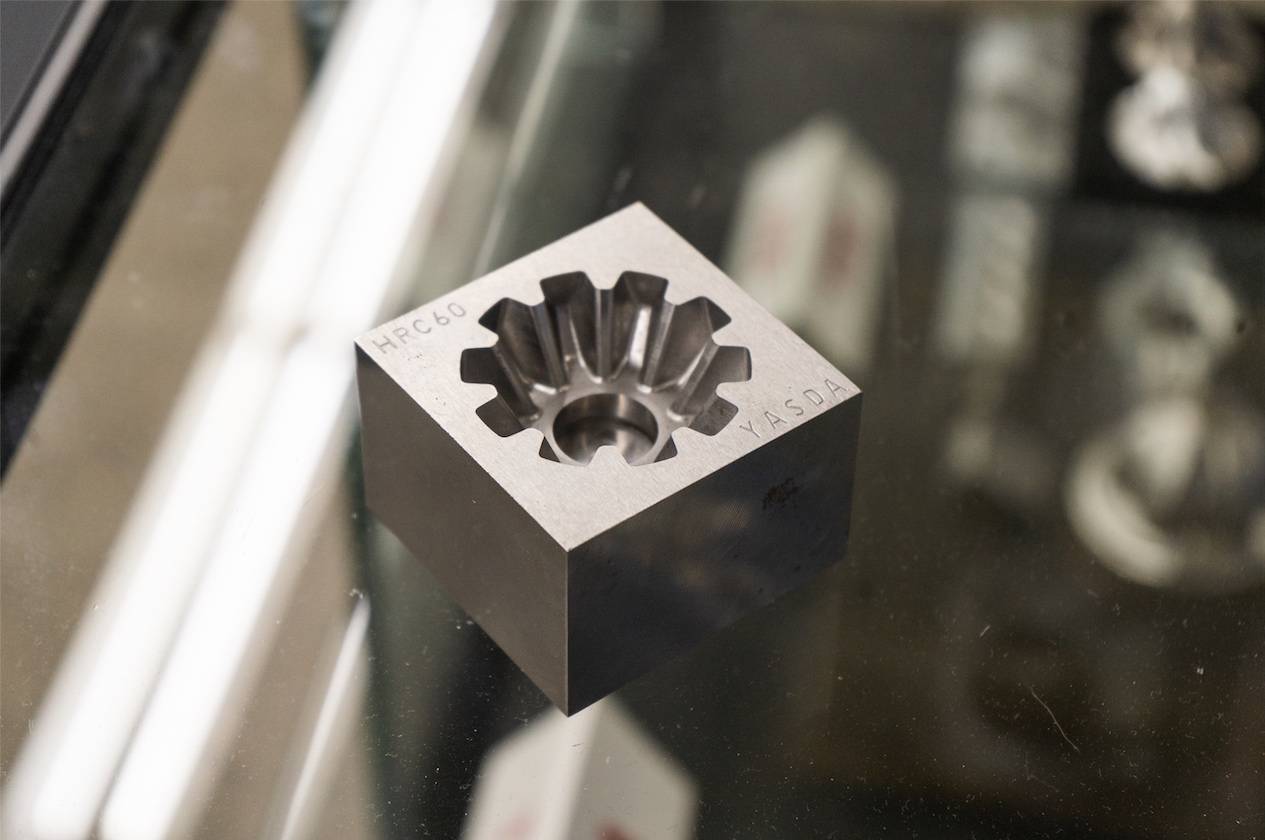

Machining molds for rapid prototyping and low-volume production requires precision engineering and material selection based on application, part complexity, and production volume. At Honyo Prototype, we specialize in delivering high-quality machined molds in aluminum and steel, with T1 sample parts available within 7 days from project kickoff. These molds are typically used for injection molding processes to produce plastic components in materials such as ABS and Nylon.

The following table outlines the key technical specifications for machined molds:

| Parameter | Aluminum Mold (7075-T6, 6061-T6) | Steel Mold (P20, H13, 420 Stainless) | Compatible Plastic Materials | Lead Time for T1 Sample | Surface Finish Options | Typical Use Case |

|---|---|---|---|---|---|---|

| Material Properties | Lightweight, high thermal conductivity, good machinability | High hardness, excellent wear resistance, long lifespan | ABS, Nylon, PC, PP, PE | 7 days | As-machined, polished, textured | Prototypes, bridge tooling, low-volume production |

| Mold Base Standard | Custom modular or standard plates | Standard or custom hardened plates | – | – | – | – |

| Cavity/Multi-Cavity Options | Single to 4 cavities | Single to 8+ cavities | – | – | – | – |

| Tooling Accuracy | ±0.025 mm | ±0.015 mm | – | – | – | – |

| Maximum Mold Size | Up to 600 x 400 x 300 mm | Up to 800 x 500 x 400 mm | – | – | – | – |

| Runner System | Cold runner or cold half-hot design | Cold or hot runner systems | – | – | – | – |

| Ejection System | Pin, sleeve, or stripper plate | Pin, plate, or custom ejection | – | – | – | – |

| Cooling Channels | Straight or conformal (limited) | Straight, conformal, or optimized | – | – | – | – |

| Expected Shot Life | 10,000 – 50,000 shots | 100,000 – 1M+ shots | – | – | – | – |

| Post-Processing Options | Anodizing (aluminum), hardening, plating | Nitriding, chrome plating, PVD coating | – | – | – | – |

These machined molds support rapid validation of part design and mold functionality. Aluminum molds are ideal for fast turnaround and lower production volumes, while steel molds are recommended for extended durability and higher cycle counts. ABS and Nylon are commonly processed in these molds due to their favorable flow characteristics and mechanical properties, with mold design adjusted for shrinkage and thermal behavior specific to each resin.

From CAD to Part: The Process

Honyo Prototype Machining Molds Process Overview

Honyo Prototype executes a streamlined, technology-driven workflow for precision machining of prototype and low-volume production molds. Our process begins with secure client CAD file submission via our encrypted portal, triggering automated validation for format compatibility and geometric integrity. This initial step ensures alignment with our CNC machining capabilities, including multi-axis milling, wire EDM, and grinding systems.

AI-Powered Quoting Engine

Upon CAD validation, our proprietary AI quoting system analyzes the model against real-time machine shop data, material databases, and historical production metrics. This generates a detailed cost and timeline estimate within 2 business hours, accounting for factors like cavity complexity, steel grade selection (e.g., P20, H13, aluminum), surface finish requirements, and electrode needs for EDM. The AI cross-references toolpath simulations to flag potential overhangs or thin-wall risks, providing transparent cost drivers rather than generic pricing.

| Process Stage | Typical Duration | Key Outputs |

|---|---|---|

| CAD Upload to AI Quote | 2-4 business hours | Validated geometry, cost breakdown, preliminary lead time |

| DFM Analysis | 3-5 business days | Optimized design report, risk mitigation plan |

| Production | 10-25 business days | Machined mold, in-process inspection data |

| Delivery | 1-2 business days | Final mold, FAI report, shipping documentation |

Engineering-Driven DFM Phase

Following quote acceptance, our manufacturing engineering team conducts a rigorous Design for Manufacturability review. This is not a checklist but a collaborative engineering dialogue where we identify moldability risks such as inadequate draft angles, non-uniform cooling channels, or ejector pin interference. We provide specific, actionable recommendations—like modifying parting line locations or suggesting alternative steel grades—to enhance mold longevity and reduce cycle times. Clients receive a formal DFM report with annotated CAD markups, and we require sign-off before proceeding to avoid downstream rework. Approximately 18% of initial designs undergo DFM revisions, typically resolving issues that could cause 30%+ production delays.

Precision Production Execution

Mold fabrication occurs in our climate-controlled facility using hardened tool steels or aluminum alloys per specifications. Each stage follows documented work instructions: rough milling on 5-axis DMG MORI machines, finish machining with sub-5µm tolerances, and critical EDM operations for intricate details. In-process inspections via Zeiss CMMs and optical comparators verify critical dimensions at defined checkpoints, with real-time data fed into our quality management system. For multi-cavity molds, we implement cavity balancing protocols to ensure uniform filling. All electrodes are digitally tracked, and surface textures (e.g., SPI-A2, VDI 3400) are verified against master samples.

Quality-Assured Delivery

Prior to shipment, molds undergo dry-cycle validation on our in-house press to confirm ejection, venting, and alignment. We deliver the mold with a comprehensive First Article Inspection report per AS9102 standards, including CMM data for all critical features, material certifications, and maintenance guidelines. Shipping includes custom crating with moisture control for international logistics, and our team schedules a post-delivery technical handoff to confirm client readiness for molding trials. This end-to-end traceability ensures molds arrive production-ready, typically achieving first-pass molding success rates above 92%.

Start Your Project

Looking for precision machining services for molds? Honyo Prototype offers high-quality mold machining solutions with fast turnaround times. Our state-of-the-art facility in Shenzhen ensures tight tolerances, excellent surface finishes, and consistent quality for injection molds, die-casting molds, and more.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Factory location: Shenzhen, China

Let us support your prototyping and production needs with expert engineering and reliable manufacturing performance.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.