Contents

Manufacturing Insight: Machining Medical Devices

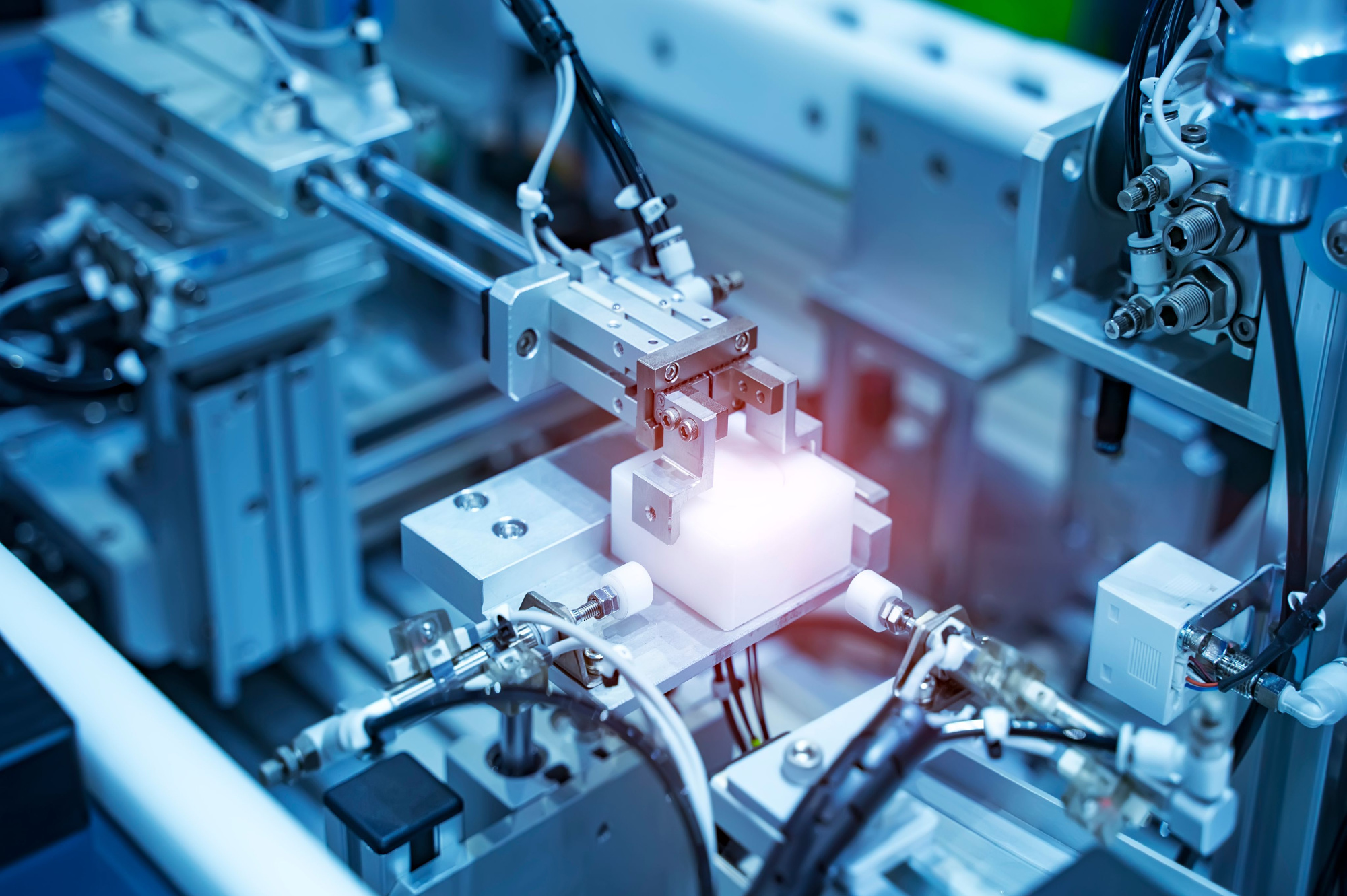

Precision CNC Machining for Critical Medical Device Applications

Honyo Prototype delivers advanced CNC machining solutions engineered specifically for the stringent demands of the medical device industry. Our ISO 13485-certified manufacturing ecosystem ensures uncompromising precision, material integrity, and full regulatory traceability for components ranging from surgical instruments and implantable devices to diagnostic equipment housings. We specialize in machining biocompatible materials including titanium alloys, medical-grade stainless steels (316L, 17-4 PH), PEEK, and engineered polymers to tolerances as tight as ±0.0002 inches, adhering strictly to FDA QSR and ISO 13485 documentation protocols. Every process—from 5-axis milling and Swiss turning to micro-machining and cleanroom assembly—is validated to eliminate contamination risks and guarantee repeatability for life-critical applications.

Accelerate Development with Seamless Quoting

Traditional medical device prototyping faces delays in quotation cycles, hindering rapid iteration. Honyo Prototype eliminates this bottleneck through our proprietary Online Instant Quote platform. Upload your STEP or IGES file, specify material and quantity requirements, and receive a detailed, factory-validated quotation within minutes—not days. This integration of engineering expertise with digital efficiency ensures your project moves from design validation to production-ready components faster, while maintaining full compliance with medical device regulatory frameworks.

The following table contrasts conventional medical device machining workflows with Honyo’s optimized process:

| Process Stage | Traditional Workflow | Honyo Prototype Workflow |

|---|---|---|

| Quotation Turnaround | 3-7 business days | Instant (under 2 minutes) |

| Material Certification | Post-order verification | Pre-vetted biocompatible stock |

| First Article Inspection | External third-party lab | In-house ASQ-certified metrology |

| Regulatory Compliance | Client-managed documentation | Integrated ISO 13485 traceability |

Leverage Honyo Prototype’s CNC machining expertise to transform complex medical designs into certified, high-performance components. Initiate your project with confidence by accessing our Online Instant Quote system—where precision engineering meets accelerated time-to-market for life-saving innovations.

Technical Capabilities

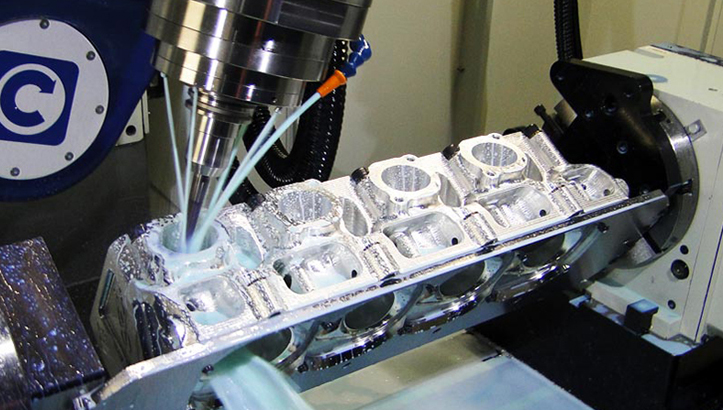

Technical specifications for machining medical devices require high precision, exceptional surface finishes, and strict adherence to regulatory standards due to the critical nature of medical applications. Multi-axis milling and turning operations are commonly employed to produce complex geometries found in surgical instruments, implants, and diagnostic equipment. These processes support tight tolerances, often in the range of ±0.0002″ (±0.005 mm), and demand advanced process control and metrology.

Key machining capabilities include 3-axis, 4-axis, and 5-axis CNC milling for intricate 3D contours and undercuts, as well as precision CNC turning for cylindrical components such as bone screws or instrument shafts. Materials commonly used include medical-grade metals and plastics, each selected for biocompatibility, strength, corrosion resistance, or sterilization compatibility.

Below is a summary of technical specifications relevant to machining medical devices:

| Parameter | Specification Details |

|---|---|

| Machining Processes | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (including Swiss-type) |

| Typical Tolerances | ±0.0002″ (±0.005 mm); critical features may require ±0.0001″ (±0.0025 mm) |

| Surface Finish (Ra) | 8–16 μin (0.2–0.4 μm) typical; polished finishes down to 2–4 μin (0.05–0.1 μm) possible |

| Materials – Metals | Aluminum 6061, 7075; Stainless Steel 316L, 17-4 PH; Titanium (Grade 5); MP35N |

| Materials – Plastics | Medical-grade ABS, Nylon (PA6, PA12), PEEK, PTFE, Polycarbonate |

| Work Envelope (Milling) | Up to 24″ x 36″ x 20″ (600 x 900 x 500 mm) for 3/4/5-axis systems |

| Work Envelope (Turning) | Bar feed up to 2″ (50 mm) diameter; max length 12″ (300 mm) |

| Spindle Speed (Milling) | 20,000–40,000 RPM for micro-machining; 8,000–12,000 RPM for general use |

| Tooling | Carbide, diamond-coated, and micro-tools; automatic tool changers (ATC) |

| Coolant/Lubrication | Flood coolant, mist coolant, or dry machining; compatible with cleanroom environments |

| Metrology | CMM, optical comparators, laser scanning, in-process probing |

| Compliance Standards | ISO 13485, FDA 21 CFR Part 820, ASTM F899, ASTM F138 (for implants) |

These specifications ensure that machined medical components meet functional, safety, and regulatory requirements. The use of 5-axis milling allows for single-setup machining of complex parts, reducing error and improving repeatability. Turning operations are optimized for high aspect ratio and small-diameter features. Material selection is critical—stainless steel and titanium are favored for implants due to biocompatibility and corrosion resistance, while ABS and nylon are used for housings, connectors, and non-implantable devices requiring sterilization compatibility.

From CAD to Part: The Process

Honyo Prototype Medical Device Machining Process Overview

Honyo Prototype executes medical device machining through a rigorously controlled five-stage workflow designed for regulatory compliance, precision, and accelerated time-to-market. This process adheres strictly to ISO 13485:2016 standards and integrates engineering oversight at critical control points to mitigate risks inherent in medical manufacturing. Below is a technical breakdown of each phase.

CAD Upload & Validation

Clients initiate the process via our secure, encrypted customer portal supporting native CAD formats (STEP, IGES, Parasolid) and neutral files. All uploads undergo automated validation for geometric integrity, unit consistency, and metadata completeness. Files requiring medical device classification per FDA 21 CFR Part 820 or EU MDR Annex VIII trigger mandatory material biocompatibility documentation checks (e.g., ISO 10993-1 compliance for polymers). Non-conforming submissions receive immediate feedback with specific error diagnostics to prevent downstream delays.

AI-Powered Preliminary Quoting

Our proprietary AI engine analyzes validated CAD geometry against live shop-floor data including machine availability, material costs, and historical cycle times. The algorithm factors medical-specific variables: required surface finish (e.g., Ra ≤ 0.8 µm for implant interfaces), tight tolerances (±0.005 mm typical), and secondary processes like electropolishing. Quotes include preliminary lead time estimates and flag features requiring manual engineering review. Note: This output is a non-binding estimate; final pricing is confirmed post-DFM.

Engineering-Led DFM Analysis

A dedicated medical device manufacturing engineer conducts comprehensive Design for Manufacturability (DFM) review within 24 hours of quote acceptance. This phase focuses on:

Regulatory alignment (e.g., eliminating crevices violating FDA cleanability guidelines)

Material suitability verification against ASTM F86 for passivation or ISO 7153 for surgical alloys

Geometric feasibility assessment for micro-features (e.g., catheter lumens <0.5 mm diameter)

Cost-risk optimization (e.g., suggesting alternative toolpaths to avoid wire EDM for titanium spinal fixtures)

A formal DFM report with actionable recommendations is issued, requiring client sign-off before production release.

Precision Production Execution

Approved designs enter our climate-controlled Class 10,000 cleanroom facility. Production employs:

Multi-axis CNC machining (Swiss-type lathes, 5-axis mills) with real-time SPC monitoring

Dedicated material lots with full traceability from mill certificate to finished part

In-process inspections using calibrated CMMs and optical comparators per AS9102

Automated documentation of critical parameters (e.g., spindle load, coolant pressure) for audit trails

Typical production capabilities for medical components are summarized below.

| Parameter | Capability Range | Compliance Standard |

|---|---|---|

| Tolerances | ±0.0025 mm (critical features) | ISO 2768-mK |

| Surface Finish | Ra 0.1 – 1.6 µm (as required) | ASTM B912 |

| Materials | Ti-6Al-4V ELI, ASTM F138 CoCr, PEEK, MP35N | USP Class VI, ISO 10993 |

| Max Part Size | Ø 250 mm x 500 mm | – |

| Batch Traceability | Individual UDI serialization | FDA 21 CFR Part 1271 |

Regulatory-Ready Delivery

All shipments include a complete documentation package: Certificate of Conformance, Material Test Reports, First Article Inspection (FAI) per AS9102, and process validation records. Parts are double-bagged in ISO Class 5 packaging with ESD protection. Final delivery coordinates with client quality teams for JIT inventory integration, with full shipment tracking and customs documentation managed for global logistics. This end-to-end traceability ensures seamless integration into your Design History File (DHF) for regulatory submissions.

This structured workflow reduces prototyping-to-production lead times by 30-45% versus industry averages while maintaining zero non-conformances in recent FDA audits. We prioritize engineering collaboration at every phase to transform complex medical designs into manufacturable, compliant components.

Start Your Project

For precision machining of medical devices, contact Susan Leo at [email protected]. Our ISO-compliant manufacturing facility in Shenzhen delivers high-accuracy components with strict adherence to medical industry standards. Turnkey solutions from prototyping to volume production.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.