Contents

Manufacturing Insight: Machining Materials

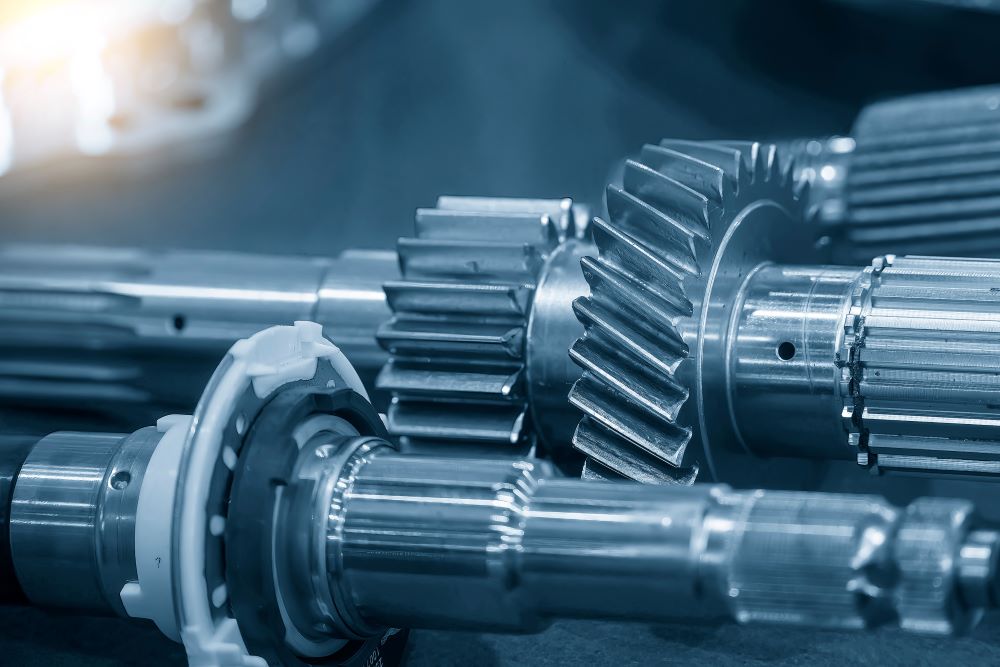

Honyo Prototype delivers precision CNC machining services engineered for mission-critical applications where material integrity directly impacts performance and reliability. Our technical expertise spans complex geometries across aerospace alloys, medical-grade stainless steels, engineering thermoplastics, and advanced composites, ensuring optimal material utilization and part functionality. We recognize that suboptimal material selection or inadequate process control can lead to field failures, increased lifecycle costs, and project delays—risks we mitigate through rigorous metallurgical validation and process optimization.

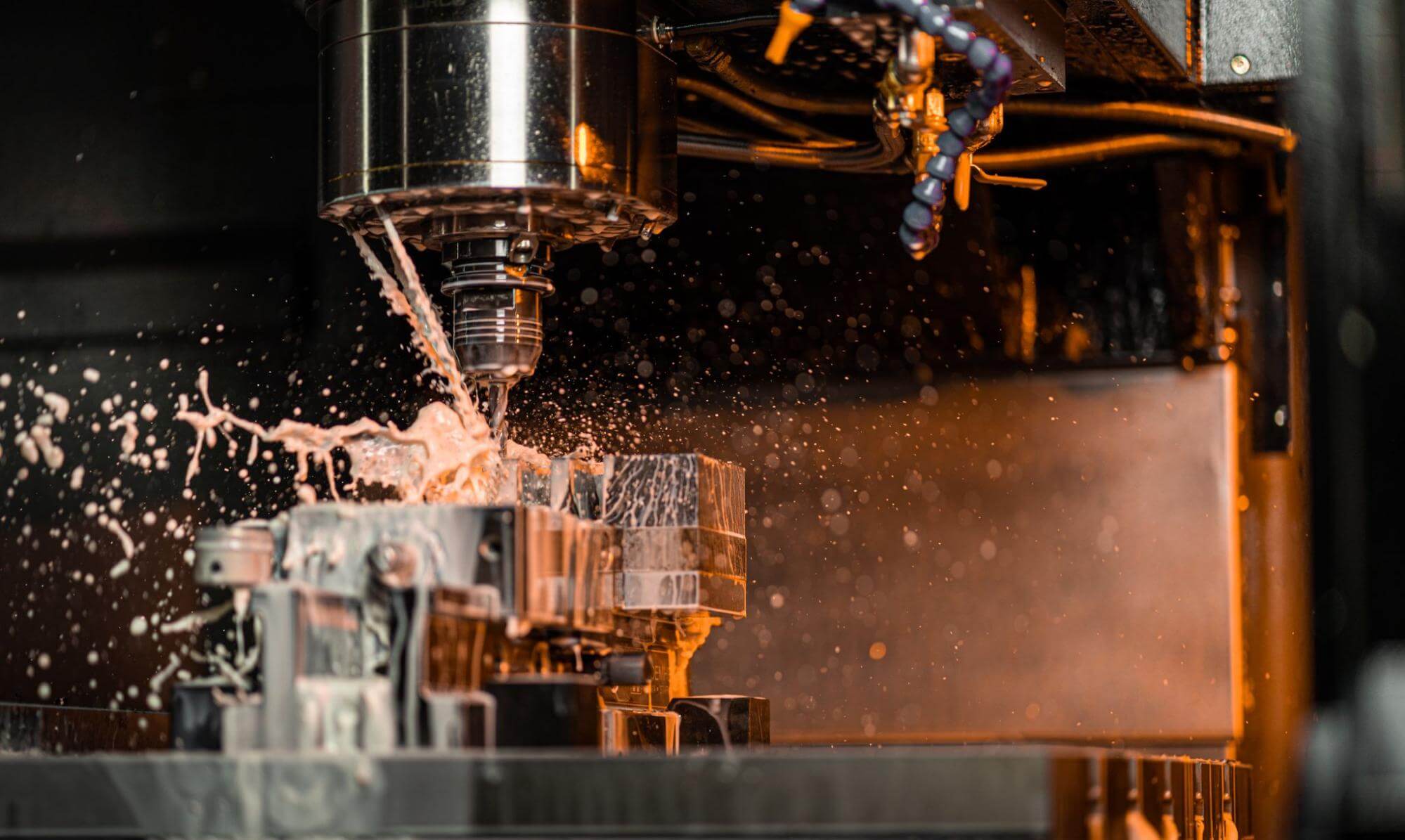

Our vertically integrated facility features state-of-the-art 3-axis, 4-axis, and 5-axis milling centers alongside precision turning capabilities, all operated by AS9100-certified technicians. This infrastructure enables us to machine challenging materials like Inconel 718, Titanium Ti-6Al-4V, PEEK, and carbon fiber-reinforced polymers to tight tolerances (±0.0002″) while maintaining strict adherence to surface finish and thermal stability requirements. Every project undergoes comprehensive process planning, including material traceability documentation and in-process CMM verification, guaranteeing compliance with ISO 2768-mK and customer-specific specifications.

Material suitability analysis is foundational to our engineering approach. We provide actionable guidance on material grade selection, machinability trade-offs, and post-processing requirements during the design phase—transforming theoretical specifications into manufacturable, high-yield solutions. To accelerate your prototyping or low-volume production timeline, leverage our Online Instant Quote system. Simply upload your 3D CAD model to receive a detailed manufacturability assessment and competitive pricing within minutes, backed by our commitment to technical transparency and on-time delivery. Begin your precision machining project with validated expertise at honyoprototype.com/quote.

Technical Capabilities

Below are the technical specifications and material characteristics relevant to machining processes including 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, with emphasis on tight tolerance applications. The materials covered are Aluminum (6061-T6), Steel (4140), ABS (Acrylonitrile Butadiene Styrene), and Nylon (6/66). These materials are commonly used in precision prototyping and production at Honyo Prototype.

| Material | Form Available | Typical Tolerance (Machined) | Machinability Rating | Surface Finish (As-Machined) | Thermal Stability | Key Considerations for Machining |

|---|---|---|---|---|---|---|

| Aluminum 6061-T6 | Bar, Plate, Billet | ±0.0005″ (12.7 µm) | Excellent (9/10) | 32–64 µin Ra | Moderate | High material removal rate; excellent for 3–5-axis milling; minimal tool wear; ideal for tight tolerance components; use sharp carbide tools to avoid built-up edge |

| Steel 4140 (Annealed) | Bar, Forging | ±0.0002″ (5 µm) | Good (6/10) | 16–32 µin Ra | High | Requires rigid setup; suitable for precision turning and multi-axis milling; tight tolerances achievable with proper tooling and coolant; prone to work hardening if parameters are incorrect |

| ABS (Thermoplastic) | Rod, Sheet | ±0.005″ (127 µm) | Very Good (8/10) | 64–125 µin Ra | Low | Low melting point; use sharp tools with high rake angles and low feed rates; avoid excessive heat buildup; ideal for non-structural prototypes; not recommended for high-temp environments |

| Nylon 6/66 | Rod, Sheet, Tube | ±0.005″ (127 µm) | Good (7/10) | 64–125 µin Ra | Low to Moderate | High moisture absorption; pre-dry if moisture-sensitive grades; slight dimensional change post-machining possible; excellent wear and chemical resistance; suitable for functional prototypes and low-friction parts |

Notes on Process Compatibility:

3-axis, 4-axis, and 5-axis milling are all capable of achieving tight tolerances with aluminum and steel when proper fixturing, tool selection, and thermal compensation strategies are employed. Aluminum 6061-T6 is particularly well-suited for complex geometries in 5-axis setups due to its excellent machinability and dimensional stability during cutting.

Steel 4140 is frequently used in high-strength, tight-tolerance applications such as aerospace and tooling components. It requires slower speeds and feeds compared to aluminum but delivers superior repeatability and surface integrity when machined under controlled conditions.

ABS and Nylon, while less dimensionally stable than metals, are routinely machined in precision environments for prototypes, jigs, and non-metallic components. Dimensional tolerances are looser due to material creep and hygroscopic behavior, especially in humid environments. Machining should be followed by inspection under controlled conditions if tight fitment is required.

For all materials, tight tolerance machining (±0.001″ and finer) demands high-precision CNC equipment, in-process metrology, and thermal management—especially critical in multi-day 5-axis operations.

From CAD to Part: The Process

Honyo Prototype Machining Materials Process Overview

Honyo Prototype employs a rigorously defined workflow to ensure precision, efficiency, and technical alignment from initial design to final delivery for machined components. This process integrates advanced digital tools with deep manufacturing expertise, specifically optimized for diverse material properties and client requirements. Below is a detailed technical breakdown of each phase.

CAD Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native formats like SOLIDWORKS) via Honyo’s secure portal. Our system performs immediate geometric validation, checking for non-manufacturable features, unit inconsistencies, or topology errors. Material specifications embedded in the CAD file—such as alloy grade (e.g., 6061-T6 aluminum, 304 stainless steel), heat treatment, or surface finish requirements—are extracted and cross-referenced against Honyo’s material database. This step ensures material feasibility before proceeding to quoting, eliminating downstream errors caused by ambiguous or incomplete design data.

AI-Powered Quoting Engine

The validated CAD data feeds into Honyo’s proprietary AI quoting system, which leverages a decade of shop-floor machining data, material-specific cost drivers, and real-time machine utilization metrics. Unlike generic online quoters, our AI analyzes material machinability indices (e.g., AISI B1112 free-machining steel vs. Inconel 718 nickel alloy), tool wear rates, coolant requirements, and thermal deformation risks unique to the selected material. The output is a technically grounded quote with lead time estimates, cost drivers broken down by material waste, cycle time, and post-processing, and explicit assumptions (e.g., “Quote assumes stress-relieved 7075-T6 aluminum; as-cast material incurs +15% cost”). This transparency prevents scope creep and aligns client expectations with physical manufacturing constraints.

Engineering-Led DFM Analysis

Following quote acceptance, Honyo’s manufacturing engineers conduct a formal Design for Machinability (DFM) review. This phase is material-centric: for brittle materials like cast iron, we flag thin-wall sections prone to chatter; for thermally sensitive alloys like titanium, we identify deep pockets requiring specialized toolpaths to prevent warping. DFM reports detail actionable revisions—such as adjusting corner radii to match standard end mill sizes, modifying tolerances to account for material spring-back, or recommending alternative alloys (e.g., switching 2024 aluminum to 7075 for critical fatigue applications). Clients receive a collaborative portal to approve, reject, or discuss DFM suggestions, with all iterations tracked for auditability. Crucially, DFM sign-off requires explicit validation of material suitability, ensuring production begins only when the design is optimized for the target material’s behavior under machining stresses.

Precision Production Execution

Approved designs move to Honyo’s CNC facility, where material-specific protocols govern production. Raw stock undergoes incoming inspection (certificates of conformance, hardness testing, and ultrasonic flaw detection for critical aerospace alloys). Machining parameters are dynamically adjusted per material: high-speed steel tools for plastics, carbide with reduced feed rates for hardened tool steels, and cryogenic cooling for magnesium to suppress combustion risks. In-process inspections at critical stages—using CMMs, optical comparators, and surface roughness testers—verify dimensional stability, especially for materials prone to thermal drift (e.g., copper alloys). All toolpaths are validated via simulation software that models material removal rates and chip evacuation, preventing collisions or surface defects unique to the workpiece material.

Quality-Controlled Delivery

Final inspection includes material-specific verification: salt-spray testing for corrosion-resistant alloys, XRF analysis for material composition, and microstructure sampling for critical applications. Components are packaged with anti-corrosion inhibitors for reactive metals (e.g., aluminum, magnesium) and shipped with full traceability documentation—heat numbers, inspection reports, and as-machined vs. nominal dimension deviations. Delivery timelines are rigorously maintained through real-time production tracking, with expedited options for urgent material-critical projects (e.g., medical titanium implants).

Material-Specific Process Parameters

Honyo’s deep material expertise ensures optimal handling across common machining substrates:

| Material Category | Example Alloys | Key Machining Considerations | Honyo Process Adjustment |

|---|---|---|---|

| Aluminum Alloys | 6061-T6, 7075-T6 | Low melting point; prone to built-up edge | High-speed machining with air blast cooling; sharp carbide tools |

| Stainless Steels | 304, 316L, 17-4PH | Work hardening; galling risks | Rigid setups; interrupted cut strategies; low-RPM finishing |

| Titanium Alloys | Ti-6Al-4V (Grade 5) | Low thermal conductivity; reactivity with tooling | Flood coolant; slow feed rates; minimal depth of cut |

| Engineering Plastics | PEEK, Delrin | Thermal deformation; chip evacuation challenges | Sharp polycrystalline diamond tools; vacuum chip removal |

| Exotic Alloys | Inconel 718, Monel 400 | Extreme hardness; high cutting forces | Cryogenic cooling; specialized ceramic inserts |

This end-to-end workflow ensures Honyo transforms CAD designs into high-integrity machined components by treating material properties as a foundational constraint—not an afterthought. Every phase is engineered to mitigate material-specific risks, delivering parts that meet stringent functional and regulatory requirements on time. For complex material challenges, our engineers provide direct consultation to refine specifications before production commences.

Start Your Project

Explore our full range of precision machining materials engineered for performance and reliability. From aluminum and steel to brass, titanium, and advanced engineering plastics, Honyo Prototype delivers consistent quality for prototyping and low-volume production.

All machining services are performed at our ISO-certified factory in Shenzhen, ensuring tight tolerances, fast turnaround, and full traceability across every batch.

For material specifications, quotes, or project support, contact Susan Leo at [email protected]. Let’s build your next prototype with the right material and precision.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.