Contents

Manufacturing Insight: Machining Fixtures

Precision Fixture Engineering for Uncompromised CNC Machining Outcomes

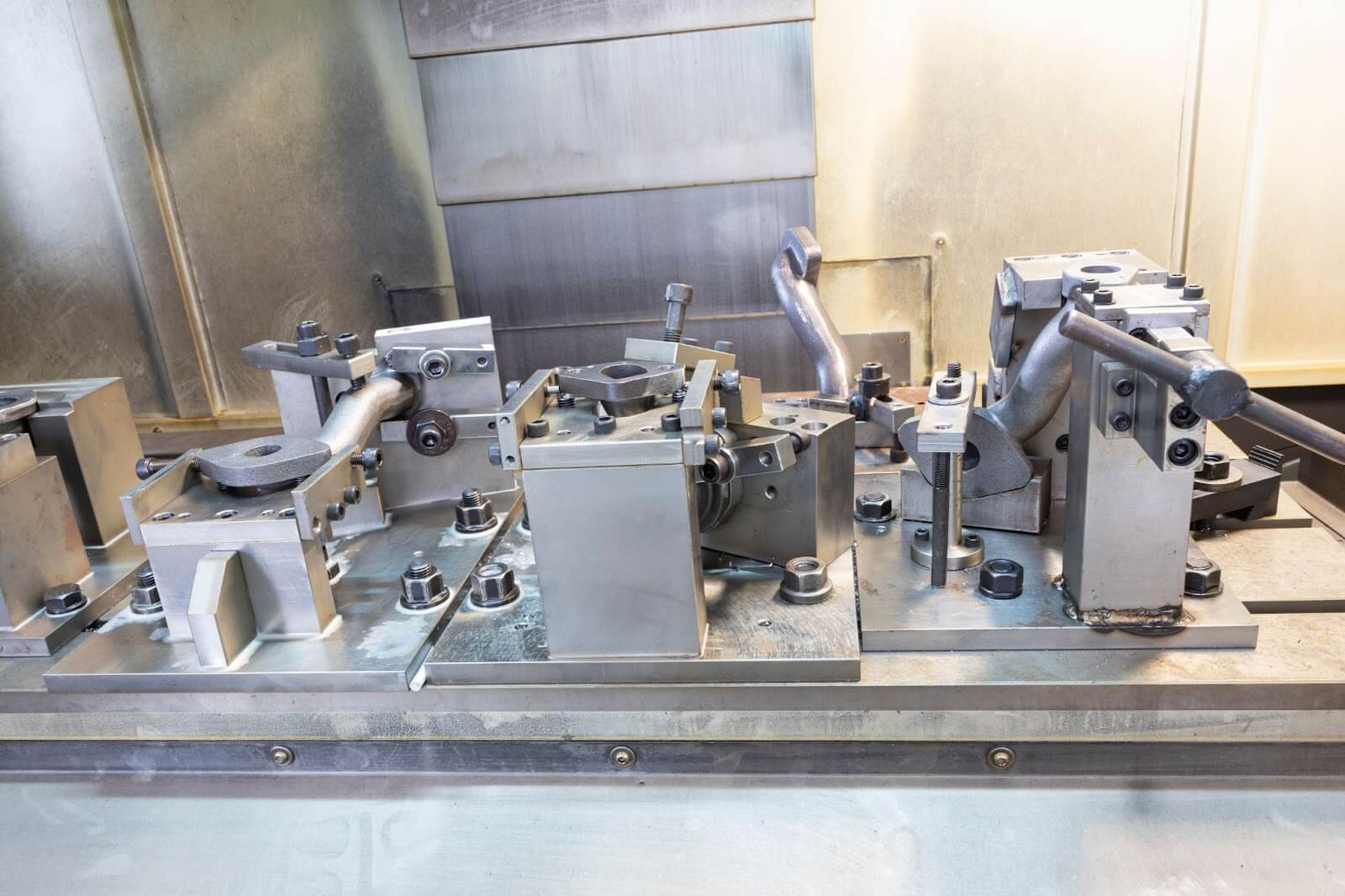

Machining fixtures represent the critical foundation for achieving geometric integrity and repeatability in high-precision CNC operations. At Honyo Prototype, we engineer purpose-built fixtures that eliminate workpiece deflection, vibration, and positioning errors during complex milling, turning, and multi-axis processes. Our fixtures are designed to stringent tolerances—typically holding positional accuracy within ±0.0002 inches—ensuring consistent part quality across production runs while maximizing machine utilization.

Leveraging decades of manufacturing expertise, Honyo integrates material science, stress analysis, and rapid prototyping techniques to deliver fixtures optimized for your specific component geometry and production volume. Whether for aerospace turbine blades requiring thermal stability or medical device components demanding micron-level repeatability, our solutions reduce setup times by up to 70% and scrap rates by over 40% compared to generic tooling. All fixtures undergo rigorous in-house validation on the same CNC platforms used for final part production, guaranteeing seamless integration into your workflow.

Accelerate your project timeline with Honyo’s Online Instant Quote system. Upload CAD files to receive comprehensive machining and fixture cost estimates within minutes—not days—enabling faster decision-making without sacrificing technical rigor. Our platform provides transparent pricing for both standard and custom fixture configurations, reflecting real-time capacity and material costs.

Honyo Prototype transforms fixture design from a production bottleneck into a strategic advantage. Partner with us to achieve dimensional certainty, reduce non-value-added cycle time, and accelerate time-to-market for your most demanding machined components. Initiate your precision machining project with confidence through our instant quoting portal today.

Technical Capabilities

Machining Fixtures – Technical Specifications

Machining fixtures are precision workholding devices used to securely position and support workpieces during CNC operations. For high-accuracy applications such as 3/4/5-axis milling and turning with tight tolerances (±0.0005″ to ±0.001″), fixture design and material selection are critical to ensure rigidity, thermal stability, and repeatability. Below are key technical specifications based on machining type, tolerance requirements, and common fixture materials.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Considerations |

|---|---|---|---|---|---|

| Primary Function | Secure part for X/Y/Z linear motion | Adds indexed or continuous A-axis (rotary) | Full multi-axis simultaneous motion with A/B or A/C axes | Hold cylindrical or symmetric parts radially | Minimize deflection, vibration, and thermal drift |

| Fixture Rigidity Requirement | High | High | Very High | High | Maximum – critical for sub-0.001″ tolerances |

| Typical Materials | Aluminum (6061-T6), Steel (1018, 4140), ABS, Nylon | Aluminum (7075-T6), Steel, ABS | Steel (4140, hardened), Aluminum (7075-T6) | Steel (4140), Aluminum (6061) | Steel preferred; Aluminum for lightweight, non-load-bearing components |

| Aluminum (e.g., 6061-T6, 7075-T6) | Common for prototypes; lightweight, good machinability | Used in rotary tables and light-duty vises; moderate strength | Limited to non-critical setups; good for rapid iteration | Rarely used for main chucks; used in custom soft jaws | Not ideal for high-precision long runs due to lower stiffness and thermal expansion |

| Steel (e.g., 1018, 4140, Hardened Alloys) | Preferred for production; high rigidity and durability | Standard for high-load rotary fixtures; excellent wear resistance | Dominant material for high-accuracy 5-axis nests and tombstones | Standard for collets, chucks, and custom face drivers | Best for tight tolerance work; high E-modulus, low deflection, stable under thermal variation |

| ABS (3D Printed or Machined) | Used for low-force prototyping, alignment aids | Occasionally for lightweight inspection fixtures | Rare; only for non-contact positioning models | Not recommended | Only for non-critical, low-temperature setups; high thermal expansion and creep |

| Nylon (e.g., PA6, PA12) | Used for clamping inserts, soft jaws to protect part finish | Used in non-marring clamping arms | Limited to protective interfaces | Used in part support or non-abrasive contact points | Low stiffness; not suitable for high precision; good for cosmetic protection |

| Thermal Stability | Moderate importance | Important due to extended cycle times | Critical – thermal growth affects vector accuracy | Important during long turning cycles | Steel offers best thermal performance; avoid plastics in precision zones |

| Design Complexity | Moderate – flat datum interfaces | Higher – rotary clearance and indexing | Highest – multi-surface access, minimal interference | Moderate to high – balanced clamping | Modular, low-profile designs with precision-ground datums and repeatable locators |

| Tolerance Matching | Fixture features typically held to ±0.001″ | ±0.0005″ on critical locators | ±0.0002″ to ±0.0005″ on datums and bores | ±0.0005″ for collet alignment and runout | Ground steel components, use of kinematic mounts, CMM validation required |

Notes

For tight tolerance work, steel remains the preferred material for core structural components due to its high modulus of elasticity and dimensional stability.

Aluminum fixtures are acceptable in 3- and 4-axis applications where weight savings or rapid prototyping is a priority, but must be reinforced for high-precision use.

Polymer materials (ABS, Nylon) are generally restricted to non-load-bearing, non-critical, or protective roles and are not recommended in high-accuracy zones.

All high-tolerance fixtures should be validated using CMM or laser probing and designed with minimal overhang, optimized clamping force distribution, and thermal compensation in mind.

From CAD to Part: The Process

Honyo Prototype Machining Fixture Development Process

Honyo Prototype delivers precision machining fixtures through a rigorously controlled workflow designed to eliminate errors, optimize lead times, and ensure seamless integration into client production lines. Our process begins with CAD data submission and culminates in validated fixture delivery, leveraging AI-driven efficiency without compromising engineering oversight.

CAD Upload and Initial Processing

Clients submit 3D CAD models in STEP, IGES, or native formats via our secure portal. Our system automatically validates file integrity, checks for geometric completeness, and flags missing critical elements such as tolerance callouts, material specifications, or datum references. Incomplete submissions trigger immediate client notifications with precise requirements, preventing downstream delays. Only fully compliant CAD data advances to quoting, ensuring accuracy in subsequent stages.

AI-Assisted Quoting with Engineering Validation

Proprietary AI algorithms analyze the validated CAD geometry to generate a preliminary quote within 2 business hours. The system calculates material consumption, machine time, and complexity factors like undercuts or micro-features. Crucially, this AI output undergoes mandatory review by a Senior Manufacturing Engineer who verifies feasibility, adjusts for real-world constraints (e.g., tool access limitations), and incorporates client-specific requirements such as NIST-traceable calibration. Clients receive a formal quote with transparent cost breakdowns and lead time commitments, not AI-generated estimates.

Engineering-Led DFM Analysis

Every fixture undergoes a comprehensive Design for Manufacturing review led by our fixture specialists. This phase focuses on functional reliability:

Clamping force distribution simulations to prevent part deformation

Thermal expansion compensation for high-precision applications

Modular design optimization for future reconfiguration

Verification of datum alignment with client’s target machining process

DFM findings are documented in a collaborative report with actionable recommendations, not generic suggestions. Clients receive detailed 3D markup files showing exact modifications, typically within 48 hours. Approval of the DFM report locks the design for production, eliminating scope creep.

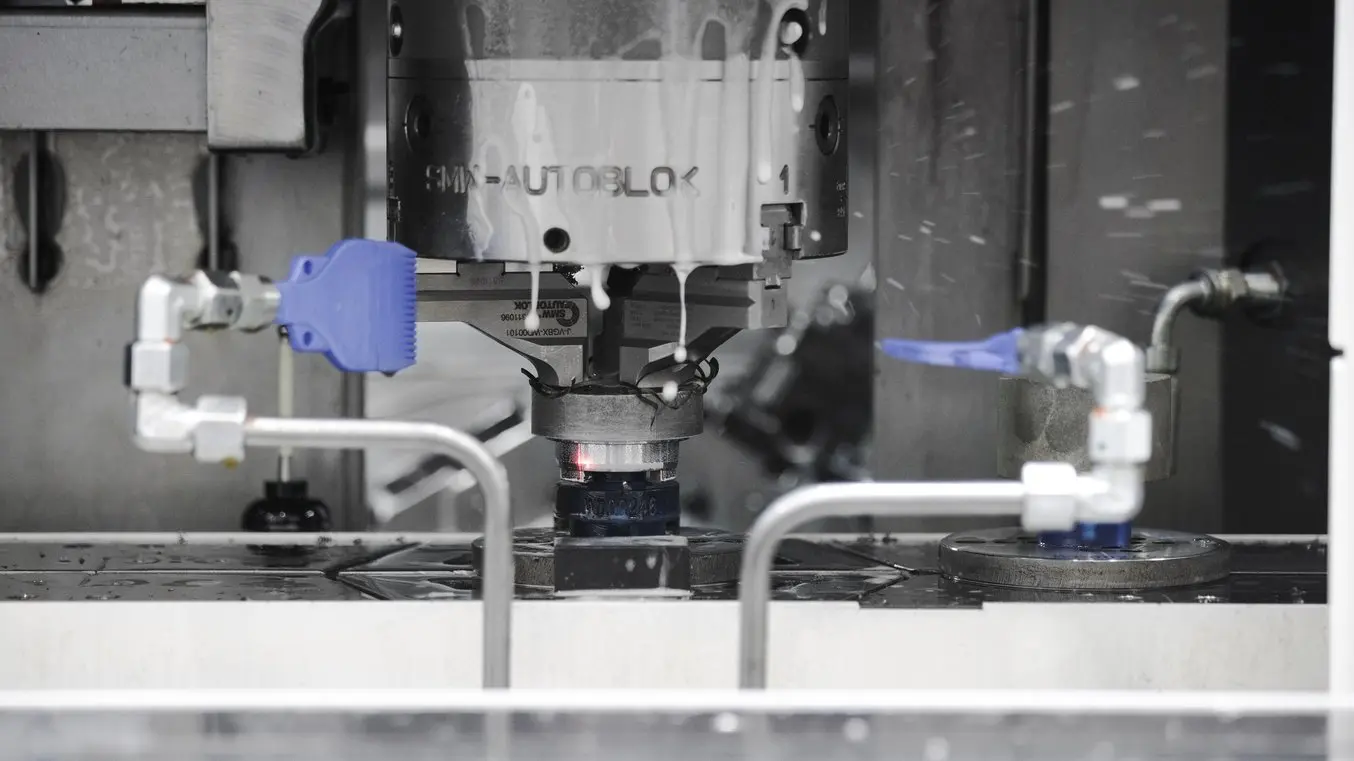

Precision Production and In-Process Validation

Fixtures are manufactured in our climate-controlled facility using hardened tool steels or aerospace-grade aluminum, with all critical features held to ±0.005mm tolerances. Key protocols include:

Dedicated CNC programs verified via third-party simulation software

In-process CMM checks at 50% and 100% completion stages

Surface finish validation against client’s part contact requirements

Load testing with actual production parts under simulated machining forces

Each fixture includes a serialized traceability tag linking to its full production log, including material certs and inspection data.

Delivery and Operational Handoff

Fixtures ship with comprehensive documentation:

As-built 3D model with dimensional verification report

Step-by-step setup instructions including torque specs for locators

Video demonstration of part loading/unloading sequences

Calibration certificate for critical datums

All fixtures undergo final functional validation in our test cell using the client’s actual part geometry before release. We provide post-delivery support for 30 days, including remote troubleshooting to ensure immediate production integration.

This end-to-end process ensures fixtures arrive ready for first-pass success in client operations, reducing changeover times by 40% and eliminating scrap due to workholding errors. Honyo’s integration of AI efficiency with deep manufacturing expertise delivers fixtures that perform reliably from day one.

Start Your Project

For expert machining fixtures designed to ensure precision and repeatability in your manufacturing processes, contact Susan Leo at [email protected]. Our production facility is based in Shenzhen, leveraging advanced capabilities and strict quality control to deliver custom fixture solutions tailored to your prototyping and low-volume production needs. Reach out today to discuss your project requirements and optimize your machining operations.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.