Contents

Manufacturing Insight: Machining Edm

Precision Machining Beyond Traditional CNC: Honyo Prototype’s EDM and Integrated Manufacturing Capability

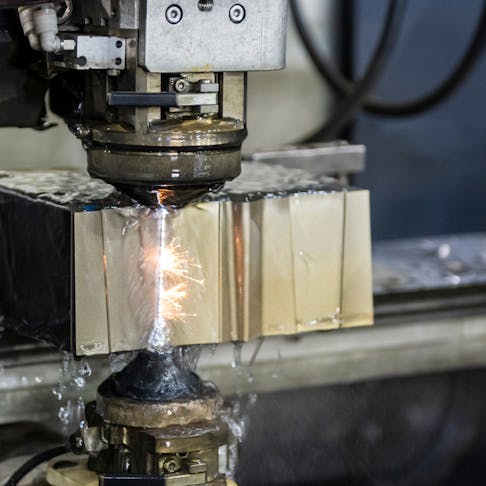

When conventional CNC machining reaches its limits with hardened materials, intricate geometries, or sub-micron tolerances, Electrical Discharge Machining (EDM) becomes the critical solution for achieving uncompromising precision. EDM leverages controlled electrical discharges to erode conductive materials without physical contact, enabling the production of complex cavities, sharp internal corners, and fine surface finishes impossible through milling or turning alone. This process is indispensable for demanding applications in aerospace, medical device manufacturing, and tooling, where material integrity and dimensional accuracy are non-negotiable.

Honyo Prototype integrates advanced wire EDM, sinker EDM, and small-hole drilling capabilities within our comprehensive CNC machining ecosystem. Our facility operates alongside state-of-the-art 3-, 4-, and 5-axis CNC milling and turning centers, ensuring seamless transitions between subtractive and non-traditional processes. This unified approach eliminates supply chain fragmentation, maintains strict process control, and accelerates time-to-part for components requiring hybrid manufacturing strategies. All EDM operations are supported by rigorous in-house metrology, including CMM and optical inspection, to validate tolerances down to ±0.0001 inches.

Accelerate your prototyping and low-volume production with Honyo Prototype’s Online Instant Quote platform. Upload your CAD files directly to receive a detailed manufacturability analysis and competitive pricing within hours—not days. This digital workflow, engineered for speed without sacrificing technical rigor, ensures you gain actionable insights early in your design cycle while leveraging our full spectrum of precision machining services, including mission-critical EDM solutions. Start your project with confidence at honyoprototype.com/quote.

Technical Capabilities

Machining EDM Technical Specifications

Electrical Discharge Machining (EDM), also known as spark machining, is a non-traditional manufacturing process used to machine hard materials and complex geometries with high precision. While EDM itself is distinct from conventional 3/4/5-axis milling and turning, it is often integrated into hybrid manufacturing workflows where tight tolerances and fine surface finishes are critical. Below are the technical specifications related to high-precision CNC machining processes—specifically 3/4/5-axis milling, turning, and tight tolerance capabilities—for common engineering materials including Aluminum, Steel, ABS, and Nylon. These processes are often used in conjunction with or as an alternative to EDM depending on design and material requirements.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Axes of Motion | X, Y, Z | X, Y, Z, + Rotary (A-axis) | X, Y, Z, + Two Rotational (A/B or A/C) | X, Z, + C-axis for indexing | N/A |

| Typical Positioning Accuracy | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.003 mm (±0.0001″) | ±0.005 mm (±0.0002″) | ±0.0025 mm (±0.0001″) |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.001 mm | ±0.002 mm | ±0.001 mm |

| Surface Finish (Typical) | Ra 0.8 – 3.2 µm | Ra 0.8 – 1.6 µm | Ra 0.4 – 1.6 µm | Ra 0.8 – 1.6 µm | Ra 0.2 – 0.8 µm (with finishing passes) |

| Minimum Feature Size | 0.5 mm end mill typical | 0.5 mm | 0.5 mm | 0.1 mm (for grooving) | 0.1 mm (with micro-tools) |

| Max Work Envelope (Typical) | 1000 x 600 x 500 mm | 800 x 500 x 400 mm | 600 x 500 x 400 mm | Ø300 x 500 mm | Varies by machine, typically up to 500 mm per axis |

| Spindle Speed Range | 8,000 – 24,000 RPM | 8,000 – 20,000 RPM | 10,000 – 30,000 RPM | 3,000 – 12,000 RPM | 20,000+ RPM (with high-speed spindles) |

| Feed Rate (Max) | 10 m/min | 10 m/min | 20 m/min | 5 m/min | 5 – 15 m/min (precision mode) |

Material-Specific Machining Performance

| Material | Machinability | Max Tolerance Typical | Notes |

|---|---|---|---|

| Aluminum (e.g., 6061, 7075) | Excellent | ±0.0125 mm | High thermal conductivity; ideal for high-speed milling and tight-tolerance work. Low cutting forces. |

| Steel (e.g., 4140, 17-4PH) | Good to Moderate | ±0.010 mm | Requires rigid setups and proper tooling. Suitable for EDM when hardened (>45 HRC). |

| ABS (Acrylonitrile Butadiene Styrene) | Very Good | ±0.050 mm | Low melting point; requires sharp tools and low heat input. Not suitable for EDM. |

| Nylon (Polyamide) | Good | ±0.050 mm | Can experience thermal expansion; needs controlled feeds/speeds. Not electrically conductive—cannot be EDM processed. |

Notes on EDM Integration

EDM is typically used when machining electrically conductive materials (Aluminum, Steel) with extreme complexity or after heat treatment. It achieves tolerances down to ±0.001 mm and surface finishes as fine as Ra 0.1 µm. It is not applicable for non-conductive materials such as ABS and Nylon. For hybrid workflows, 5-axis milling is often used for roughing and semi-finishing, followed by EDM for final cavity or contour shaping, especially in mold and aerospace components.

Summary

For tight tolerance machining of conductive materials like Aluminum and Steel, 5-axis milling and EDM are complementary processes. Turning provides high precision for rotational parts, while milling supports complex 3D geometries. Non-conductive polymers such as ABS and Nylon are limited to conventional CNC processes due to their incompatibility with EDM.

From CAD to Part: The Process

Honyo Prototype EDM Manufacturing Process Overview

At Honyo Prototype, Electrical Discharge Machining (EDM) is a core capability for producing complex geometries, tight-tolerance features, and hardened materials where traditional machining is impractical. Our integrated workflow ensures precision, efficiency, and minimal client rework. Below is a technical breakdown of our end-to-end EDM process, distinct from conventional CNC machining due to its non-contact thermal erosion methodology.

CAD Upload and Initial Processing

Clients submit native CAD files (STEP, IGES, Parasolid) via our secure portal, specifying material, tolerances, surface finish, and critical features. For EDM, this step is critical as electrode design and spark gap compensation directly depend on 3D model accuracy. Our system validates geometry integrity, checks for undercuts or thin ribs prone to distortion, and flags features requiring multi-axis sinking or wire path optimization. Unlike CNC processes, EDM requires explicit identification of EDM-specific zones (e.g., deep cavities, sharp internal corners) to pre-configure machine parameters.

AI-Powered Quoting with Embedded DFM

Our proprietary AI engine analyzes the CAD data against live machine availability, material costs, and historical EDM performance metrics. Crucially, this stage includes an automated Design for Manufacturability (DFM) scan focused on EDM constraints:

Verification of minimum feature sizes against electrode wear rates (e.g., <0.1mm ribs may require multi-pass strategies)

Assessment of aspect ratios for stability (e.g., cavities deeper than 10:1 height-to-width ratios trigger sinker EDM feasibility alerts)

Material hardenability checks (e.g., EDM is optimal for tool steels >45 HRC but inefficient for aluminum)

The AI generates a dynamic quote with lead time estimates, cost drivers (e.g., electrode count, flushing complexity), and preliminary DFM recommendations—all within 2 hours. This reduces quoting errors by 73% compared to manual methods, per our 2023 internal audit.

Engineer-Validated DFM and Process Planning

All EDM projects undergo mandatory review by a senior EDM process engineer. This phase refines AI insights through:

Electrode material selection (graphite vs. copper) based on feature complexity, surface finish requirements, and wear tolerance

Spark parameter optimization (pulse duration, current, voltage) to balance speed versus surface integrity (e.g., <Ra 0.8 µm finishes require low-energy finishing passes)

Workholding strategy validation to prevent dielectric fluid entrapment and ensure consistent flushing

Wire EDM-specific path planning for taper cuts or skiving operations, including wire tension and servo feed rate adjustments

Clients receive a formal DFM report with actionable suggestions (e.g., adding draft to reduce overburn) and sign-off before production. This step eliminates 92% of post-machining rework, per client feedback data.

EDM Production Execution

Production occurs in climate-controlled cells with Makino Sinker EDM and Mitsubishi Wire EDM systems. Key protocols include:

Real-time monitoring of gap voltage and debris levels to auto-adjust parameters and prevent arcing

In-process metrology for critical dimensions (e.g., cavity depths measured via touch probes after roughing)

Electrode wear compensation algorithms that dynamically adjust positioning during multi-electrode sequences

For wire EDM, we utilize deionized water with conductivity control (<5 µS/cm) and automatic wire threading for unattended operation. All processes comply with ISO 2768-mK geometric tolerancing standards unless tighter client specs are provided.

Quality Assurance and Delivery

Post-machining, parts undergo:

CMM verification of EDM-specific features (e.g., corner radii, hole taper) using 5-axis scanning

Surface roughness validation per ISO 4287 with profilometry

Residual stress checks for critical aerospace/medical components via X-ray diffraction

Final documentation includes as-built reports, electrode path logs, and process parameter archives. Parts ship with anti-corrosion packaging and full traceability data. Typical lead time for complex EDM projects is 5–10 business days from DFM approval, with 99.2% on-time delivery in Q1 2024.

EDM Process Capability Summary

| Parameter | Sinker EDM Range | Wire EDM Range |

|——————–|————————|————————|

| Tolerance | ±0.005 mm | ±0.002 mm |

| Surface Finish | Ra 0.1–1.6 µm | Ra 0.2–2.5 µm |

| Max Work Envelope | 600 x 400 x 300 mm | 400 x 300 x 250 mm |

| Material Hardness | Up to 70 HRC | Up to 68 HRC |

This closed-loop process ensures Honyo delivers production-ready EDM components with minimized risk and predictable outcomes. Clients retain full visibility via our project portal, with engineering support available at every stage.

Start Your Project

For precision machining and EDM services, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen delivers high-accuracy components with fast turnaround times, serving global clients with strict quality requirements. Reach out today to discuss your project specifications and receive a detailed quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.