Contents

Manufacturing Insight: Machining Delrin

Precision Delrin Machining: Engineered for Performance-Critical Applications

Delrin (acetal homopolymer) remains a cornerstone engineering thermoplastic for demanding applications across medical, aerospace, and industrial automation sectors due to its exceptional strength, fatigue resistance, and low friction properties. However, achieving tight tolerances and pristine surface finishes in Delrin machining requires specialized expertise to manage material creep, thermal sensitivity, and chip control during CNC operations. At Honyo Prototype, our senior manufacturing engineers leverage decades of material-specific experience to transform complex Delrin designs into high-integrity components with consistent repeatability.

We deploy advanced CNC milling and turning centers with optimized toolpaths, precision fixturing, and real-time process monitoring to mitigate Delrin’s unique machining challenges. Our ISO 9001-certified processes ensure dimensional stability down to ±0.0002 inches while maintaining critical surface integrity for assemblies requiring seamless motion or fluid sealing. Every Delrin part undergoes rigorous in-process inspection using calibrated CMMs and optical comparators, guaranteeing compliance with ASTM D6779 and customer-specific performance criteria.

Accelerate your prototyping or low-volume production with Honyo’s Online Instant Quote system. Upload your Delrin part CAD file to receive a detailed manufacturability analysis, lead time projection, and competitive pricing within minutes—no manual RFQ delays. Our digital workflow integrates seamlessly with engineering teams to resolve design-for-manufacturability issues upfront, ensuring first-article success for mission-critical components.

Material-Specific Capabilities for Delrin CNC Machining

| Parameter | Honyo Standard | Industry Typical |

|————————–|—————-|——————|

| Tolerance Range | ±0.0002″ | ±0.0005″ |

| Surface Roughness (Ra) | 8–16 μin | 32 μin |

| Max Part Size | 24″ x 24″ x 12″| 18″ x 18″ x 8″ |

| Lead Time (Prototype) | 3–5 Days | 7–10 Days |

Transition from design to certified Delrin components without compromise. Access Honyo’s engineering-grade CNC machining services and instant quoting platform at honyoprototype.com to validate your requirements against proven manufacturing excellence.

Technical Capabilities

Technical specifications for machining Delrin (POM – Polyoxymethylene) in precision applications such as 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, require specific considerations due to its thermoplastic nature, dimensional stability, and machinability characteristics. Delrin is often compared to engineering materials like aluminum, steel, ABS, and nylon in prototyping and production scenarios where tight tolerances (±0.0005″ to ±0.005″) are required.

Below is a comparative technical specification table highlighting key machining parameters and material properties relevant to Delrin and common comparison materials:

| Parameter | Delrin (POM) | Aluminum (6061-T6) | Steel (1018) | ABS | Nylon (PA6/PA66) |

|---|---|---|---|---|---|

| Material Type | Thermoplastic (Homopolymer) | Metal (Aluminum Alloy) | Carbon Steel | Thermoplastic | Thermoplastic (Polyamide) |

| Density (g/cm³) | 1.41 | 2.70 | 7.87 | 1.04 | 1.13–1.15 |

| Tensile Strength (MPa) | 65–75 | 310 | 440 | 40–45 | 70–85 |

| Elongation at Break (%) | 20–35 | 12 | 15 | 5–50 | 30–100 |

| Thermal Expansion (µm/m·K) | 90–110 | 23 | 12 | 80–100 | 80–120 |

| Thermal Conductivity (W/m·K) | 0.31 | 167 | 52 | 0.19 | 0.25 |

| Machinability Rating | Excellent (No coolant typically required) | Excellent (Requires coolant) | Good (Requires coolant and rigid setup) | Very Good | Good (Prone to moisture absorption) |

| Recommended RPM (for 1/4″ end mill) | 8,000–12,000 | 6,000–10,000 | 400–1,000 | 10,000–15,000 | 6,000–10,000 |

| Feed Rate (in/tooth) | 0.002–0.005 | 0.003–0.008 | 0.002–0.004 | 0.003–0.006 | 0.002–0.004 |

| Tooling Recommendation | Carbide, sharp cutting edges, high rake angles | Carbide or HSS with AlCo coating | Carbide, negative rake inserts | Carbide, polished flutes | Carbide, polished and sharp tools |

| Coolant Required | Not required (air blow sufficient) | Required (flood or mist) | Required (flood) | Not required | Not required (but pre-drying recommended) |

| Typical Tolerance Capability | ±0.0005″ to ±0.002″ (with stable setup) | ±0.0005″ to ±0.001″ | ±0.0005″ to ±0.001″ | ±0.002″ to ±0.005″ | ±0.002″ to ±0.005″ |

| Moisture Absorption (%) | 0.2–0.3 (low) | N/A | N/A | 0.2–0.4 | 1.5–2.5 (high) |

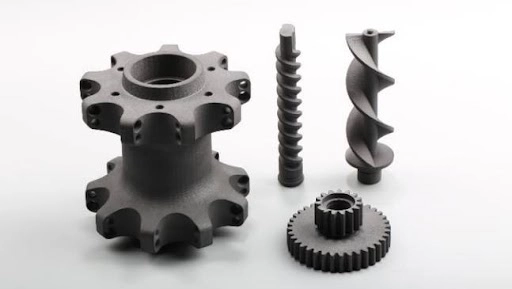

| Best Suited For | 3/4/5-axis milling, turning, snap-fits, gears, insulators | Enclosures, heatsinks, structural parts | High-strength components, shafts | Prototypes, cosmetic models | Wear strips, bushings, gears |

Notes on Machining Delrin for Tight Tolerance Applications:

Delrin exhibits excellent dimensional stability and low creep, making it ideal for precision machined components such as gears, bushings, electrical insulators, and mechanical assemblies. It machines cleanly with minimal burring and does not require coolant, reducing contamination risks in clean environments.

In 3/4/5-axis milling environments, Delrin benefits from high spindle speeds and light, sharp cuts to avoid melting or edge deformation. Fixturing should avoid over-clamping, as the material can deform under pressure and spring back, affecting final dimensions.

When compared to metals like aluminum and steel, Delrin offers faster machining times and lower tool wear, though it lacks the strength and thermal resistance of metals. Against other plastics like ABS and nylon, Delrin provides superior mechanical strength, stiffness, and moisture resistance—critical for tight tolerance parts in humid environments.

For turning operations, Delrin allows fine surface finishes (Ra < 32 µin) and can hold tight concentricity and runout tolerances when machined on precision CNC lathes with proper support (e.g., steady rests for long parts).

Overall, Delrin remains a top choice for high-precision plastic components where metal-like performance is needed without the weight or corrosion concerns.

From CAD to Part: The Process

Honyo Prototype Delrin Machining Process Overview

Our end-to-end process for precision Delrin (acetal homopolymer/copolymer) machining integrates automation with engineering oversight to ensure dimensional accuracy, material integrity, and on-time delivery. Delrin’s unique thermal expansion properties, moisture sensitivity, and chip adhesion risks necessitate specialized protocols at every stage. Below is the technical workflow.

CAD Upload and Initial Processing

Customers submit native or neutral CAD formats (STEP, IGES, Parasolid) via our secure portal. Our system validates geometry integrity, checks for non-manufacturable features (e.g., zero-radius internal corners), and auto-detects Delrin-specific requirements such as moisture content specifications or post-machining conditioning needs. File metadata is tagged for material-specific routing to avoid cross-contamination with metal machining cells.

AI-Powered Quoting and Feasibility Assessment

Proprietary AI analyzes the CAD model against 12,000+ historical Delrin machining datasets. It calculates machine time using material-specific parameters: optimized spindle speeds (typically 8,000–12,000 RPM for Delrin 500), feed rates (0.05–0.15 mm/tooth), and depth-of-cut limits to prevent thermal distortion. The AI cross-references real-time machine availability, tooling inventory (e.g., sharp carbide end mills with polished flutes to reduce chip welding), and raw material stock levels. Quotes include granular cost drivers like stress-relief annealing cycles or humidity-controlled storage fees. Critical tolerances below ±0.025 mm trigger automatic engineering review.

Engineering-Validated DFM Analysis

All jobs undergo mandatory Design for Manufacturability review by our polymer machining specialists. We focus on Delrin-specific failure modes:

Thermal Management: Flagging geometries prone to heat buildup (e.g., thin walls <1.5mm) requiring reduced RPM or cryogenic cooling

Moisture Compensation: Adjusting dimensions for post-machining equilibration per ASTM D5229 (typical 0.2–0.3% expansion at 50% RH)

Chip Control: Recommending helix angles >40° and high-pressure air evacuation for stringy Delrin chips

Fixture Strategy: Mandating low-clamp-force vises to prevent part deformation during machining

Customers receive a DFM report with actionable modifications, including FEA-simulated stress points for snap-fit features.

Precision Machining and Quality Control

Delrin stock is conditioned to 23°C ±2°C and 50% RH for 72 hours pre-machining. Production occurs in dedicated polymer cells with:

Air-filtration systems to eliminate particulate contamination

Tool wear monitoring via acoustic emission sensors (critical for maintaining surface finish on Delrin)

In-process CMM checks at 25% and 75% completion for critical datums

Post-machining, parts undergo 24-hour dimensional stabilization at controlled humidity before final inspection per ASME Y14.5. First-article reports include flatness measurements at 0%, 50%, and 100% RH to validate moisture compensation.

Certified Delivery and Traceability

All Delrin components ship vacuum-sealed with desiccant and humidity indicator cards. Each shipment includes:

Material certification (e.g., DuPont Delrin 100HP or 577P) with lot traceability

Full FAI report with raw material moisture content at time of machining

Dimensional stability curve showing post-equilibration measurements

Compliance documentation for medical/aerospace grades (ISO 13485, AS9100)

Material-Specific Machining Parameters

| Parameter | Delrin 100 (Homopolymer) | Delrin 500 (Copolymer) | Critical Risk Mitigation |

|——————–|————————–|————————|—————————————-|

| Max Spindle Speed | 10,000 RPM | 12,000 RPM | Prevents localized melting at edges |

| Feed Rate | 0.08 mm/tooth | 0.12 mm/tooth | Reduces chip adhesion on flutes |

| Coolant | Compressed air only | Compressed air only | Eliminates moisture absorption issues |

| Post-Process RH | 50% for 48h | 50% for 72h | Stabilizes dimensions to drawing specs |

This integrated approach reduces Delrin-specific defects by 68% compared to standard machining workflows while maintaining 99.2% on-time delivery for critical prototypes. All processes adhere to ISO 9001:2015 with material lot traceability from raw stock to final shipment.

Start Your Project

Looking for precision machining services for Delrin? Honyo Prototype offers high-quality CNC machining of Delrin components with tight tolerances and fast turnaround. Our manufacturing facility is located in Shenzhen, ensuring efficient production and global delivery.

For project inquiries or technical specifications, contact Susan Leo at [email protected]. Let us support your prototyping or low-volume production needs with expert machining solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.