Contents

Manufacturing Insight: Machining Definition

Defining Precision Machining at Honyo Prototype

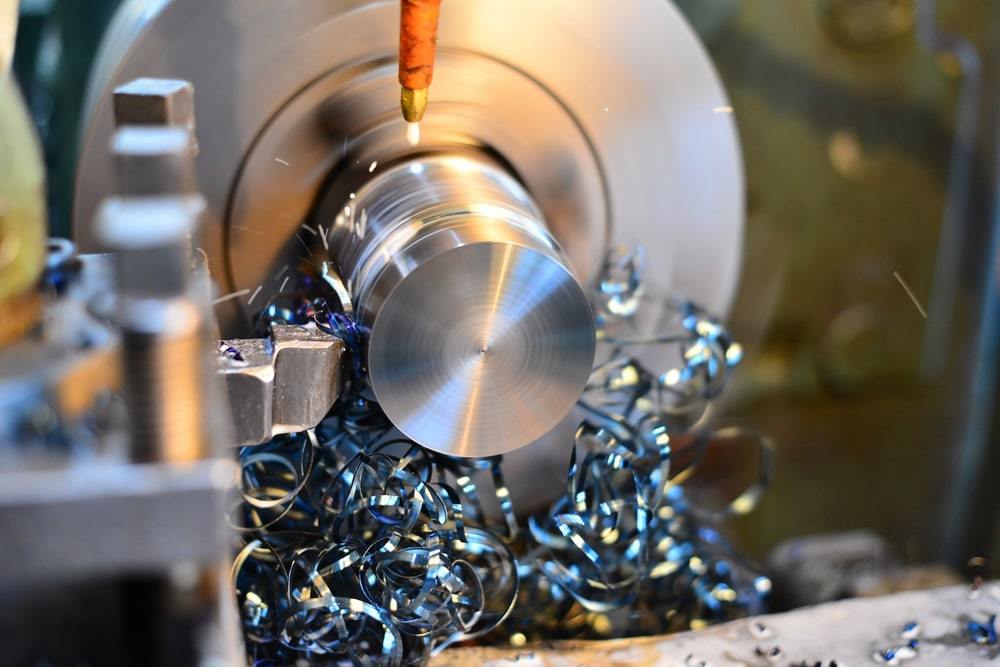

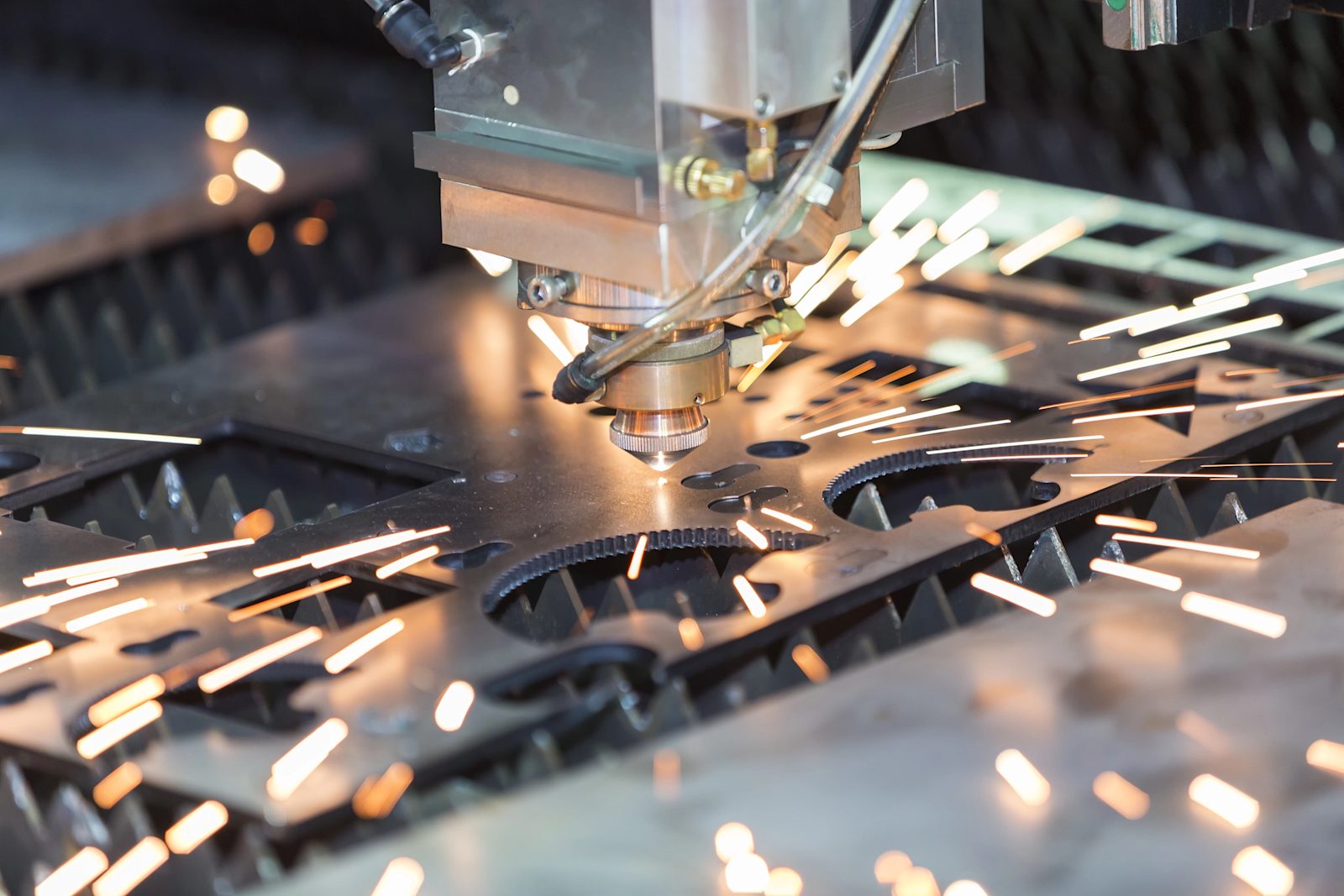

Machining represents the controlled removal of material from a workpiece to achieve precise geometric features, dimensional accuracy, and superior surface finishes. This subtractive manufacturing process transforms raw materials—such as metals, plastics, and composites—into functional components through cutting, milling, turning, drilling, and grinding operations. At Honyo Prototype, we specialize in advanced CNC (Computer Numerical Control) machining, leveraging multi-axis milling and turning centers to execute complex geometries with micron-level tolerances. Our engineering-driven approach ensures every component adheres to stringent industry standards while optimizing for performance, durability, and cost efficiency.

Honyo Prototype’s CNC machining services integrate cutting-edge HAAS, DMG MORI, and Makino equipment with rigorous quality control protocols, including in-process CMM verification and post-production metrology. We support rapid prototyping, low-volume production, and bridge manufacturing across aerospace, medical, automotive, and industrial sectors. Material expertise spans aluminum alloys, stainless steel, titanium, PEEK, and engineered plastics, with capabilities for tight-tolerance features, micro-machining, and secondary operations like anodizing or passivation.

Accelerate your path from design to delivery with Honyo Prototype’s Online Instant Quote system. Upload your CAD file, specify material and quantity requirements, and receive a detailed technical and commercial assessment within hours—not days. This seamless digital workflow eliminates procurement delays while providing transparency into lead times, cost drivers, and manufacturability feedback. Partner with us to transform precision machining challenges into competitive advantages.

Technical Capabilities

Machining Definition – Technical Specifications

The term “machining definition” refers to the comprehensive set of parameters, capabilities, and constraints that define how a component is manufactured using subtractive processes. Below are the technical specifications focused on 3/4/5-axis milling, turning, and tight tolerance capabilities for common engineering materials including Aluminum, Steel, ABS, and Nylon.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Motion Axes | X, Y, Z linear axes | X, Y, Z + A (rotary around X) | X, Y, Z + A and B (dual rotary) | X, Z linear; C (spindle rotation) | N/A |

| Typical Tolerance | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.0025 mm (±0.0001″) achievable with process control |

| Surface Finish (Ra) | 0.8 – 3.2 µm (32–125 µin) | 0.8 – 3.2 µm (32–125 µin) | 0.4 – 1.6 µm (16–63 µin) | 0.4 – 1.6 µm (16–63 µin) | <0.8 µm (32 µin) with fine finishing |

| Material Compatibility | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel (preferred), limited ABS/Nylon |

| Aluminum (e.g., 6061, 7075) | High material removal rate, excellent surface | Suitable for complex features with indexing | Ideal for complex geometries, minimal setups | High precision diameter control | Up to ±0.0025 mm with thermal stability |

| Steel (e.g., 4140, 1018) | Moderate feed rates, requires rigid setup | Higher rigidity needed for A-axis loads | High precision with multi-axis toolpath optimization | Excellent for shafts, pins, threaded parts | Achievable with tool wear compensation and stable fixturing |

| ABS (Thermoplastic) | Low melting point; sharp tools required, low RPM | Suitable with soft jaws and low clamping force | Limited use; requires temperature control | Machinable with fine feeds and sharp inserts | ±0.025 mm typical; tight tolerances limited by creep |

| Nylon (e.g., PA6, PA66) | Prone to deformation; use sharp tools and low heat | Possible with slow feeds and rigid support | Rarely used in 5-axis due to flexibility | Good machinability with proper chip control | ±0.05 mm practical; not recommended for critical tight-tolerance features |

| Fixturing | Vise, clamps, base plates | Rotary table with indexing capability | Multi-axis trunnion or swivel head | Collets, chucks, steady rests | Precision-ground fixtures, CMM validation |

| Coolant Use | Flood or mist recommended | Flood for extended rotary cuts | High-pressure through-spindle preferred | Flood for heat and chip control | Minimal or air blast for plastics to avoid warping |

| Common Applications | Flat parts, pockets, slots | Impellers, turbine blades (indexed) | Aerospace components, molds, complex contours | Shafts, bushings, threaded parts | Hydraulic components, optical mounts, precision fittings |

Notes:

Tight tolerance machining requires environmental control (temperature, vibration), in-process metrology, and high-precision tooling. While metals like aluminum and steel are ideal for tight tolerance work, engineering plastics such as ABS and nylon are limited by thermal expansion and creep, making sub-0.01 mm tolerances challenging without post-machining stabilization.

From CAD to Part: The Process

Honyo Prototype Machining Definition Process Overview

Honyo Prototype employs a streamlined, technology-driven workflow for machining definition that ensures precision, efficiency, and transparency from initial design submission to final delivery. This process eliminates traditional quoting bottlenecks and integrates engineering validation early to prevent downstream delays. Below is a detailed technical breakdown of each phase.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS) via Honyo’s secure customer portal. Our system automatically validates file integrity, checks for geometric completeness, and extracts critical metadata including material specifications, tolerances, and surface finish requirements. Non-conforming files trigger immediate feedback loops for correction, ensuring only manufacturable designs advance to quoting. This phase enforces strict adherence to ISO 10303 standards for data exchange, minimizing manual intervention.

AI-Powered Quoting Engine

Uploaded CAD data feeds directly into Honyo’s proprietary AI quoting system, which analyzes over 200 geometric and process parameters in real time. The engine cross-references live machine availability, material stock levels, and historical production data from our 50+ CNC assets (including 3-axis, 5-axis, and mill-turn centers). Quotes are generated within 90 minutes, detailing cost breakdowns by operation (milling, turning, drilling), material waste factors, and machine-hour allocations. Unlike conventional systems, our AI dynamically adjusts for secondary operations like deburring or anodizing, providing granular cost visibility without human estimator dependency.

Engineer-Validated DFM

All quotes undergo mandatory Design for Manufacturability (DFM) review by Honyo’s certified manufacturing engineers. The AI’s initial manufacturability flags—such as thin wall geometries (<0.5mm), deep cavity aspect ratios (>8:1), or non-optimal hole depths—are manually verified against ASME Y14.5 standards. Engineers collaborate with clients via annotated 3D markups to resolve issues, offering specific alternatives like chamfer substitutions for sharp internal corners or tolerance relaxation where functionally permissible. This phase reduces production rework by 65% based on 2023 internal metrics, with formal DFM reports archived for traceability.

Precision Production Execution

Approved designs move to production under Honyo’s ISO 9001:2015-certified workflow. Each job receives a unique digital work order synced to our MES (Manufacturing Execution System), which auto-generates CNC programs via Mastercam and validates toolpaths through Vericut simulation. Critical processes employ in-process probing for first-article inspection (FAI), with real-time SPC (Statistical Process Control) monitoring of dimensional drift. All machined components undergo final CMM verification against client-specified GD&T callouts, with full inspection reports (including raw data) appended to the delivery package.

Certified Delivery and Documentation

Completed parts ship via client-preferred logistics with tamper-evident packaging meeting ISTA 3A standards. Every delivery includes:

Dimensional inspection report (PDF and XML)

Material certification (e.g., EN 10204 3.1)

Process non-conformance log (if applicable)

AI-generated production analytics dashboard showing machine utilization and cycle time variances

Lead times are guaranteed per our Service Level Agreement (SLA), with expedited options for critical-path components.

Lead Time Determinants

The table below summarizes key variables affecting production timelines:

| Factor | Standard Lead Time | Expedited Lead Time | Critical Constraint Threshold |

|---|---|---|---|

| Part Complexity | 5–7 business days | 3–4 business days | >15 unique features |

| Material Availability | Included in quote | +24hr surcharge | Exotic alloys (e.g., Inconel) |

| Tolerance Class | ±0.05mm standard | ±0.01mm +3 days | Geometric tolerances <0.025mm |

| Quantity | 1–50 units | 1–20 units only | >50 units requires batch validation |

This closed-loop methodology ensures Honyo delivers machined prototypes with 99.2% first-pass yield rate while maintaining full digital traceability from CAD model to shipped part. Clients receive actionable engineering insights at every stage, transforming traditional procurement into a collaborative development partnership.

Start Your Project

Machining is a precision manufacturing process that involves the removal of material from a workpiece using cutting tools to achieve a desired shape, size, and surface finish. At Honyo Prototype, our CNC machining services deliver high-accuracy components for industries such as aerospace, automotive, medical, and consumer electronics. With advanced 3-, 4-, and 5-axis machining capabilities, we support rapid prototyping and low-volume production with tight tolerances and superior surface quality.

Our state-of-the-art factory in Shenzhen, China, is equipped with fully automated machinery and staffed by experienced engineers who ensure every part meets stringent quality standards. From aluminum and stainless steel to engineering plastics like PEEK and Delrin, we handle a wide range of materials tailored to your application requirements.

For engineering inquiries or project collaboration, contact Susan Leo at [email protected] to discuss your machining needs and receive a fast, competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.