Contents

Manufacturing Insight: Machining Cost

Understanding Machining Cost in Precision CNC Manufacturing

Accurate machining cost estimation is critical for project viability in rapid prototyping and low-volume production. At Honyo Prototype, we recognize that cost drivers extend beyond raw material and machine time—they encompass geometric complexity, tolerance requirements, secondary operations, and production scalability. Our engineering-led approach dissects these variables to deliver transparent, optimized pricing without compromising on the precision or speed your projects demand.

Honyo’s CNC machining services leverage advanced 3-, 4-, and 5-axis capabilities alongside rigorous in-process quality control, ensuring complex components meet exact specifications on the first pass. This reduces waste, minimizes rework, and directly lowers your total cost of ownership. Crucially, we eliminate quoting bottlenecks through our Online Instant Quote platform. By inputting your part geometry, material, and finish requirements, you receive a detailed, real-time cost analysis within minutes—not days—enabling faster design validation and procurement decisions.

For engineering teams prioritizing cost predictability and accelerated time-to-market, Honyo integrates manufacturing expertise with digital efficiency. Start optimizing your next project’s cost structure today through our instant quoting system, where technical accuracy meets operational agility.

Technical Capabilities

Technical specifications influencing machining cost in 3-axis, 4-axis, and 5-axis milling, as well as turning operations, are driven by complexity, precision requirements, material properties, and machine time. Tight tolerance demands (e.g., ±0.001″ or tighter) significantly impact cost due to increased setup time, tooling requirements, inspection frequency, and reduced cycle speeds. Below is a breakdown of key cost drivers across these processes and materials.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | Turning | Notes |

|---|---|---|---|---|---|

| Base Setup Cost | Low | Moderate | High | Low to Moderate | 5-axis requires complex fixturing and alignment; 4-axis adds rotational indexing; 3-axis and turning are simpler and faster to set up |

| Machine Hourly Rate | $75–$120 | $100–$150 | $130–$200 | $60–$100 | Higher axis count increases machine cost and operator skill requirements |

| Tight Tolerance Impact | +20–40% | +30–50% | +40–70% | +25–45% | Achieving ±0.001″ or better requires precision tooling, slow feeds/speeds, in-process probing, and CMM validation |

| Material – Aluminum (e.g., 6061, 7075) | Moderate material cost, high machinability, fast cycle times | Slightly longer cycles due to indexing | Longest cycles due to tool path complexity | Excellent for high-speed turning | Low tool wear; minimal post-processing; cost-effective for prototypes and production |

| Material – Steel (e.g., 4140, 1018) | High tool wear, slower speeds, higher machine load | Increased cycle time due to indexing complexity | Highest machine load and tooling cost | High power requirements, slower RPM | Requires carbide tooling; heat management critical; +30–60% cost vs. aluminum |

| Material – ABS (Thermoplastic) | Low cutting forces, fast speeds | Moderate fixturing care (low heat tolerance) | Requires rigid fixturing and low vibration | Suitable for small-diameter parts | Low cost material; prone to melting; minimal tool wear; good for non-structural prototypes |

| Material – Nylon (e.g., PA6, PA66) | Challenging due to elasticity and chip evacuation | Requires sharp tooling and high clearance angles | Difficult to hold tight tolerances | Can be turned but requires support to prevent deflection | Hygroscopic; may require drying; low thermal conductivity; +15–25% machining cost vs. ABS |

| Tolerance Capability (Typical) | ±0.005″ standard, ±0.001″ with precision | ±0.003″ standard, ±0.001″ achievable | ±0.002″ standard, ±0.0005″ with metrology support | ±0.002″ standard, ±0.0005″ with precision turning | Achieving tight tolerances requires environmental control, calibrated tools, and iterative inspection |

| Lead Time Impact (Tight Tolerance) | +1–2 days | +2–3 days | +3–5 days | +1–3 days | Includes setup validation, first article inspection (FAI), and potential rework |

Summary Notes

Machining cost scales with axis count, tolerance stringency, and material machinability. Aluminum remains the most cost-effective metal for complex milled parts, while steel increases cost due to slower processing and tooling wear. Among plastics, ABS is preferred for ease of machining, whereas Nylon demands greater process control. Tight tolerance machining across all materials and processes necessitates investment in inspection (e.g., CMM, optical comparators) and skilled programming (e.g., high-precision CAM toolpaths), contributing significantly to overall cost.

From CAD to Part: The Process

As Senior Manufacturing Engineer at Honyo Prototype, I detail our machining cost process with technical precision for engineering and procurement partners. Our integrated workflow ensures cost transparency, manufacturability, and on-time delivery while minimizing downstream rework.

Upload CAD

Clients submit native or neutral CAD formats (STEP, IGES, Parasolid) via our secure portal. Our system validates geometry integrity and extracts critical manufacturing data: material type, part dimensions, tolerances (per ISO 2768 or custom GD&T), surface finishes, and feature complexity. This phase establishes the foundational dataset for accurate cost modeling. Incomplete submissions trigger automated notifications specifying missing requirements before progression.

AI Quote Generation

Our proprietary algorithm processes the CAD data through a multi-parameter cost engine. It calculates machine time based on verified CNC parameters (spindle RPM, feed rates, toolpath length), material waste factors, fixture requirements, and secondary operations. The AI cross-references real-time data from our ERP including current machine utilization rates, material spot pricing, and labor costs. Unlike static quoting systems, it dynamically adjusts for batch size economies and geometric complexity factors such as deep cavity machining or thin-wall features. The output is a detailed cost breakdown showing material, machining, finishing, and overhead components within 2 business hours.

DFM Analysis

This is where Honyo delivers critical value beyond basic quoting. Our manufacturing engineers conduct a rigorous Design for Manufacturability review using specialized CAM simulation tools. We identify cost drivers like non-standard tool requirements, excessive setups, or tolerance conflicts that inflate machining time. Typical cost-saving interventions include:

Recommending tolerance relaxation on non-critical features (e.g., changing ±0.05mm to ±0.1mm)

Suggesting feature consolidation to reduce milling operations

Flagging undercuts requiring specialized tooling

Optimizing stock size to minimize material waste

Clients receive a formal DFM report with annotated CAD markups and quantified cost impact per suggestion. This collaborative phase typically reduces total project cost by 15-30% through design refinement.

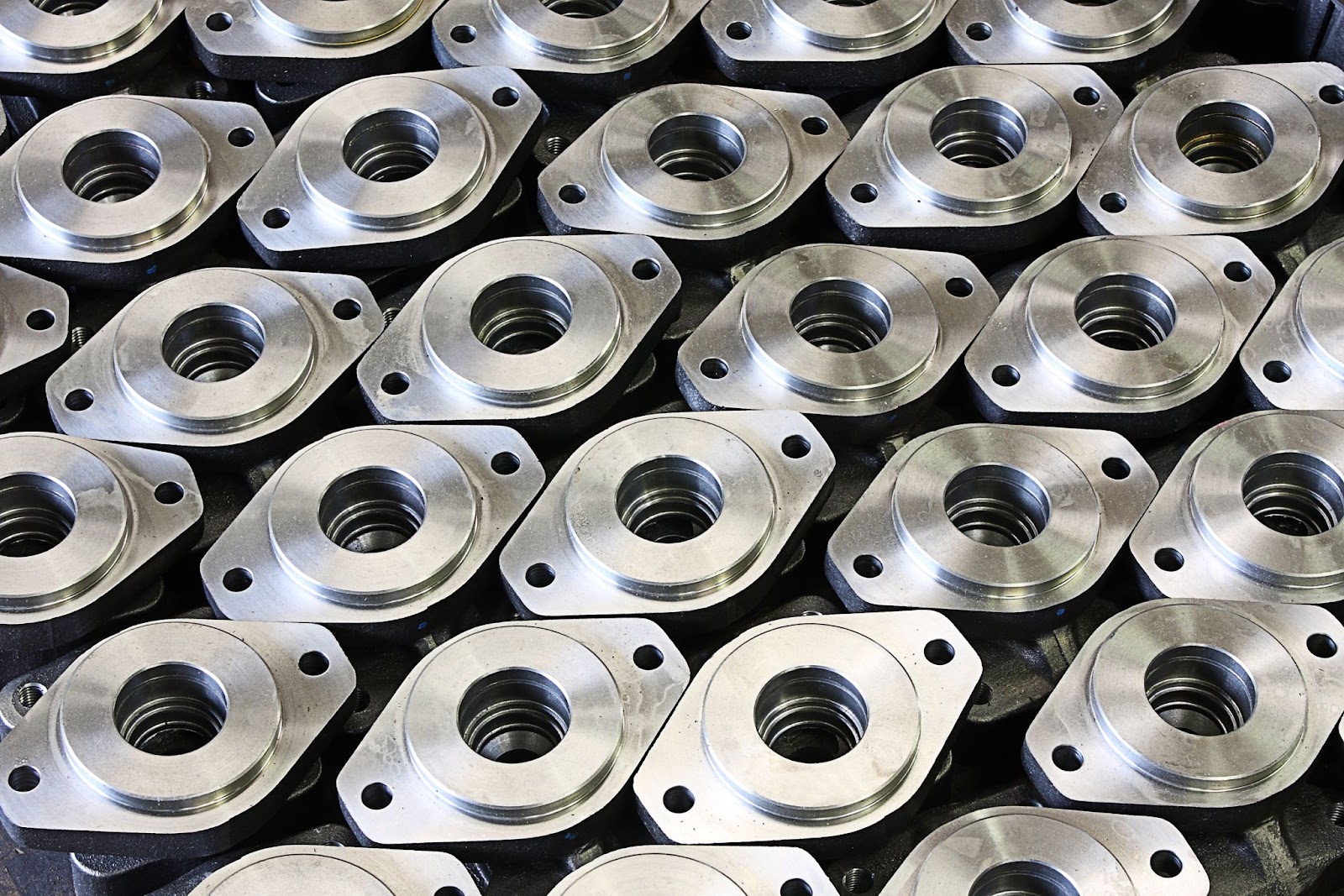

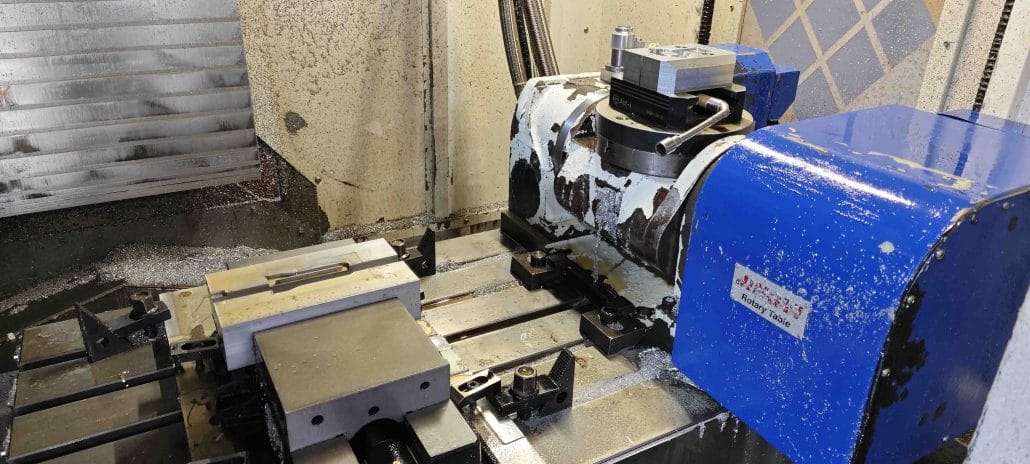

Production Execution

Approved designs move to our climate-controlled facility with 32 CNC machines (3/4/5-axis mills, lathes). Our MES system enforces strict process controls:

First-article inspection per AS9102

In-process CMM verification at critical stages

Real-time machine telemetry monitoring for tool wear

Material traceability from certified mills

All production parameters are locked per the validated DFM plan to prevent cost creep. We maintain NADCAP accreditation for precision machining, ensuring repeatability for volume runs.

Delivery Assurance

Final inspection packages include FAI reports, material certs, and dimensional data per client specifications. Parts ship in custom anti-corrosion packaging with serialized tracking. Crucially, our initial AI quote incorporates landed cost factors:

Consolidated shipping based on regional logistics data

Import duty calculations for global clients

Buffer for customs clearance variability

This prevents unexpected charges, a common pain point in offshore manufacturing.

Cost Process Comparison

Traditional quoting often fails to capture hidden costs, whereas Honyo’s integrated approach delivers predictable outcomes:

| Phase | Traditional Approach | Honyo Prototype Process | Cost Impact |

|---|---|---|---|

| Quoting | Manual spreadsheet estimation | AI-driven parametric cost modeling | 20-40% more accurate initial quote |

| DFM | Optional post-quote review | Mandatory pre-production engineering | Prevents 25% average rework costs |

| Production | Reactive tolerance adjustment | DFM-locked process parameters | Eliminates 15% process variation |

| Delivery | Base cost + surprise fees | Landed cost modeled upfront | Avoids 8-12% hidden logistics costs |

This closed-loop system ensures the quoted machining cost becomes the delivered cost. We partner with engineering teams to transform designs into manufacturable solutions where every dollar spent delivers verified value. For complex projects, we provide phase-gated cost validation at DFM sign-off and pre-shipment audit to maintain budget integrity.

Start Your Project

Looking to optimize your machining costs? Contact Susan Leo at [email protected] to receive a detailed quote tailored to your prototyping and production needs. With our advanced manufacturing capabilities and efficient processes at our Shenzhen factory, Honyo Prototype delivers high-precision machining at competitive prices. Let us help you reduce costs without compromising quality. Reach out today to streamline your project and accelerate time to market.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.