Contents

Manufacturing Insight: Machining Collets

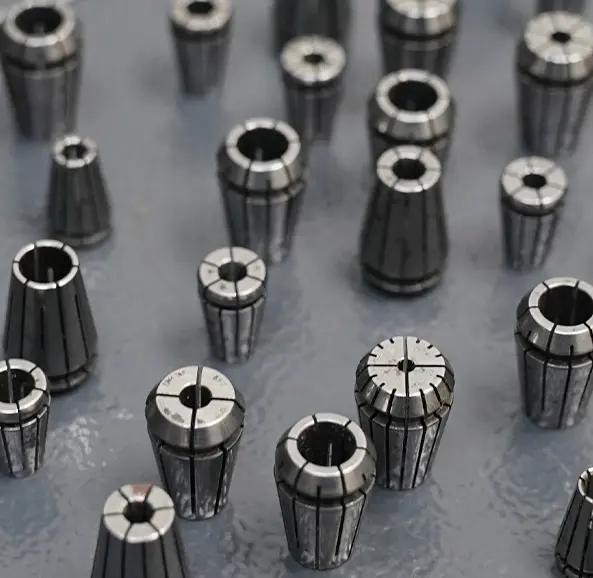

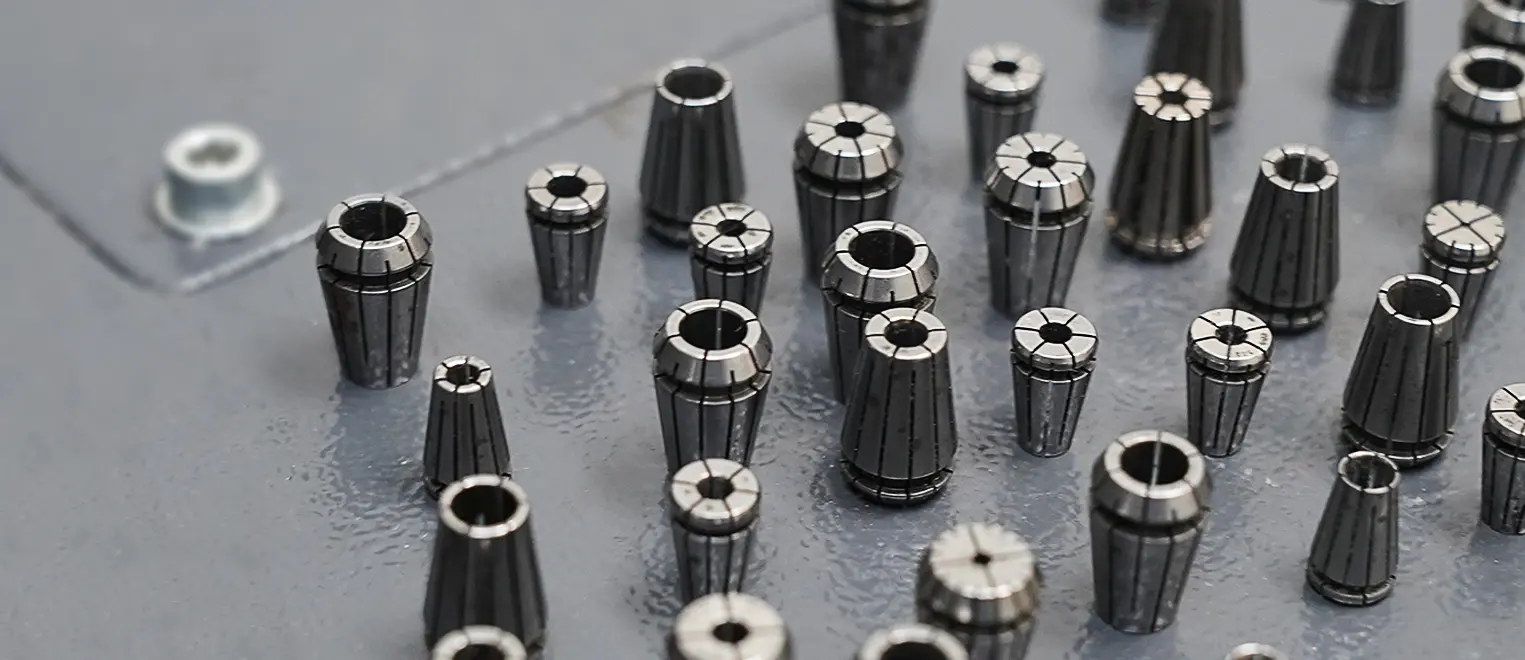

Machining Collets: Precision Components for CNC Excellence

Machining collets are critical precision components that directly impact the accuracy, repeatability, and efficiency of CNC operations. At Honyo Prototype, we specialize in manufacturing high-integrity collets engineered to meet the exacting demands of modern machining environments. Our CNC Machining services leverage advanced 5-axis milling and turning centers, coupled with stringent in-process metrology, to achieve tolerances as tight as ±0.0002″ and surface finishes under Ra 8 μin. We utilize premium materials including nitrided steel, spring steel, and specialized alloys, ensuring optimal grip force, thermal stability, and extended service life under high-RPM conditions. Every collet undergoes comprehensive runout validation and hardness testing to guarantee sub-micron concentricity and zero-defect performance in your spindle.

Honyo’s end-to-end process spans precision blank preparation, heat treatment coordination, precision grinding, and final assembly validation, all executed within our ISO 9001-certified facility. This integrated approach minimizes lead times while maintaining absolute consistency from prototype to full production volumes. For immediate project assessment, access our Online Instant Quote platform to receive a detailed manufacturing evaluation and competitive pricing within hours—streamlining your path from design to functional hardware without quotation delays. Partner with Honyo to transform collet performance into a measurable advantage for your machining operations.

Technical Capabilities

Machining Collets – Technical Specifications

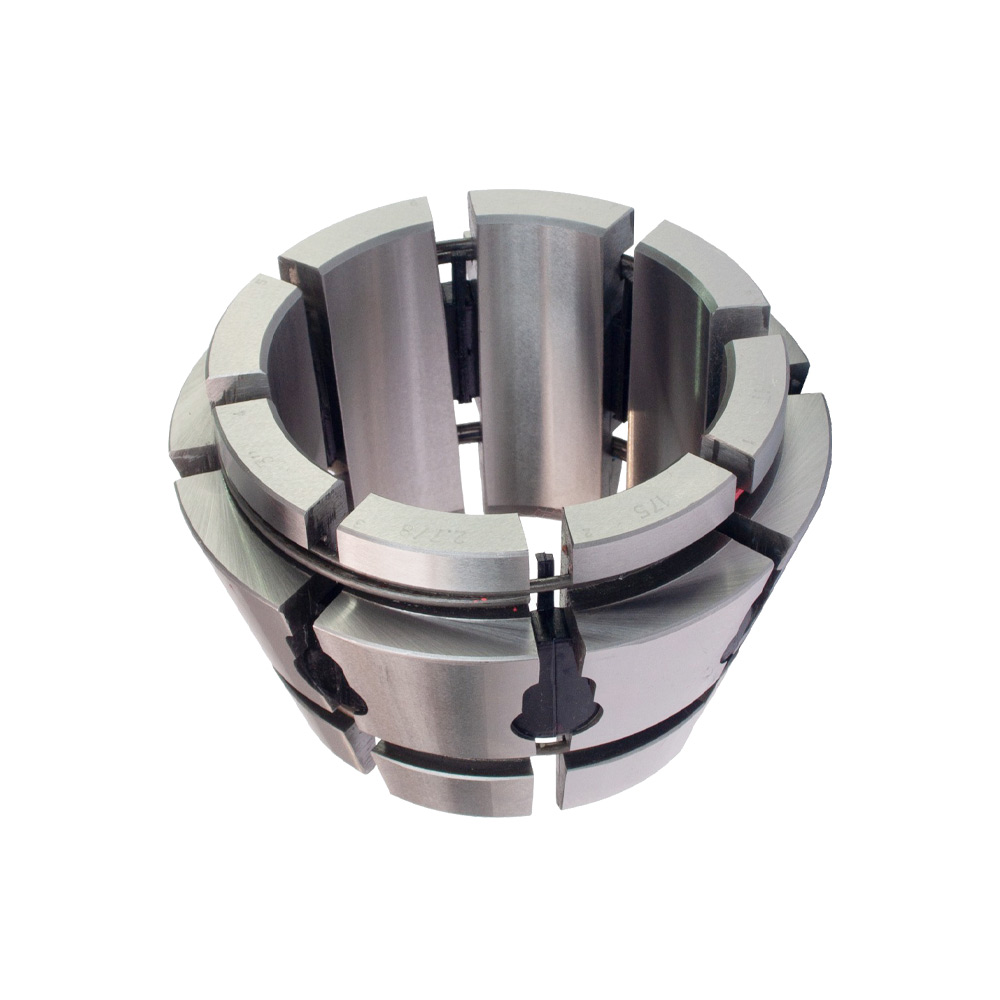

Collets are precision workholding devices used in CNC machining to securely hold tools or workpieces during milling, turning, and multi-axis operations. They are critical for achieving tight tolerances, high repeatability, and minimal runout. Below are key technical specifications for collets used in 3/4/5-axis milling and turning applications, with considerations for common workpiece materials such as Aluminum, Steel, ABS, and Nylon.

| Parameter | Specification / Detail |

|---|---|

| Collet Type | ER, TG, SK, 5C, R8, or proprietary high-precision variants |

| Compatibility | 3-axis, 4-axis, and 5-axis CNC milling centers; CNC lathes (for workholding collets) |

| Clamping Diameter Range | Typically 1–13 mm (ER-16), 1–20 mm (ER-25), 1–32 mm (ER-32); custom ranges available |

| Runout Accuracy | ≤ 0.003 mm (0.12 mils) at full clamping range (high-precision ground collets) |

| Tolerance Class | H6 to H7 for internal bore; ground to ISO 15488 or DIN 6499 standards |

| Material (Collet Body) | High-strength spring steel (e.g., 6150, 52100) with heat treatment (HRC 44–48) |

| Surface Treatment | Black oxide, nitriding, or TiN coating for wear resistance and corrosion protection |

| Clamping Force | 20–60 kN depending on size and drawbar force; optimized for minimal deformation |

| Operating Speed | Up to 30,000 RPM (high-balance versions rated for 50,000+ RPM with dynamic balancing) |

| Workpiece Materials | Aluminum, Steel, ABS, Nylon – collet design adjusts for material-specific grip needs |

| Grip Characteristics | Soft jaws or coated inserts used for non-marring grip on Aluminum, ABS, and Nylon |

| Thermal Stability | Designed for minimal expansion under heat; suitable for continuous high-speed machining |

| Repeatability | ±0.002 mm over 100+ tool changes (with proper maintenance and torque) |

| Torque Transmission | Serrated or key-driven designs for high-torque milling and heavy cutting applications |

| Standards Compliance | ISO 15488, DIN 6499, ANSI B5.40, or OEM-specific specifications |

Notes on Material-Specific Use:

For Aluminum and Steel, standard precision collets with appropriate clamping pressure are used. Aluminum requires lower clamping force to avoid deformation, while steel demands higher grip strength. For ABS and Nylon—being thermoplastics—special consideration is given to clamping pressure to prevent creep or deformation. Soft-jaw collets or collets with elastomeric liners are often employed to distribute pressure evenly and avoid surface damage.

Collets used in tight tolerance applications (±0.005 mm or better) must be regularly inspected for wear, cleaned, and torqued to manufacturer specifications. In 5-axis milling, compact, low-profile collet systems are preferred to maximize tool clearance and reduce interference.

Proper collet selection and maintenance are essential for achieving micron-level accuracy and surface finish in high-precision manufacturing environments.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined workflow for machining precision collets, leveraging automation and engineering expertise to ensure optimal manufacturability, quality, and speed. Our process begins with seamless digital integration and concludes with certified delivery, specifically tailored to the geometric and functional demands of collet components.

CAD Upload and Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system performs immediate format validation and geometric integrity checks, flagging potential issues like non-manifold edges or unit inconsistencies. For collets—which require extreme concentricity and thin-wall stability—this stage verifies critical parameters such as taper angles, jaw segmentation, and relief features against baseline manufacturability thresholds. Validated files automatically trigger the quoting phase without manual intervention.

AI-Powered Quoting

Honyo’s proprietary AI quoting engine, ProtoPulse, analyzes the validated CAD geometry alongside material specifications, quantity, and tolerance requirements. For collets, the system specifically evaluates factors such as wall thickness ratios (critical for elastic deformation), surface finish requirements on sealing surfaces, and the complexity of internal/external tapers. ProtoPulse cross-references real-time machine availability, tooling libraries, and historical production data from over 12,000+ collet jobs to generate a technically accurate quote within 15 minutes. This includes explicit identification of high-risk features requiring engineering review, such as sub-0.5mm wall sections or micron-level runout tolerances.

Engineering-Led DFM Analysis

All collet projects undergo mandatory Design for Manufacturability (DFM) review by our precision machining engineering team. We focus on mitigating inherent collet challenges:

Thin-wall stability: Recommending stress-relief sequences or adaptive roughing paths to prevent chatter during machining.

Taper accuracy: Validating taper angles against machine spindle capabilities and suggesting datum strategies for in-process measurement.

Jaw segmentation: Optimizing cut sequences to maintain symmetry and minimize residual stress.

Material utilization: Proposing near-net-shape blanks to reduce cycle time for high-value alloys like 4140 or 17-4PH.

Common DFM findings and resolutions are summarized below:

| Common Collet DFM Issue | Honyo Engineering Resolution |

|---|---|

| Wall thickness < 0.8mm at full extension | Recommend multi-stage heat treatment or alternative blank geometry |

| Taper angle tolerance ±0.005° | Implement Renishaw probe in-process verification at each machining phase |

| Non-uniform jaw segmentation | Redesign cut paths using synchronized C-axis milling to ensure harmonic balance |

| Surface finish Ra 0.4µm on sealing face | Specify diamond-turned finish with tool nose radius optimization |

Precision Production Execution

Approved designs move to production on dedicated Swiss-type CNC lathes (Tornos, Star) or multi-axis mill-turn centers, selected based on collet diameter and complexity. Key production protocols include:

Machining in temperature-stabilized environments (±1°C) to maintain dimensional stability.

In-process metrology using Zeiss O-Inspect systems after critical operations (e.g., taper generation, slotting).

Custom collet-specific workholding to prevent distortion during secondary operations.

Real-time tool wear monitoring via spindle power analytics, with automatic compensation for flank wear.

All collets undergo 100% functional testing: concentricity verification on custom mandrels, spring rate validation, and pressure testing for hydraulic variants per ISO 15488 standards.

Certified Delivery and Traceability

Completed collets are packaged in anti-corrosion VCI bags with individual serialized traceability tags. Each shipment includes:

First-article inspection reports (FAIR) with full GD&T verification.

Material certificates (MTRs) and heat treatment reports.

Functional test data showing runout, clamping force, and repeatability metrics.

Digital twin comparison between as-machined point cloud data and original CAD.

Delivery timelines are guaranteed through our dynamic scheduling system, with expedited shipping options for urgent collet replacements in live production lines.

This integrated workflow ensures collets meet the stringent performance demands of aerospace, medical, and semiconductor applications while minimizing time-to-part. For complex collet designs, we recommend engaging our engineering team during the CAD phase via our Collaborative Design Review service to optimize for precision manufacturability. Contact Honyo Prototype Engineering to discuss your specific collet requirements.

Start Your Project

For precision machining collets and custom solutions, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen ensures tight tolerances, fast turnaround, and consistent quality for your high-precision applications. Reach out today to discuss your project requirements and discover how our expertise in collet machining can support your production needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.