Contents

Manufacturing Insight: Machining Brass Parts

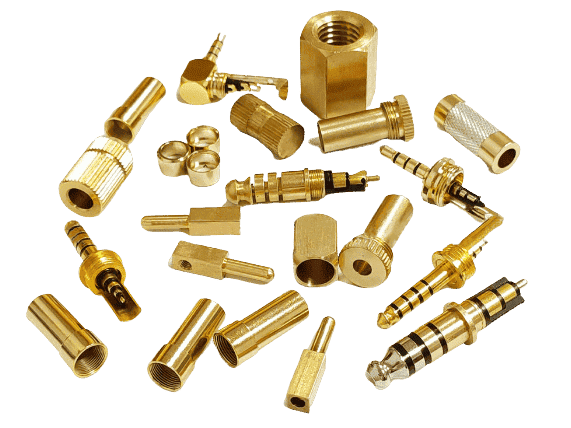

Precision Brass Machining: Optimized for Performance and Efficiency

Brass remains a critical material choice across demanding industries like fluid handling, electrical components, and precision instrumentation due to its excellent machinability, corrosion resistance, and electrical conductivity. However, achieving tight tolerances and flawless surface finishes in brass parts requires specialized expertise to overcome challenges such as chip control, thermal management, and maintaining dimensional stability during high-speed CNC operations. Suboptimal machining can lead to burring, galling, or compromised part integrity, directly impacting product performance and assembly.

At Honyo Prototype, our CNC machining services are engineered specifically for the unique demands of brass alloys including C36000, C26000, and C22000. We leverage advanced multi-axis milling and turning centers with rigid tooling setups and optimized coolant strategies to ensure consistent part quality, minimize material waste, and deliver exceptional surface finishes down to Ra 0.8 µm. Our process-controlled environment and in-house metrology capabilities guarantee adherence to stringent tolerances as tight as ±0.0002 inches, critical for sealing surfaces, threaded features, and intricate geometries common in brass components.

Accelerate Your Prototyping and Production Timeline

Eliminate procurement delays with Honyo’s Online Instant Quote platform. Upload your brass part CAD file, specify material grade and quantity requirements, and receive a detailed, transparent cost analysis within hours—not days. This seamless integration with our manufacturing workflow ensures your project transitions smoothly from quotation to finished part, supported by our engineering team’s proactive DFM feedback to optimize manufacturability and cost without sacrificing performance. Partner with Honyo for brass machining where precision, speed, and technical rigor converge.

Technical Capabilities

Technical Specifications for Machining Brass Parts – Focus on 3/4/5-Axis Milling and Turning with Tight Tolerances

Brass is a preferred material in precision machining due to its excellent machinability, corrosion resistance, and dimensional stability. At Honyo Prototype, we specialize in high-accuracy brass component manufacturing using advanced 3-axis, 4-axis, and 5-axis CNC milling, as well as CNC turning. Our processes are optimized for tight tolerance requirements, typically holding ±0.0002″ (±0.005 mm) on critical features, depending on part geometry and feature size.

While brass is the primary focus, our capabilities extend across a range of engineering materials including aluminum, steel, ABS, and nylon. Each material has unique machining characteristics that influence tool selection, feed rates, spindle speeds, and fixturing strategies.

Below is a comparative overview of key technical specifications and machining parameters:

| Parameter | Brass (C36000) | Aluminum (6061-T6) | Steel (1018/4140) | ABS (Thermoplastic) | Nylon (PA6/PA66) |

|---|---|---|---|---|---|

| Machinability Rating | Excellent (100%) | Good (75–80%) | Fair (40–50%) | Excellent (similar to brass) | Good (self-lubricating) |

| Typical Tolerance | ±0.0002″ (±0.005 mm) | ±0.0005″ (±0.013 mm) | ±0.0005″ (±0.013 mm) | ±0.001″ (±0.025 mm) | ±0.001″ (±0.025 mm) |

| Surface Finish (Ra) | 32–16 μin (0.8–0.4 μm) | 32–16 μin (0.8–0.4 μm) | 32–16 μin (0.8–0.4 μm) | 63–32 μin (1.6–0.8 μm) | 63–32 μin (1.6–0.8 μm) |

| Max Spindle Speed (RPM) | 6,000–12,000 (varies by tool) | 8,000–15,000 | 3,000–6,000 | 10,000–18,000 | 8,000–12,000 |

| Feed Rate (in/min) | 200–400 | 250–500 | 80–150 | 300–600 | 200–400 |

| Tooling Recommendations | Carbide, High-Speed Steel | Carbide with ZrN/TiAlN coat | Carbide, TiN-coated | Carbide, sharp rake angles | Carbide, positive rake tools |

| Coolant Requirement | Light flood or mist | Flood coolant recommended | Flood coolant required | Air blast or no coolant | Air blast preferred |

| Chatter Resistance | High | Moderate | Moderate to Low | Low (vibration-sensitive) | Moderate (damping properties) |

| Typical Applications | Connectors, fittings, gears | Enclosures, brackets, heatsinks | Shafts, fixtures, tooling | Prototypes, housings, jigs | Gears, bushings, wear components |

Notes on Multi-Axis Machining:

3-Axis Milling: Ideal for prismatic brass parts with features aligned to the primary planes. Efficient for high-volume production with minimal setup.

4-Axis Milling: Adds rotary indexing (A-axis), enabling machining of cylindrical features and angled holes in brass without secondary operations.

5-Axis Milling: Fully continuous contouring allows complex geometries such as manifolds, valve bodies, and ergonomic components to be completed in a single setup, maintaining tight tolerances and improving part accuracy.

Turning Capabilities:

CNC turning is highly effective for cylindrical brass components such as bushings, shafts, and threaded fittings. Our turning centers support live tooling for milling features (e.g., flats, slots, cross-holes), enabling complete part fabrication in one operation. Sub-micron-level tolerances are achievable with in-process probing and precision collet systems.

Material Notes:

Brass (C36000): Superior chip formation, minimal tool wear, ideal for high-speed, tight-tolerance machining.

Aluminum: Lightweight and thermally conductive; requires proper chip evacuation to avoid built-up edge.

Steel: Higher strength but increased tool wear; slower cycle times due to lower speeds/feeds.

ABS: Low melting point; requires sharp tools and minimal heat input to prevent deformation.

Nylon: Hygroscopic and flexible; proper fixturing and post-machining conditioning may be required.

All parts are inspected using CMM, optical comparators, and surface roughness testers to ensure compliance with drawing specifications, including GD&T callouts.

From CAD to Part: The Process

Honyo Prototype Brass Machining Process Overview

Honyo Prototype specializes in precision brass component manufacturing, leveraging a streamlined workflow optimized for materials like C36000 free-cutting brass, C26000 cartridge brass, and other copper alloys. Our process ensures geometric accuracy, surface integrity, and material property retention critical for hydraulic, electrical, and aerospace applications. Below is the end-to-end sequence.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure client portal. Our system validates file integrity and extracts critical parameters including dimensions, tolerances (typically ±0.005mm for critical features), surface finish requirements (Ra 0.8µm standard), and material specifications. Brass-specific annotations—such as stress relief requirements or plating notes—are prioritized during ingestion.

AI-Powered Quoting Engine

Honyo’s proprietary AI engine analyzes the CAD geometry against real-time shop floor data, including brass alloy machinability factors, tooling availability, and historical cycle times. The algorithm factors in brass-specific variables:

Chip evacuation complexity for high-zinc alloys

Thermal expansion coefficients during machining

Secondary operation sequencing (e.g., threading before finishing)

Quotes include material cost breakdowns (brass market pricing volatility is modeled), NRE charges for custom brass-specific fixtures, and lead time projections. Typical turnaround is under 2 hours for standard brass geometries.

DFM Analysis with Brass Material Expertise

Our engineering team conducts a rigorous Design for Machinability review, focusing on brass-specific pitfalls:

Recommending minimum wall thicknesses ≥0.5mm to prevent chatter in free-machining brass

Flagging deep cavities prone to built-up edge formation

Optimizing toolpaths to minimize galling in high-torque features

Suggesting alternative alloys (e.g., C36000 vs. C37700) for improved chip control

Critical DFM outputs include tolerance stack-up validation and brass-specific surface finish guidance. Below are key brass alloy considerations addressed during this phase:

| Alloy | Machinability Rating | Common Applications | Critical Machining Note |

|---|---|---|---|

| C36000 | 100% (Benchmark) | Valves, fittings | Avoid slow feeds to prevent smearing |

| C26000 | 55% | Electrical connectors | Requires rigid setups for burr control |

| C37700 | 70% | Hydraulic components | Coolant concentration critical |

Precision Production Execution

Brass parts enter production on dedicated Swiss-type lathes and 5-axis mills with brass-optimized parameters:

Tooling: Carbide inserts with polished flutes and specialized brass coatings (e.g., TiB₂) to reduce adhesion

Coolant: Non-chlorinated, low-viscosity formulations to prevent dezincification

Fixturing: Custom vises with non-marring jaws to avoid surface damage on soft brass

In-process inspection: Laser micrometers verify diameters on rotating parts to compensate for thermal growth

All brass chips are segregated for immediate recycling, maintaining clean workcells. First-article inspection reports (FAIRs) include material certification traceability to mill test reports.

Quality-Controlled Delivery

Final inspection validates conformance to ASME Y14.5 GD&T standards using CMMs with temperature-controlled environments (20±0.5°C) to counter brass’s high thermal expansion. Critical checks include:

Thread pitch diameter verification per ASME B1.1

Hardness testing (50-100 HB for most alloys)

Visual inspection for micro-cracks in high-stress zones

Parts undergo ultrasonic cleaning to remove residual brass fines, followed by VCI paper wrapping. Delivery includes full traceability documentation: material certs, FAIRs, and process parameter logs. Typical lead time from CAD upload to shipment is 7–12 business days for quantities under 500 pieces, with expedited options available.

Honyo’s brass machining process integrates material science expertise with digital manufacturing rigor, ensuring components meet stringent functional requirements while minimizing scrap rates through brass-specific process controls.

Start Your Project

Looking for precision-machined brass parts? Honyo Prototype delivers high-quality CNC machining services with fast turnaround times. Our manufacturing facility in Shenzhen is equipped to handle both prototypes and production runs with strict quality control and tight tolerances.

For quotes and project inquiries, contact Susan Leo at [email protected]. We specialize in brass components for automotive, electronics, and industrial applications—engineered to meet your exact specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.