Contents

Manufacturing Insight: Machining Bolts

Precision Bolt Machining: Engineering Reliability from Concept to Production

At Honyo Prototype, we understand that bolts are far more than simple fasteners—they are critical load-bearing components demanding uncompromising dimensional accuracy, material integrity, and repeatability. In aerospace, automotive, and industrial applications, even micron-level deviations can compromise structural safety and system performance. Our CNC machining services specialize in transforming raw bar stock or forgings into mission-critical bolts with tolerances as tight as ±0.0002″ (5µm), leveraging advanced multi-axis milling and turning centers to ensure geometric precision across all features including threads, undercuts, and custom geometries.

We machine high-performance materials ranging from aerospace-grade titanium (Ti-6Al-4V) and Inconel 718 to hardened steel alloys (4340, 8740) and corrosion-resistant stainless grades (304, 316), applying optimized toolpaths and in-process metrology to maintain strict compliance with ASME Y14.5, ISO 2768, and customer-specific specifications. Every bolt undergoes rigorous first-article inspection using CMMs and optical comparators, with full traceability from material certs to final QA documentation.

Accelerate your prototyping or low-volume production with Honyo’s Online Instant Quote platform. Upload your STEP, IGES, or DWG file to receive a detailed manufacturability analysis and competitive pricing within hours—no manual RFQ delays. Our engineering team proactively identifies cost-saving opportunities through design-for-manufacturability insights while guaranteeing adherence to your technical requirements.

For mission-critical bolt applications where failure is not an option, Honyo Prototype delivers precision, speed, and engineering partnership you can trust.

| Capability | Specification Range |

|---|---|

| Tolerance Control | ±0.0002″ (5µm) |

| Materials | Titanium, Inconel, Stainless, Alloy Steel |

| Max Bolt Diameter | 4.0″ (101.6mm) |

| Threads per ASME B1.1 | Unified National, Metric, Custom |

| Lead Time (Prototype) | As fast as 5 business days |

Technical Capabilities

Honyo Prototype provides high-precision machining services for bolt components using advanced 3, 4, and 5-axis CNC milling and turning technologies. Our processes are optimized for tight-tolerance applications across a range of engineering materials including aluminum, steel, ABS, and nylon. Below are the technical specifications for machining bolts under these conditions.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Axis Configuration | X, Y, Z linear axes | X, Y, Z + A-axis (rotary) | X, Y, Z + A and B axes (dual rotary) | X, Z linear + C-axis (spindle) | Full 5-axis simultaneous motion |

| Typical Bolt Features | Flats, hex heads, slots, holes | Angled features, multi-face milling | Complex contours, undercuts | Threaded shanks, concentric steps | Multi-feature bolt geometries |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm | ±0.002 mm |

| Repeatability | ±0.003 mm | ±0.003 mm | ±0.002 mm | ±0.002 mm | ±0.001 mm |

| Surface Finish (Typical) | Ra 1.6–3.2 µm | Ra 1.6–3.2 µm | Ra 0.8–1.6 µm | Ra 0.8–1.6 µm | Ra 0.4–0.8 µm (polished options) |

| Materials Supported | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel | Aluminum, Steel, ABS, Nylon | Aluminum, Steel |

| Aluminum Machining Speed | Up to 1,500 m/min (milling) | Up to 1,200 m/min | Up to 1,000 m/min | Up to 800 m/min (turning) | Optimized for minimal deflection |

| Steel Machining Speed | Up to 250 m/min | Up to 200 m/min | Up to 180 m/min | Up to 150 m/min | Carbide tooling, cryo cooling |

| ABS & Nylon Capability | Yes (low heat, sharp tooling) | Yes (fixture stability critical) | Limited (thermal deformation risk) | Yes (low feed, chip control) | Possible with environmental control |

| Minimum Feature Size | 1.0 mm radius | 0.8 mm radius | 0.5 mm radius | 0.3 mm groove width | 0.2 mm radius (micro-tooling) |

| Typical Tolerance (General) | ±0.025 mm | ±0.025 mm | ±0.015 mm | ±0.025 mm | ±0.005 mm to ±0.01 mm |

| Thread Accuracy | Class 6g (metric), 2A (inch) | Class 6g, 2A | Class 6g, 2A | Class 6g, 2A (single-point/cut) | Class 4g / 1A–2A (gage-certified) |

| Secondary Operations | Deburring, tapping, anodizing, plating | Same as 3-axis | Same + complex surface treatments | Parting, threading, knurling | CMM inspection, laser marking |

Note: Tight tolerance machining is performed under controlled thermal environments with in-process probing and tool wear compensation. Material selection impacts achievable tolerances and surface quality—steel and aluminum are preferred for high-precision bolt applications, while ABS and nylon are used for prototypes and non-structural components requiring chemical or electrical insulation.

From CAD to Part: The Process

As Senior Manufacturing Engineer at Honyo Prototype, I will detail our precision machining process for bolts, emphasizing technical rigor and seamless integration across stages. This workflow ensures manufacturability, cost efficiency, and on-time delivery for critical fastener components.

CAD Upload and Validation

Clients initiate the process via our secure web portal, uploading native CAD files (STEP, IPT, SLDPRT preferred) or neutral formats. Our system performs immediate geometric validation, checking for unit consistency, watertight solids, and critical bolt-specific parameters like thread callouts (ISO, UNF, metric), head geometry, and undercuts. Incompatible formats trigger automated feedback requesting corrections. File validation occurs within 15 minutes, ensuring no downstream delays from flawed geometry. Note that we exclusively machine bolts from bar stock; forged blanks require separate quotation.

AI-Powered Quoting with Engineering Oversight

Validated CAD data feeds into our proprietary AI quoting engine, which analyzes 200+ parametric variables including material grade (e.g., A286, 4140, 17-4PH), thread tolerance class (6g/6H), surface finish requirements, and secondary operations like plating or passivation. The AI cross-references real-time machine availability, material costs, and historical cycle times from our 50,000+ part database. Crucially, all AI-generated quotes undergo mandatory review by our applications engineering team. They verify thread production methodology (roll-formed vs. cut), assess head feature complexity, and confirm material suitability for the specified alloy. This hybrid approach delivers accurate quotes within 2 business hours while preventing AI over-reliance on edge cases.

DFM Analysis Focused on Bolt Integrity

Our DFM phase is where engineering expertise critically impacts bolt performance. We conduct a targeted review addressing fastener-specific failure points:

| DFM Checkpoint | Common Bolt Issue Detected | Honyo Resolution Path |

|---|---|---|

| Thread Root Geometry | Insufficient minor diameter causing stress risers | Recommend adjusted tap drill size per ASME B1.1 |

| Head Undercut | Sharp transitions risking fatigue cracks | Propose controlled radius per ISO 4753 |

| Material Specification | Non-standard alloy for environment | Suggest equivalent AMS/ASTM grade with corrosion data |

| Plating Interference | Thread tolerance incompatible with cadmium thickness | Adjust class 2A to 1A pre-plate dimensions |

This stage includes explicit communication with the client via our portal, providing annotated CAD markups and tolerance stack-up analyses. For aerospace bolts, we validate against NASM/MIL-SPEC requirements before proceeding.

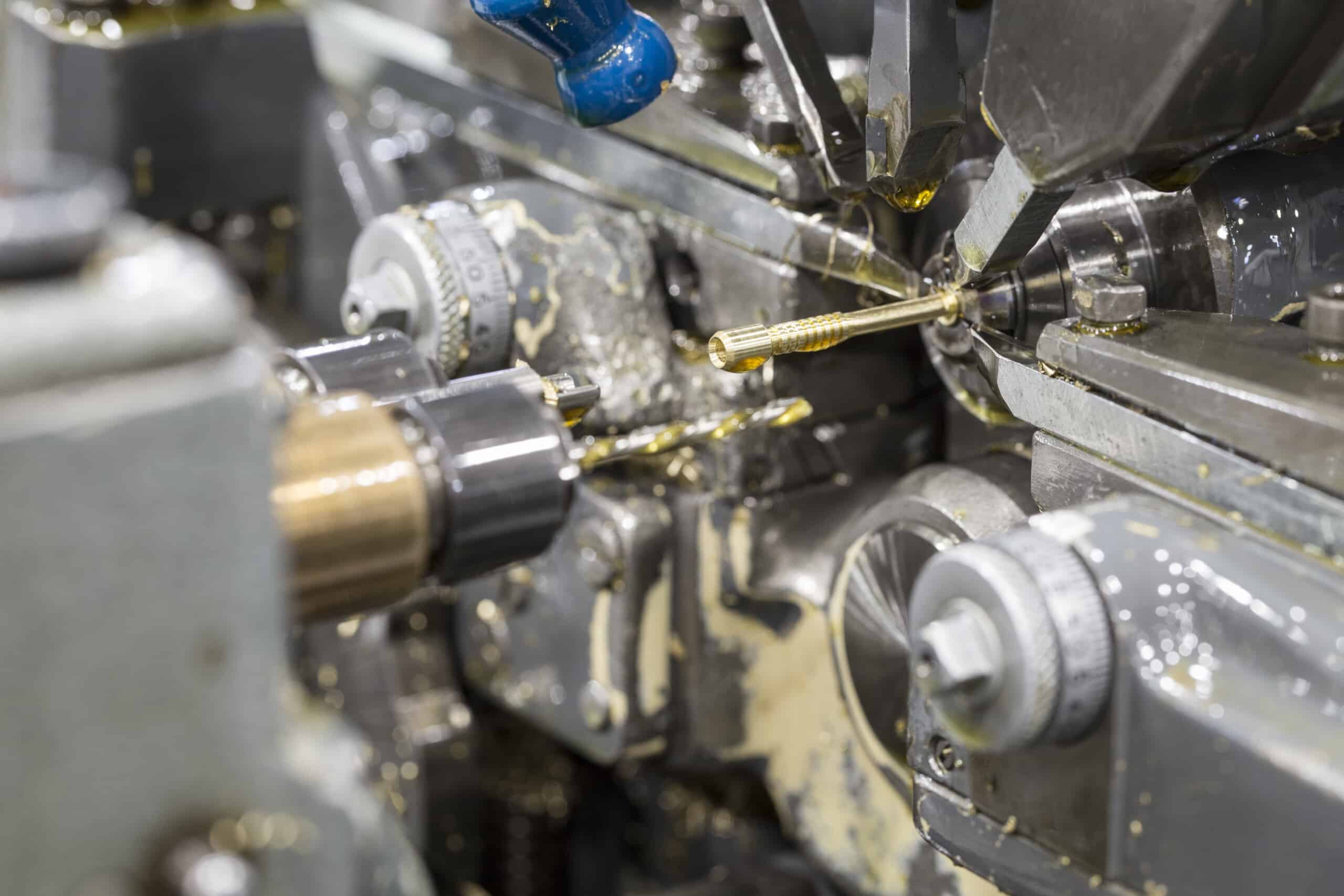

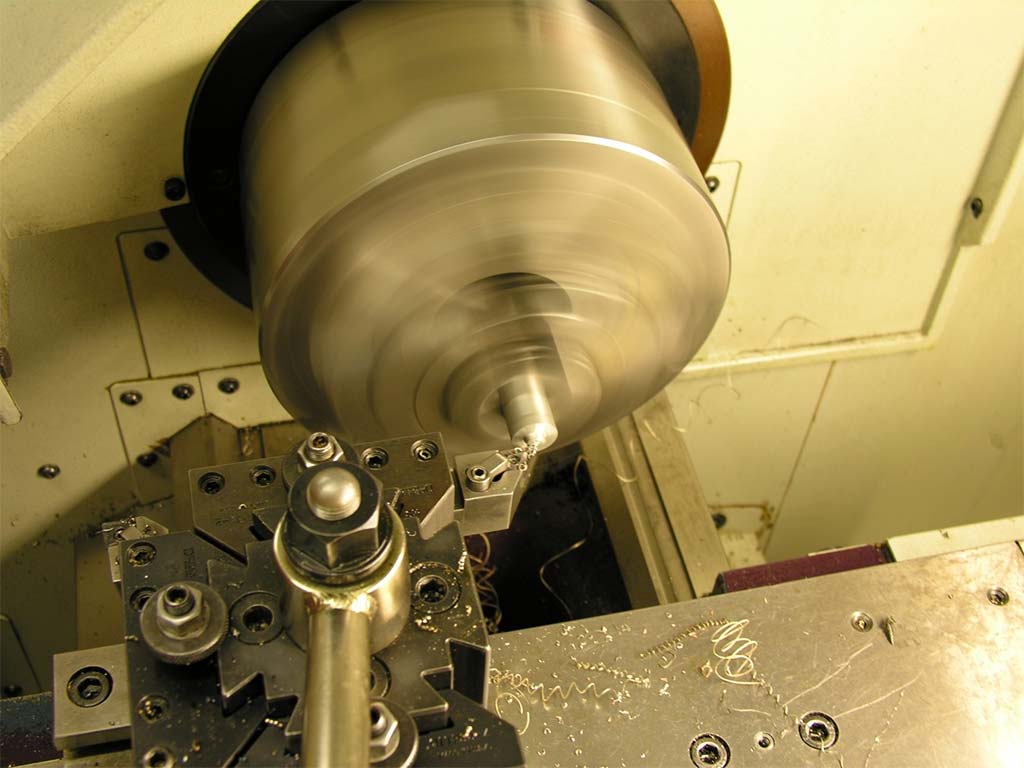

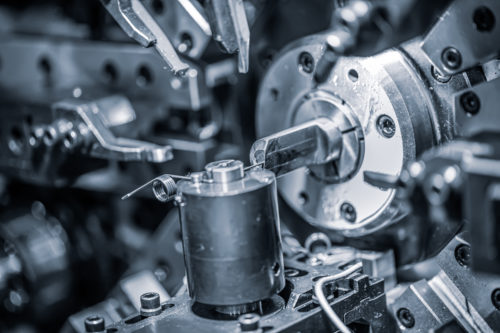

Precision Machining and Secondary Operations

Approved designs move to production on dedicated Swiss-type lathes (Tornos, Star) or multi-axis mills for complex head geometries. Bolt-specific protocols include:

Thread production via single-point cutting for prototypes or precision rolling for volumes >100 pcs

In-process verification using Renishaw probes for pitch diameter and lead error per ASME B1.2

Strict material traceability with heat code documentation

Controlled environment machining for high-temp alloys to prevent thermal distortion

Secondary operations like heat treatment (per AMS 2759) or non-embrittlement plating are coordinated through our certified supply chain partners with integrated scheduling to avoid bottlenecks.

Delivery with Full Traceability

All bolts undergo final inspection using calibrated thread comparators and CMMs, with reports showing GD&T compliance per the original CAD. We package parts in anti-tamper containers with serialized lot labels linking to:

Material certs (MTRs with full chemistry)

Process flow documentation

FAI reports for critical dimensions

Plating thickness validation

Shipments include digital delivery certificates accessible via our client portal, with real-time logistics tracking. Typical lead time from CAD upload to delivery is 7-10 business days for standard bolts, with expedited options for emergency requirements.

This integrated process eliminates traditional handoffs between quoting, engineering, and production teams. By embedding bolt-specific expertise at each phase—from thread tolerance validation in DFM to plating interference mitigation—we ensure your fasteners meet functional requirements while optimizing cost and delivery. For complex bolt assemblies, we recommend initiating with a pre-production DFM consultation to address interface tolerances early.

Start Your Project

Looking for precision-machined bolts? Honyo Prototype delivers high-quality machining services with tight tolerances and fast turnaround. All production is handled at our Shenzhen factory, ensuring reliable manufacturing standards and efficient lead times.

For inquiries or quotes, contact Susan Leo at [email protected].

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.