Contents

Manufacturing Insight: Machining Aluminum Parts

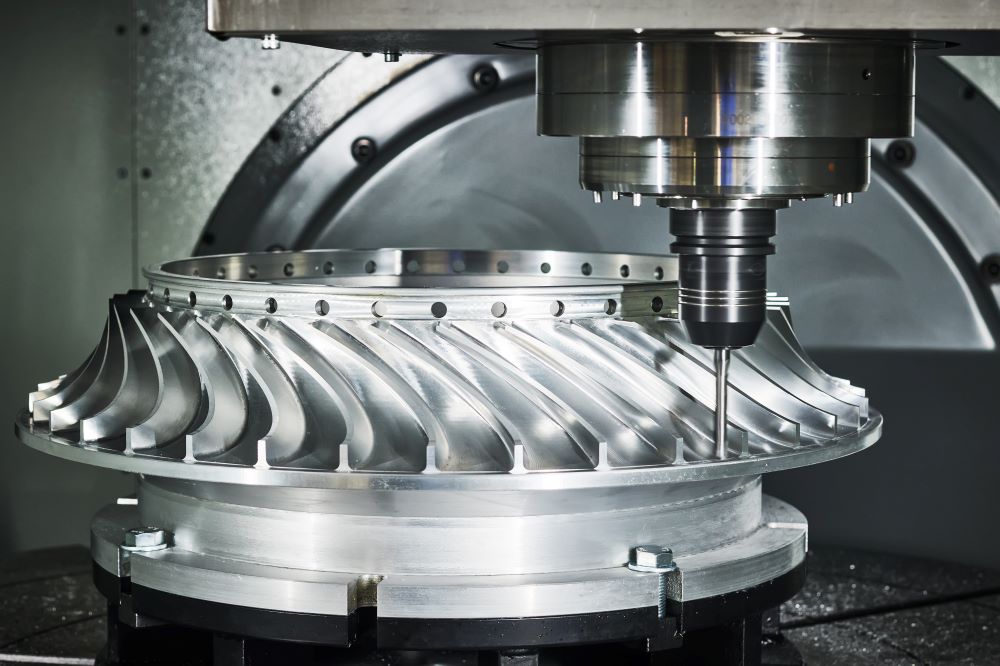

Precision Aluminum Machining Solutions for Demanding Applications

Aluminum remains the material of choice for rapid prototyping and low-volume production across aerospace, medical, and industrial sectors due to its optimal strength-to-weight ratio, thermal conductivity, and machinability. At Honyo Prototype, our CNC machining services transform complex aluminum designs—from 6061-T6 structural components to 7075-T6 high-stress aerospace fittings—into precision-engineered realities. Our ISO 9001-certified facility leverages advanced 3-, 4-, and 5-axis milling and turning centers to achieve tight-tolerance features down to ±0.0002 inches, ensuring dimensional accuracy and surface finishes meeting stringent industry specifications.

We specialize in overcoming aluminum-specific challenges such as chip evacuation, thermal deformation, and burr control through optimized toolpaths, coolant strategies, and real-time in-process inspection. Every part undergoes rigorous first-article inspection with CMM and optical comparators, supported by secondary services including anodizing, deburring, and laser marking to deliver fully finished components ready for integration.

Accelerate your development cycle with Honyo Prototype’s Online Instant Quote platform. Upload your STEP or IGES file to receive a detailed manufacturability analysis and competitive pricing within hours—not days—enabling faster iteration and time-to-market for your critical aluminum assemblies.

Technical Capabilities

Technical Specifications for Machining Aluminum Parts – Focus on 3/4/5-Axis Milling and Turning with Tight Tolerances

Machining aluminum parts with high precision requires advanced CNC capabilities, particularly using 3-axis, 4-axis, and 5-axis milling systems, as well as CNC turning. These processes support tight tolerances, complex geometries, and high repeatability. While aluminum is the primary material due to its machinability and strength-to-weight ratio, Honyo Prototype also machines steel, ABS, and nylon for multi-material applications.

Below is a comparative summary of technical specifications across materials and processes:

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Typical Materials |

|---|---|---|---|---|---|

| Spindle Speed Range | 8,000 – 24,000 RPM | 8,000 – 24,000 RPM | 10,000 – 30,000 RPM | 1,500 – 8,000 RPM | Aluminum 6061-T6, 7075-T6 |

| Positioning Accuracy | ±0.005 mm (0.0002″) | ±0.005 mm (0.0002″) | ±0.003 mm (0.0001″) | ±0.005 mm (0.0002″) | Steel (e.g., 4140, 17-4PH) |

| Repeatability | ±0.003 mm (0.0001″) | ±0.003 mm (0.0001″) | ±0.002 mm (0.00008″) | ±0.003 mm (0.0001″) | ABS (acrylonitrile butadiene styrene) |

| Standard Tolerance | ±0.0125 mm (±0.0005″) | ±0.0125 mm (±0.0005″) | ±0.010 mm (±0.0004″) | ±0.0125 mm (±0.0005″) | Nylon (PA6, PA66) |

| Tight Tolerance Capability | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.0025 mm (±0.0001″) | ±0.005 mm (±0.0002″) | |

| Surface Finish (Typical) | Ra 0.8 – 1.6 µm (32–63 µin) | Ra 0.8 – 1.6 µm (32–63 µin) | Ra 0.4 – 0.8 µm (16–32 µin) | Ra 0.8 – 1.6 µm (32–63 µin) | |

| Tooling System | HSK-63 or BT-30 | HSK-63 or BT-30 | HSK-63 or HSK-40 | Capto C4 or ISO 2850 | |

| Axis Travel (X/Y/Z typical) | 500 x 400 x 350 mm | 500 x 400 x 350 mm | 400 x 300 x 250 mm | Max. Diameter: 300 mm | |

| Rotary Axis (if applicable) | N/A | A-axis (0–360° indexing) | A/B or A/C (continuous 5-axis) | C-axis (live tooling) | |

| Coolant System | Flood, Mist, or Through-Spindle | Flood, Mist, or Through-Spindle | High-pressure through-tool | Flood or Mist | |

| Max Workpiece Size (Milling) | 600 x 500 x 400 mm | 600 x 500 x 400 mm | 500 x 400 x 300 mm | Diameter: 300 mm, Length: 500 mm |

Notes on Material Suitability

Aluminum 6061-T6 and 7075-T6 are most commonly machined due to excellent strength, corrosion resistance, and chip formation. These alloys respond well to high-speed machining, enabling fine surface finishes and tight tolerances.

Steel components are machined when higher strength or wear resistance is required. However, machining steel involves lower cutting speeds and higher tool wear compared to aluminum.

ABS and nylon are used for non-metallic prototypes or functional components requiring electrical insulation or reduced weight. These materials are machined with sharp carbide tools at high speeds and low feed rates to prevent melting or burring.

Tight Tolerance Considerations

Achieving tolerances down to ±0.0025 mm requires thermal control, high-precision tooling, in-process probing, and post-machining inspection via CMM (Coordinate Measuring Machine). 5-axis milling reduces setup steps and improves accuracy for complex parts.

All processes are supported by ISO 9001-compliant quality systems and CAD/CAM programming using Siemens NX, Mastercam, or Autodesk Fusion 360.

From CAD to Part: The Process

Honyo Prototype Aluminum Machining Process Overview

Our streamlined workflow for precision aluminum part manufacturing integrates digital efficiency with expert engineering oversight. This ensures rapid turnaround without compromising on quality or manufacturability. The process begins when a client uploads their CAD model to our secure customer portal. We accept industry-standard formats including STEP AP203/AP214, IGES, Parasolid (.x_t), and native files from SOLIDWORKS, Creo, and Fusion 360. Upon upload, the system initiates an automated geometry analysis.

AI-Powered Quoting System

The CAD data is processed by our proprietary AI engine which evaluates critical parameters such as part volume, feature complexity, geometric tolerances, and surface finish requirements. This analysis generates an instant, detailed quote within minutes, including precise cost breakdowns for material, machining time, and finishing operations. The AI system references real-time machine shop capacity and material costs, providing transparent pricing with no hidden fees. Clients receive immediate visibility into lead times and cost drivers before formal commitment.

Engineer-Validated DFM Analysis

Following quote acceptance, our manufacturing engineering team conducts a rigorous Design for Manufacturability review specific to aluminum alloys. This phase is critical due to aluminum’s unique machining characteristics including thermal expansion, chip evacuation challenges, and susceptibility to burring. Engineers assess wall thickness stability, tool access for internal features, optimal stock allowance, and fixture requirements. We provide actionable feedback with suggested modifications to reduce cycle time or improve dimensional stability, typically resolving 85% of potential issues before programming begins. Clients receive a formal DFM report with annotated recommendations.

Precision CNC Production

Approved designs move to our climate-controlled machining floor equipped with 5-axis CNC mills (DMG MORI, HAAS) and lathes with live tooling. Key production parameters for aluminum include:

| Parameter | Typical Range for Aluminum | Control Method |

|——————–|—————————-|——————————|

| Spindle Speed | 8,000 – 24,000 RPM | High-speed spindles withThrough-Coolant |

| Feed Rate | 500 – 2,500 mm/min | Adaptive clearing strategies |

| Tool Material | Carbide with ZrN coating | Vendor-specific tool libraries |

| Tolerance Capability | ±0.025 mm (standard) | In-process probing |

| Surface Finish | Ra 0.8 – 3.2 µm | Dedicated finishing passes |

All aluminum parts undergo first-article inspection against the original CAD model using CMM and optical comparators. Secondary operations like deburring, anodizing coordination, or custom packaging are sequenced within the production schedule.

Quality-Controlled Delivery

Completed parts undergo final dimensional verification and visual inspection per AS9102 standards. We provide certified material test reports and first-article inspection documentation. Parts are packaged in anti-static, crush-resistant containers with desiccant for moisture-sensitive finishes. Shipments include real-time logistics tracking, with standard lead times of 5-10 business days for prototype quantities. Our process guarantees no minimum order quantities and full traceability from raw material lot to finished component.

Start Your Project

Looking for precision-machined aluminum parts? Partner with Honyo Prototype for high-quality CNC machining services tailored to your specifications. With our factory located in Shenzhen, we offer fast turnaround, tight tolerances, and consistent quality for prototyping and low-volume production.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.