Contents

Manufacturing Insight: Machining 304 Stainless Steel

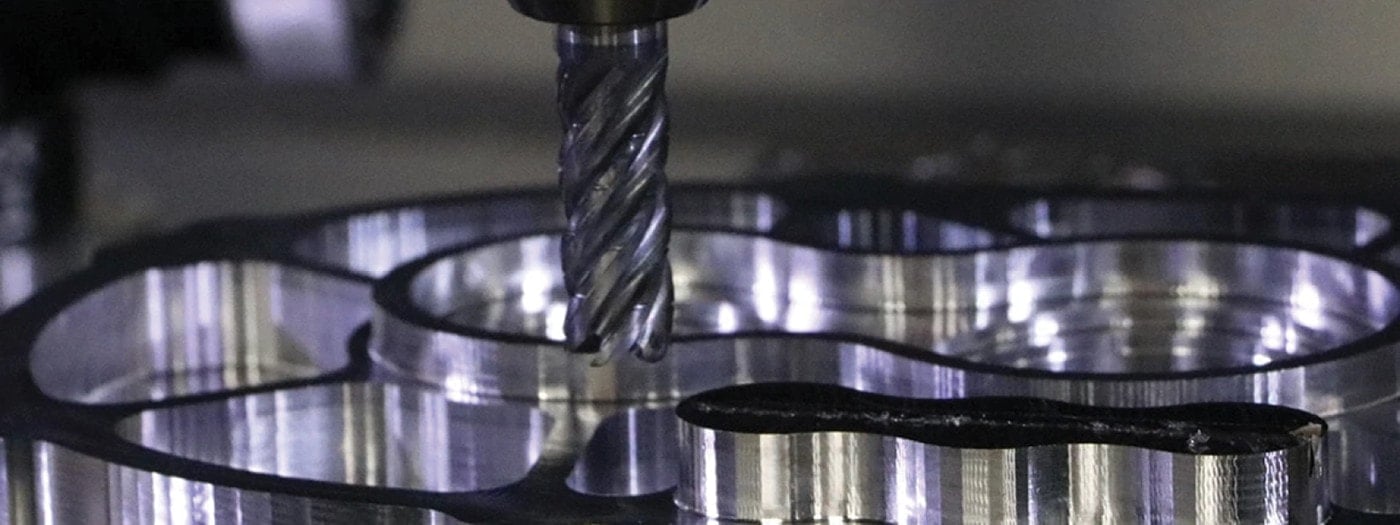

Precision Machining of 304 Stainless Steel: Honyo Prototype’s CNC Expertise

Machining 304 stainless steel demands specialized expertise due to its inherent work-hardening characteristics, thermal conductivity limitations, and stringent surface finish requirements for critical applications. Achieving tight tolerances and optimal part integrity in this versatile austenitic alloy requires precise toolpath strategies, optimized cutting parameters, and deep material science understanding to prevent galling, built-up edge, and dimensional instability.

Honyo Prototype delivers exceptional CNC machining services specifically engineered for 304 stainless steel components. Our advanced 3-, 4-, and 5-axis milling and turning centers, operated by veteran manufacturing engineers, utilize carbide tooling geometries and coolant strategies proven for stainless alloys. We consistently produce complex geometries with tolerances down to ±0.0002 inches while maintaining the material’s essential corrosion resistance and mechanical properties, serving demanding sectors including medical devices, fluid handling, and aerospace subsystems.

Accelerate your 304 stainless steel prototyping and low-volume production with Honyo Prototype’s Online Instant Quote system. Upload your STEP or IGES file to receive a detailed manufacturability analysis and competitive pricing within hours, not days—enabling faster iteration and time-to-market for your critical stainless components.

Technical Capabilities

Machining 304 stainless steel requires precise control of cutting parameters due to its high work-hardening rate, toughness, and low thermal conductivity. The following technical specifications outline recommended practices for 3-axis, 4-axis, and 5-axis milling, as well as turning operations, with an emphasis on achieving tight tolerances (±0.0005″ / ±0.013 mm). While the primary focus is 304 stainless steel, comparative notes are included for aluminum, steel (carbon/low alloy), ABS, and nylon to provide context across common prototype and production materials.

| Parameter | 304 Stainless Steel (Milling) | 304 Stainless Steel (Turning) | Aluminum (6061-T6) | Carbon/Low Alloy Steel | ABS (Thermoplastic) | Nylon (PA6/PA66) |

|---|---|---|---|---|---|---|

| Cutting Speed (SFM) | 200–350 | 250–400 | 800–1,200 | 300–600 | 500–1,000 | 400–800 |

| Feed Rate (IPR) | 0.002–0.006 (per tooth) | 0.005–0.015 (per revolution) | 0.005–0.012 | 0.004–0.010 | 0.008–0.020 | 0.006–0.015 |

| Spindle Speed (RPM) | 1,500–4,000 (based on tool diameter) | 1,000–3,500 | 5,000–12,000 | 2,000–5,000 | 3,000–8,000 | 2,500–6,000 |

| Tool Material | Carbide (TiAlN or AlCrN coating) | Carbide (CVD/PVD coated) | Carbide or HSS | Carbide (CVD-coated) | Carbide (sharp, polished) | Carbide (sharp, polished) |

| Coolant | High-pressure through-tool coolant | Flood or high-pressure coolant | Flood or air | Flood coolant | Air or air mist | Air or minimal oil mist |

| Tolerance Capability | ±0.0005″ (±0.013 mm) achievable | ±0.0005″ (±0.013 mm) achievable | ±0.0002″ (±0.005 mm) | ±0.0005″ (±0.013 mm) | ±0.001″ (±0.025 mm) | ±0.001″ (±0.025 mm) |

| Surface Finish (Ra) | 16–32 μin (milling), 16–63 μin (turning) | 16–63 μin | 8–32 μin | 16–63 μin | 32–125 μin | 32–125 μin |

| Machinability Rating | 45% (relative to B1112 steel) | 45% | 90–100% | 50–70% | Excellent (soft, low melt) | Moderate (tough, hygroscopic) |

| Workholding Considerations | High clamping force; avoid distortion | Rigid setup; minimize vibration | Moderate clamping | High rigidity required | Low force; vacuum or soft jaws | Moderate; watch for creep |

| 5-Axis Suitability | High (for complex geometries) | Limited (typically 2-axis or turning) | High | High | Medium | Medium |

Notes on Tight Tolerance Machining:

Achieving tight tolerances in 304 stainless steel demands thermal stability, minimized tool deflection, and consistent tool wear monitoring. Use of shrink-fit or hydraulic tool holders is recommended to ensure runout <0.0002″. For 5-axis milling, continuous tool path optimization and tilt strategies reduce stepovers and improve surface consistency. In-process probing and thermal compensation systems enhance repeatability.

Aluminum allows higher speeds and tighter tolerances due to its machinability and thermal conductivity. ABS and nylon require sharp tools and controlled feeds to prevent melting or burring, but generally cannot hold tolerances as tightly as metals due to material compliance and moisture absorption (especially nylon).

At Honyo Prototype, we apply these parameters within controlled environments using calibrated CNC systems to ensure dimensional accuracy and repeatability across all materials, with special protocols for stainless steel to mitigate work hardening and tool wear.

From CAD to Part: The Process

Honyo Prototype 304 Stainless Steel Machining Process Overview

Honyo Prototype utilizes a rigorously defined workflow for 304 stainless steel machining, optimized to address the material’s unique challenges including work hardening, thermal conductivity limitations, and corrosion resistance requirements. The process begins with a validated CAD model and progresses through integrated quality gates to ensure dimensional accuracy and surface integrity.

Step 1: CAD Upload and Validation

Clients submit industry-standard CAD files (STEP, IGES, or native formats) via our secure portal. Our system performs automated geometry validation, checking for unit consistency, manifold errors, and manufacturability flags specific to 304SS. Critical 304SS considerations at this stage include verifying wall thicknesses above 0.8mm to prevent distortion and confirming radii alignment with tooling capabilities to minimize work hardening. Files failing validation trigger immediate client notification with precise error diagnostics.

Step 2: AI-Powered Quoting Engine

Our proprietary AI engine analyzes the CAD geometry, material properties, and historical 304SS machining data to generate a technical quote within 2 hours. The algorithm factors in 304SS-specific parameters:

Predicted tool wear rates based on hardness (typically 149–200 HB)

Coolant requirements (mandatory high-pressure soluble oil emulsion)

Estimated secondary operations for stress relief

Work hardening compensation in feed/speed calculations

Quotes include explicit tolerancing options validated against ASME Y14.5 standards for stainless steel, with default capabilities documented below.

Step 3: DFM Analysis and 304SS Optimization

All 304SS projects undergo mandatory Design for Machinability review by senior engineers. This 72-hour phase focuses exclusively on stainless steel challenges:

Redesigning thin walls using FEA to counter thermal distortion

Specifying minimum 0.5mm corner radii to prevent tool chipping

Recommending peck drilling cycles for deep holes to evacuate stringy chips

Flagging areas requiring slow traverse rates to avoid HAZ (Heat Affected Zones)

Clients receive a digital DFM report with annotated CAD revisions and a revised timeline reflecting stainless-specific process adjustments.

Step 4: Precision Production Execution

Machining occurs in climate-controlled cells with dedicated 304SS tooling protocols:

Carbide end mills with TiAlN coating (Roughing: 180 m/min; Finishing: 120 m/min)

Flood coolant at 1000 psi minimum to control temperatures below 150°C

In-process CMM verification after critical features to monitor spring-back

Dedicated workholding with non-marring stainless vise jaws

All operations follow documented work instructions referencing AMS 5639 material specs, with real-time SPC tracking of critical dimensions.

Step 5: Post-Processing and Delivery

Completed 304SS parts undergo mandatory post-machining steps:

Vibratory deburring with non-ferrous media to prevent surface contamination

Electropolishing or passivation per ASTM A967 Method E to restore corrosion resistance

Final inspection against first-article requirements including Ra surface checks

Vacuum packaging with VCI inhibitors for salt-spray resistance during transit

Delivery includes full traceability: material certs, CMM reports, and process validation data. Typical lead time from CAD approval is 12–15 business days for complex 304SS components.

Critical Tolerancing Capabilities for 304 Stainless Steel

| Feature Type | Standard Capability | Tight Tolerance Option | Measurement Method |

|————–|———————|————————|——————-|

| Linear Dimensions | ±0.05 mm | ±0.0125 mm | CMM with thermal compensation |

| Hole Diameter | +0.025/-0 mm | +0.005/-0 mm | Air gaging or plug gauges |

| Surface Roughness | Ra 1.6 μm | Ra 0.4 μm | Contact profilometer |

| Flatness | 0.05 mm/m | 0.0125 mm/m | Optical flat inspection |

This end-to-end process ensures 304 stainless steel components meet aerospace, medical, and semiconductor industry requirements while mitigating inherent machining risks through material-specific engineering controls. All stages comply with ISO 9001:2015 and IATF 16949 standards.

Start Your Project

Looking for precision machining of 304 stainless steel? Honyo Prototype delivers high-accuracy CNC machining services with tight tolerances and fast turnaround, ideal for prototypes and low-volume production. Our Shenzhen-based factory is equipped with advanced machinery and quality control systems to ensure consistent, reliable results.

Contact Susan Leo today to discuss your 304 stainless steel machining requirements. Email at [email protected] for a quick quote and technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.