Guide Contents

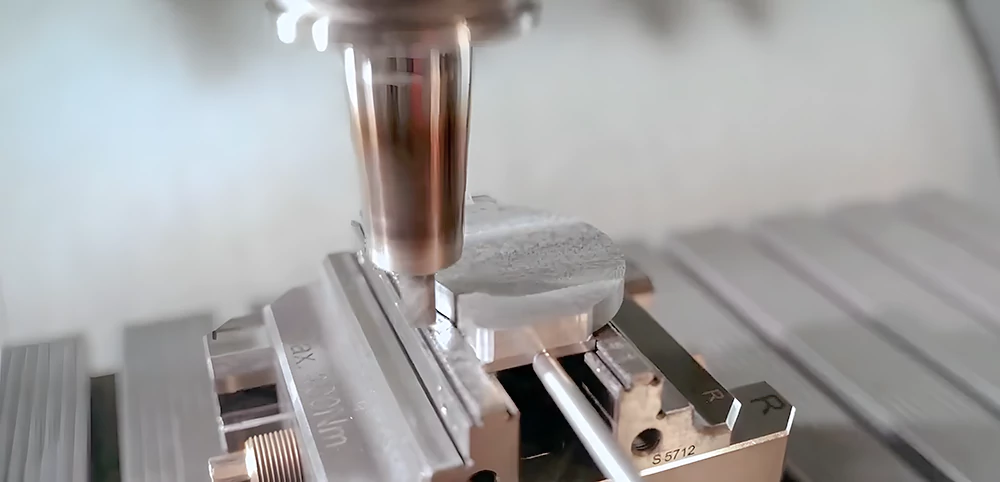

Project Insight: Machining 304 Stainless

Mastering 304 Stainless Steel Machining: Precision Meets Speed for Product Innovation

At Honyo Prototype (Shenzhen, China), founded by Susan Leo, we blend cutting-edge CNC technology with AI-driven precision to transform 304 stainless steel designs into functional prototypes and end-use parts—faster, more cost-effectively, and with uncompromising quality.

Why 304 Stainless Steel Demands Expertise

Work Hardening Challenge: 304SS hardens rapidly during machining, causing tool wear, heat buildup, and dimensional inaccuracies if not optimized.

Cost Implications: Material costs ($2.5–$3.5/kg) escalate quickly with inefficient processes—slow speeds, frequent tool changes, and rework can inflate total costs by 20–30%.

Performance Criticality: Microscopic deviations compromise corrosion resistance and mechanical integrity, especially in medical, aerospace, or food-grade applications.

How Honyo’s AI-Powered Platform Solves These Challenges

Real-Time Optimization: Our AI analyzes CAD files to recommend optimal cutting parameters, toolpaths, and annealing options—reducing machining time by 30%+ while maintaining ±0.01mm tolerances.

Multi-Axis Precision: 3/4/5-axis CNC capabilities handle complex geometries with minimal setups, eliminating alignment errors and accelerating production.

Material-Specific Expertise: Specialized tooling and cooling systems designed for 304SS, paired with annealed 304SS options that enable 200% faster machining and 50% lower tooling costs without sacrificing corrosion resistance.

Your Partner for Rapid, Transparent Manufacturing

Instant Online Quote: Upload your design, get a cost breakdown in <60 seconds—no manual quotes, no hidden fees.

Guaranteed Fast Turnaround: Prototypes in 3 days, production runs in 7 days—with precision guaranteed at every step.

End-to-End Support: From DFMA feedback to post-processing, our engineers ensure your 304SS parts meet exact specifications—so you iterate faster and launch with confidence.

“At Honyo, we don’t just machine parts—we engineer solutions that accelerate your innovation cycle. Your vision, our precision.”

— Susan Leo, Founder & CEO, Honyo Prototype

Honyo Capabilities & Technology

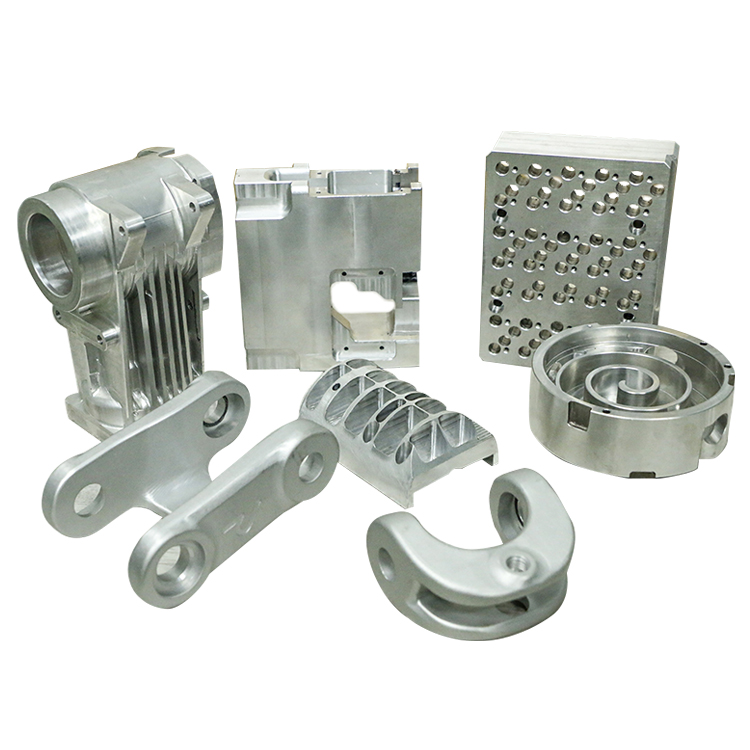

Honyo’s Precision Machining Capabilities for 304 Stainless Steel

At Honyo Prototype, we leverage cutting-edge technology and deep material expertise to deliver exceptional 304 stainless steel components—combining precision, speed, and cost efficiency for your most demanding applications.

Advanced CNC Machining Technology

3/4/5-axis machining for complex geometries without repositioning

Tight tolerances of ±0.01mm for functional prototypes and end-use parts

Optimized toolpaths and coolant strategies to minimize heat buildup and tool wear in 304SS

Material-Specific Optimization

Strategic annealing process to enhance machinability, reducing processing time by 200% and cutting tooling costs by 50%

Expertise in balancing corrosion resistance with machining efficiency for aerospace, medical, and industrial applications

Scalable Production Capacity

Seamlessly transition from 1 prototype to 10,000+ production parts with zero quality compromise

Dedicated production lines for rapid scaling—no setup delays for high-volume runs

ISO-Certified Quality Assurance

Strict in-process inspections at every machining stage

Comprehensive GD&T analysis and surface finish verification (Ra 0.4μm achievable)

Full traceability and documentation for regulatory compliance (ISO 9001:2015 certified)

Smart Technology for Accelerated Delivery

Online Instant Quote: AI-powered platform delivers real-time pricing and lead times in seconds—no waiting, no guesswork.

AI-Optimized Workflow: Dynamic adjustments to machining parameters ensure maximum efficiency for 304SS, reducing lead times by up to 30%.

Fast Turnaround Guarantee: Standard parts delivered in 5 business days; expedited options available for urgent projects.

Powered by Susan Leo’s vision of innovation-driven manufacturing—where precision meets speed, and complexity meets simplicity.

Materials & Surface Finishes

Material Options & Finishes

At Honyo Prototype, we combine precision engineering with innovative digital tools to streamline your manufacturing process. Our AI-powered platform delivers instant quotes, expert material recommendations, and fast turnaround times—ensuring your 304 stainless steel parts are delivered on schedule and within budget.

Strategic Material Selection for Stainless Steel Applications

304 Stainless Steel: The go-to choice for cost-effective, general-purpose applications. Offers excellent corrosion resistance for food processing, medical devices, and architectural components. Annealed 304 can be machined up to 200% faster with reduced tooling costs, making it ideal for high-volume prototyping.

316 Stainless Steel: Superior corrosion resistance for marine, chemical, and high-salinity environments. Higher molybdenum content increases cost but ensures longevity in harsh conditions. Our advanced CNC processes optimize machining efficiency to minimize lead times.

Alternative Materials:

Aluminum 6061: Lightweight and easy to machine; perfect for structural prototypes. Anodizing enhances surface durability and aesthetics.

Aluminum 7075: High-strength alloy for aerospace applications; requires specialized tooling but delivers exceptional performance.

Brass: Excellent electrical conductivity and machinability; ideal for connectors and decorative parts.

PEEK: High-performance polymer for extreme temperature and chemical resistance; used in medical and aerospace sectors.

Tailored Surface Finishes for Enhanced Performance

Electropolishing: For stainless steel, creates a smooth, sterile surface with improved corrosion resistance—ideal for medical and food-grade applications.

Passivation: Removes surface contaminants, boosting corrosion resistance without dimensional changes.

Mirror Polishing: Achieves a reflective finish for visible components; requires precision CNC finishing.

Bead Blasting: Uniform matte finish for stainless steel, enhancing adhesion for coatings and improving aesthetics.

Anodizing (Aluminum Only): Increases wear resistance and allows color customization for decorative or functional parts.

Powder Coating: Durable, color-rich finish for aluminum and steel parts; ideal for outdoor applications.

Why Choose Honyo Prototype?

AI-Powered Instant Quotes: Upload your CAD file for real-time pricing and material recommendations—no delays, no guesswork.

Precision Engineering: Tight tolerances (±0.01mm) ensure your parts meet exact specifications for functional prototypes and end-use applications.

Fast Turnaround: Standard orders delivered in 3–5 days, with expedited options available for urgent projects.

Expert Guidance: Our team of manufacturing engineers provides tailored advice on material selection, finishes, and process optimization.

Innovate with confidence: From concept to delivery, Honyo Prototype’s digital-first approach eliminates guesswork—so you focus on what matters most: building the future.

From Quote to Part: Our Process

How It Works: From CAD to Part

Upload CAD File

Instant file validation: Upload STEP, STL, IGES, or native CAD formats—our system checks for manufacturability issues in seconds.

No manual delays: Cloud-based processing ensures your design is ready for analysis immediately.

Secure & scalable: Enterprise-grade encryption protects your IP while handling complex geometries effortlessly.

AI-Powered Instant Quote

Real-time pricing in 60 seconds: AI analyzes geometry, material (304 stainless), tolerances (±0.01mm), and quantity for precise, transparent costs.

Clear cost breakdown: Material ($2.5–$3.5/kg for 304), machining time, finishing, and overhead—zero hidden fees.

Smart optimizations: AI flags opportunities like annealing 304 stainless to slash machining time by 200% and reduce tooling costs by 50%—automatically reflected in your quote.

Smart DFM Analysis

Proactive feedback within minutes: AI-driven design for manufacturability (DFM) insights highlight cost-saving tweaks before production starts.

Material-specific recommendations: Optimize wall thickness, minimize undercuts, or suggest heat treatments for 304 stainless to enhance machinability and part performance.

Rework prevention: Catch design flaws early—saving you 30%+ in prototyping time and costs.

Precision Manufacturing & Delivery

±0.01mm tolerances: 5-axis CNC machining ensures functional-grade parts for prototypes or end-use applications.

Fully automated workflow: From setup to final inspection—zero human bottlenecks, maximum consistency.

Speed without compromise: Track your order in real-time; prototypes delivered in 3–5 days, production runs in 7–10 days.

Certified quality: In-process checks + ISO-compliant inspection reports delivered with every shipment.

Why Honyo?

We turn complexity into simplicity. Our AI-powered platform eliminates guesswork, accelerates time-to-market, and delivers precision-engineered parts—because innovation shouldn’t wait.

Start Your Project with Honyo

Start Your Project with Honyo

Precision Engineered for Your Success

Achieve ±0.01mm tolerances with 5-axis CNC capabilities for functional prototypes and end-use parts

Expertise in 304 stainless steel optimization – reducing costs while maintaining corrosion resistance and strength

End-to-end quality control ensuring reliable performance in demanding applications

Instant Quotes, AI-Optimized Manufacturing, Fast Delivery

🚀 Online Instant Quote: Upload your CAD in seconds for real-time pricing with zero hidden fees

🤖 AI-Powered Platform: Proprietary annealing protocols and dynamic toolpath planning deliver up to 3x faster machining speeds and 50% lower tooling costs for 304 stainless steel

⏱️ Fast Turnaround: Prototypes delivered in 5 days, scalable to production volumes with expedited options

Let’s Build Something Great Together

Founder Susan Leo and our Shenzhen/Dongguan engineering team are ready to bring your vision to life. Contact us today:

📧 [email protected]

📞 +86 139 2843 8620

📍 Visit our facilities for hands-on collaboration

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.