Introduction: Navigating the Global Market for machined threads

In today’s competitive global marketplace, sourcing machined threads that meet specific application needs poses a significant challenge for B2B buyers. The intricacies of selecting the right type of thread, whether internal or external, can greatly impact the efficiency and functionality of the final product. This guide serves as a comprehensive resource, delving into the various types of machined threads, their applications across industries, and essential insights for supplier vetting. We will also explore cost considerations, production methods, and best practices to ensure optimal performance.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, navigating the complexities of the machined thread market is crucial. This guide empowers decision-makers with the knowledge needed to make informed purchases. By understanding the nuances of thread specifications and machining processes, buyers can confidently identify reliable suppliers and secure high-quality products that align with their project requirements.

By the end of this guide, you will be equipped with actionable insights and strategies that facilitate effective sourcing, ultimately enhancing your competitive advantage in your respective market. Let’s embark on this journey to demystify the world of machined threads and streamline your procurement process.

Understanding machined threads Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Internal Threads | Machined on the inside of a component; requires taps. | Used in fittings, valves, and mechanical assemblies. | Pros: Secure fit for components; Cons: Limited to concave surfaces. |

| External Threads | Machined on the outside; commonly produced using lathes. | Common in screws, bolts, and fasteners. | Pros: Versatile applications; Cons: Requires precise machining for quality. |

| Unified Threads | Standardized thread form (UNC and UNF); common in North America. | Widely used in automotive and machinery sectors. | Pros: Compatibility with many fasteners; Cons: May not suit all international standards. |

| Metric Threads | Based on the metric system; widely adopted globally. | Preferred in European and Asian manufacturing. | Pros: Easy to integrate into metric systems; Cons: Not as familiar in North America. |

| Acme Threads | Flat-top profile; designed for power transmission. | Used in lead screws and linear motion applications. | Pros: High load capacity; Cons: Limited to specific mechanical applications. |

What Are Internal Threads and Their B2B Applications?

Internal threads are machined into the interior of a component, typically using taps. This design is essential for applications that require screw insertions, such as in fittings and valves. When selecting internal threads, B2B buyers should consider the compatibility of the thread size with their components, as well as the machining capabilities of their suppliers. Internal threads provide a secure fit, but their application is limited to concave surfaces, which may restrict design options in certain projects.

How Do External Threads Differ in Application?

External threads are machined on the outside of components, primarily using lathes or dies. This type is prevalent in screws, bolts, and various fasteners. For B2B buyers, the versatility of external threads makes them suitable for a wide range of mechanical applications. However, precision in machining is crucial, as any discrepancies can lead to poor fit and function. Buyers should evaluate the supplier’s machining capabilities to ensure high-quality external threads that meet their specifications.

Why Choose Unified Threads for Your Projects?

Unified threads, particularly UNC (coarse) and UNF (fine), are standardized thread forms commonly used in North America. They are essential in automotive and machinery sectors, where compatibility with various fasteners is crucial. B2B buyers benefit from the widespread availability of unified threads, but they should also consider whether these standards align with international requirements, especially when dealing with global suppliers. While unified threads offer excellent compatibility, they may not suit all international applications, necessitating careful consideration.

What Advantages Do Metric Threads Offer to Global Buyers?

Metric threads are based on the metric system and are widely adopted across Europe and Asia. They provide a seamless integration into metric-based systems, making them an ideal choice for B2B buyers in these regions. When sourcing metric threads, businesses should ensure they understand the specifications, including pitch and diameter, to avoid compatibility issues. While metric threads are advantageous for international projects, they may not be as familiar in North America, which can pose challenges in cross-border sourcing.

How Are Acme Threads Used in Mechanical Applications?

Acme threads feature a flat-top profile and are specifically designed for power transmission applications, such as in lead screws and linear motion systems. B2B buyers should consider the load capacity and mechanical advantages offered by Acme threads, making them suitable for heavy-duty applications. However, their use is somewhat niche, so businesses should confirm that this type of threading aligns with their specific operational needs. Acme threads provide strength and durability, but they may not be suitable for all applications requiring general fastening.

Key Industrial Applications of machined threads

| Industry/Sector | Specific Application of machined threads | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Fastening components in aircraft assembly | Enhances safety and reliability in high-stress environments | Compliance with aerospace standards; precision tolerances |

| Automotive | Manufacturing engine components and chassis parts | Ensures durability and performance under extreme conditions | Material quality; compatibility with global standards |

| Oil & Gas | Connecting pipes and valves in drilling operations | Prevents leaks and ensures efficient resource extraction | Resistance to corrosion; custom thread sizes |

| Medical Devices | Assembly of surgical instruments and implants | Guarantees precision and sterility in critical applications | Biocompatibility; strict regulatory compliance |

| Construction | Joining structural elements in buildings and bridges | Provides structural integrity and safety for large projects | Load-bearing capacity; local material availability |

How Are Machined Threads Used in the Aerospace Industry?

In the aerospace sector, machined threads are critical for fastening components during aircraft assembly. They ensure that parts such as wings, fuselage, and engines are securely joined, which is vital for safety and performance. Given the high-stress environments experienced during flight, the threads must meet stringent aerospace standards for strength and reliability. International buyers must prioritize suppliers who can provide high-precision threads and adhere to certifications like AS9100.

What Role Do Machined Threads Play in the Automotive Sector?

Machined threads are extensively used in the automotive industry for manufacturing engine components and chassis parts. They provide the necessary connections that withstand the rigors of high-speed travel and extreme temperatures. The durability of these threads is paramount, as failures can lead to catastrophic results. Buyers in this sector should focus on sourcing materials that meet global automotive standards, ensuring compatibility and performance across different vehicle models.

How Are Machined Threads Essential in Oil & Gas Applications?

In the oil and gas industry, machined threads are used to connect pipes and valves during drilling operations. The integrity of these connections is crucial to prevent leaks, which can lead to significant environmental and financial repercussions. Additionally, threads must be designed to resist corrosion from harsh chemicals found in drilling environments. Buyers should seek suppliers who can offer custom thread sizes and materials specifically engineered for high-pressure and corrosive conditions.

Why Are Machined Threads Important for Medical Devices?

Machined threads are integral in the assembly of surgical instruments and implants in the medical device industry. Precision is essential, as any deviation can compromise the effectiveness of these critical tools. Furthermore, materials used must be biocompatible to avoid adverse reactions in patients. Buyers in the medical sector should ensure that their suppliers comply with strict regulatory standards, such as ISO 13485, to guarantee the safety and efficacy of their products.

How Do Machined Threads Contribute to the Construction Industry?

In construction, machined threads are vital for joining structural elements in buildings and bridges. They provide the necessary strength and stability, ensuring that structures can withstand various loads and environmental conditions. The threads must meet specific load-bearing capacities to ensure safety. Buyers should consider local material availability and compliance with regional building codes when sourcing machined threads for construction projects.

3 Common User Pain Points for ‘machined threads’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Thread Type for Applications

The Problem:

B2B buyers often encounter challenges when selecting the appropriate type of machined threads for their specific applications. This issue can arise from a lack of understanding of thread classifications, such as internal versus external threads or the difference between fine and coarse threads. In industries like automotive or aerospace, using the wrong thread type can lead to catastrophic failures, increased costs, and delays in production. Buyers may feel overwhelmed by the variety of options available and unsure of how to assess which thread specifications best suit their needs.

The Solution:

To effectively choose the right thread type, buyers should begin by conducting a thorough analysis of their project requirements. This includes understanding the mechanical load that the threaded connection will bear, the environmental conditions (e.g., corrosion resistance), and the compatibility with existing components. It is beneficial to engage with suppliers who offer technical support and have extensive catalogs that detail the properties of various threads. Utilizing resources such as thread charts and consultation with machining experts can also help clarify which type of thread—internal or external, fine or coarse—will ensure optimal performance. Additionally, consider investing in prototypes to test different thread types before full-scale production, allowing for adjustments based on real-world performance.

Scenario 2: Challenges with Thread Tolerances and Quality Control

The Problem:

A common pain point for B2B buyers in the manufacturing sector is maintaining the required tolerances and quality standards for machined threads. Variations in thread quality can arise due to machine calibration issues, tool wear, or inconsistent raw materials. For industries that require high precision, such as aerospace and medical device manufacturing, even minor deviations in thread specifications can lead to significant operational failures, safety hazards, and compliance issues.

The Solution:

To mitigate these quality control challenges, buyers should implement a robust quality assurance process that includes regular inspection and calibration of CNC machines used for thread machining. Establishing standard operating procedures (SOPs) for the machining process can help ensure consistency in production. Additionally, utilizing advanced measurement tools, such as thread gauges and coordinate measuring machines (CMM), can provide precise verification of thread dimensions and tolerances. Collaborating with suppliers who adhere to recognized quality management standards, such as ISO 9001, will also enhance the assurance that the machined threads meet the necessary specifications. Furthermore, consider integrating feedback loops into your supply chain to continually improve the quality of machined threads based on performance data from end-users.

Scenario 3: Complications in Thread Repair and Maintenance

The Problem:

B2B buyers often face difficulties when dealing with damaged or worn-out threads in critical components. The inability to easily repair or maintain these threads can lead to costly downtime and inefficient operations. For example, in the construction or machinery sectors, stripped threads in bolts or fasteners can render equipment inoperable, necessitating expensive replacements or repairs that disrupt workflow.

The Solution:

To address the issue of thread repair, buyers should consider investing in thread repair kits and tools designed specifically for the types of threads they frequently use. Options such as thread inserts (e.g., Helicoils) can effectively restore stripped internal threads, providing a durable solution that extends the life of components. Additionally, training maintenance staff on proper techniques for thread repair can significantly reduce downtime. Establishing a proactive maintenance schedule that includes regular inspections of threaded connections can also help identify wear early, allowing for timely repairs before failures occur. Finally, working with suppliers who provide support and resources for thread maintenance can enhance operational efficiency and minimize the impact of thread-related issues on production timelines.

Strategic Material Selection Guide for machined threads

What Materials Are Commonly Used for Machined Threads?

When selecting materials for machined threads, it’s essential to consider their properties, applications, and suitability for specific environments. Below is an analysis of four common materials used in the production of machined threads, focusing on their key characteristics and implications for international B2B buyers.

1. Carbon Steel

Key Properties:

Carbon steel is known for its high tensile strength and hardness, making it suitable for high-stress applications. It typically has a temperature rating up to 400°F (204°C) and can withstand moderate pressure. However, its corrosion resistance is limited unless treated.

Pros & Cons:

The primary advantage of carbon steel is its durability and strength, which makes it ideal for heavy machinery and automotive applications. It is relatively inexpensive compared to other materials. However, the downside is its susceptibility to rust and corrosion, which can limit its use in humid or corrosive environments without protective coatings.

Impact on Application:

Carbon steel is compatible with many media, including air and oil, but is not recommended for corrosive substances. Its performance can be significantly impacted by environmental factors, necessitating protective measures in certain applications.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM A36 for structural steel. Additionally, understanding the availability of corrosion-resistant treatments is crucial for applications in humid climates.

2. Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance, particularly in harsh environments, and can withstand temperatures up to 1,500°F (815°C). It provides a good balance of strength and ductility, making it versatile for various applications.

Pros & Cons:

The main advantage of stainless steel is its durability and resistance to corrosion, which makes it ideal for food processing, marine, and chemical applications. However, it is more expensive than carbon steel, and its manufacturing processes can be more complex, requiring specialized tools.

Impact on Application:

Stainless steel is suitable for applications involving corrosive media, such as saltwater or acidic solutions. Its resistance to oxidation and staining makes it a preferred choice in industries where hygiene is critical.

Considerations for International Buyers:

International buyers should be aware of compliance with standards like ASTM A240 for stainless steel sheets. In regions like the Middle East, where high humidity is common, choosing the right grade (e.g., 316 for marine environments) is essential.

3. Aluminum

Key Properties:

Aluminum is lightweight, with a high strength-to-weight ratio, and can withstand temperatures up to 400°F (204°C). It has good corrosion resistance due to its natural oxide layer, making it suitable for various environments.

Pros & Cons:

Aluminum’s lightweight nature makes it ideal for applications where weight reduction is critical, such as aerospace and automotive. However, it is generally less durable than steel and can be more expensive. Additionally, its lower tensile strength may limit its use in high-stress applications.

Impact on Application:

Aluminum is compatible with non-corrosive media and is often used in applications involving air and water. Its lightweight nature can enhance the efficiency of mechanical systems.

Considerations for International Buyers:

Buyers should consider compliance with standards like ASTM B211 for aluminum alloys. In regions like Europe, preferences may lean towards specific aluminum grades that meet local regulations for environmental impact.

4. Brass

Key Properties:

Brass is a copper-zinc alloy known for its excellent machinability and corrosion resistance. It can withstand moderate temperatures and pressures, making it suitable for plumbing and electrical applications.

Pros & Cons:

The primary advantage of brass is its resistance to corrosion, particularly in water applications, and its aesthetic appeal. However, it is more expensive than carbon steel and can be less durable under high-stress conditions.

Impact on Application:

Brass is ideal for applications involving water and low-pressure systems. Its antimicrobial properties make it suitable for plumbing fixtures and medical devices.

Considerations for International Buyers:

International buyers should ensure compliance with standards like ASTM B36 for brass. In regions with stringent regulations on lead content, such as Europe, selecting lead-free brass options may be necessary.

Summary Table of Material Selection for Machined Threads

| Material | Typical Use Case for machined threads | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Heavy machinery, automotive | High strength and durability | Susceptible to rust and corrosion | Low |

| Stainless Steel | Food processing, marine applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Aerospace, automotive | Lightweight and good corrosion resistance | Lower tensile strength | Medium |

| Brass | Plumbing, electrical applications | Corrosion resistance and aesthetic appeal | More expensive and less durable | Medium |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions regarding machined threads, ensuring optimal performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for machined threads

What Are the Key Stages in the Manufacturing Process for Machined Threads?

The manufacturing process for machined threads is a multi-stage procedure that ensures precision and quality. Understanding these stages can significantly benefit international B2B buyers by enabling them to assess suppliers based on their capabilities and production standards.

1. Material Preparation: Selecting the Right Materials

The first step in manufacturing machined threads involves selecting the appropriate materials. Common materials include various grades of steel, aluminum, and plastics, depending on the application. The choice of material affects the mechanical properties, corrosion resistance, and overall durability of the threaded components.

Once the material is selected, it must be prepared through processes such as cutting and shaping to the desired dimensions. This preparation often includes creating blanks that are then subjected to further machining. Buyers should inquire about the material sourcing practices of suppliers, including certifications and compliance with international standards.

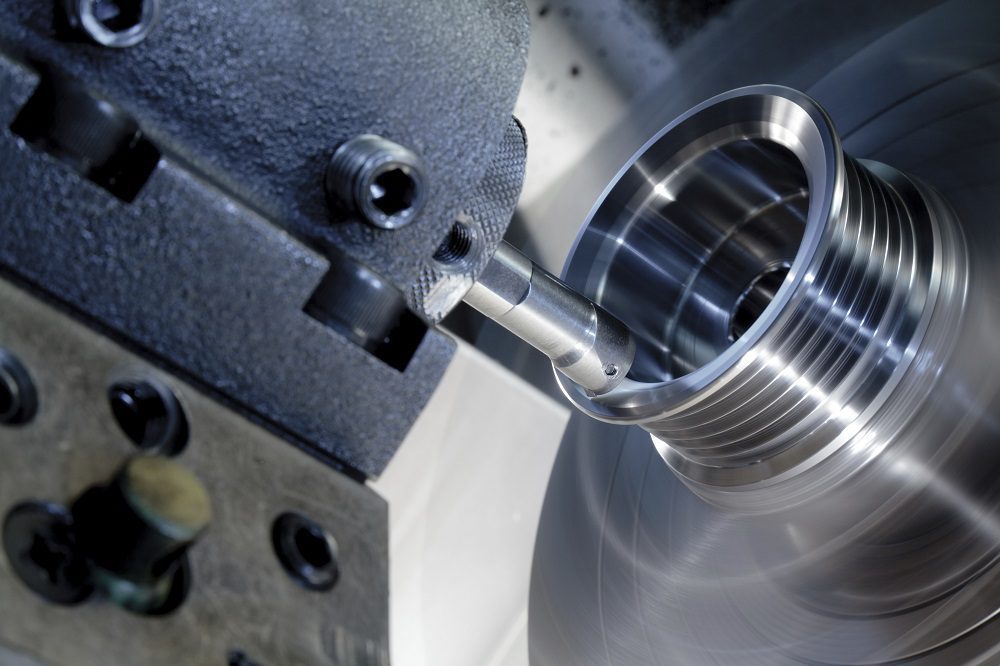

2. Forming: Techniques for Thread Creation

The forming stage is critical for producing internal and external threads. Two primary techniques are commonly employed:

-

CNC Machining: This is the most prevalent method for creating threads due to its precision and efficiency. CNC lathes and mills are programmed to cut threads with exact specifications. The process involves rotating the workpiece while a cutting tool shapes the thread profile. This method allows for the production of complex geometries and can accommodate various thread types and sizes.

-

Thread Rolling: This is a cold-forming process that produces threads by deforming the material rather than cutting it. Thread rolling is often used for high-volume production as it enhances material properties and yields a stronger thread. It’s particularly beneficial for external threads on fasteners.

Buyers should evaluate suppliers based on their capabilities in these techniques and their ability to meet specific project requirements.

3. Assembly: Ensuring Compatibility and Fit

In some cases, machined threads are part of larger assemblies. The assembly process involves fitting threaded components with other parts, such as nuts and bolts, to ensure proper alignment and functionality. This stage may also include surface treatments to enhance corrosion resistance and reduce friction during assembly.

B2B buyers should consider suppliers’ expertise in assembling threaded components, especially if they require precision in multi-part systems. Ask about their assembly techniques and quality checks during this stage.

4. Finishing: Achieving the Desired Surface Quality

Finishing processes are crucial for enhancing the aesthetic and functional qualities of machined threads. Common finishing techniques include:

- Deburring: Removing sharp edges and burrs that can affect functionality and safety.

- Coating: Applying protective coatings to improve corrosion resistance and reduce wear. Common coatings include zinc plating, anodizing, and powder coating.

Buyers should assess the finishing capabilities of suppliers and inquire about the types of finishes they offer, as well as their compliance with relevant standards.

What Quality Assurance Practices Should B2B Buyers Expect?

Quality assurance (QA) is vital in ensuring that machined threads meet the required specifications and standards. International B2B buyers should look for suppliers who adhere to robust QA practices.

1. Adherence to International Standards: What Should Be Considered?

Suppliers should comply with relevant international standards such as ISO 9001, which sets criteria for quality management systems. Additionally, industry-specific standards like CE marking for European markets or API specifications for the oil and gas sector may apply.

Buyers should request documentation proving that suppliers are certified to these standards. This can include quality management system (QMS) certificates and compliance reports.

2. What Are the Key Quality Control Checkpoints?

Quality control checkpoints throughout the manufacturing process are essential for maintaining high standards. Key checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitoring and testing during the manufacturing process to catch defects early.

- Final Quality Control (FQC): Comprehensive inspection of finished products before shipment, ensuring they conform to specifications.

Buyers should inquire about the specific QC processes implemented by suppliers and how they document and address any discrepancies.

3. Common Testing Methods: How Are They Conducted?

Testing methods for machined threads may include:

- Dimensional Inspection: Using tools like calipers and gauges to verify that threads meet specified dimensions.

- Tensile Testing: Assessing the strength and durability of threaded components under stress.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing to detect internal flaws without damaging the product.

Understanding the testing methodologies used by suppliers can provide insight into their commitment to quality.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of a supplier’s quality control practices is essential for mitigating risks and ensuring product reliability. Here are some strategies:

- Supplier Audits: Conducting on-site audits can provide firsthand insight into a supplier’s manufacturing processes, quality control measures, and compliance with standards.

- Requesting Quality Reports: Buyers should request access to quality control reports, including IQC, IPQC, and FQC documentation, to assess the supplier’s performance.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality assurance practices.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, understanding the nuances of quality control is crucial. Different regions may have varying standards and expectations for quality assurance. For example, buyers in Europe may prioritize compliance with CE standards, while those in the Middle East might focus on API certifications.

Moreover, language barriers and cultural differences can affect communication regarding quality expectations. Establishing clear lines of communication and detailed agreements can help mitigate these issues.

In conclusion, an in-depth understanding of the manufacturing processes and quality assurance practices for machined threads is vital for B2B buyers. By focusing on material selection, forming techniques, assembly processes, and stringent quality control measures, buyers can make informed decisions and select reliable suppliers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘machined threads’

Introduction

In the intricate landscape of manufacturing, sourcing machined threads is a critical step for ensuring the reliability and functionality of your products. This guide provides a practical, step-by-step checklist for B2B buyers to streamline the procurement process of machined threads, ensuring you select the right suppliers and specifications for your needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is essential to avoid miscommunication and ensure compatibility. Consider factors such as thread type (internal vs. external), dimensions, material specifications, and tolerances. Providing precise specifications helps suppliers understand your needs and deliver products that meet your standards.

Step 2: Research Industry Standards and Compliance

Understanding the relevant industry standards for machined threads is crucial. Familiarize yourself with international standards like ISO, ANSI, or JIS, which dictate the quality and dimensions of threads. Ensure that your suppliers can comply with these standards to guarantee the quality and safety of your components.

Step 3: Evaluate Potential Suppliers

Before committing, it’s vital to vet potential suppliers thoroughly. Look for company profiles, certifications, and references from other buyers in your industry or region. A reputable supplier should provide documentation of their quality management systems, such as ISO 9001 certification, and be willing to share case studies that demonstrate their expertise.

Step 4: Request Samples and Prototypes

Once you’ve narrowed down your supplier options, request samples or prototypes of the machined threads. This step allows you to assess the quality, precision, and suitability of the threads for your applications. Pay attention to details such as the finish, accuracy of dimensions, and the overall performance of the samples.

Step 5: Assess Production Capabilities

Investigate the production capabilities of your shortlisted suppliers. Understanding their machinery, technologies, and capacity can help you determine if they can meet your volume requirements within your timeline. Additionally, inquire about their lead times and flexibility in production to accommodate future changes in demand.

Step 6: Verify Quality Control Processes

Quality control is paramount in the machining industry. Ensure that your suppliers have robust quality assurance processes in place, such as regular inspections, testing methods, and documentation practices. A reliable supplier should be willing to share their quality control protocols and how they address any non-conformities.

Step 7: Establish Communication Channels

Effective communication is vital for a successful sourcing relationship. Establish clear communication channels with your suppliers to discuss project updates, address concerns, and ensure timely delivery. Regular check-ins can help prevent misunderstandings and foster a collaborative relationship, ultimately leading to better outcomes for your projects.

By following this checklist, B2B buyers can make informed decisions when sourcing machined threads, ensuring they select suppliers that align with their technical requirements and quality standards.

Comprehensive Cost and Pricing Analysis for machined threads Sourcing

What Are the Key Cost Components in Machined Threads Sourcing?

When sourcing machined threads, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The type and quality of raw materials significantly impact the overall cost. Common materials for machined threads include stainless steel, carbon steel, aluminum, and specialized alloys. Higher-quality materials that meet international standards typically incur higher costs but can lead to improved durability and performance.

-

Labor: Labor costs are influenced by the complexity of the machining process and the skill level required. CNC machining, which is commonly used for producing threads, requires skilled operators. The geographic location of the supplier can also affect labor costs, with regions having lower wage structures potentially offering more competitive pricing.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help mitigate these overheads, thus impacting the final pricing.

-

Tooling: Tooling costs refer to the expenses incurred in creating or maintaining the necessary tools and dies for machining threads. Custom tooling for unique thread specifications can add significantly to the upfront costs but may lead to better efficiency in mass production.

-

Quality Control (QC): Ensuring that machined threads meet specified standards requires investment in quality assurance processes. This can include inspections, testing, and certifications, which are crucial for maintaining quality, especially in industries like aerospace and automotive.

-

Logistics: Shipping and handling costs can vary greatly depending on the supplier’s location and the destination market. International shipping costs should factor in duties, taxes, and potential delays, particularly for buyers from Africa, South America, the Middle East, and Europe.

-

Margin: Suppliers will typically add a profit margin to the total production cost. This margin can vary based on the supplier’s business model, market demand, and competitive landscape.

How Do Price Influencers Affect Machined Threads Sourcing?

Several factors can influence the pricing of machined threads:

-

Volume/MOQ: Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to maximize cost-efficiency.

-

Specifications and Customization: Custom thread designs, special dimensions, and unique material requirements can increase costs. Standardized threads usually offer more favorable pricing due to established production processes.

-

Material Selection: The choice of material can greatly affect pricing. Exotic materials or those requiring specialized machining processes will typically cost more than standard options.

-

Quality and Certifications: Suppliers that offer higher quality and certifications (like ISO or AS9100) may charge a premium. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may command higher prices but can reduce risks associated with sourcing.

-

Incoterms: Understanding Incoterms is crucial for international buyers, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. This knowledge can help buyers avoid unexpected costs.

What Are the Best Practices for Negotiating Costs on Machined Threads?

-

Conduct Comprehensive Market Research: Understand current market prices and trends in machined threads to inform your negotiations.

-

Build Relationships with Suppliers: Establishing long-term relationships with suppliers can lead to better pricing and service, as they may be more willing to negotiate for loyal customers.

-

Focus on Total Cost of Ownership (TCO): Rather than just considering the initial purchase price, evaluate the long-term costs associated with maintenance, durability, and performance of the threads.

-

Be Transparent About Requirements: Clearly communicate your specifications and expectations to avoid misunderstandings that could lead to additional costs.

-

Leverage Competition: Obtain quotes from multiple suppliers to compare pricing and services, using this information to negotiate better terms.

Disclaimer on Indicative Prices

Prices for machined threads can vary widely based on the factors discussed above. It is essential for buyers to obtain quotes specific to their project requirements and market conditions to ensure accurate budgeting.

Alternatives Analysis: Comparing machined threads With Other Solutions

Exploring Alternatives to Machined Threads in Industrial Applications

When evaluating manufacturing processes, it’s essential to consider various alternatives to traditional methods like machined threads. Different technologies can achieve similar goals of fastening and connecting components, each with unique advantages and limitations. This analysis compares machined threads against two viable alternatives: welded joints and adhesive bonding.

| Comparison Aspect | Machined Threads | Welded Joints | Adhesive Bonding |

|---|---|---|---|

| Performance | High precision and load-bearing capacity | Excellent strength for permanent bonds | Varies by adhesive type; good for lightweight applications |

| Cost | Moderate cost, depends on complexity | Generally lower material costs, but higher labor costs | Low material costs but variable labor costs |

| Ease of Implementation | Requires specialized machinery and skills | Requires welding equipment and trained personnel | Simple application, no special equipment needed |

| Maintenance | May require periodic inspection | Permanent; minimal maintenance needed | Can degrade over time, requiring checks |

| Best Use Case | Mechanical components needing disassembly | Structural applications, heavy loads | Lightweight assemblies, non-load bearing applications |

In-Depth Analysis of Alternatives

Welded Joints

Welding is a method that creates a permanent bond between metal parts by melting them together. This process is particularly advantageous in applications where strength and integrity are paramount, such as in structural components in construction and heavy machinery. The major benefits of welded joints include their exceptional load-bearing capacity and durability. However, they require skilled labor and specialized equipment, which can increase initial costs and lead time. Additionally, welded joints are not easily disassembled, making repairs or modifications more complex.

Adhesive Bonding

Adhesive bonding involves using various types of adhesives to bond materials together. This method is gaining popularity due to its simplicity and the ability to bond dissimilar materials, such as metal to plastic. Adhesives can provide a sufficient bond for lightweight applications and are often more economical than mechanical fastening methods. However, the performance of adhesive bonds can be highly variable and is dependent on factors such as surface preparation and environmental conditions. They may also require periodic checks to ensure bond integrity over time, particularly in high-stress applications.

Making the Right Choice for Your Application

Choosing the right fastening solution depends on specific project requirements, including load-bearing needs, cost constraints, and the importance of disassembly. For applications requiring high precision and the ability to disassemble parts, machined threads are often the best choice. Conversely, if the application demands structural integrity and permanence, welded joints may be more suitable. For applications where weight savings are critical and the bond is not subject to heavy loads, adhesive bonding can provide an effective alternative.

In conclusion, B2B buyers should assess their unique project requirements and operational capabilities when selecting between machined threads and alternative solutions. Understanding the pros and cons of each method will enable informed decision-making, ultimately contributing to the project’s success and efficiency.

Essential Technical Properties and Trade Terminology for machined threads

What Are the Key Technical Properties of Machined Threads?

Understanding the essential technical properties of machined threads is crucial for B2B buyers involved in manufacturing, as these specifications directly impact the performance and compatibility of threaded components in various applications. Here are some critical properties to consider:

1. Material Grade

The material grade of threaded components influences their strength, durability, and resistance to corrosion. Common materials include stainless steel, carbon steel, and aluminum. Choosing the right material grade is vital for ensuring that the threads can withstand operational stresses and environmental conditions specific to their application. For instance, stainless steel is often preferred for marine applications due to its corrosion resistance, while carbon steel is more cost-effective for general use.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. In thread machining, precise tolerances are essential for ensuring proper fit and functionality between mating parts. A tighter tolerance usually results in a higher quality fit, which can improve the performance of mechanical systems. For B2B buyers, understanding tolerance specifications helps in selecting the right suppliers and ensuring that components meet operational requirements.

3. Pitch

Pitch is the distance between adjacent threads and is a critical factor in determining the compatibility of threaded parts. Different applications may require fine or coarse pitch threads, affecting the ease of assembly and the strength of the connection. B2B buyers should consider pitch specifications to ensure that the threaded components will function as intended in their specific applications.

4. Helix Angle

The helix angle is the angle between the thread axis and the helix itself. This property affects the load distribution and the efficiency of the connection. A proper helix angle can enhance the strength of the threaded connection and reduce wear over time. Understanding this parameter enables buyers to select threads that meet their operational and design needs.

5. Surface Finish

The surface finish of machined threads can significantly affect their performance, particularly in applications where friction and wear are concerns. A smoother finish can reduce friction, enhance assembly, and prolong the life of the components. Buyers should inquire about surface finish standards when sourcing threaded parts to ensure optimal performance.

What Are Common Trade Terms Related to Machined Threads?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are several key terms that every buyer should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable sources for machined threads that meet specific quality and performance standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers when budgeting and planning inventory, as it can affect overall procurement costs and supply chain efficiency.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. Buyers should prepare detailed RFQs to ensure they receive accurate quotes that reflect their needs for machined threads, including specifications and quantities.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers negotiate better deals and understand their obligations in cross-border transactions.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For threaded components, understanding lead times can help buyers plan their production schedules and manage inventory effectively.

In conclusion, grasping the essential technical properties and trade terminology related to machined threads is crucial for B2B buyers aiming for efficiency and quality in their procurement processes. By leveraging this knowledge, buyers can make informed decisions that enhance operational performance and drive business success.

Navigating Market Dynamics and Sourcing Trends in the machined threads Sector

What Are the Current Market Trends Impacting the Machined Threads Sector?

The machined threads market is experiencing significant growth driven by the increasing demand for precision-engineered components across various industries, including automotive, aerospace, and manufacturing. As global supply chains evolve, international B2B buyers are witnessing a shift toward advanced machining technologies, such as CNC (Computer Numerical Control) machining and automated manufacturing processes. These technologies enhance efficiency, reduce lead times, and improve product quality, making them attractive options for companies in Africa, South America, the Middle East, and Europe.

Furthermore, the rise of Industry 4.0 is facilitating the integration of smart manufacturing techniques, enabling real-time monitoring and data analytics. This advancement allows manufacturers to optimize their production processes, leading to cost savings and increased competitiveness in the global marketplace. Buyers should remain attuned to emerging sourcing trends, including the move towards digital platforms for procurement and collaboration with manufacturers that offer flexible production capabilities.

Another key trend is the growing emphasis on customization. As industries become more specialized, there is an increasing need for tailored solutions, prompting suppliers to offer bespoke threading options that meet specific application requirements. This presents an opportunity for B2B buyers to engage with suppliers who can provide adaptable solutions that align with their unique operational needs.

How Are Sustainability and Ethical Sourcing Influencing the Machined Threads Market?

Sustainability has become a crucial consideration for international B2B buyers in the machined threads sector. The environmental impact of manufacturing processes is under scrutiny, prompting businesses to seek suppliers that prioritize eco-friendly practices. This includes the use of recycled materials, energy-efficient machinery, and sustainable production methods that minimize waste.

Ethical sourcing is equally important, as companies are increasingly held accountable for their supply chain practices. Buyers should look for suppliers that maintain transparent supply chains and adhere to ethical labor practices. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Moreover, the demand for ‘green’ certifications and materials is on the rise. B2B buyers can leverage these certifications to enhance their brand reputation and appeal to environmentally conscious consumers. By partnering with suppliers who prioritize sustainability, companies can not only mitigate their environmental footprint but also align their operations with the growing global movement towards responsible manufacturing.

How Has the Machined Threads Sector Evolved Over Time?

The evolution of the machined threads sector can be traced back to the industrial revolution when the need for standardized fasteners became apparent. The introduction of standardized thread profiles, such as the Unified Thread Standard (UTS), streamlined manufacturing processes and improved interoperability between components.

Over the decades, advancements in machining technology, including the development of CNC machines, have revolutionized the way threads are produced. These technologies allow for greater precision, consistency, and efficiency, enabling manufacturers to meet the increasing demands of modern industries. Today, the machined threads market is characterized by a focus on high-quality, customizable products, driven by advancements in technology and changing buyer expectations.

As international markets continue to expand, the machined threads sector is poised for further growth, with a strong emphasis on innovation, sustainability, and ethical sourcing practices that resonate with the values of today’s B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of machined threads

-

How do I solve issues with thread compatibility in my projects?

To address compatibility issues with machined threads, start by identifying the thread type required for your application, such as UNF, UNC, internal, or external threads. Ensure that the dimensions, pitch, and tolerances of the threads match your components. It’s crucial to consult with your supplier about any specific standards or certifications required for your industry. Conducting thorough testing with sample parts can also help identify potential compatibility problems before full-scale production. -

What is the best thread type for high-stress applications?

For high-stress applications, consider using coarse threads, such as UNC, as they provide greater resistance to stripping and are less likely to loosen under vibration. Additionally, incorporating features like thread locking compounds or specialized fasteners can enhance performance. If the application involves significant shear or tensile loads, external threads on bolts or screws with a larger diameter may also be beneficial. Always consult with your engineering team to evaluate the specific requirements of your project. -

How can I ensure quality assurance when sourcing machined threads?

To ensure quality assurance, choose suppliers who adhere to international quality standards such as ISO 9001. Request certifications and inspect their quality control processes, including material inspection, dimensional checks, and surface finish evaluations. It’s also wise to ask for samples before placing large orders to assess the quality firsthand. Establishing clear communication about your quality expectations and conducting periodic audits can further enhance quality assurance throughout the production process. -

What are the typical minimum order quantities (MOQs) for machined threads?

Minimum order quantities for machined threads can vary significantly by supplier and thread type. Generally, MOQs may range from a few hundred to several thousand pieces. It’s essential to discuss your specific needs with potential suppliers, as many are willing to accommodate lower quantities for initial orders or prototypes. Additionally, building a long-term relationship with a supplier can sometimes lead to more flexible MOQ terms in future transactions. -

What payment terms should I expect when sourcing machined threads internationally?

Payment terms for international transactions typically range from upfront payments to net 30 or net 60 days. Common practices include a deposit upon order confirmation and the balance upon delivery. However, terms can vary based on the supplier’s policies, your relationship with them, and the size of the order. It’s advisable to negotiate terms that offer both parties sufficient security, and consider using secure payment methods like letters of credit for larger transactions to mitigate risk. -

How can I vet potential suppliers for machined threads?

Vetting suppliers involves assessing their experience, capabilities, and reputation in the industry. Begin by researching their history, customer testimonials, and case studies related to machined threads. Request references and visit their facilities if possible. Evaluate their production processes, quality control measures, and adherence to international standards. Additionally, consider engaging in a trial order to evaluate their responsiveness and product quality before committing to a larger contract. -

What logistics considerations should I keep in mind when importing machined threads?

When importing machined threads, consider factors such as shipping methods, lead times, and customs regulations. Choose a reliable logistics partner who understands international shipping and can navigate customs clearance efficiently. Be aware of potential tariffs or import duties that may apply, and ensure that all documentation is accurate and complete to avoid delays. Additionally, planning for contingencies, such as delays in shipping, can help maintain your production schedule. -

Can I customize the threads to fit specific applications?

Yes, many suppliers offer customization options for machined threads to meet specific application requirements. Customization can include altering thread dimensions, pitch, or materials based on your project needs. When discussing customization, provide detailed specifications and drawings to ensure clarity. Collaborating closely with your supplier during the design phase can help optimize the thread for performance and functionality in your application.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Machined Threads Manufacturers & Suppliers List

1. Wayken – Thread Machining Solutions

Domain: waykenrm.com

Registered: 2013 (12 years)

Introduction: Thread machining is a subtractive method used in CNC machining to create external and internal threads of various sizes. It involves the circular movement of a rotating tool calibrated for specific thread depth and density. Key parameters include Helix angle, Root, Crest, Flank, and Pitch. Types of threads include internal (female) and external (screw) threads. Internal threads are cut using singl…

2. Reddit – Machining Threads

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Machining Threads, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Protolabs – CNC Machined Parts Threading Guide

Domain: protolabs.com

Registered: 2006 (19 years)

Introduction: A Guide to Adding Threading to CNC Machined Parts. Key considerations include: 1. Types of Threading: External (found on screws and bolts) and Internal (resides inside the main part). 2. Thread Pitch: Options include UNC (coarse pitch, 20 tpi), UNF (fine pitch, 28 tpi), and UNEF (extra fine pitch, 32 tpi). 3. Placement: Threads can be placed almost anywhere accessible by equipment, but depth consi…

4. Accu Components – Rolled vs Cut Thread

Domain: accu-components.com

Registered: 2020 (5 years)

Introduction: Rolled Thread vs Cut Thread – The Differences And Benefits Of Each Thread Type. Cut threads are produced by removing material, resulting in a neat finish, lower tooling costs, and fewer limitations on thread diameter and length. However, they can leave burrs, have higher manufacturing costs, and create swarf. Rolled threads are formed by deforming material, offering higher quality, tensile strengt…

5. Earnest Machine – Threading Solutions

Domain: earnestmachine.co.uk

Registered: 2014 (11 years)

Introduction: Cut threads (machined threads) are made by removing material to create the thread form, while rolled threads are formed by cold forming the steel without cutting, resulting in a rounded root radius. Rolled threads have superior strength due to the cold working process, especially in non-heat-treated bolts (grade 2, grade A, low carbon steel). For heat-treated bolts (grade 5 and grade 8), cut and r…

6. 3ERP – CNC Machining & Injection Molding Services

Domain: 3erp.com

Registered: 2000 (25 years)

Introduction: CNC Machining Services: CNC Milling Service, CNC Turning Service, 5-Axis CNC Machining, Precision Machining; Injection Molding Services: Mold Tool Making, Rapid Tooling, Plastic Injection Molding, Liquid Silicone Rubber Molding; Sheet Metal Services: Laser Cutting, Metal Bending; Additional Services: 3D Printing, Custom Extrusion, Urethane Casting, Die Casting Solutions, Rapid Prototyping, Low-vol…

7. Hanshin Neji – Thread Machining vs. Rolling

Domain: hanshin-neji.com

Registered: 2004 (21 years)

Introduction: Machining and Rolling Threads Comparison: 1. Machining Process: Involves cutting a metal bar into thread shapes using milling inserts. 2. Rolling Process: Involves pressing a metal bar into thread shapes using rolling dies. Strength Comparison: – Rolled Threads: 171.85 KN (1,094.5N/mm²) – Machined Threads: 177.40 KN (1,129.9N/mm²) – Both met tensile strength specifications. Surface Inspection: Mac…

8. Rapid Axis – CNC Thread Solutions

Domain: rapidaxis.com

Registered: 2018 (7 years)

Introduction: Threads are a crucial component in CNC machined parts, allowing for removable assemblies across various industries. Key details include: 1. Types of Threads: Internal (like a nut) and External (like a bolt). 2. Thread Pitch: Standard pitches include Unified National Coarse (UNC), Unified National Fine (UNF), and Unified National Extra Fine (UNEF). Example: A 1/4-20 UNC bolt has 20 threads per inch…

9. UC Components – Fasteners and Custom Solutions

Domain: uccomponents.com

Registered: 2001 (24 years)

Introduction: UC Components, Inc. offers a variety of fasteners including standard and vented screws, washers, and hex nuts. They provide numerous finish options, specialized venting designs, complete custom product development, and Class 100/ISO Class 5 Cleanroom cleaning & packaging. The fasteners are suitable for applications in industries such as aerospace, automotive, construction, and general manufacturin…

Strategic Sourcing Conclusion and Outlook for machined threads

In navigating the complexities of machined threads, B2B buyers must recognize the critical role of strategic sourcing in optimizing their operations. Understanding the various types of threads—both internal and external—and the machining processes involved enables businesses to select the most suitable solutions for their specific applications. By leveraging advanced machining technologies, organizations can ensure precision, enhance product quality, and reduce costs, ultimately driving competitive advantage in global markets.

As international buyers from regions such as Africa, South America, the Middle East, and Europe increasingly engage in this sector, the emphasis on sourcing high-quality machined threads becomes paramount. The diversity of thread specifications and the importance of tailoring choices to unique project requirements underscore the need for informed decision-making.

Looking ahead, businesses should prioritize partnerships with reliable suppliers who understand the nuances of threading technology and can provide tailored solutions. By doing so, companies can not only meet current demands but also position themselves to adapt to evolving market trends. Engage with trusted manufacturers today to elevate your sourcing strategy and ensure that your projects achieve the highest standards of quality and performance.