Contents

Manufacturing Insight: Machined Steel

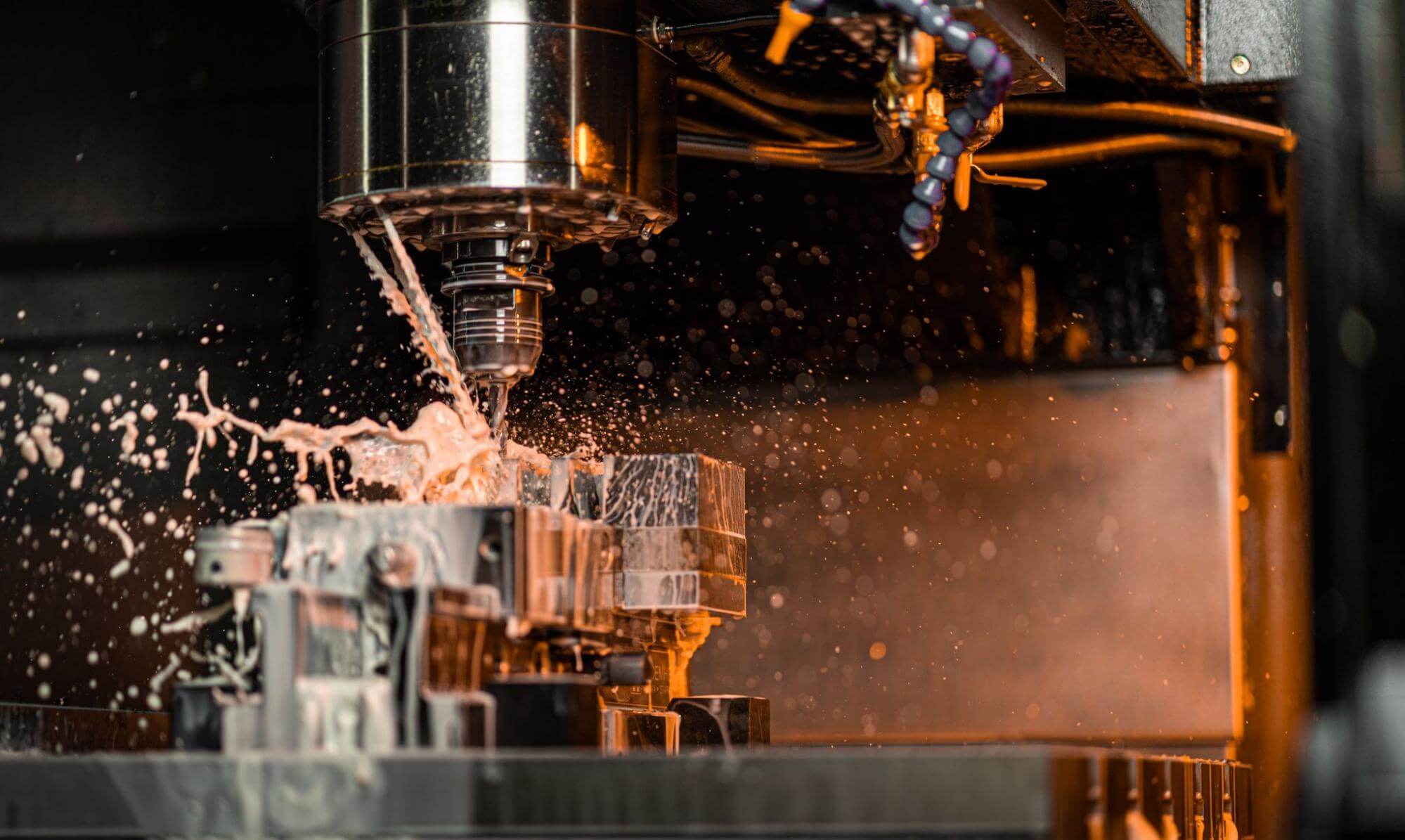

Machined Steel Solutions Engineered for Performance and Precision

Honyo Prototype delivers exceptional machined steel components for demanding industrial applications, leveraging advanced CNC machining capabilities to transform raw steel into mission-critical parts with uncompromising accuracy. Our expertise spans a comprehensive range of steel alloys—including 4140, 1018, 17-4 PH, and tool steels—ensuring optimal material selection for strength, wear resistance, and thermal stability in your final assembly. Through tightly controlled processes across multi-axis milling, precision turning, and complex 5-axis operations, we consistently achieve tolerances down to ±0.0002″ while maintaining rigorous surface finish and geometric integrity.

Integrated Digital Workflow for Rapid Project Execution

Beyond technical execution, we eliminate traditional procurement bottlenecks with our industry-leading Online Instant Quote system. Upload your steel part CAD file, specify material, quantity, and critical tolerances, and receive a detailed, binding quotation within minutes—not days. This seamless digital interface provides immediate cost transparency and lead time visibility, accelerating your design-to-manufacturing timeline without sacrificing engineering oversight. Our platform dynamically factors in steel grade machinability, feature complexity, and secondary operations to deliver accurate pricing reflective of true production feasibility.

Commitment to Technical Partnership

Honyo operates at the intersection of engineering rigor and agile manufacturing. Every steel component undergoes stringent in-process inspections using calibrated CMMs and vision systems, with full material traceability from certified mills. We collaborate early in your design phase to optimize for manufacturability, minimizing waste and maximizing performance in high-stress environments. For prototypes, bridge production, or full-scale runs, our steel machining services provide the repeatability and metallurgical accountability your projects require.

Initiate your project with confidence: utilize our Online Instant Quote tool today to experience how Honyo’s precision steel machining capabilities and responsive digital infrastructure deliver superior parts on your timeline.

Technical Capabilities

Machined steel components are commonly produced using advanced CNC machining processes such as 3-axis, 4-axis, and 5-axis milling, as well as precision turning. These methods enable high repeatability, complex geometries, and tight tolerances required in aerospace, medical, automotive, and industrial applications. While “machined steel” refers specifically to steel alloys, CNC machining services at Honyo Prototype also support other materials including aluminum, ABS, and nylon—each with distinct machinability characteristics.

Below is a comparative technical specification table outlining key parameters across materials and processes:

| Parameter | Aluminum (e.g., 6061-T6) | Steel (e.g., 4140, 1018) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (Polyamide, e.g., PA6) |

|---|---|---|---|---|

| Typical Machining Process | 3/4/5-Axis Milling, Turning | 3/4/5-Axis Milling, Turning | 3/4-Axis Milling, Limited Turning | 3/4-Axis Milling, Turning |

| Tolerance Capability | ±0.005 mm (±0.0002″) | ±0.010 mm (±0.0004″) | ±0.025 mm (±0.001″) | ±0.025 mm (±0.001″) |

| Surface Finish (Typical) | 0.8–3.2 µm Ra | 1.6–6.3 µm Ra | 3.2–6.3 µm Ra (as-machined) | 3.2–6.3 µm Ra |

| Material Hardness | 95 HB | 200–300 HB (varies by alloy) | Shore D 100–110 | Rockwell M 90–100 |

| Machinability Rating | Excellent (High) | Moderate to Good | Excellent (Low cutting forces) | Good (Can be gummy) |

| Coolant Requirement | Recommended | Required | Optional (Air blast often sufficient) | Optional |

| Common Applications | Aerospace, Enclosures, Jigs | Tooling, Shafts, High-strength parts | Prototypes, Housings, Models | Gears, Wear parts, Insulators |

| Post-Processing Options | Anodizing, Bead Blast, Paint | Plating, Passivation, Heat Treat | Painting, Sanding, Gluing | Dyeing, Sanding |

Notes on Machining Capabilities:

3-axis milling is suitable for prismatic parts with flat or planar features, while 4-axis and 5-axis milling enable complex contours, undercuts, and reduced setup次数 by allowing workpiece rotation. 5-axis machining is particularly advantageous for tight tolerance components requiring high precision across multiple faces, such as impellers or structural aerospace brackets.

Turning is used for cylindrical parts such as shafts, bushings, and threaded components. Multi-axis turning centers (e.g., Swiss-type lathes) support tight tolerances down to ±0.005 mm and are ideal for high-precision steel and aluminum parts.

For steel, proper tool selection (carbide or ceramic), controlled feed rates, and rigid setups are essential to maintain dimensional accuracy and surface integrity. Aluminum, being softer, allows higher feed and spindle speeds but requires chip evacuation management to prevent built-up edge.

ABS and nylon, as engineering plastics, are easier to machine but sensitive to heat and tool geometry. Sharp tools and optimized speeds minimize melting or deformation, especially in thin-walled features.

At Honyo Prototype, all machined parts—regardless of material—are inspected using CMM, optical comparators, or laser scanning to ensure compliance with specified tolerances and GD&T requirements.

From CAD to Part: The Process

Honyo Prototype Machined Steel Process Overview

Honyo Prototype executes a streamlined, technology-driven workflow for machined steel components, ensuring precision, cost efficiency, and rapid turnaround. The process begins with CAD file submission and progresses through integrated digital and engineering phases to final delivery. Each stage is optimized for steel-specific machining challenges, including material hardness, thermal management, and surface integrity requirements.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via Honyo’s secure customer portal. Our system automatically performs initial geometry validation, checking for non-manifold edges, unit inconsistencies, and unsupported file formats. For steel parts, critical parameters like material specification (e.g., 4140, 304SS, 1018), tolerance callouts, and surface finish requirements are extracted for downstream processing. This phase typically completes within 15 minutes, with immediate feedback if file corrections are needed.

AI Quote

Honyo’s proprietary AI quotation engine analyzes the validated CAD model against real-time shop floor data, including steel grade availability, machine utilization, and tooling constraints. The algorithm calculates material costs based on exact stock dimensions (bar stock, plate, or forgings), machining time estimates using feature recognition (e.g., pocket depths, thread types), and secondary operation requirements (e.g., heat treatment, plating). Quotes are generated in under 2 hours, detailing cost drivers specific to steel machining such as:

Tool wear adjustments for hardened alloys

Coolant/lubricant requirements for stainless steel

Secondary operation sequencing impact on lead time

DFM (Design for Manufacturability)

Our engineering team conducts a rigorous DFM review focused on steel-specific manufacturability. This phase identifies risks like:

Thin-wall deformation during milling due to steel’s high modulus of elasticity

Inadequate draft angles for deep cavity milling in tool steels

Non-optimal hole depth-to-diameter ratios causing drill breakage

Unnecessary tight tolerances increasing cost without functional benefit

The DFM report provides actionable recommendations with technical rationale, such as suggesting alternative steel grades for improved machinability or modifying radii to reduce tool deflection. Client approval of DFM suggestions is required before production, ensuring alignment on quality and cost targets.

Production

Machined steel parts enter production on Honyo’s dedicated CNC milling and turning centers, equipped with high-pressure coolant systems and rigid tooling optimized for ferrous materials. Key production protocols include:

Material certification verification against ASTM/AMS standards prior to machining

In-process CMM checks for critical steel-specific features (e.g., thread pitch accuracy in hardened materials)

Adaptive toolpath strategies to minimize vibration during deep cavity milling

Post-machining stress relief cycles for precision components to prevent distortion

All steel parts undergo 100% first-article inspection per AS9102 standards, with full dimensional reports and surface roughness validation.

Delivery

Final parts are cleaned per steel-specific protocols (e.g., vapor degreasing for stainless, rust-inhibiting oil for carbon steel) and packaged in anti-corrosive materials. Delivery includes:

Material test reports (MTRs) traceable to heat number

FAI documentation with geometric dimensioning and tolerancing (GD&T) validation

Shipping with serialized tracking and real-time logistics updates

Standard lead time for machined steel components is 7–12 business days from DFM approval, with expedited options available. All deliveries comply with ISO 9001:2015 and IATF 16949 quality management systems.

Process Performance Metrics

Honyo maintains strict benchmarks for steel machining accuracy and efficiency:

| Metric | Target for Steel Components | Measurement Method |

|---|---|---|

| Dimensional Accuracy | ±0.0002″ (5µm) | CMM with 4:1 TUR calibration |

| Surface Roughness (Ra) | 32–63 µin (0.8–1.6 µm) | Profilometer per ASME B46.1 |

| Lead Time Adherence | ≥95% on-time delivery | ERP system tracking |

| First-Pass Yield | ≥92% | In-process inspection logs |

This integrated approach ensures machined steel components meet aerospace, medical, and industrial application demands while minimizing cost and schedule risk through digital continuity from design to delivery.

Start Your Project

Looking for high-precision machined steel components? Partner with Honyo Prototype for reliable, quality-driven manufacturing solutions.

Our Shenzhen-based factory delivers tight-tolerance machining for industrial, automotive, and prototyping applications. From low-volume prototypes to high-volume production runs, we ensure consistent accuracy and fast turnaround.

Contact Susan Leo today to discuss your machined steel requirements.

Email: [email protected]

Let’s build precision together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.