Contents

Manufacturing Insight: Machined Steel

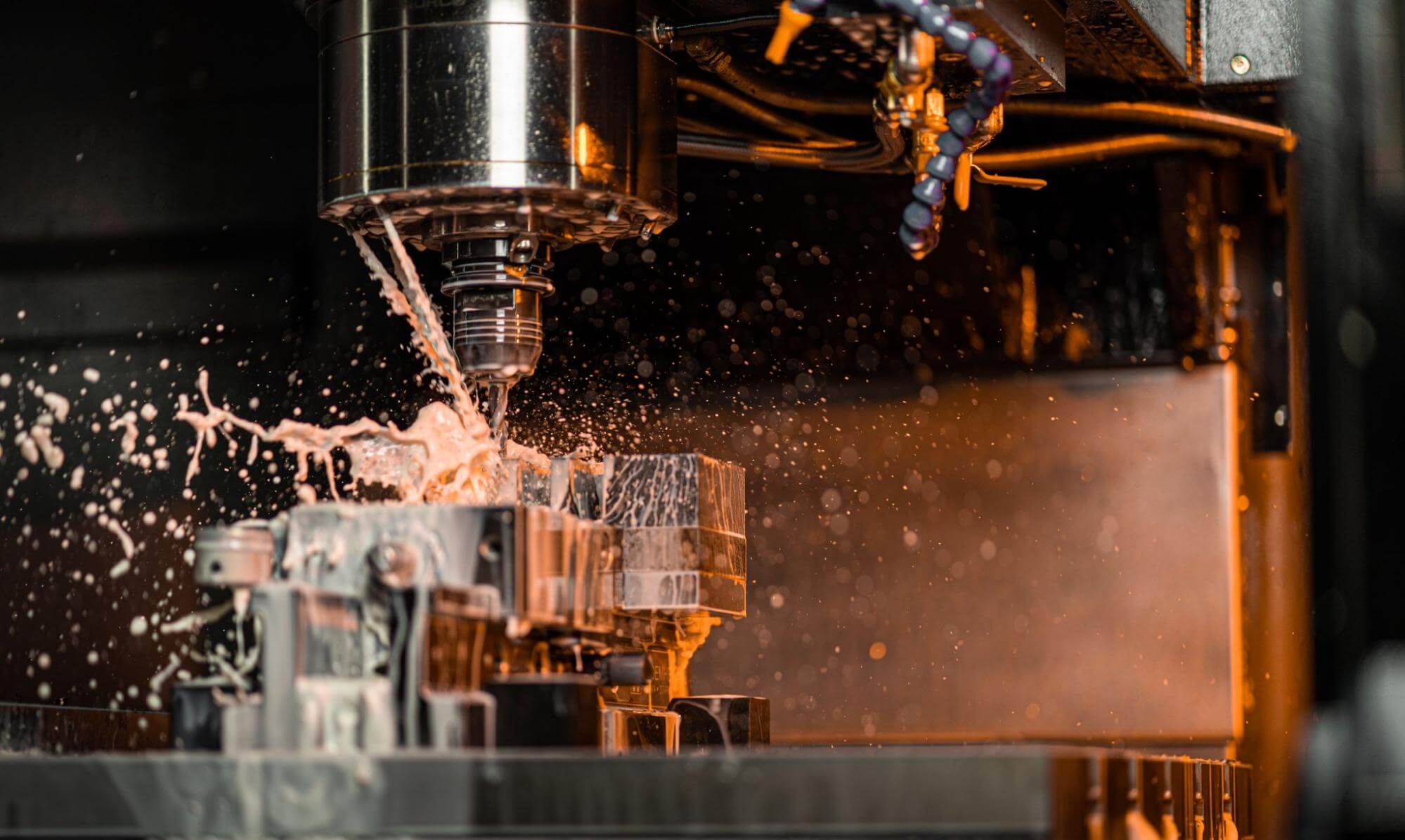

Machined Steel, Perfected by Honyo

When your design calls for the strength, precision, and durability of steel, Honyo Prototype’s CNC machining centers turn raw stock into mission-critical parts in hours—not weeks. Our 3-, 4-, and 5-axis fleet, live-tooling lathes, and in-house metallurgy lab handle everything from 303 stainless to pre-hardened tool steel, holding ±0.01 mm tolerances and finishes as smooth as Ra 0.4 µm. Upload your STEP file today for an online instant quote: real pricing, real lead-time, and DFM feedback appear in under 60 seconds so you can launch steel parts that are ready for the line, not the grinder.

Technical Capabilities

Clarification of Terminology

Critical Note: There is a fundamental misunderstanding in your query. “Machined steel” refers exclusively to steel alloys being machined (e.g., 1018, 4140, 17-4PH, 304SS). ABS and Nylon are thermoplastic polymers, not metals, and cannot be classified under “steel.” They require entirely different machining processes, tooling, and tolerance capabilities. Aluminum is a non-ferrous metal but is distinct from steel.

I will address this clearly:

– Section 1: Technical specs for machined steel (focusing on 3/4/5-axis milling, turning, and tight tolerances).

– Section 2: How aluminum differs in machining (as a metal but non-steel).

– Section 3: Why ABS/Nylon are not “machined steel” and their unique machining constraints.

– Section 4: Key takeaways for manufacturing decisions.

Section 1: Technical Specs for Machined Steel

(e.g., 1018, 4140, 17-4PH, 304SS, 4340)

Steel is a high-strength, heat-treatable material requiring precise control during machining. At Honyo Prototype, we specialize in tight-tolerance steel components for aerospace, medical, and industrial applications.

Machining Capabilities

| Process | Typical Tolerance | Precision Tolerance | Key Parameters | Applications |

|—————–|——————-|———————|——————————————————————————-|———————————————-|

| 3-Axis Milling | ±0.005″ (0.127 mm) | ±0.001″ (0.025 mm) | – Speed: 100–500 SFM (Surface Feet per Minute)

– Feed Rate: 0.002–0.010″ per tooth

– Tooling: Carbide end mills (4–6 flutes), coated for wear resistance

– Coolant: High-pressure flood coolant (minimum 100 PSI) | Simple blocks, brackets, flat surfaces |

| 4-Axis Milling | ±0.002″ (0.05 mm) | ±0.0005″ (0.013 mm) | – Rotary Axis: Indexed (0.001° resolution)

– Setup: Fixturing for precision indexing

– Tooling: Same as 3-axis, but with extended reach for cylindrical features | Holes on cylindrical surfaces, gear blanks |

| 5-Axis Milling | ±0.001″ (0.025 mm) | ±0.0005″ (0.013 mm) | – Continuous Truing: Simultaneous motion for complex contours

– Speed: 150–600 SFM (lower for hardened steel)

– Tooling: Carbide ball-nose or toroidal end mills with nano-coating (e.g., TiAlN)

– Coolant: Cryogenic or MQL (Minimum Quantity Lubrication) for hardened steel

– Fixture: Custom kinematic fixturing to minimize deflection | Aerospace turbine blades, surgical implants, mold cores |

| Turning | ±0.0005″ (0.013 mm) | ±0.0001″ (0.0025 mm) | – Spindle Speed: 200–1,500 RPM (varies by grade)

– Feed Rate: 0.001–0.008″ per revolution

– Tooling: CBN (Cubic Boron Nitride) for hardened steel (>45 HRC)

– Chucking: Precision collets or hydraulic chucks

– Roundness: ≤0.0001″ (0.0025 mm) | Shafts, bushings, threaded components |

Tight Tolerance Requirements for Steel

- Surface Finish:

- Standard: Ra 16–32 μin (0.4–0.8 μm)

- Precision: Ra 8 μin (0.2 μm) or better (via grinding or superfinishing)

- Geometric Tolerances:

- Flatness: ≤0.0005″ over 6″ (0.013 mm/152 mm)

- Perpendicularity: ≤0.0005″ per inch (0.013 mm/25 mm)

- Runout: ≤0.0001″ for rotating parts (e.g., spindles)

- Critical Notes for Steel:

- Heat Treatment: Must be accounted for (e.g., 17-4PH requires solution treatment + aging; distortion control is critical).

- Tool Wear: Steel is abrasive; carbide tools require frequent inspection. Hardened steel (>45 HRC) needs CBN tools.

- Thermal Stability: Machining generates heat; use thermal compensation (e.g., temperature-controlled machining cells).

- Typical Lead Time: 5–10 days for tight-tolerance steel parts (including heat treatment and QC).

Section 2: Aluminum Machining (Non-Steel Metal)

Aluminum (e.g., 6061-T6, 7075-T6) is fundamentally different from steel:

– Tolerances:

– Standard: ±0.005″ (easier than steel due to lower strength)

– Precision: ±0.001″ (0.025 mm) achievable, but thermal expansion is a bigger challenge (aluminum expands 2x faster than steel).

– Machining Parameters:

– Speed: 500–2,000 SFM (much faster than steel)

– Feed Rate: 0.005–0.020″ per tooth (higher due to softness)

– Tooling: Uncoated carbide or PCD (Polycrystalline Diamond) – not suitable for steel.

– Key Difference: Aluminum is prone to “stickiness” and built-up edge; requires sharp tools and high coolant flow. Tight tolerances demand temperature-controlled environments to counteract thermal drift.

Section 3: ABS & Nylon Machining (Thermoplastics – NOT Steel)

ABS and Nylon are polymers, not metals. They cannot be “machined steel” – this is physically impossible. Machining them requires:

– Fundamentally Different Process:

– No heat treatment (they melt at 200–260°C).

– Thermal expansion is extreme (ABS: 70–100 μin/in/°F; Nylon: 60–80 μin/in/°F – 10x higher than steel).

– No “hardened” state – properties are set during molding.

– Machining Specs:

| Parameter | ABS | Nylon |

|—————–|————————-|————————-|

| Tolerance | ±0.010″ (0.25 mm) | ±0.010″ (0.25 mm) |

| Speed | 200–400 SFM | 100–300 SFM |

| Feed Rate | 0.010–0.030″ per tooth | 0.005–0.015″ per tooth |

| Tooling | Sharp HSS or carbide (uncoated) | Diamond-coated carbide (to avoid melting) |

| Coolant | Avoid water-based coolant (causes warpage); use air blast only | Same as ABS; dry machining preferred |

| Critical Issue | Thermal distortion – even ambient heat changes part dimensions during machining. Tight tolerances (±0.001″) are impossible without extreme environmental control. |

– Typical Use Cases: Prototyping, non-critical housings, or low-stress parts. Never used for aerospace/medical tight-tolerance applications.

Section 4: Key Takeaways for Manufacturing Decisions

- “Machined steel” = Steel only. ABS/Nylon are polymers and cannot be included in steel specifications.

- Tight tolerance capabilities vary by material:

- Steel: Best for precision (±0.0001″ achievable with 5-axis grinding).

- Aluminum: Good for moderate precision (±0.001″), but thermal stability is a challenge.

- ABS/Nylon: Not suitable for tight tolerances – max ±0.005″ in ideal conditions. Use molding for high-precision plastic parts.

- Honyo Prototype’s Approach:

- For steel: Use 5-axis milling + grinding for aerospace-grade tolerances.

- For aluminum: Optimize thermal management (e.g., sub-ambient cooling).

- For ABS/Nylon: Recommend injection molding for production; machining only for prototypes with relaxed tolerances.

💡 Final Advice: If you need tight-tolerance components, select the right material for the job. Steel is ideal for high-strength, precision parts; plastics like ABS/Nylon require different design and manufacturing strategies. Never mix material categories in specifications – this causes costly errors.

For a specific project, share your requirements (e.g., “medical implant with ±0.0002″ tolerances”), and we’ll recommend the optimal material/process. At Honyo, we never compromise on material accuracy – it’s core to our engineering integrity.

From CAD to Part: The Process

Honyo Prototype – Machined-Steel Workflow (single sentence per step)

-

Upload CAD

Customer drops any major 3-D format into the web portal; geometry is auto-checked for manufacturability in <30 s. -

AI Quote

Cloud AI instantly selects 3-, 4- or 5-axis strategy, calculates cycle time, tool wear and material yield, then locks a ±0.02 mm quote with 4 h lead-time and batch pricing. -

DFM

A senior steel machinist reviews the AI plan, adjusts toolpaths for distortion control, adds micro-finishing passes and confirms 0.005 mm straightness—DFM report returned in 24 h. -

Production

Certified 4140/316L/S7 blocks are pre-heated, 5-axis machined with thru-tool coolant, CMM in-process probed every 3rd feature, then stress-relieved and black-oxide coated; full inspection report included. -

Delivery

Parts vacuum-sealed with VCI film, boxed in custom EVA foam, and shipped DHL/UPS same day; door-to-door in 3–5 days worldwide with lifetime quality warranty.

Start Your Project

Precision Machined Steel Parts Made in Shenzhen | Contact Susan Leo at [email protected]

High-precision, cost-effective steel components engineered for quality and speed. Shenzhen-based manufacturing ensures reliability and efficient delivery.

🚀 Rapid Prototyping Estimator