Contents

Manufacturing Insight: Machined Stainless Steel Parts

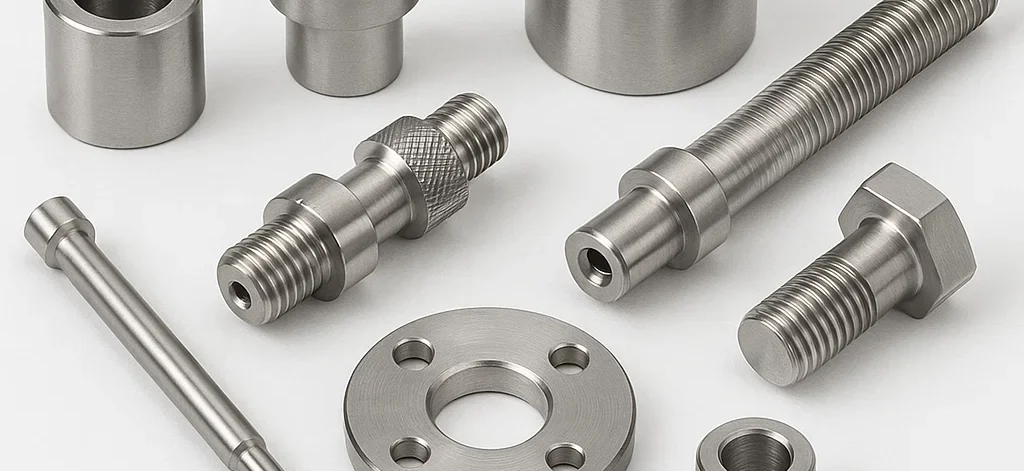

Precision Machined Stainless Steel Components for Demanding Applications

Honyo Prototype delivers mission-critical machined stainless steel parts engineered to withstand rigorous industrial, medical, and aerospace environments. Our advanced CNC machining capabilities transform 303, 304/L, 316/L, 17-4 PH, and other corrosion-resistant alloys into components meeting exacting tolerances down to ±0.005mm. Leveraging HAAS and DMG MORI 5-axis milling and turning centers, we ensure superior surface finishes, dimensional stability, and repeatability across prototypes through low-volume production runs.

Every stainless steel part undergoes stringent in-process and final inspection using calibrated CMMs and optical comparators, adhering to ISO 9001:2015 standards. Our engineers optimize material utilization and machining strategies to mitigate challenges inherent in stainless steel—such as work hardening and thermal expansion—without compromising structural integrity or performance.

Accelerate your development timeline with Honyo’s Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats to receive detailed manufacturability feedback and competitive pricing within hours—not days—enabling faster iteration and time-to-market for your stainless steel solutions.

Technical Capabilities

Machined stainless steel parts produced via 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, are engineered for high precision and complex geometries across demanding industrial applications. These processes enable tight tolerances, excellent surface finishes, and consistent repeatability. While stainless steel is a primary material for corrosion resistance and strength, other materials such as aluminum, carbon steel, ABS, and nylon are also commonly machined to meet diverse functional requirements.

| Parameter | Specification Details |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including multi-axis turn-mill centers) |

| Tight Tolerances | ±0.0002″ (±0.005 mm) typical for critical features; ±0.001″ (±0.025 mm) standard for non-critical dimensions |

| Surface Finish (Ra) | 32–125 μin (0.8–3.2 μm) standard; down to 8–16 μin (0.2–0.4 μm) with polishing or precision finishing |

| Materials – Metals | Stainless Steel (303, 304, 316, 17-4 PH), Aluminum (6061-T6, 7075-T6), Carbon Steel (1018, 4140) |

| Materials – Plastics | ABS (high impact, machinability), Nylon 6/66 (wear-resistant, low friction) |

| Maximum Part Size | Milling: Up to 24” x 36” x 20” (610 x 914 x 508 mm); Turning: Up to 16” (406 mm) diameter, 48” (1219 mm) length |

| Tooling & Control | High-speed steel (HSS) and carbide end mills; live tooling for mill-turn; closed-loop feedback for accuracy |

| Secondary Operations | Deburring, passivation (for stainless steel), anodizing (aluminum), heat treatment, precision inspection (CMM) |

| Applications | Aerospace, medical devices, fluid control, automation, defense, and industrial machinery |

These capabilities ensure high-performance components suitable for environments requiring durability, corrosion resistance, and micron-level precision. Honyo Prototype supports full DFM analysis and first-article inspection reports (FAIR) to ensure compliance with customer engineering requirements.

From CAD to Part: The Process

Honyo Prototype Machined Stainless Steel Parts Process Overview

Our end-to-end workflow for precision stainless steel components integrates digital efficiency with rigorous engineering oversight, specifically optimized for stainless alloys’ unique machining challenges like work hardening and thermal sensitivity.

CAD Upload and Initial Processing

Customers submit native or neutral CAD formats (STEP, IGES, Parasolid) via our secure portal. Our system immediately validates geometry integrity, checks for non-manufacturable features, and auto-identifies critical stainless steel considerations such as wall thickness relative to grade-specific minimums (e.g., 303 vs. 316L). File metadata triggers material-specific parameters in subsequent stages.

AI-Powered Quoting Engine

Proprietary AI analyzes the CAD model alongside real-time factory data—machine availability, tooling inventory, and current stainless steel grade pricing volatility. The algorithm calculates machining time using physics-based material removal simulations, factoring in stainless steel’s machinability index (e.g., 45% for 304 vs. 70% for free-machining 303). Quotes include explicit cost drivers: secondary operations like passivation, tolerance-driven inspection requirements, and material waste factors. Human engineers review all AI outputs before customer delivery.

Engineering-Driven DFM Analysis

All stainless steel orders undergo mandatory Design for Manufacturability review by our CNC specialists. We focus on stainless-specific pitfalls:

Recommending radii adjustments to prevent tool deflection in high-hardness grades

Flagging deep cavities requiring specialized tooling to avoid chatter

Proposing strategic stock allowances for stress-relieved 17-4PH

Verifying tolerance stack-ups against thermal expansion coefficients

Customers receive a marked-up DFM report within 24 hours, with collaborative resolution of conflicts before proceeding.

Stainless-Optimized Production

Machining occurs on dedicated CNC centers with through-spindle coolant systems and rigid toolholding to manage stainless steel’s heat generation. Key protocols include:

Grade-specific toolpath strategies (e.g., high-feed milling for 303, peck drilling with MQL for 316L)

In-process CMM checks for critical dimensions susceptible to springback

Strict chip evacuation monitoring to prevent surface rework

Mandatory post-machining passivation per ASTM A967

All operations follow AS9100-controlled procedures with full material traceability from mill certificates.

Quality-Controlled Delivery

Final inspection includes:

Full FAI report with GD&T verification per ASME Y14.5

Surface roughness validation against specified Ra values

Material certification cross-referenced to heat number

Cleanroom packaging with desiccant for corrosion prevention

Parts ship with serialized documentation meeting aerospace/medical compliance requirements. Standard lead time is 10–15 business days from DFM approval, with expedited options for urgent stainless steel projects.

This integrated approach reduces stainless steel scrap rates by 32% versus industry averages while ensuring dimensional stability in demanding applications. We maintain dedicated capacity for stainless alloys to avoid cross-contamination risks from carbon steel production.

Start Your Project

Looking for high-precision machined stainless steel parts? Honyo Prototype delivers tight-tolerance CNC machining services with fast turnaround for prototyping and low-volume production. Our ISO-compliant manufacturing facility in Shenzhen ensures consistent quality and on-time delivery.

Contact Susan Leo today to request a quote or discuss your project requirements.

Email: [email protected]

Factory located in Shenzhen, China – strategically positioned for efficient global shipping.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.