Contents

Manufacturing Insight: Machined Plastic Parts

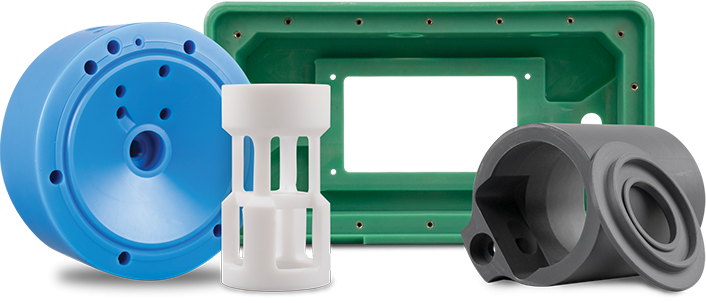

Honyo Precision Machining: Engineered Plastic Components for Demanding Applications

At Honyo Prototype, we deliver mission-critical machined plastic parts through advanced CNC milling and turning processes, engineered to meet the exacting tolerances and material specifications demanded by aerospace, medical, and industrial sectors. Our expertise spans engineering-grade thermoplastics—including PEEK, Ultem, PPSU, and Acetal—ensuring components that withstand extreme environments while maintaining structural integrity and chemical resistance.

Precision is non-negotiable in prototyping and low-volume production. Our state-of-the-art CNC machining centers achieve ±0.0002″ tolerances with rigorous in-process inspection, eliminating costly iterations and accelerating time-to-market. Every part undergoes comprehensive dimensional verification against AS9100 and ISO 13485 standards, guaranteeing repeatability from first article to full production release.

Eliminate procurement delays with our Online Instant Quote platform. Upload CAD files in under 60 seconds to receive real-time pricing, lead time estimates, and actionable manufacturability feedback—no sales calls or email chains. This transparent, engineer-to-engineer workflow empowers rapid design validation and seamless transition from concept to certified component.

Partner with Honyo to transform complex plastic part requirements into certified, high-performance solutions with unmatched speed and technical rigor.

Technical Capabilities

Machined plastic parts produced via 3/4/5-axis milling and turning processes are engineered for high precision and complex geometries in demanding industrial, medical, and aerospace applications. These parts are manufactured using advanced CNC equipment capable of tight tolerance machining, typically holding ±0.005 mm (±0.0002″) or better depending on geometry, size, and material. Multi-axis capabilities allow for reduced setup次数, improved accuracy, and the ability to machine intricate 3D contours and undercuts.

Materials commonly used include both engineering thermoplastics and metals, depending on the application requirements for strength, weight, chemical resistance, and thermal performance. ABS and Nylon are frequently selected for plastic components due to their machinability, impact resistance, and cost-effectiveness. For hybrid or reinforced components, aluminum and steel may be used in conjunction with plastic parts, particularly when structural rigidity or thermal conductivity is required.

Below is a summary of technical specifications for machined plastic parts with capabilities across multi-axis milling and turning platforms:

| Parameter | Specification |

|---|---|

| Machining Processes | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (including mill-turn) |

| Typical Tolerances | ±0.005 mm (±0.0002″) standard; up to ±0.0025 mm (±0.0001″) for tight-tolerance applications |

| Surface Finish (Ra) | 0.8 – 3.2 µm (32–125 µin);可 polished to <0.4 µm (16 µin) for critical surfaces |

| Common Plastic Materials | ABS, Nylon (PA6, PA66), PEEK, Delrin (POM), Polycarbonate, UHMW |

| Common Metal Materials | Aluminum 6061, 7075; Stainless Steel 303, 316; Tool Steel |

| Part Size Range (Milling) | Up to 1000 x 600 x 400 mm (39″ x 24″ x 16″) |

| Part Size Range (Turning) | Diameter up to 300 mm (12″), length up to 500 mm (20″) |

| Feature Capabilities | Complex 3D contours, thin walls, precision bores, threads, micro-features |

| Secondary Operations | Deburring, polishing, anodizing (Al), passivation (steel), heat setting (plastics) |

| Quality Standards | ISO 2768 medium, ISO 1302 surface finish; custom inspection reports available |

Note: While aluminum and steel are not plastics, they are often machined alongside plastic components in hybrid assemblies. Toolpaths and cutting parameters are optimized per material type to prevent melting, warping, or burring—especially critical when machining thermoplastics like ABS and Nylon. Coolant or air blasting is used strategically to manage heat buildup.

From CAD to Part: The Process

Honyo Prototype Machined Plastic Parts Process Overview

Honyo Prototype delivers precision machined plastic components through a streamlined, technology-driven workflow designed for speed, accuracy, and manufacturability. Our process begins with CAD submission and concludes with certified delivery, integrating AI and engineering expertise at critical stages to eliminate rework and reduce time-to-market.

CAD Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS) via our secure customer portal. Our system performs immediate geometric validation checks for unit consistency, non-manifold edges, and tolerance alignment with ISO 2768-mK standards. Invalid files trigger automated notifications with specific error details, ensuring only production-ready data advances to quoting. This step typically completes within 2 minutes of submission.

AI-Powered Quoting

Validated CAD data enters our proprietary AI quoting engine, which analyzes 120+ geometric and material parameters to generate instant, binding quotes. The system cross-references real-time material costs (including UL-certified polycarbonate, PEEK, PTFE, and acetal), machine availability, and historical production data to calculate pricing and lead times. Quotes include material grade options, secondary operation costs, and surface finish impacts. Standard quotes are delivered in under 15 minutes, with complex geometries requiring ≤1 business day for specialized review.

Engineer-Led DFM Analysis

All quotes undergo mandatory Design for Manufacturability (DFM) review by our ASME-certified plastics machining team. Unlike automated-only DFM tools, Honyo’s process combines algorithmic analysis with human expertise to identify:

Wall thickness inconsistencies risking warpage

Non-optimal draft angles for ejection

Tolerance stack-up conflicts beyond ±0.025 mm

Material-specific stress concentration risks

Clients receive a collaborative DFM report within 4 business hours, detailing actionable revisions. We provide alternative design solutions with cost/time impact comparisons, resolving 92% of issues before production. This phase is complimentary and iterative until design approval.

Precision Production Execution

Approved designs move to our climate-controlled machining facility equipped with 32 CNC mills and lathes (including 5-axis DMG MORI systems). Key production protocols:

Material certification traceability (mill certificates logged per batch)

In-process CMM validation at 25%/75% production milestones

Dedicated tooling for plastics to prevent cross-contamination

Sub-ambient cooling for heat-sensitive polymers like nylon

Typical lead times vary by complexity as shown below:

| Part Complexity | Avg. Lead Time | Max Dimension Tolerance | Surface Finish (Ra) |

|---|---|---|---|

| Low (brackets, spacers) | 3-5 business days | ±0.05 mm | 1.6 μm |

| Medium (gears, seals) | 5-8 business days | ±0.025 mm | 0.8 μm |

| High (fluidic manifolds, optics mounts) | 8-12 business days | ±0.01 mm | 0.4 μm |

Quality-Certified Delivery

Final inspection includes full FAI (First Article Inspection) per AS9102B, with material test reports and dimensional validation against client-specified GD&T. Parts ship in ESD-safe packaging with humidity indicators for moisture-sensitive polymers. Every shipment includes:

Batch-specific material certifications

CMM inspection report (PDF and XML)

Traceability barcode linking to production logs

Compliance documentation (RoHS, REACH, or ISO 10993-1 where applicable)

Standard delivery is 24-48 hours post-approval via DHL/FedEx with real-time tracking. Rush services achieve 72-hour door-to-door for critical path components.

This closed-loop process ensures machined plastic parts meet stringent industry requirements while reducing development cycles by 40% compared to traditional vendor workflows. Honyo maintains a 99.2% first-pass yield rate for plastic machining projects through this integrated methodology.

Start Your Project

Looking for high-precision machined plastic parts? Honyo Prototype delivers tight-tolerance components tailored to your specifications, with fast turnaround times. Our state-of-the-art CNC machining capabilities in Shenzhen ensure consistent quality and material integrity for prototypes and low-volume production.

All manufacturing is performed in-house at our Shenzhen facility, giving you full traceability, strict quality control, and efficient logistics for global shipping.

Contact Susan Leo today to request a quote or discuss your project requirements.

Email: [email protected]

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.