Contents

Manufacturing Insight: Machined Aluminum Extrusions

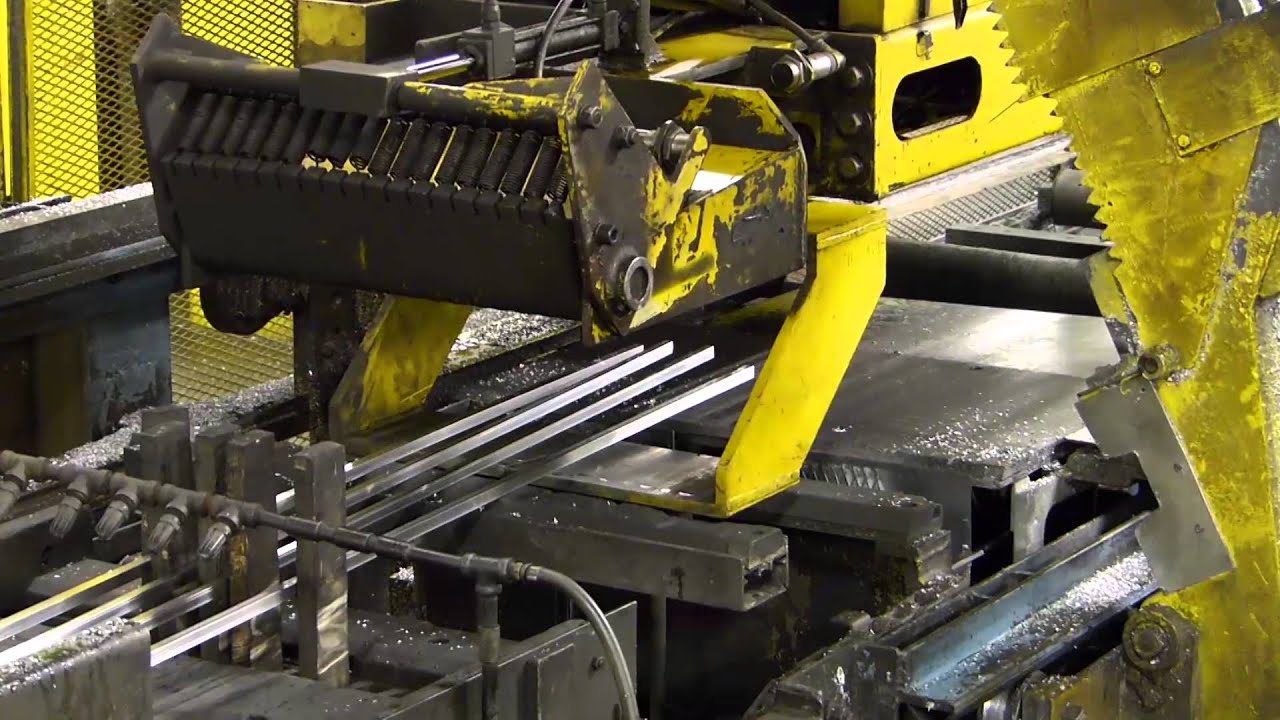

Precision Machined Aluminum Extrusions: Engineered for Performance

Aluminum extrusions offer exceptional strength-to-weight ratios and thermal conductivity, making them indispensable for aerospace, electronics, and industrial automation applications. However, raw extrusions rarely meet the exacting dimensional and functional requirements of modern engineering. At Honyo Prototype, we transform standard aluminum profiles into mission-critical components through advanced CNC machining, ensuring seamless integration into your assemblies while maintaining structural integrity and performance specifications.

Our ISO 9001-certified facility leverages 5-axis milling, precision turning, and multi-axis Swiss machining to achieve tolerances down to ±0.005mm on complex extrusion geometries. We specialize in secondary operations including custom slotting, threaded inserts, anodizing compatibility preparation, and surface finishing—turning extruded blanks into fully functional parts ready for deployment. Material expertise spans 6061-T6, 7075-T73, and custom alloys, with rigorous in-process CMM validation to eliminate rework and accelerate time-to-market.

For rapid project initiation, utilize our Online Instant Quote platform. Upload CAD files to receive detailed manufacturability feedback, lead time projections, and competitive pricing within hours—not days. This digital workflow eliminates procurement delays while ensuring your machined extrusion requirements align with DFM best practices from the outset. Partner with Honyo to convert extrusion potential into engineered reality.

Technical Capabilities

Machined aluminum extrusions are precision components derived from aluminum profiles that have been post-processed using advanced CNC techniques such as 3-axis, 4-axis, and 5-axis milling, as well as CNC turning. These processes enable complex geometries, high repeatability, and tight tolerances required in aerospace, automotive, robotics, and industrial equipment applications.

While the base extrusion is typically aluminum, secondary machining operations can accommodate a range of materials including aluminum alloys, steel, ABS, and nylon—either as inserts, mating components, or alternative material options for prototyping and production. The following table outlines the key technical specifications related to the machining of aluminum extrusions with emphasis on multi-axis milling, turning, and dimensional accuracy.

| Specification Category | Details |

|---|---|

| Primary Material (Extrusion) | 6061-T6, 6082-T6, 7075-T6 Aluminum Alloys – High strength-to-weight ratio, excellent machinability, and corrosion resistance |

| Secondary Materials (Machining) | Mild Steel, Stainless Steel (303, 304, 316), ABS (thermoplastic), Nylon (PA6, PA66) – Used for inserts, fasteners, wear components, or prototyping |

| Machining Capabilities | 3-Axis Milling: Standard planar and prismatic features 4-Axis Milling: Indexed rotary axis for drilling and profiling on multiple sides 5-Axis Milling: Simultaneous multi-axis contouring for complex geometries, reduced setup count |

| Turning Operations | CNC Turning: Outer/inner diameter machining, threading, grooving, parting off – Ideal for cylindrical features integrated into extrusion assemblies |

| Tolerance Range | Standard: ±0.005″ (0.13 mm) Tight Tolerance Machining: ±0.0005″ to ±0.001″ (0.013–0.025 mm) achievable with precision tooling, thermal control, and high-resolution feedback systems |

| Surface Finish | Typical: 32–125 μin Ra Smooth Finish: 16–32 μin Ra with fine milling or polishing passes |

| Feature Accuracy | Positional accuracy: ±0.001″ (0.025 mm) Profile control per ASME Y14.5 with GD&T support |

| Maximum Work Envelope | Milling: Up to 120″ (3050 mm) in length for long extrusion runs Turning: Diameter up to 12″ (300 mm), length up to 24″ (610 mm) |

| Common Applications | Enclosures, frames, robotics arms, optical mounts, pneumatic/hydraulic manifolds, custom brackets |

| Post-Processing Options | Anodizing (Type II & III), powder coating, passivation (for steel), bead blasting, laser marking |

These specifications reflect standard industrial capabilities at Honyo Prototype for high-integrity machined aluminum extrusion components, supporting both low-volume prototyping and high-precision production runs.

From CAD to Part: The Process

Honyo Prototype Machined Aluminum Extrusions Process Overview

Honyo Prototype delivers precision machined aluminum extrusions through a streamlined digital workflow designed for speed, accuracy, and manufacturability. Our integrated process minimizes delays while ensuring rigorous engineering validation at critical stages. Below is the end-to-end sequence for customer projects.

Step 1: CAD Upload and Initial Processing

Customers upload native CAD files (STEP, IPT, SLDPRT, or Parasolid formats) via our secure client portal. The system automatically validates file integrity, extracts key geometric data, and assigns a unique project ID. We accept all common aluminum extrusion profiles (e.g., 6061-T6, 6063-T5) with tolerances per ISO 2768-mK or customer-specified standards. File validation confirms minimum wall thicknesses, hole-to-edge distances, and feature accessibility for machining.

Step 2: AI-Powered Quoting with Human Oversight

Our proprietary AI engine analyzes the CAD geometry against live material costs, machine capacity, and historical production data to generate a preliminary quote within 2 hours. This AI layer identifies high-risk features (e.g., thin webs, deep pockets) that could impact cost or lead time. All AI outputs undergo mandatory review by a senior manufacturing engineer who adjusts parameters for real-world constraints like tool deflection in aluminum or secondary operation sequencing. The final quote includes detailed cost breakdowns for extrusion sourcing, CNC milling, deburring, and finishing.

Step 3: Collaborative DFM Analysis

Before order confirmation, our cross-functional team conducts a formal Design for Manufacturability review. This phase involves:

Material optimization recommendations (e.g., suggesting 6063 over 7075 for complex profiles requiring tighter bends)

Modification of non-critical features to reduce machining time (e.g., standardizing hole sizes to available tooling)

Thermal distortion mitigation strategies for long extrusions during milling

Validation of datum schemes for CMM inspection feasibility

Customers receive an interactive DFM report with annotated suggestions and trade-off analysis. Approval requires explicit sign-off via the portal to prevent scope ambiguity.

Step 4: Integrated Production Execution

Upon DFM approval, the project enters production with synchronized extrusion and machining workflows. Key stages include:

Sourcing extrusions from ISO-certified partners with material certs (Mill Test Reports)

Precision CNC milling using 5-axis Haas machines with Renishaw probing for in-process gauging

In-house anodizing or powder coating for surface treatment (optional)

First-article inspection per AS9102 with full FAI documentation

Step 5: Quality-Controlled Delivery

All machined extrusions undergo final verification against the original CAD model using Zeiss CMMs. We provide:

Dimensional reports with GD&T callouts

Material certification traceability

Packaging tailored to part geometry (e.g., custom foam inserts for fragile profiles)

Standard lead time from order to delivery is 12–18 business days, with expedited options available. Shipping includes real-time logistics tracking and customs documentation for international clients.

Typical Lead Time Breakdown

| Process Stage | Standard Duration | Expedited Option |

|————————-|——————-|——————|

| CAD to Quote | ≤2 business hours | ≤1 business hour |

| DFM Review & Approval | 1–3 business days | 24 hours |

| Extrusion Sourcing | 5–7 business days | 3–4 business days|

| Machining & Finishing | 4–6 business days | 2–3 business days|

| QA & Delivery Prep | 2 business days | 1 business day |

This closed-loop process ensures machined aluminum extrusions meet aerospace, medical, and industrial equipment requirements while maintaining Honyo’s 99.2% on-time delivery rate. All projects include lifetime access to digital manufacturing records via our client portal.

Start Your Project

Looking for high-precision machined aluminum extrusions tailored to your specifications? Honyo Prototype delivers reliable, on-time manufacturing solutions from our state-of-the-art facility in Shenzhen. With advanced CNC machining and extrusion capabilities, we support prototyping and low-to-mid volume production for demanding industries.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Leverage our engineering expertise and streamlined production process to accelerate your product development cycle.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.