Introduction: Navigating the Global Market for machine shop in queens ny

In today’s global marketplace, sourcing reliable machine shops in Queens, NY, presents a unique challenge for international B2B buyers. Navigating through a myriad of options can be daunting, especially when quality, expertise, and cost-effectiveness are critical to operational success. This guide is designed to streamline your decision-making process by providing comprehensive insights into the various types of machine shops available in Queens, including those specializing in custom metal fabrication, engine rebuilding, and general machining.

We delve into the specific applications of these services across different industries, highlighting how each shop can cater to distinct needs, whether it’s precision machining for automotive components or heavy-duty machinery repairs. Furthermore, we offer valuable advice on how to vet suppliers effectively, ensuring that you partner with shops that uphold high standards of quality and reliability.

By equipping international buyers—especially from regions such as Africa, South America, the Middle East, and Europe—with actionable insights on cost structures and service capabilities, this guide aims to empower informed purchasing decisions. Whether you’re looking to establish long-term supplier relationships or seeking immediate project support, our resource serves as your roadmap to successfully navigating the vibrant machine shop landscape in Queens, NY.

Understanding machine shop in queens ny Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automotive Machine Shops | Focus on vehicle repair, engine rebuilding, and parts. | Automotive maintenance, fleet services. | Pros: Specialized skills; quick turnaround. Cons: Limited to automotive applications. |

| Custom Metal Fabrication Shops | Specialize in bespoke metalwork and fabrication. | Construction, manufacturing, custom projects. | Pros: Tailored solutions; high versatility. Cons: Potentially higher costs for custom work. |

| Industrial Machinery Repair Shops | Focus on repairing heavy machinery and equipment. | Manufacturing, energy, transportation sectors. | Pros: Expertise in complex repairs; minimizes downtime. Cons: May require longer lead times. |

| Precision Machining Shops | Emphasize high-tolerance machining for intricate parts. | Aerospace, medical devices, high-tech industries. | Pros: High precision; suitable for specialized parts. Cons: Equipment can be expensive; longer production times. |

| Welding and Fabrication Shops | Offer welding services and structural fabrication. | Construction, automotive, industrial applications. | Pros: Strong structural integrity; versatile services. Cons: Limited to specific welding processes and materials. |

What Are the Characteristics of Automotive Machine Shops?

Automotive machine shops in Queens, NY, focus on vehicle repairs, engine rebuilding, and manufacturing parts. They serve a critical role in maintaining fleets and individual vehicles, providing services such as crankshaft grinding and cylinder head rebuilding. B2B buyers in the automotive sector should consider the shop’s specialization, turnaround times, and certifications, as these factors can significantly impact service quality and reliability.

How Do Custom Metal Fabrication Shops Meet Diverse Needs?

Custom metal fabrication shops specialize in creating bespoke metal products tailored to specific client needs. These shops often cater to industries such as construction and manufacturing, providing unique solutions that standard products cannot address. When selecting a custom metal fabricator, B2B buyers should evaluate the shop’s portfolio, capabilities, and material options to ensure alignment with their project requirements and budget.

What Services Are Offered by Industrial Machinery Repair Shops?

Industrial machinery repair shops focus on maintaining and repairing heavy machinery and equipment essential for manufacturing and other sectors. They provide services like emergency repairs and scheduled maintenance, helping businesses minimize downtime. B2B buyers should assess the shop’s experience with their specific machinery, service response times, and availability of spare parts to ensure efficient operations.

Why Are Precision Machining Shops Important for High-Tech Industries?

Precision machining shops emphasize high-tolerance machining, producing intricate parts for industries like aerospace and medical devices. These shops utilize advanced technology to achieve exact specifications, making them essential for high-quality manufacturing. Buyers in high-tech sectors should prioritize shops with a proven track record in precision work and inquire about their quality control processes to guarantee product reliability.

How Do Welding and Fabrication Shops Contribute to Structural Integrity?

Welding and fabrication shops in Queens provide essential services for constructing and repairing metal structures. They are vital in industries such as construction and automotive, where structural integrity is paramount. When selecting a welding shop, B2B buyers should consider the types of welding processes offered, material compatibility, and the shop’s experience with similar projects to ensure optimal outcomes.

Key Industrial Applications of machine shop in queens ny

| Industry/Sector | Specific Application of machine shop in queens ny | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine reconditioning and repair | Enhances vehicle performance and extends lifespan | Quality of parts, turnaround time, and expertise in specific engine types |

| Heavy Equipment | Custom parts manufacturing for machinery | Reduces downtime and improves operational efficiency | Material specifications, precision machining capabilities, and lead times |

| Aerospace | Precision components fabrication | Ensures safety and compliance with regulatory standards | Certifications, quality control processes, and delivery reliability |

| Manufacturing | Custom tooling and fixture production | Increases production efficiency and product quality | Customization options, machining capabilities, and cost-effectiveness |

| Marine | Rebuilding and repairing marine engine components | Improves engine reliability and performance | Expertise in marine engines, quality of materials, and service availability |

How is ‘machine shop in queens ny’ utilized in the automotive industry?

In the automotive sector, machine shops in Queens, NY, specialize in engine reconditioning and repair services. This includes tasks like crankshaft grinding, cylinder head rebuilding, and general machining. By utilizing these services, automotive businesses can enhance vehicle performance, reduce emissions, and extend the lifespan of engines. International buyers should consider the quality of parts and the shop’s expertise in handling specific engine types to ensure optimal results.

What are the benefits of custom parts manufacturing in heavy equipment?

Machine shops also play a crucial role in the heavy equipment industry by manufacturing custom parts tailored to specific machinery needs. This application is vital for minimizing downtime and enhancing operational efficiency, especially in sectors like construction and mining. When sourcing these services, businesses must evaluate the shop’s precision machining capabilities, material specifications, and lead times to align with their operational requirements.

How do machine shops support the aerospace industry?

In the aerospace sector, precision component fabrication is critical for safety and compliance with stringent regulatory standards. Machine shops in Queens, NY, provide high-precision machining services that meet the exacting demands of aerospace applications. Buyers from this sector should prioritize shops with relevant certifications and robust quality control processes to ensure that all components meet safety and performance benchmarks.

Why is custom tooling essential in manufacturing?

Custom tooling and fixture production is another significant application of machine shops in Queens, serving the manufacturing industry. These shops help businesses improve production efficiency and product quality by creating specialized tools that fit their unique processes. When sourcing these services, companies should focus on customization options, machining capabilities, and the overall cost-effectiveness of the solutions offered.

What role do machine shops play in marine engine repair?

Machine shops are essential for rebuilding and repairing marine engine components, helping to improve engine reliability and performance. This application is particularly important for businesses operating in the marine industry, where equipment uptime is critical. International buyers should look for shops with expertise in marine engines, quality materials, and reliable service availability to ensure effective repairs and maintenance.

3 Common User Pain Points for ‘machine shop in queens ny’ & Their Solutions

Scenario 1: Delays in Production Due to Machine Shop Backlogs

The Problem: A manufacturing company in Germany is facing production delays because their current machine shop in Queens, NY, is overwhelmed with orders. This backlog means they can’t get essential components machined on time, leading to halted production lines and dissatisfied customers. The stress of meeting tight deadlines is compounded by the fear of losing future contracts, creating pressure on procurement managers to find a reliable solution quickly.

The Solution: To address this issue, B2B buyers should perform thorough research to identify machine shops in Queens that have a reputation for reliability and timely delivery. This can be achieved by checking online reviews and testimonials, particularly from businesses in similar industries. It’s crucial to establish clear communication with potential machine shops about your specific lead time requirements. Inquire about their current workload and capacity to ensure they can handle your order without significant delays. Additionally, consider building a partnership with multiple machine shops to diversify your sourcing and mitigate risks associated with backlogs. Establishing long-term relationships can lead to prioritized service during peak times.

Scenario 2: Difficulty in Sourcing Custom Parts

The Problem: A business in Nigeria specializing in agricultural machinery is struggling to find a machine shop in Queens that can manufacture custom components tailored to their specific needs. The lack of available options for bespoke parts has led to increased downtime for their equipment, affecting their operations and profitability. They require precision machining but are unsure how to effectively communicate their specifications to the shops.

The Solution: To overcome this hurdle, buyers should first develop a clear and detailed specification document that outlines all necessary dimensions, materials, tolerances, and any unique requirements for the custom parts. Engaging with machine shops that specialize in custom fabrication and have experience working with international clients can be advantageous. It’s recommended to set up initial consultations to discuss your project in detail, allowing the shop to provide input on manufacturability and potential challenges. Additionally, utilizing 3D modeling software to create visual representations of the parts can greatly assist in conveying your requirements more clearly. Following this, request prototypes or small batch runs to test the components before committing to larger orders, ensuring they meet your specifications.

Scenario 3: Quality Control Issues with Machined Components

The Problem: A company in South America has been receiving machined components from a Queens-based machine shop but has encountered recurring quality control issues. Defective parts are leading to product failures, which not only impacts their manufacturing efficiency but also damages their reputation in the market. The challenge lies in addressing these quality concerns while maintaining a good relationship with the supplier.

The Solution: To rectify this situation, it’s essential for buyers to implement a robust quality assurance process. Begin by documenting all instances of quality issues and the specific defects observed. Communicate these concerns directly with the machine shop, presenting your findings in a constructive manner. Request a meeting to discuss potential improvements and inquire about their quality control processes. Establishing clear quality benchmarks and expectations moving forward can help both parties align on quality standards. Additionally, consider integrating periodic quality audits into your supply chain management to monitor the consistency of the parts being produced. If necessary, explore alternative machine shops in Queens that specialize in quality assurance and have certifications like ISO 9001, which can provide additional assurance of their commitment to quality.

Strategic Material Selection Guide for machine shop in queens ny

What Are the Key Properties of Common Materials Used in Machine Shops in Queens, NY?

When selecting materials for machining processes, several factors such as performance, cost, and suitability for specific applications must be considered. Here, we analyze four common materials used in machine shops in Queens, NY: Steel, Aluminum, Brass, and Plastics. Each material has distinct properties and implications for international B2B buyers.

How Does Steel Perform in Machining Applications?

Steel is one of the most widely used materials in machining due to its excellent strength and durability. It typically has a high-temperature rating and good corrosion resistance, especially when alloyed. However, the specific properties can vary depending on the type of steel, such as stainless, carbon, or tool steel.

Pros: Steel is highly durable and can withstand significant stress, making it suitable for heavy-duty applications. It is also relatively cost-effective, especially in bulk.

Cons: The machining complexity can be higher for certain types of steel, which may require specialized tools. Additionally, steel can be heavier than other materials, impacting transportation costs.

Impact on Application: Steel is compatible with various media, including oils and gases, making it suitable for automotive and industrial applications.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Europe and the Middle East may prefer specific grades of steel that meet their regulatory requirements.

What Are the Advantages of Using Aluminum in Machining?

Aluminum is favored for its lightweight and corrosion-resistant properties. It has a lower density compared to steel, making it easier to handle and transport. Aluminum is also known for its excellent thermal conductivity.

Pros: The primary advantage of aluminum is its lightweight nature, which can lead to reduced shipping costs. It is also easy to machine, allowing for faster production times.

Cons: Aluminum is generally less strong than steel, which may limit its use in high-stress applications. It can also be more expensive than steel, depending on the grade.

Impact on Application: Aluminum is compatible with various environments, including marine applications, due to its corrosion resistance.

Considerations for International Buyers: Buyers should ensure that the aluminum grades comply with standards like JIS and ASTM. In regions like Africa and South America, sourcing may be affected by local availability and market prices.

Why Choose Brass for Precision Machining?

Brass is often used in precision machining applications due to its excellent machinability and aesthetic appeal. It is highly resistant to corrosion and has good electrical conductivity.

Pros: The machinability of brass allows for intricate designs and tight tolerances, making it ideal for components like fittings and valves. Its aesthetic properties also make it suitable for decorative applications.

Cons: Brass can be more expensive than steel and aluminum, which may affect its use in cost-sensitive projects. Additionally, it may not be suitable for high-pressure applications.

Impact on Application: Brass is compatible with a variety of fluids, making it suitable for plumbing and electrical applications.

Considerations for International Buyers: Compliance with specific standards such as ASTM B16 is essential. Buyers from Europe may have preferences for certain brass alloys that meet stringent quality controls.

What Role Do Plastics Play in Machine Shops?

Plastics are increasingly used in machining due to their versatility and lightweight properties. Common types include ABS, Nylon, and Polycarbonate, each with unique characteristics.

Pros: Plastics are highly resistant to corrosion and chemicals, making them suitable for various applications. They are also lightweight and can often be produced at a lower cost than metals.

Cons: Plastics may not withstand high temperatures or mechanical stresses as well as metals, which can limit their applications. Additionally, they may require specialized machining techniques.

Impact on Application: Plastics are compatible with various chemical environments, making them ideal for industries like food processing and pharmaceuticals.

Considerations for International Buyers: Buyers should be aware of compliance with regulations such as REACH in Europe. In regions like the Middle East, sourcing may depend on local manufacturing capabilities.

Summary Table of Material Selection for Machine Shops in Queens, NY

| Material | Typical Use Case for machine shop in queens ny | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty machinery parts | High strength and durability | Higher machining complexity | Medium |

| Aluminum | Lightweight automotive components | Lightweight and easy to machine | Less strength than steel | Medium to High |

| Brass | Precision fittings and valves | Excellent machinability | Higher cost and pressure limitations | High |

| Plastics | Chemical-resistant components | Corrosion resistance | Limited temperature tolerance | Low to Medium |

This guide provides essential insights into material selection for machine shops in Queens, NY, helping international B2B buyers make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for machine shop in queens ny

What Are the Main Stages of the Manufacturing Process in a Machine Shop in Queens, NY?

Manufacturing processes in machine shops typically encompass several key stages: material preparation, forming, assembly, and finishing. Each stage plays a crucial role in ensuring that the final product meets the desired specifications and quality standards.

How Is Material Prepared for Machining?

Material preparation is the first step in the manufacturing process. This involves selecting the appropriate raw materials based on the specifications required by the end product. Common materials used in machine shops include metals like aluminum, stainless steel, and brass, as well as plastics for specific applications. Once the material is selected, it undergoes processes such as cutting to size, deburring, and cleaning to remove any contaminants that could affect the machining process.

What Techniques Are Used in the Forming Stage?

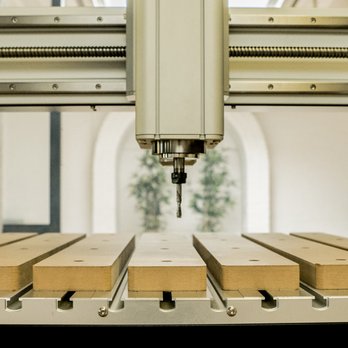

The forming stage involves shaping the prepared materials into the desired form. Techniques such as CNC (Computer Numerical Control) machining, turning, milling, and grinding are commonly employed. CNC machining is particularly prevalent due to its precision and ability to produce complex geometries. Machine shops in Queens may also utilize laser cutting and waterjet cutting for intricate designs, which are essential for both automotive and industrial applications.

How Does the Assembly Process Work?

After forming, components are assembled as per engineering specifications. This may involve welding, soldering, or mechanical fastening, depending on the requirements of the final product. For instance, in automotive applications, components may be welded together to ensure structural integrity, while electronic assemblies might use soldering techniques. Quality during assembly is critical, as any misalignment or improper joining can lead to product failure.

What Finishing Techniques Enhance Product Quality?

Finishing is the final stage of the manufacturing process, which enhances the aesthetic and functional properties of the product. Techniques such as anodizing, plating, and powder coating are commonly used to improve corrosion resistance and surface finish. In machine shops, finishing processes are critical not only for appearance but also for durability, especially for components used in harsh environments.

How Is Quality Assurance Implemented in Machine Shops?

Quality assurance (QA) in machine shops is pivotal to ensuring that products meet both client specifications and regulatory standards. This process involves several checkpoints and adherence to international and industry-specific standards.

What Are the Relevant International Standards for Quality Assurance?

Many machine shops, including those in Queens, adhere to ISO 9001, an international standard that specifies requirements for a quality management system (QMS). ISO 9001 certification demonstrates a commitment to quality and continuous improvement. Additionally, industry-specific standards such as CE marking for European markets and API (American Petroleum Institute) standards for the oil and gas sector may be relevant, depending on the product’s application.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure that any deviations from standards are identified and rectified. These include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): This occurs during the manufacturing process to monitor quality and make adjustments as needed.

- Final Quality Control (FQC): The final inspection is conducted to ensure that the completed product meets all specifications before delivery.

What Common Testing Methods Are Used in Quality Assurance?

Testing methods vary based on the type of product being manufactured. Common methods include dimensional inspection using calipers and gauges, non-destructive testing (NDT) for welds and materials, and performance testing for mechanical components. Each method helps verify that the product adheres to the specified tolerances and performance criteria.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure reliable partnerships.

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits is an effective way to assess a machine shop’s quality management practices. Buyers can request to visit the facility to observe operations, review quality control documentation, and check certifications. During audits, buyers should inquire about the supplier’s adherence to ISO standards and their processes for handling non-conformities.

How Important Are Quality Reports and Third-Party Inspections?

Quality reports provide detailed insights into a supplier’s manufacturing processes and quality metrics. B2B buyers should request these reports regularly to monitor performance. Additionally, third-party inspections can provide an unbiased assessment of a supplier’s quality assurance practices. Engaging with independent inspectors or certification bodies can further validate the supplier’s compliance with international standards.

What Are the QC and Certification Nuances for International B2B Buyers?

Understanding the nuances of quality control and certification is vital for international B2B buyers. Different regions may have varying standards and compliance requirements, which can impact product acceptance in local markets. For instance, products exported to Europe may need CE marking, while those intended for the Middle East might require GSO certification. Buyers should ensure that their suppliers are familiar with these requirements to avoid costly delays and rejections.

Conclusion

Machine shops in Queens, NY, offer a diverse array of manufacturing processes and quality assurance measures that cater to various industries. By understanding the manufacturing stages, quality assurance practices, and how to verify supplier compliance, international B2B buyers can make informed decisions that enhance their supply chain reliability and product quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘machine shop in queens ny’

Introduction

This guide serves as a practical checklist for international B2B buyers seeking to procure services from machine shops in Queens, NY. As the manufacturing landscape becomes increasingly global, understanding how to effectively evaluate and select a machine shop is crucial for ensuring quality, reliability, and efficiency in your sourcing strategy.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements of your project before initiating contact with potential suppliers. This includes dimensions, materials, tolerances, and any specific machining processes required. Having well-defined specifications helps eliminate ambiguity and allows suppliers to provide accurate quotes and timelines.

- What to include: Material types (e.g., stainless steel, aluminum), desired finish (e.g., anodized, polished), and any certifications needed (e.g., ISO).

Step 2: Conduct Market Research

Before selecting a machine shop, research the local market to identify the capabilities and specializations of various suppliers in Queens. Understanding the competitive landscape will help you recognize which shops are best suited to meet your needs.

- Tips for research: Utilize platforms such as Yelp, Google Reviews, and industry directories to gather insights about customer experiences and service quality.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they align with your business standards. Request company profiles, case studies, and references from similar industries or regions. This step is vital to ascertain their experience and reliability.

- Key questions to ask: What industries do they typically serve? Can they provide examples of past projects similar to yours?

Step 4: Verify Supplier Certifications

Ensure that the machine shops you are considering have the necessary certifications and licenses. This not only signifies compliance with industry standards but also assures you of their commitment to quality.

- Important certifications to look for: ISO 9001 for quality management, AS9100 for aerospace manufacturing, or specific industry certifications relevant to your needs.

Step 5: Request Detailed Quotes

Once you have narrowed down your options, request detailed quotes from your top choices. A comprehensive quote should break down costs, lead times, payment terms, and any additional fees.

- What to compare: Look for transparency in pricing and clarity in terms. This will help prevent misunderstandings later in the project.

Step 6: Visit the Shop (If Possible)

If feasible, arrange a visit to the machine shop to assess their operations firsthand. This provides an opportunity to evaluate their equipment, workforce, and overall facility cleanliness and organization.

- What to observe: The condition of machinery, workflow efficiency, and the professionalism of staff can all be indicators of the shop’s capability and reliability.

Step 7: Establish Communication Protocols

Finally, establish clear communication channels with the chosen machine shop. Discuss how you will communicate throughout the project, including updates, changes, and any issues that may arise.

- Recommended practices: Set regular check-ins and preferred methods of communication (e.g., email, video calls) to ensure both parties remain aligned throughout the process.

By following this structured checklist, B2B buyers can streamline their sourcing process and build strong partnerships with machine shops in Queens, NY, leading to successful project outcomes.

Comprehensive Cost and Pricing Analysis for machine shop in queens ny Sourcing

What Are the Key Cost Components for Machine Shops in Queens, NY?

When sourcing from machine shops in Queens, NY, understanding the cost structure is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of raw materials such as metals, plastics, and composites can vary significantly based on market demand and sourcing locations. For instance, stainless steel and aluminum are commonly used materials that may fluctuate in price due to global supply chain dynamics.

-

Labor: Labor costs in Queens are influenced by local wage standards and the skill level required for specific machining tasks. Highly skilled labor, especially in precision machining and custom fabrication, typically commands higher wages, impacting overall project costs.

-

Manufacturing Overhead: This includes costs related to the operation of the machine shop, such as utilities, equipment maintenance, and facility rental. Overhead can vary widely depending on the shop’s size, efficiency, and location within Queens.

-

Tooling: The investment in tooling—such as CNC machines, cutting tools, and fixtures—affects pricing. Custom tooling may be necessary for specialized projects, increasing upfront costs but potentially lowering long-term production costs.

-

Quality Control (QC): Adherence to quality standards often requires additional testing and inspection processes. Shops that are ISO certified or have specific industry certifications may charge premium prices due to their higher QC standards.

-

Logistics: Shipping costs can vary depending on the destination and mode of transport. For international buyers, understanding Incoterms is crucial, as they dictate the responsibilities of buyers and sellers in shipping arrangements.

-

Margin: The profit margin for machine shops typically ranges between 10% to 30% based on complexity, competition, and demand. Understanding this can help buyers gauge the fairness of the pricing offered.

What Influences Pricing for Machine Shop Services in Queens, NY?

Several factors can influence the pricing structure of machine shop services:

-

Volume/MOQ: Higher order volumes often lead to lower per-unit costs. Establishing a minimum order quantity (MOQ) can help secure better pricing for larger projects.

-

Specifications and Customization: Custom projects require more time and resources, which can lead to higher costs. Providing detailed specifications can minimize misunderstandings and potential cost overruns.

-

Material Quality and Certifications: The choice of materials and the need for specific certifications (e.g., ASTM, ASME) can significantly affect pricing. Higher quality materials generally come at a premium.

-

Supplier Factors: The reputation and experience of the machine shop can influence pricing. Established shops with a track record of quality may charge more but can offer reliability and expertise.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is essential for international buyers. These terms affect pricing by determining who bears shipping costs and risks.

What Tips Can Help International Buyers Negotiate Better Prices?

-

Negotiate Terms: Engage in open discussions about pricing, payment terms, and delivery schedules. Many shops may be willing to adjust pricing based on the potential for repeat business.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the upfront cost. Consider long-term benefits such as durability, maintenance, and service quality.

-

Understand Pricing Nuances: Be aware of the economic factors that may affect pricing in different regions. For instance, exchange rates, local labor costs, and material availability can influence prices for buyers in Africa, South America, the Middle East, and Europe.

-

Build Relationships: Establishing a long-term relationship with suppliers can lead to better pricing and service. Trust can result in more favorable terms and quicker responses to urgent needs.

Disclaimer

Pricing information and cost structures provided are indicative and can vary based on specific project requirements, market conditions, and other factors. It is recommended that buyers conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing machine shop in queens ny With Other Solutions

Exploring Viable Alternatives to Machine Shops in Queens, NY

When evaluating machine shops in Queens, NY, it is crucial for international B2B buyers to consider alternative solutions that can also meet their manufacturing and machining needs. This analysis highlights two viable alternatives: Outsourcing to Overseas Machine Shops and Utilizing Advanced Manufacturing Technologies. Each option presents unique advantages and potential drawbacks, making it essential to assess them based on various performance metrics.

| Comparison Aspect | Machine Shop In Queens, NY | Outsourcing to Overseas Machine Shops | Utilizing Advanced Manufacturing Technologies |

|---|---|---|---|

| Performance | High precision and quality, local expertise | Variable quality, dependent on supplier | Consistent quality, technology-dependent |

| Cost | Generally higher due to local labor rates | Typically lower due to reduced labor costs | Initial high investment, long-term savings |

| Ease of Implementation | Straightforward, local access | Language and time zone barriers | Requires specialized training and setup |

| Maintenance | Easier to manage locally | Complicated logistics for repairs | Requires ongoing updates and maintenance |

| Best Use Case | Custom, high-quality work with tight deadlines | Mass production with lower costs | Complex designs requiring automation |

Understanding Outsourcing to Overseas Machine Shops

Outsourcing to overseas machine shops offers significant cost savings, particularly for bulk orders. Countries like China and India have well-established manufacturing sectors that can deliver lower prices due to reduced labor costs. However, this method comes with risks, including potential quality inconsistencies, communication barriers, and longer lead times. B2B buyers must consider these factors against their specific project needs, especially if precision and timeliness are critical.

Evaluating Advanced Manufacturing Technologies

Utilizing advanced manufacturing technologies, such as 3D printing and CNC machining, can revolutionize the production process. These technologies often provide high precision and enable the creation of complex parts that traditional machining methods may struggle to achieve. While the initial investment in equipment and training can be high, the long-term savings and efficiency gains can justify the costs. However, companies must ensure they have the expertise and resources to implement and maintain these technologies effectively.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right machining solution ultimately depends on the specific requirements of the B2B buyer. For those needing rapid turnaround times and high-quality, customized parts, a local machine shop in Queens, NY, may be the best option. Conversely, if cost reduction is a priority and the project allows for longer lead times, outsourcing may be the appropriate choice. Lastly, for businesses looking to innovate and enhance their manufacturing capabilities, investing in advanced technologies could provide a competitive edge. Buyers should weigh these alternatives carefully, considering factors such as quality, cost, and operational capabilities, to make an informed decision that aligns with their business objectives.

Essential Technical Properties and Trade Terminology for machine shop in queens ny

What Are the Key Technical Properties for Machine Shops in Queens, NY?

Understanding the essential technical properties relevant to machine shops can greatly enhance the decision-making process for international B2B buyers. Here are some critical specifications to consider:

1. Material Grade

Material grade refers to the classification of materials based on their properties and intended use. Common grades include stainless steel, aluminum, and various alloys. The choice of material affects durability, corrosion resistance, and suitability for specific applications. For instance, stainless steel is preferred in environments requiring high corrosion resistance, making it ideal for automotive or marine applications. B2B buyers should ensure that the material grade aligns with their project requirements to prevent costly failures.

2. Tolerance

Tolerance defines the allowable deviation from a specified dimension in machining processes. It is crucial for ensuring parts fit together correctly. For example, a tolerance of ±0.001 inches might be specified for precision components in aerospace manufacturing. Understanding tolerance levels helps buyers ensure that the components they order will meet their operational standards, minimizing risks associated with assembly and functionality.

3. Surface Finish

Surface finish refers to the texture and smoothness of a machined part’s surface. Common finishes include polished, anodized, and sandblasted. The right surface finish can enhance the aesthetic quality of a product while also affecting its performance, such as reducing friction or improving corrosion resistance. Buyers must specify their surface finish requirements to ensure that the final product meets both functional and visual standards.

4. Hardness

Hardness indicates a material’s resistance to deformation or scratching. Measured on scales such as Rockwell or Brinell, hardness is vital for applications requiring wear resistance, such as cutting tools or industrial machinery components. For buyers, selecting the correct hardness level can significantly impact the longevity and performance of the parts they procure.

5. Machining Process

Different machining processes, such as CNC machining, turning, or milling, produce parts in unique ways and are suited to various applications. Understanding these processes helps buyers select the right machine shop based on their specific needs. For example, CNC machining is ideal for producing complex geometries with high precision, making it a go-to choice for advanced manufacturing.

What Are Common Trade Terms Used in Machine Shops?

Familiarity with trade terminology is essential for effective communication and negotiation in the machine shop industry. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of machine shops, OEM parts are often required for repairs or replacements. Buyers should ensure that the machine shop can supply OEM specifications to maintain compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory effectively and ensure cost-efficiency. A machine shop may have an MOQ for custom parts, impacting project budgets and timelines.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and availability for specific products or services. For B2B buyers, issuing an RFQ is an important step in sourcing parts, allowing them to compare offers and negotiate terms effectively.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules defining the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B buyers to avoid misunderstandings and ensure smooth logistics in cross-border transactions.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. In the context of machine shops, lead time can vary based on the complexity of the parts and the shop’s current workload. Buyers should inquire about lead times to align their production schedules and avoid operational delays.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when engaging with machine shops in Queens, NY, ultimately leading to successful partnerships and project outcomes.

Navigating Market Dynamics and Sourcing Trends in the machine shop in queens ny Sector

What Are the Current Market Dynamics and Key Trends in the Machine Shop Sector in Queens, NY?

The machine shop sector in Queens, NY, is experiencing a robust transformation driven by several global trends. One significant driver is the increasing demand for precision engineering and custom fabrication across various industries, including automotive, aerospace, and manufacturing. As international B2B buyers seek reliable partners, machine shops that offer advanced capabilities such as CNC machining, laser cutting, and custom metal fabrication are positioned favorably. Additionally, the integration of Industry 4.0 technologies, such as IoT, AI, and automation, is reshaping operational efficiencies, enabling machine shops to optimize processes and reduce lead times.

Emerging sourcing trends also highlight the importance of agile supply chains. Buyers from Africa, South America, the Middle East, and Europe are increasingly prioritizing suppliers that can provide rapid prototyping and flexible manufacturing solutions. This demand aligns with the global push for faster time-to-market for products, which necessitates close collaboration between machine shops and their clients. Moreover, sustainability is becoming a pivotal concern, with buyers favoring machine shops that implement eco-friendly practices and materials in their operations.

How Is Sustainability and Ethical Sourcing Impacting the Machine Shop Sector?

Sustainability and ethical sourcing are no longer optional in the B2B landscape; they are essential components of business strategy. Machine shops in Queens, NY, are increasingly focusing on minimizing their environmental impact by adopting energy-efficient practices and utilizing recycled materials. This shift not only aligns with global sustainability goals but also appeals to international buyers who are becoming more conscious of their supply chain’s environmental footprint.

The importance of ethical supply chains cannot be overstated. Buyers are now more inclined to partner with machine shops that demonstrate transparency in their sourcing practices and uphold ethical labor standards. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) are becoming valuable assets for machine shops aiming to attract international clientele. By incorporating ‘green’ materials and processes, such as water-based coatings and sustainable machining practices, machine shops can enhance their marketability and build long-term relationships with environmentally conscious buyers.

What Is the Historical Context of the Machine Shop Industry in Queens, NY?

The machine shop industry in Queens, NY, has a rich history dating back to the mid-20th century, evolving from traditional craftsmanship to advanced manufacturing techniques. Initially, these shops primarily catered to local businesses, providing essential machining services and repairs. Over the decades, the industry has adapted to technological advancements, integrating CNC machinery and computer-aided design (CAD) to enhance precision and efficiency.

This evolution has positioned Queens as a significant hub for machining and fabrication services, attracting a diverse range of industries. Today, machine shops are not just service providers; they are strategic partners in innovation, helping businesses across the globe develop high-quality components and products. This historical context underscores the importance of reliability and expertise, which are critical for B2B buyers seeking to establish long-term partnerships in the machine shop sector.

Frequently Asked Questions (FAQs) for B2B Buyers of machine shop in queens ny

-

How do I ensure quality when sourcing from a machine shop in Queens, NY?

To guarantee quality, start by verifying the machine shop’s certifications and industry standards, such as ISO 9001. Request samples of previous work to assess craftsmanship and precision. Additionally, engage in direct communication with the shop’s management to discuss your specific requirements. Establishing clear quality assurance protocols, including inspections and testing of materials, will further ensure that the products meet your expectations. -

What is the best way to communicate my specifications to a machine shop?

Effective communication is key to successful collaboration. Prepare detailed specifications, including technical drawings, material types, dimensions, and tolerances. Utilize visual aids such as CAD files when possible. Schedule a consultation to discuss your needs directly with the shop’s engineers, ensuring that all parties understand the project scope and deadlines. This proactive approach minimizes misunderstandings and sets the stage for a successful partnership. -

What are the typical payment terms when working with machine shops in Queens?

Payment terms can vary, but many machine shops typically require a deposit of 30-50% upfront, with the balance due upon completion or delivery. It’s advisable to negotiate terms that align with your cash flow and project timelines. Additionally, consider discussing payment methods, such as wire transfers or letters of credit, especially for international transactions, to ensure a secure payment process. -

What is the minimum order quantity (MOQ) for custom parts?

Minimum order quantities can differ significantly between machine shops based on their capabilities and the complexity of the parts. Generally, smaller shops may accommodate lower MOQs, while larger operations might require higher quantities to justify setup costs. When sourcing, inquire directly about the MOQ for your specific project, and consider discussing options for batch production to optimize costs. -

How can I vet a machine shop before making a commitment?

Vetting a machine shop involves researching their reputation and capabilities. Check online reviews, request references, and examine their portfolio of past projects. Visiting the facility, if possible, allows you to assess their equipment and processes firsthand. Additionally, engage with their team to gauge their expertise and customer service responsiveness, ensuring they align with your business values and quality expectations. -

What logistics should I consider when importing machine parts from Queens?

When importing machine parts, consider shipping costs, delivery timelines, and customs regulations. Collaborate with the machine shop to determine the best packaging methods to prevent damage during transport. Work with a reliable freight forwarder familiar with U.S. export regulations to streamline the process. Be mindful of tariffs and import duties that may apply in your country to avoid unexpected expenses. -

Can I request custom modifications after placing an order?

Yes, many machine shops offer flexibility in accommodating custom modifications, but it’s crucial to communicate any changes as soon as possible. Depending on the stage of production, alterations may incur additional costs and extend lead times. Establishing a clear line of communication with the shop can facilitate adjustments while minimizing disruptions to the project timeline. -

What quality assurance processes should a reputable machine shop have?

A reputable machine shop should implement rigorous quality assurance processes, including inspection at multiple stages of production. This may involve dimensional checks, material testing, and adherence to specified tolerances. Look for certifications that reflect their commitment to quality, such as ISO or AS9100. Engaging in regular audits and feedback sessions can also help ensure that the shop consistently meets your quality standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Machine Shop In Queens Ny Manufacturers & Suppliers List

1. Yelp – Best Machine Shops in Queens, NY

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, Yelp – Best Machine Shops in Queens, NY, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Westchester Crankshaft – Engine Remanufacturing & Machining Services

Domain: westchestercrankshaft.com

Registered: 2018 (7 years)

Introduction: Westchester Crankshaft offers a range of services including: Crankshaft Grinding & Welding, Cylinder Head Rebuilding, Connecting Rod Reconditioning, Cylinder Block Machining, Engine Remanufacturing, General Machining, Heavy Duty Performance Engine Parts, and Fleet Supplies. They specialize in reconditioning industrial engines and provide cylinder heads on exchange for popular models such as DT466E…

3. H&W Machinery – Expert Machine Repair Services

Domain: hwmachineryrepair.com

Registered: 2014 (11 years)

Introduction: This company, H&W Machinery – Expert Machine Repair Services, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. J & S Precision Balancing – Mechanical Machinery Repairs

Domain: jsprecisionbalancing.com

Registered: 2011 (14 years)

Introduction: J & S Precision Balancing specializes in mechanical machinery repairs in Queens, NY. They offer a variety of services including precision balancing, gear cutting, machining, metal finishing, and repairs for all types of industrial machinery. Their capabilities include working with materials such as brass, bronze, steel, aluminum, and plastic. They provide on-site consulting, 24/7 emergency callout…

5. H & W Machinery Corp – Custom Plastic Solutions

Domain: yellowpages.com

Registered: 1996 (29 years)

Introduction: Machine shops in Queens, NY offer a variety of services including automobile machine shop services, custom plastic solutions, general machining and metal fabrication, rebuilding of extruder screws and barrels, and architectural millwork. Specific companies mentioned include H & W Machinery Corp, General Precision Machining, Norwood Screw Machine & Products, and Sandhill Plastics Inc., among others…

6. C.L. Precision – Precision Machining Services

Domain: clpny.com

Registered: 2009 (16 years)

Introduction: C.L. Precision (CLP) is a full manufacturing service provider established in 1973, offering precision machining of components from a wide range of materials including steel alloys, stainless steel, Inconel, titanium, magnesium, bronze, brass, copper, aluminum alloys, and plastics. Services include prototype and production machining, CNC manufacturing, conventional machining, and assembly services….

7. NYC Engine & Machine – Wholesale Engine Parts

Domain: nycengine.com

Registered: 2004 (21 years)

Introduction: NYC Engine & Machine Inc is a wholesale supplier of engines, cylinder heads, crankshafts kits, engine parts, and machine shop supply.

8. Silverjan Industries – Precision Machining Services

Domain: silverjan.com

Registered: 2023 (2 years)

Introduction: Silverjan Industries is a machine shop located in Queens, NY specializing in producing small parts in low quantities. Services offered include CNC milling, CNC plasma cutting, turning, 3D printing, fabrication, and manual machining. Materials worked with include steel, aluminum, copper, and plastics.

Strategic Sourcing Conclusion and Outlook for machine shop in queens ny

In evaluating the machine shop landscape in Queens, NY, it becomes evident that strategic sourcing is not just beneficial, but essential for international B2B buyers. Local machine shops offer a diverse range of services from custom metal fabrication to precision machining, catering to various industries including automotive, aerospace, and industrial manufacturing. Engaging with these specialized facilities enables buyers to access expert craftsmanship, timely service, and competitive pricing, all of which can significantly enhance operational efficiency and reduce lead times.

Moreover, the proximity of these machine shops to major transportation hubs facilitates faster shipping and logistics, further optimizing supply chains for businesses across Africa, South America, the Middle East, and Europe. By fostering relationships with local suppliers, international buyers can ensure a reliable source for high-quality components, which is critical in today’s fast-paced market.

Looking ahead, the potential for collaboration with Queens-based machine shops is immense. As global demand for customized manufacturing solutions continues to rise, now is the time to explore partnerships that can drive innovation and growth. International buyers are encouraged to reach out to these local experts and leverage their capabilities to gain a competitive edge in their respective markets.