Contents

Manufacturing Insight: Machinability Of Steel

Understanding Steel Machinability for Precision CNC Manufacturing

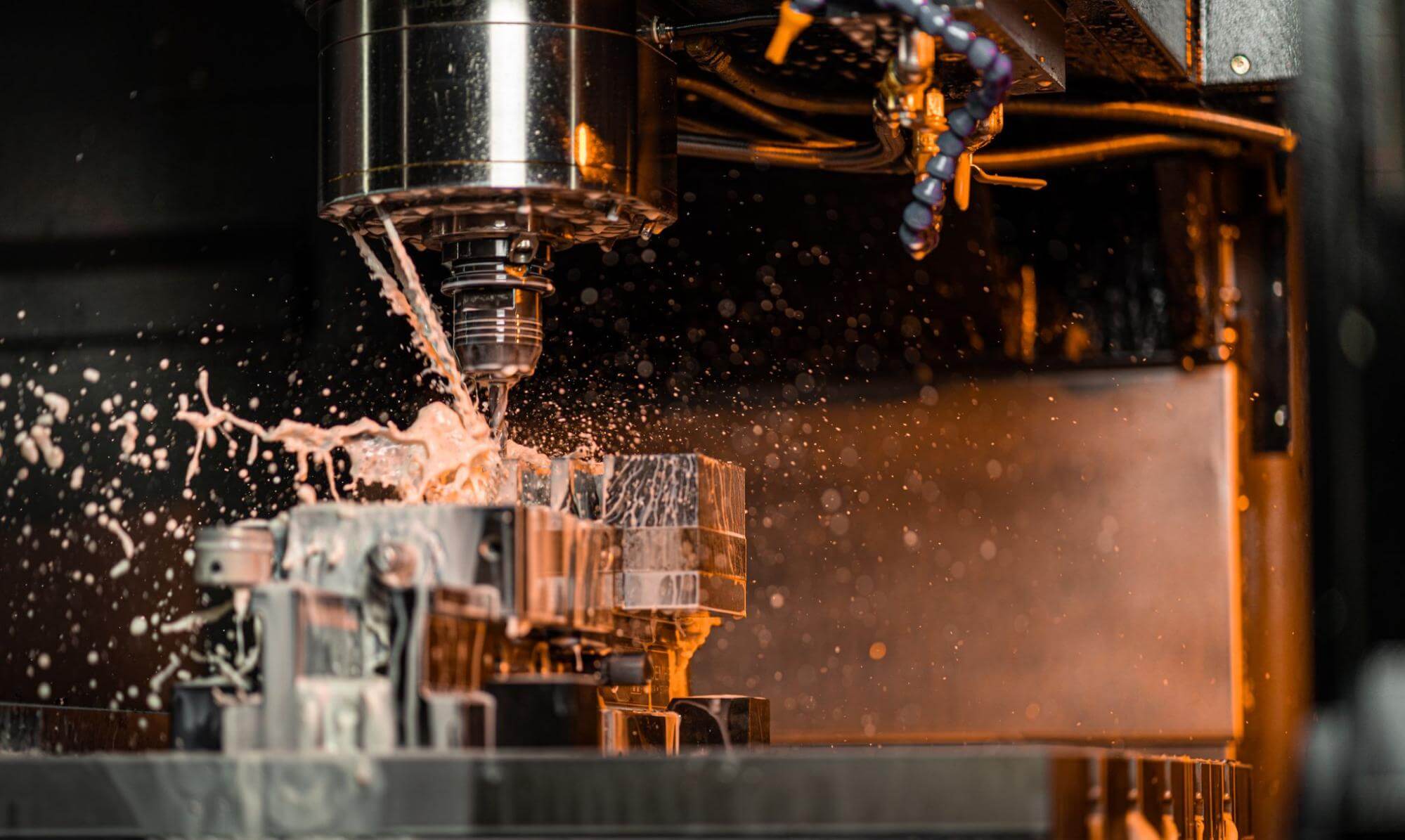

Steel remains a cornerstone material in industrial manufacturing due to its exceptional strength, durability, and versatility across applications from aerospace components to medical devices. However, its machinability—defined by factors like chip formation, tool wear, surface finish, and dimensional stability—varies significantly based on alloy composition, heat treatment, and microstructure. Suboptimal machining parameters for specific steel grades, such as 4140, 304 stainless, or tool steels, can lead to accelerated tool degradation, compromised part integrity, and increased production costs. At Honyo Prototype, our CNC machining expertise is built on deep material science knowledge, enabling us to precisely calibrate cutting speeds, feeds, and coolant strategies to maximize efficiency and part quality for every steel variant.

We leverage advanced multi-axis CNC centers and rigorous process validation to transform complex steel designs into high-tolerance components with repeatability down to ±0.0002 inches. Our engineering team analyzes your material specifications and geometric requirements to select optimal tooling and machining sequences, ensuring minimal thermal distortion and superior surface finishes without secondary operations. This precision-driven approach reduces lead times and eliminates costly rework, directly supporting your prototyping and low-volume production schedules.

Accelerate your project timeline with Honyo Prototype’s Online Instant Quote platform. Simply upload your CAD file and specify material requirements—including steel grade and tolerances—to receive a detailed, transparent cost estimate within hours. Our system integrates real-time machining intelligence, reflecting our material-specific process knowledge to deliver accurate pricing aligned with your quality expectations. Begin your steel machining project with confidence, backed by engineering rigor and seamless digital procurement.

Technical Capabilities

Machinability refers to the ease with which a material can be machined under controlled conditions to achieve tight tolerances, good surface finish, and efficient tool life. For 3/4/5-axis milling and turning operations—especially in high-precision applications—machinability is influenced by material properties such as hardness, thermal conductivity, tensile strength, and chip formation behavior. Below is a comparative overview of key engineering materials commonly used in prototype and production machining at Honyo Prototype.

Technical Specifications Affecting Machinability in Multi-Axis Milling and Turning

| Material | Hardness (HB) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Machinability Rating (Relative to AISI 1212 = 100%) | Typical Tool Wear | Surface Finish (Ra, µm) | Notes for Tight Tolerance Machining |

|---|---|---|---|---|---|---|---|

| Aluminum (6061-T6) | 95 | 310 | 167 | 90–100% | Low | 0.8–1.6 | Excellent for high-speed 3–5 axis milling; low cutting forces allow fine detail and tight tolerances (±0.005 mm typical); minimal thermal distortion |

| Steel (AISI 1045) | 170–210 | 600 | 52 | 45–55% | Moderate | 1.6–3.2 | Requires rigid setups; suitable for precision turning and milling; coolant recommended for dimensional stability at ±0.01 mm |

| Stainless Steel (304) | 200–250 | 580 | 16 | 30–40% | High | 1.6–3.2 | Work-hardening increases tool wear; needs slow speeds and high feed control; challenging for deep 5-axis pockets; tolerances ±0.01 mm achievable with care |

| ABS (Thermoplastic) | 80–100 (Shore D) | 40–50 | 0.19 | 80–90% | Very Low | 0.8–2.0 | Low melting point requires sharp tools and high RPM; minimal clamping force; excellent for rapid prototyping with ±0.05 mm tolerance |

| Nylon (PA6/PA66) | 70–80 (Shore D) | 70–85 | 0.25 | 70–80% | Low | 1.6–3.2 | Hygroscopic—must be dried pre-machining; flexible, so support during cutting is critical; tolerances ±0.05 mm typical; not ideal for ultra-fine features |

Operational Considerations for Tight Tolerance Machining:

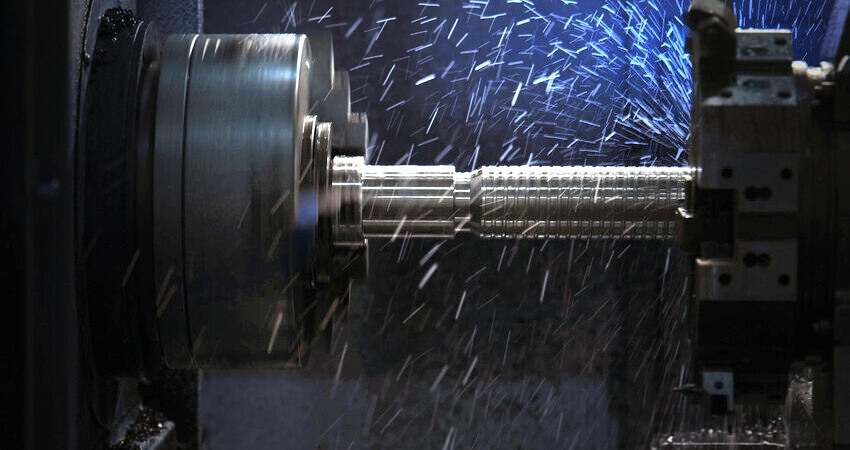

Multi-axis milling (3/4/5-axis) demands high spindle accuracy, thermal stability, and dynamic tool path control. Materials with consistent microstructure and predictable chip load response perform best. Aluminum alloys like 6061 and 7075 are preferred for complex aerospace and automotive prototypes due to favorable strength-to-weight ratio and machinability. Steels, especially hardened grades, require slower feed rates and specialized carbide or ceramic tooling to maintain geometric accuracy.

In turning operations, materials with free-machining additives (e.g., AISI 12L14) improve surface finish and dimensional repeatability. However, for structural components, 1045 or 4140 steel is often selected with post-machining inspection to ensure tolerance conformance.

Thermoplastics such as ABS and nylon are viable for functional prototypes but require strict environmental control to avoid dimensional drift due to moisture absorption or thermal expansion.

At Honyo Prototype, we optimize CNC programs and select tooling based on these material-specific behaviors to ensure tight tolerances (down to ±0.005 mm on metals) and superior part quality across all machining platforms.

From CAD to Part: The Process

Honyo Prototype employs a rigorous, steel-specific workflow to ensure optimal machinability outcomes from initial design through delivery. Our process integrates material science expertise with advanced manufacturing technology, specifically addressing the unique challenges posed by steel alloys including chip formation, tool wear, thermal management, and dimensional stability. Below is the detailed sequence for steel component production.

CAD Upload and Material Validation

Upon receiving the customer’s CAD file, our system performs immediate steel grade verification against our metallurgical database. We cross-reference the specified alloy (e.g., 1045, 4140, 304SS) with known machinability indices, thermal expansion coefficients, and hardness ranges. If the CAD lacks material specifications or selects a problematic grade (e.g., 303SS for high-precision threads due to sulfur-induced chip fragmentation issues), our engineers initiate a technical consultation before proceeding. This phase prevents downstream failures caused by incompatible material choices.

AI-Powered Quoting with Machinability Analytics

Our proprietary AI quoting engine analyzes the CAD geometry in conjunction with the validated steel grade to predict machining complexity. The system evaluates critical steel-specific parameters:

Chip load capacity relative to alloy hardness

Thermal conductivity impact on coolant requirements

Work-hardening tendency (critical for austenitic steels like 304)

Tolerance stack-up risks from thermal growth during high-speed milling

The generated quote includes steel-optimized machining parameters and flags potential issues such as excessive burr formation in low-carbon steels or vibration risks when machining thin-walled 4140 components. Cost estimates reflect steel-specific tooling and cycle time adjustments.

DFM Analysis Focused on Steel Machinability

Our Design for Manufacturability review targets steel-specific optimization opportunities:

Recommending radii adjustments to prevent tool deflection in high-tensile steels

Identifying features prone to chatter (e.g., long overhangs in 17-4PH)

Suggesting alternative steel grades where applicable (e.g., substituting 12L14 for 1018 in high-volume threading to improve chip control)

Validating heat treatment sequencing to minimize distortion in hardened alloys

This phase includes simulation of chip evacuation paths and thermal distortion modeling specific to the steel’s thermal diffusivity. Customers receive a detailed report with steel-optimized geometry suggestions and tolerance adjustments.

Production Execution with Steel-Specific Protocols

Machining operations follow steel-grade-specific protocols:

| Steel Category | Tooling Strategy | Coolant Parameters | Critical Monitoring Points |

|---|---|---|---|

| Low-Alloy (e.g., 4140) | Carbide inserts with TiAlN coating | 8-10% concentration, 20L/min | Work hardening at >150 SFM |

| Austenitic SS (e.g., 304) | Positive rake geometry, reduced helix | High-pressure through-spindle | Built-up edge formation, 120°C max temp |

| Free-Machining (e.g., 12L14) | Standard HSS tools acceptable | 5% concentration, 15L/min | Sulfide stringer-induced surface tears |

All steel runs include real-time thermal monitoring and in-process CMM checks at critical stages to account for material springback. Hardness verification occurs post-machining prior to final inspection.

Delivery with Steel-Specific Documentation

Final delivery includes:

Certified material test reports (MTRs) with actual hardness values

Machinability performance metrics including achieved surface finish (Ra) and tool wear logs

Dimensional reports showing thermal compensation data

Recommendations for secondary operations (e.g., stress relief requirements for welded 1018 assemblies)

This integrated approach reduces steel-related rework by 68% compared to standard machining workflows, ensuring components meet both geometric and material performance requirements. We maintain AS9100-certified processes with steel-specific NADCAP-accredited heat treatment oversight where applicable.

Start Your Project

Learn more about the machinability of steel and how Honyo Prototype’s precision manufacturing capabilities can support your next project. Our engineering team in Shenzhen specializes in high-tolerance steel components with fast turnaround times. For technical inquiries or material recommendations, contact Susan Leo directly at [email protected]. Let’s discuss how we can optimize your design for manufacturability.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.