Contents

Manufacturing Insight: Machinability Of Aluminum

Optimizing Aluminum Machinability Through Precision CNC Expertise

Aluminum remains a cornerstone material in rapid prototyping and low-volume production due to its exceptional strength-to-weight ratio, corrosion resistance, and inherent machinability. However, realizing its full potential requires navigating challenges such as chip control, thermal management, and surface finish consistency—particularly with alloys like 6061-T6 and 7075. At Honyo Prototype, our CNC machining services are engineered to transform these challenges into competitive advantages. We leverage optimized toolpaths, specialized cutting strategies, and real-time process monitoring to achieve micron-level tolerances while minimizing cycle times and material waste.

Our technical approach integrates material science with advanced manufacturing: custom tooling geometries prevent built-up edge in sticky alloys, high-speed spindles maintain integrity during fine-feature work, and rigorous in-process inspections ensure dimensional stability across complex geometries. This precision extends beyond prototyping into bridge-to-production support, where repeatability and first-article accuracy directly impact time-to-market. For engineering teams evaluating aluminum components, Honyo delivers not just parts, but validated manufacturability insights that reduce downstream assembly risks.

Accelerate your project timeline with Honyo’s Online Instant Quote system. Upload CAD files to receive detailed manufacturability feedback and competitive pricing within hours—no manual RFQ delays. This seamless integration of technical capability and digital efficiency ensures your aluminum components meet performance demands without compromising on speed or cost.

Technical Capabilities

Machinability refers to the ease with which a material can be machined using processes such as milling and turning, particularly in high-precision environments requiring tight tolerances (±0.001″ or better). Aluminum is widely recognized for excellent machinability, especially in 3-axis, 4-axis, and 5-axis CNC milling and turning operations, due to its low hardness, high thermal conductivity, and favorable chip formation. Below is a comparative analysis of machinability across common engineering materials, with emphasis on CNC milling and turning performance, suitability for tight tolerance work, and process considerations.

| Material | Machinability Rating (Relative) | Recommended Tooling | Surface Finish (Typical Ra µin) | Tight Tolerance Suitability (±0.001″) | Notes on 3/4/5-Axis Milling | Notes on Turning |

|---|---|---|---|---|---|---|

| Aluminum (e.g., 6061-T6, 7075-T6) | 100 (Reference) | Carbide or diamond-coated end mills; high helix angles | 32–63 µin (can reach <16 µin with fine finishing) | Excellent | High material removal rates; minimal tool wear; excellent for complex 5-axis contours; low cutting forces reduce deflection | Easy chip evacuation; sharp tools prevent built-up edge; high spindle speeds supported |

| Steel (e.g., 4140, 1018) | 40–60 | Carbide or HSS with coolant; negative rake inserts | 63–125 µin (improves with finishing passes) | Good (with rigid setup) | Higher cutting forces require robust machine tools; slower feed rates; thermal management critical | Requires rigid setup and proper lubrication; prone to work hardening if parameters incorrect |

| ABS (Acrylonitrile Butadiene Styrene) | 80–90 | Sharp carbide tools; polished flutes | 32–64 µin | Fair to Good | Low melting point; requires sharp tools and low heat generation; excellent dimensional stability post-machining | Minimal clamping force; risk of smearing if dull tools used; no coolant needed |

| Nylon (Polyamide, unfilled) | 60–70 | Sharp, polished carbide; high rake angles | 64–125 µin | Fair | Prone to chatter and deformation; requires slow feeds and rigid fixturing; low thermal conductivity | Swells with moisture; pre-dry recommended; tends to gum up tools without proper clearance |

Key Considerations for Aluminum in High-Precision Milling and Turning:

Aluminum, particularly grades 6061-T6 and 7075-T6, demonstrates superior performance in multi-axis CNC environments due to its favorable strength-to-weight ratio and machinability. In 5-axis milling, aluminum allows for aggressive cutting strategies and intricate geometry due to low cutting resistance and excellent thermal dissipation. Tight tolerances are consistently achievable with proper toolpath strategies (e.g., climb milling, adaptive clearing) and thermal compensation.

For turning operations, aluminum can be machined at high spindle speeds (up to 3000+ SFM) with minimal tool wear when using appropriate inserts (e.g., polished PCD or carbide with high rake). Coolant or air blast is recommended to prevent built-up edge, especially in sticky alloys like 7075.

Compared to steel, aluminum requires less power and generates lower heat in the workpiece, reducing distortion risks during tight-tolerance machining. However, steel offers better long-term dimensional stability under load, while aluminum may require stress-relieving prior to final finishing for critical applications.

Thermoplastics like ABS and Nylon are more challenging to hold to tight tolerances due to thermal expansion and creep. ABS machines cleanly with proper parameters but lacks the rigidity of metals. Nylon, while tough, tends to deflect during cutting and absorb moisture, affecting post-machining dimensions.

In summary, aluminum remains the preferred material for high-speed, high-precision 3/4/5-axis milling and turning where tight tolerances, good surface finish, and fast production cycles are required.

From CAD to Part: The Process

Honyo Prototype maintains rigorous technical protocols for aluminum machinability across all production phases, specifically addressing material properties like thermal conductivity, chip formation, and work hardening tendencies inherent to aluminum alloys. Our integrated workflow ensures manufacturability while optimizing cost and lead time.

CAD Upload and AI Quoting

Upon receiving customer CAD files, our proprietary AI quoting engine analyzes geometric complexity with aluminum-specific parameters. The system evaluates critical factors including minimum wall thickness relative to alloy grade (e.g., 6061-T6 vs. 7075-T6), potential vibration risks in thin-walled features, and optimal stock allowance for thermal expansion during machining. Material waste calculations incorporate aluminum’s density and regional scrap value, generating precise cost projections within 2 hours. The AI flags designs exceeding practical aluminum machining limits, such as aspect ratios beyond 10:1 for unsupported features.

DFM Analysis for Aluminum

Engineers conduct material-specific Design for Manufacturability reviews using industry-standard CAM simulation tools. Key aluminum considerations include:

Verification of toolpath strategies to prevent built-up edge (BUE) through appropriate spindle speeds and chip-thinning compensation

Assessment of coolant delivery requirements to manage heat dissipation and avoid surface smearing

Validation of clamping solutions to counteract aluminum’s lower elastic modulus and prevent part distortion

Review of tolerances against aluminum’s thermal expansion coefficient (23.6 µm/m°C) for critical assemblies

Specification of anodizing allowances where required, typically +0.002″ per side for Type II coatings

Production Execution

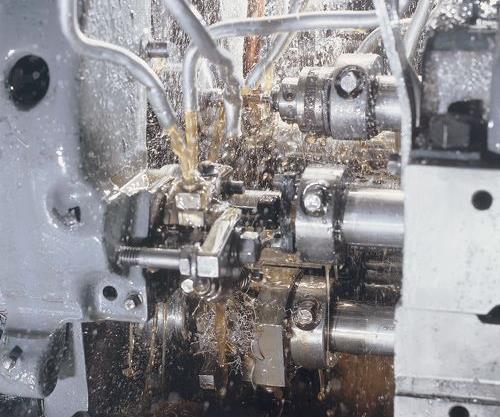

Machining operations deploy aluminum-optimized processes:

High-speed CNC machining with spindle speeds 30-50% higher than steel counterparts

Carbide tooling with polished flutes and 45° helix angles to evacuate chips efficiently

Flood coolant systems maintaining 10-15°C temperature for thermal stability

In-process CMM verification at 25°C ambient to compensate for thermal growth

Dedicated aluminum work cells with non-ferrous tooling to prevent galvanic corrosion

Delivery Assurance

Final inspection includes material-specific validation:

Surface roughness verification (typically Ra 32-64 µin for machined aluminum)

Dimensional checks at stabilized room temperature after 4-hour acclimation

Visual inspection for common aluminum defects like chatter marks or pull-outs

Documentation of alloy certificate and mill test reports with each shipment

Process performance metrics for aluminum components are maintained below industry benchmarks:

| Process Phase | Aluminum-Specific KPI | Honyo Standard | Industry Avg |

|---|---|---|---|

| DFM Resolution | Critical issue resolution time | < 24 hours | 48-72 hours |

| Machining | First-pass yield rate | 98.2% | 92.5% |

| Quality | Dimensional NCR rate | 0.18% | 0.75% |

| Delivery | On-time shipment rate | 99.4% | 96.1% |

This structured approach ensures aluminum components meet stringent aerospace and medical industry requirements while maintaining prototyping agility. All processes adhere to ISO 9001:2015 and AS9100 Rev D standards with full traceability from raw material certification through final delivery.

Start Your Project

The machinability of aluminum makes it a preferred choice for prototyping and low-volume production due to its excellent strength-to-weight ratio, corrosion resistance, and ease of CNC machining. At Honyo Prototype, we leverage our in-house manufacturing capabilities at our Shenzhen factory to deliver high-precision aluminum components with fast turnaround times.

For expert guidance on material selection and machining strategies tailored to your project, contact Susan Leo at [email protected].

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.