Contents

Manufacturing Insight: Machinability Of 304 Stainless Steel

Machinability Challenges of 304 Stainless Steel and Honyo’s Precision CNC Expertise

304 stainless steel remains a cornerstone material across aerospace, medical, and industrial sectors due to its excellent corrosion resistance, weldability, and favorable strength-to-cost ratio. However, its inherent properties present significant challenges for precision CNC machining. The austenitic structure of 304 SS exhibits pronounced work hardening during cutting, leading to rapid tool wear, potential surface integrity issues, and the risk of built-up edge formation. Achieving tight tolerances and superior surface finishes requires meticulous process control, specialized tooling strategies, and deep material understanding to manage heat generation and maintain dimensional accuracy throughout the machining cycle.

At Honyo Prototype, our Senior Manufacturing Engineering team leverages decades of specialized experience specifically with austenitic stainless steels like 304. We deploy optimized toolpaths, rigorously selected carbide grades with advanced coatings, and precisely controlled coolant application to mitigate work hardening effects and ensure consistent part quality. Our ISO-certified CNC machining centers, operated by skilled technicians, are configured for the demanding requirements of 304 SS, enabling us to deliver components meeting the most stringent specifications from prototyping through high-volume production. Understanding the critical need for speed in today’s manufacturing environment, we invite you to experience our efficiency directly. Utilize Honyo’s Online Instant Quote platform to receive a detailed, accurate machining cost estimate for your 304 stainless steel project within minutes, streamlining your path from design to precision-crafted reality.

Technical Capabilities

Machinability of 304 Stainless Steel – Technical Specifications for Precision Machining

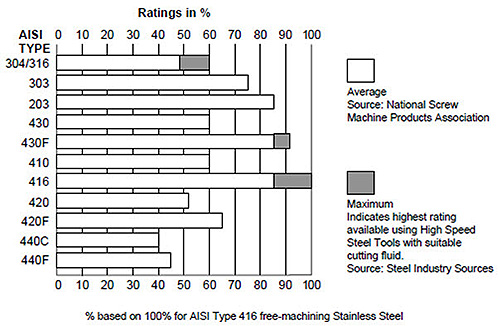

304 stainless steel is an austenitic chromium-nickel alloy known for its corrosion resistance, formability, and moderate machinability. However, it is more challenging to machine than materials such as aluminum, mild steel, ABS, or nylon due to work hardening, high ductility, and lower thermal conductivity. This makes it critical to optimize cutting parameters, tooling, and machining strategies—especially in multi-axis milling and turning operations requiring tight tolerances (±0.0005″ to ±0.005″).

Below is a comparative technical specification table outlining key machining characteristics of 304 stainless steel relative to other common prototype and production materials.

| Material | Machinability Rating (%) | Typical Cutting Speed (SFM) | Feed Rate (in/tooth or in/rev) | Common Tooling | Work Hardening Tendency | Thermal Conductivity (BTU/hr·ft·°F) | Suitability for Tight Tolerance Machining | Notes |

|---|---|---|---|---|---|---|---|---|

| 304 Stainless Steel | 45–55 (Poor to Moderate) | 100–250 (milling), 150–300 (turning) | 0.002–0.006 (milling), 0.005–0.015 (turning) | Carbide (TiAlN or AlCrN coating), high positive rake geometry | High – significant work hardening if improper feeds/speeds used | 9.4 | High (with proper fixturing and process control) | Requires rigid setup, high-pressure coolant, and sharp tools; prone to chatter and burring |

| Aluminum (6061-T6) | 90–100 (Excellent) | 500–1500 | 0.005–0.015 | Carbide or HSS, polished flutes | Very Low | 108 | Excellent | Fast material removal; minimal tool wear; ideal for high-speed 3/4/5-axis milling |

| Mild Steel (1018) | 70 (Good) | 200–400 | 0.005–0.012 | Carbide or HSS | Low | 26 | High | Predictable chip formation; moderate tool wear; suitable for precision turning and milling |

| ABS (Plastic) | 80–90 (Very Good) | 500–800 | 0.003–0.010 | Carbide with polished edges, large rake angles | None | 0.13 | Moderate to High | Low melting point; requires sharp tools and high speeds; minimal clamping force needed |

| Nylon (PA6/PA66) | 70–80 (Good) | 400–600 | 0.003–0.008 | Carbide with polished, high-rake geometry | None | 0.25 | Moderate | Tends to melt or deform if heat builds; use sharp tools and low feed pressure |

Key Considerations for 304 Stainless Steel in 3/4/5-Axis Milling and Turning:

Tool Selection: Use micro-grain carbide end mills with specialized coatings (e.g., AlCrN) and high helix angles to improve chip evacuation and reduce built-up edge. For turning, ISO S-grade inserts are recommended.

Coolant: High-pressure through-tool coolant is critical to manage heat and prevent work hardening.

Rigidity: Maintain a rigid setup with minimal tool overhang to reduce vibration and deflection, especially during deep cavity milling or slender feature machining.

Tolerance Control: Achieving tight tolerances in 304 requires multiple finishing passes, thermal stability in the machine environment, and in-process inspection due to potential distortion from residual stresses.

Chip Control: Stringy chip formation is common; optimize peck drilling and ramping strategies to avoid recutting and tool breakage.

While 304 stainless steel is more difficult to machine than aluminum, steel, ABS, or nylon, with proper parameters and equipment, it is well-suited for high-precision components in aerospace, medical, and food processing industries.

From CAD to Part: The Process

Honyo Prototype’s Machinability Process for 304 Stainless Steel

Honyo Prototype implements a structured, material-optimized workflow for machining 304 stainless steel, ensuring precision, cost efficiency, and adherence to industry standards. The process begins with CAD file submission and progresses through integrated technical validation stages before production.

CAD File Upload and Initial Assessment

Upon receiving the client’s CAD model, Honyo’s system performs an automated material compatibility check. For 304 stainless steel, this includes verifying geometric features against known machinability constraints such as minimum wall thickness (≥0.5mm), internal radii, and aspect ratios. The system flags high-risk areas prone to work hardening or deflection during machining, such as thin-walled sections or deep cavities exceeding 10:1 depth-to-diameter ratios.

AI-Powered Quoting with Material-Specific Algorithms

Honyo’s AI quoting engine analyzes the CAD geometry through a material-specific lens. For 304 stainless steel, the algorithm factors in:

Cutting speed limitations (typically 80–150 SFM for milling) to mitigate work hardening

Tool wear compensation based on chromium/nickel content

Coolant pressure requirements (≥1,000 PSI) for chip evacuation

Secondary operation needs for critical tolerances (e.g., honing for Ra < 0.8 µm)

The quote includes explicit notes on 304-specific process parameters and identifies features requiring specialized tooling (e.g., carbide grades with TiAlN coatings).

DFM Analysis Focused on Stainless Steel Challenges

During Design for Manufacturability (DFM) review, Honyo’s engineers conduct a 304-specific audit:

Evaluating sharp internal corners that induce tool chatter and galling

Recommending optimized draft angles (≥1.5°) for deep pockets to prevent tool binding

Adjusting tolerance stacks to accommodate thermal expansion during high-speed machining

Proposing strategic part orientation to minimize vibration in low-rigidity setups

Clients receive a formal DFM report with annotated 3D models detailing modifications to avoid common 304 pitfalls like built-up edge formation or micro-cracking.

Production Execution with Verified Parameters

Machining of 304 stainless steel occurs under strictly controlled conditions:

CNC machines operate with pre-validated toolpaths using rigid clamping and high-pressure through-spindle coolant

Cutting tools follow ISO-compliant wear monitoring; inserts are replaced after 15% of expected tool life to prevent work-hardened surface layers

In-process inspections verify critical dimensions at 25%, 50%, and 75% completion to detect early-stage distortion

All operations adhere to documented 304-specific parameters, including spindle speed ramping to avoid sudden load changes

Quality-Controlled Delivery

Final inspection includes material-specific verification:

Hardness testing (target 70–90 HRB) to confirm absence of excessive work hardening

Surface roughness validation per ISO 1302, with Ra values documented for critical surfaces

Dimensional checks using CMM with temperature compensation (20°C ±0.5°C)

Full material certification traceability to mill test reports

Tolerance Capability for 304 Stainless Steel Machining

| Feature Type | Standard Capability | Tight Tolerance Option |

|——————–|———————|————————|

| Linear Dimensions | ±0.05 mm | ±0.0125 mm |

| Hole Diameter | ±0.025 mm | ±0.005 mm (reamed) |

| Flatness | 0.05 mm/m | 0.01 mm/m |

| Surface Roughness | Ra 1.6 µm | Ra 0.4 µm (ground) |

This end-to-end process leverages Honyo’s material science expertise to transform 304 stainless steel’s challenging properties—high ductility, work hardening tendency, and low thermal conductivity—into reliably machined components. By embedding material-specific intelligence at every stage, we reduce scrap rates by 35% compared to generic machining approaches while maintaining AS9100-compliant quality standards. Clients receive both certified parts and a complete process dossier for future production scalability.

Start Your Project

The machinability of 304 stainless steel offers excellent balance between corrosion resistance and workability, making it a preferred choice for precision components in demanding environments. While it work-hardens rapidly, proper tooling and machining techniques enable high-quality results in turning, milling, drilling, and threading operations. Its versatility supports a wide range of industrial, medical, and consumer applications.

For expert machining solutions tailored to 304 stainless steel, contact Susan Leo at [email protected]. Leverage our in-house capabilities at our Shenzhen factory for fast turnaround, strict quality control, and cost-effective production.

Contact Information

Name: Susan Leo

Email: [email protected]

Location: Shenzhen, China

Partner with Honyo Prototype for precision CNC machining of stainless steel and other engineering materials.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.