Contents

Manufacturing Insight: M-Codes In Cnc

Understanding M-Codes: The Critical Control Layer in Precision CNC Machining

M-codes form the essential operational backbone of CNC machining, directing non-geometric machine functions such as tool changes, coolant activation, program stops, and spindle control. While G-codes define tool paths, M-codes ensure seamless machine behavior—preventing collisions, optimizing cycle times, and safeguarding part integrity. Misconfigured M-codes can lead to costly errors, extended downtime, or compromised surface finishes, directly impacting production efficiency and part quality. At Honyo Prototype, our engineering team meticulously validates every M-code sequence within your program to guarantee machine compatibility, process reliability, and adherence to tight tolerances across complex geometries.

Our end-to-end CNC machining services leverage this deep code-level expertise to transform digital designs into high-precision components for aerospace, medical, and industrial applications. From 3-axis milling to 5-axis simultaneous machining, we integrate M-code optimization into our workflow to minimize non-cut time and maximize throughput—without sacrificing accuracy. This technical rigor is embedded in every project, ensuring your parts meet stringent functional requirements on the first run.

To accelerate your path from design to delivery, Honyo Prototype offers an Online Instant Quote platform. Simply upload your CAD file, specify materials and finishes, and receive a detailed machining cost estimate within hours—not days. Our system factors in nuanced process variables, including M-code-driven operational efficiencies, to provide transparent, actionable pricing. Experience how precision engineering and responsive quoting converge to reduce your time-to-market.

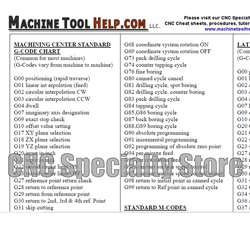

Common M-Code Functions and Production Impact

| M-Code | Function | Production Risk if Misconfigured |

|——–|———-|———————————-|

| M03 | Spindle start (CW) | Incorrect rotation direction causes tool breakage or poor surface finish |

| M06 | Automatic tool change | Unsynced tool changes induce collisions or extended cycle times |

| M08 | Coolant on | Inadequate coolant flow accelerates tool wear and thermal deformation |

| M30 | Program end/reset | Improper reset sequences disrupt batch consistency and machine readiness |

Technical Capabilities

M-codes in CNC programming are auxiliary commands that control machine functions such as coolant flow, spindle start/stop, tool changes, and pallet shifts. These codes work in conjunction with G-codes to automate machine operations. Below are key M-codes relevant to 3/4/5-axis milling, turning, and tight-tolerance manufacturing across common engineering materials including Aluminum, Steel, ABS, and Nylon.

| M-code | Function | Application in 3/4/5-Axis Milling | Application in Turning | Relevance to Tight Tolerance | Material Considerations |

|---|---|---|---|---|---|

| M03 | Spindle start (clockwise) | Initiates spindle rotation for multi-axis contouring; critical for maintaining consistent tool engagement in complex geometries | Used to begin turning operations with precise RPM control | Ensures stable spindle acceleration to avoid tool deflection and maintain ±0.0005″ tolerances | Essential for Aluminum (high RPM) and Steel (lower RPM); less critical for ABS/Nylon due to lower cutting forces |

| M04 | Spindle start (counterclockwise) | Rarely used but applicable for specialized left-hand tooling in deep cavity milling | Used for back-facing or left-hand threading operations | Minimizes vibration in asymmetric setups, improving surface finish and accuracy | Particularly useful in hardened Steel threading; not typically used for plastics |

| M05 | Spindle stop | Halts spindle during tool changes or probing cycles in multi-axis work | Stops spindle for in-process inspection or part transfer | Prevents thermal growth and vibration, critical for sub-micron repeatability | Important when switching between Aluminum (thermal expansion) and Steel (heat retention) |

| M06 | Tool change | Automates tool exchange in multi-axis mills with tool magazines; enables complex operations without manual intervention | Used in turret-based lathes for sequential operations | Ensures precise tool length and diameter offsets for high-precision features | Critical for maintaining tolerances when switching from roughing (Steel) to finishing (Aluminum or Nylon) |

| M08 | Coolant on (flood) | Delivers coolant during deep pocketing or high-speed milling in 5-axis machines | Activates coolant during continuous cutting to manage heat | Prevents thermal deformation; essential for tight-tolerance steel machining | Vital for Steel and Aluminum; not required for ABS/Nylon (prone to cracking from thermal shock) |

| M09 | Coolant off | Shuts off coolant before probing or tool changes | Turns off coolant before part handling or inspection | Prevents coolant residue affecting measurement accuracy | Especially important in inspection stages for all materials |

| M19 | Spindle orientation | Locks spindle at a specific angular position for tool probing or 4th/5th axis alignment | Sets spindle for live tooling engagement or part pickup | Enables precise tool tip positioning for ±0.001″ angular tolerances | Used when synchronizing mill-turn operations on hybrid machines |

| M30 | Program end and reset | Ends program and resets control; used after complex 5-axis sequences | Finalizes turning cycle and prepares for next blank | Confirms completion of high-precision sequence; ensures safe machine state | Applied universally across all materials after final inspection |

These M-codes are integral to maintaining precision, repeatability, and process stability in high-accuracy CNC operations. When machining tight-tolerance components from Aluminum and Steel, thermal and mechanical stability are enforced through controlled spindle and coolant management. For engineering plastics like ABS and Nylon, minimizing unnecessary coolant and managing spindle speed via M03/M05 avoids material deformation. In multi-axis and turn-mill environments, M-codes ensure seamless transitions between operations, directly supporting micron-level accuracy requirements.

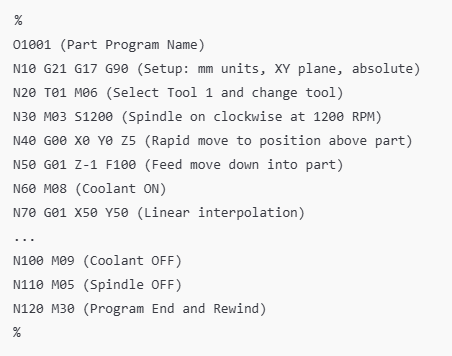

From CAD to Part: The Process

Honyo Prototype implements a structured, technology-driven workflow for CNC machining projects that ensures precision, efficiency, and client transparency. While M-codes (miscellaneous machine function codes in G-code programs) are critical to CNC operations, they are not standalone client-facing process steps. Instead, M-codes are generated and validated within specific technical phases of our workflow. Below is an accurate explanation of how M-codes integrate into our standard sequence:

Upload CAD

Clients submit native or neutral CAD files (STEP, IGES, Parasolid) via our secure portal. Our system performs initial geometry validation, but M-codes are not involved at this stage as the focus is solely on design data ingestion and file integrity checks.

AI Quote

Our proprietary AI engine analyzes CAD geometry to auto-generate preliminary cost and lead time estimates. The AI assesses feature complexity, material requirements, and machine time but does not interact with M-codes, as quoting precedes any G-code generation.

DFM (Design for Manufacturability)

This is where M-code relevance begins. Our engineering team conducts a rigorous DFM review, including CNC-specific analysis:

CAM programmers define toolpaths and machine operations based on design intent.

A machine-specific post-processor converts toolpaths into G-code, automatically inserting M-codes to control auxiliary functions. Critical M-codes implemented here include:

| M-Code | Function | Validation in DFM |

|---|---|---|

| M03 | Spindle start (clockwise) | Verified against material/tooling specs |

| M05 | Spindle stop | Confirmed for safety sequencing |

| M08 | Coolant on | Matched to material cooling requirements |

| M09 | Coolant off | Checked for cycle timing accuracy |

| M30 | Program end/reset | Validated for machine reset protocols |

DFM ensures M-codes align with machine capabilities, prevent collisions, and optimize cycle times. Clients receive a DFM report highlighting manufacturability feedback, though M-code details remain internal to our process.

Production

During CNC machining:

Verified G-code (including all M-codes) is loaded onto Haas, DMG MORI, or Makino machines.

M-codes execute machine-specific actions: coolant activation (M08/M09), spindle control (M03/M05), pallet changes, or tool changer signals.

Our quality team validates M-code functionality via dry runs and first-article inspections. Any M-code-related errors (e.g., coolant failure) trigger immediate corrective action before full production.

Delivery

Finished parts undergo final QA, including dimensional verification per AS9102. M-codes do not factor into delivery documentation, as client deliverables focus on certified inspection reports and traceability data—not machine-level programming details.

Key Clarification

M-codes are never a client-managed step in our workflow. They are embedded technical instructions generated during CAM programming (within DFM) and executed during Production. Honyo’s process ensures these codes are rigorously validated to prevent machine errors, reduce scrap, and maintain consistent output—without requiring client intervention at the M-code level. This integration exemplifies our commitment to seamless, error-resistant manufacturing execution.

Start Your Project

Learn more about M-codes in CNC programming and how they can optimize your manufacturing processes. These auxiliary commands play a critical role in controlling machine functions such as tool changes, coolant flow, and program stops—ensuring precision and efficiency in every cycle.

For technical inquiries or to discuss your custom prototyping needs, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen supports high-accuracy CNC machining with full M-code integration, delivering reliable results for complex components.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.