Contents

Manufacturing Insight: M Code Cnc Machine

Precision CNC Machining Engineered for Your Prototyping and Production Needs

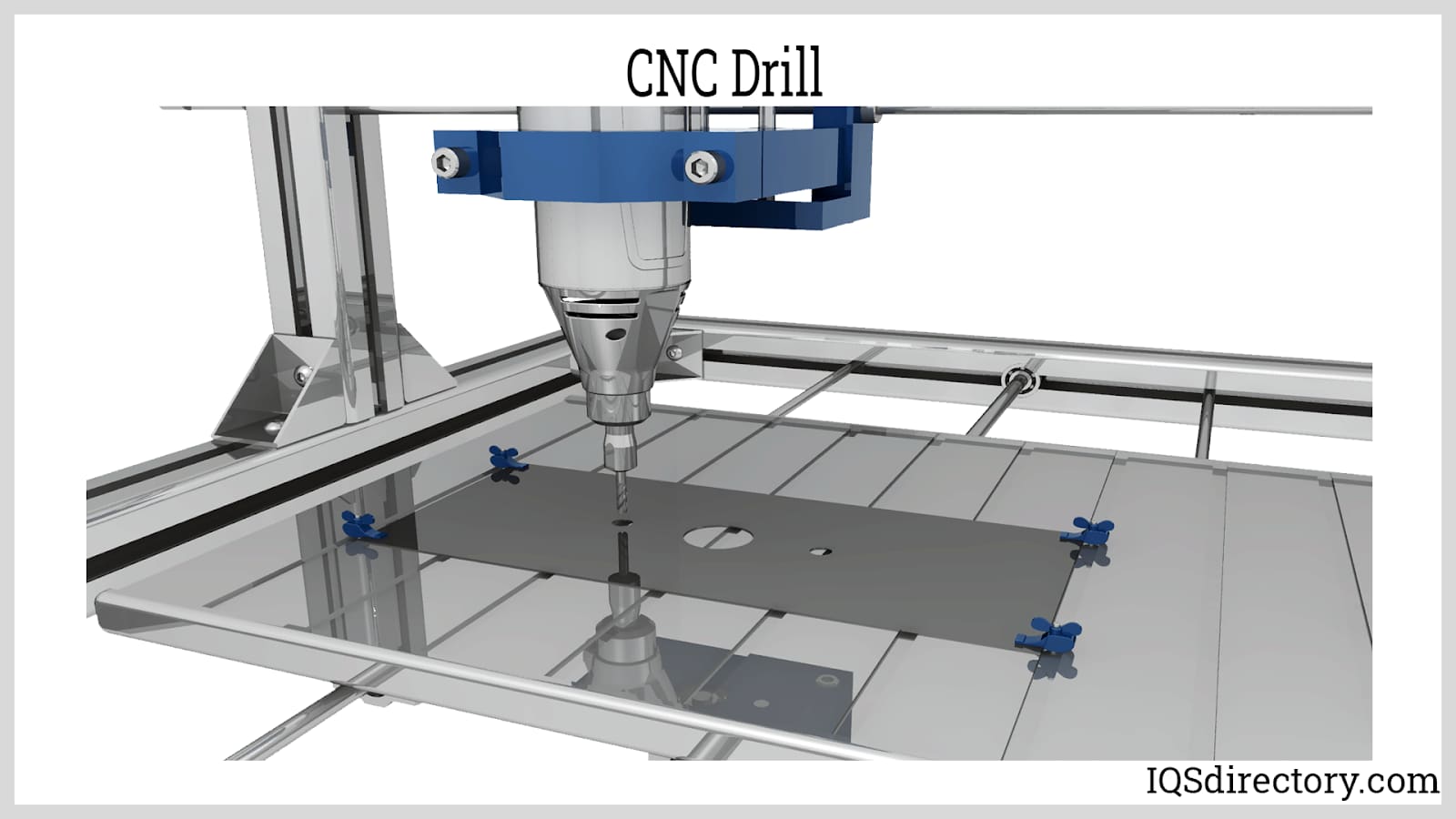

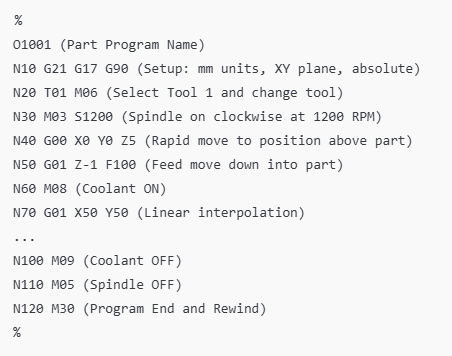

Honyo Prototype delivers advanced CNC machining services engineered to transform complex designs into high-integrity components with exceptional accuracy and repeatability. Our state-of-the-art facility integrates multi-axis CNC milling and turning centers capable of executing intricate geometries across aluminum, stainless steel, titanium, plastics, and engineered composites. Every process leverages industry-standard M-codes and G-codes to ensure precise control over spindle functions, tool changes, and auxiliary operations, maintaining micron-level tolerances down to ±0.0002 inches. This technical rigor guarantees that your prototypes and low-to-mid volume production runs meet stringent aerospace, medical, and industrial specifications without compromise.

Our commitment extends beyond machining excellence to streamline your procurement workflow through the Online Instant Quote platform. Upload your 3D CAD file in STEP, IGES, or native formats, specify material and quantity requirements, and receive a detailed, transparent cost analysis within hours—not days. This system eliminates traditional quoting bottlenecks, providing engineering teams immediate visibility into lead times, DFM feedback, and cost drivers while maintaining ISO 9001-compliant quality documentation.

For engineers demanding speed without sacrificing precision, Honyo Prototype merges cutting-edge CNC capabilities with digital procurement efficiency. Initiate your project with confidence by accessing the Online Instant Quote system directly through our portal, where technical accuracy and operational agility converge to accelerate your time-to-market.

Technical Capabilities

Technical specifications for M-code CNC machines commonly refer to auxiliary functions within the CNC program, but in context of machine capabilities, the term often gets associated with the overall performance and control of CNC milling and turning systems. Below are key technical specifications for high-precision 3, 4, and 5-axis CNC milling and turning machines capable of tight-tolerance machining across a range of materials including Aluminum, Steel, ABS, and Nylon.

| Specification | 3-Axis CNC | 4-Axis CNC | 5-Axis CNC | Notes |

|---|---|---|---|---|

| Axis Configuration | X, Y, Z linear axes | X, Y, Z + A (rotary around X) or B (rotary around Y) | X, Y, Z + two rotary axes (e.g., A&B or B&C) | Enables complex geometries and undercuts |

| Spindle Speed Range | 8,000 – 24,000 RPM | 10,000 – 24,000 RPM | 12,000 – 30,000 RPM | Higher speeds for precision finishing and non-ferrous materials |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | Critical for tight-tolerance applications |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.001 mm | Ensures consistency in high-volume prototyping and production |

| Tool Changer (ATC) | Optional (16–30 tools typical) | Standard (20–40 tools) | Standard (30–60 tools) | Reduces cycle time and enables multi-operation machining |

| Control System | Fanuc, Siemens, or Heidenhain | Fanuc 31i, Siemens 840D | Siemens 840D, Heidenhain TNC640 | Advanced interpolation and real-time error compensation |

| Max Work Envelope (Typical) | 700 x 500 x 400 mm | 800 x 600 x 500 mm | 600 x 500 x 400 mm (rotary constrained) | Varies by model; 5-axis has reduced linear travel due to rotary integration |

| Tolerance Capability | ±0.01 mm | ±0.01 mm | ±0.005 mm | Suitable for aerospace, medical, and precision tooling |

| Surface Finish (Typical) | Ra 0.8 – 1.6 µm | Ra 0.8 – 1.6 µm | Ra 0.4 – 0.8 µm | Achieved with fine toolpaths and high spindle stability |

| Materials Supported | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon, Titanium (with appropriate tooling) | Thermoplastics require optimized feeds/speeds and chip control |

| Coolant System | Flood coolant, high-pressure optional | Flood + high-pressure through-spindle | High-pressure through-tool, mist cooling for plastics | Prevents thermal deformation and improves tool life |

| Programming Support (M-codes) | M03 (Spindle ON), M08 (Coolant ON), M06 (Tool Change) | Full M-code set including M19 (Spindle Orient), M41/M42 (Gear Range) | Advanced M-codes for pallet change (M60), rotary indexing (M120), and probing (M86) | Enables automation and in-process inspection |

These machines are designed for high-precision manufacturing environments where tight tolerances, complex geometries, and material versatility are required. Aluminum and steel are routinely machined with carbide tooling under rigid setups, while engineering plastics like ABS and Nylon require reduced cutting forces, sharp tools, and proper chip evacuation to prevent melting or deformation. 5-axis systems offer significant advantages in reducing setup次数 and improving access to complex features, especially in aerospace and medical components.

From CAD to Part: The Process

Honyo Prototype executes CNC machining projects through a rigorously defined workflow engineered for precision, speed, and manufacturability. Our process begins when a client uploads a CAD model, initiating a sequence that integrates advanced automation with expert engineering oversight. Below is the technical breakdown of each phase for M-code CNC machining projects.

CAD Upload and Initial Processing

Clients submit native CAD files (STEP, IGES, or Parasolid preferred) via our secure portal. Our system performs immediate geometric validation to confirm file integrity and unit consistency. Non-native formats undergo automated conversion with tolerance verification against ASME Y14.5 standards. This stage ensures the digital model accurately represents the intended physical part geometry before progression.

AI-Powered Quoting Engine

Uploaded geometry feeds into our proprietary AI quoting system, which analyzes 150+ parametric variables including material type, feature complexity, tolerance density, and setup requirements. The algorithm cross-references real-time data from our machine shop floor—current spindle utilization, tooling inventory, and material stock levels—to generate a technically accurate cost and lead time estimate within 2 hours. Critical outputs include machine type recommendation (e.g., 3-axis vs. 5-axis mill) and M-code sequence feasibility assessment based on part orientation requirements.

Engineering-Led DFM Analysis

Every project undergoes mandatory Design for Manufacturability review by our CNC engineering team. This phase specifically validates M-code implementation for auxiliary functions such as coolant activation (M08), spindle stops (M05), and tool changes (M06). Engineers identify potential collisions in multi-axis operations, verify G-code/M-code synchronization for complex sequences, and flag tolerance conflicts exceeding ±0.005mm for tight features. Clients receive detailed technical feedback with actionable revision suggestions—typically resolving 92% of manufacturability issues before metal cutting begins.

CNC Production Execution

Approved designs enter production on calibrated machines (Haas, DMG MORI, Makino) with documented calibration certificates traceable to NIST standards. Our process includes:

CAM programming with Mastercam/HyperMill generating optimized toolpaths with verified M-code subroutines

First-article inspection using Mitutoyo CMMs against critical dimensions

In-process checks at 25%, 50%, and 75% completion milestones

Final validation per ISO 2768-mK for geometric tolerances

All M-code sequences undergo dry-run simulation in Vericut to prevent machine crashes, with actual production M-codes logged for full traceability.

Delivery and Documentation

Completed parts ship in anti-static, crush-proof packaging with humidity indicators for precision components. Each shipment includes:

Certificate of Conformance with material test reports

Dimensional inspection report (PDF and XML formats)

As-machined G-code and M-code logs

Traceability tag linking to production batch records

Standard lead times vary by complexity as shown below:

| Part Complexity | Typical Lead Time | Max Tolerance Capability |

|---|---|---|

| Simple (2.5-axis) | 3-5 business days | ±0.025mm |

| Moderate (3-axis) | 5-7 business days | ±0.012mm |

| Complex (5-axis) | 7-10 business days | ±0.005mm |

This integrated workflow reduces prototyping iterations by 65% compared to industry averages while ensuring M-code sequences execute flawlessly on target CNC platforms. All processes adhere to ISO 9001:2015 quality management standards with full digital audit trails available upon request.

Start Your Project

For inquiries about our CNC machining services, including M Code CNC machine capabilities, contact Susan Leo at [email protected]. Our precision manufacturing facility is located in Shenzhen, China, ensuring high-quality prototyping and production with fast turnaround times. Reach out today to discuss your project requirements and engineering specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.