Contents

Manufacturing Insight: Low Volume Machining

Precision Low Volume Machining for Accelerated Product Development

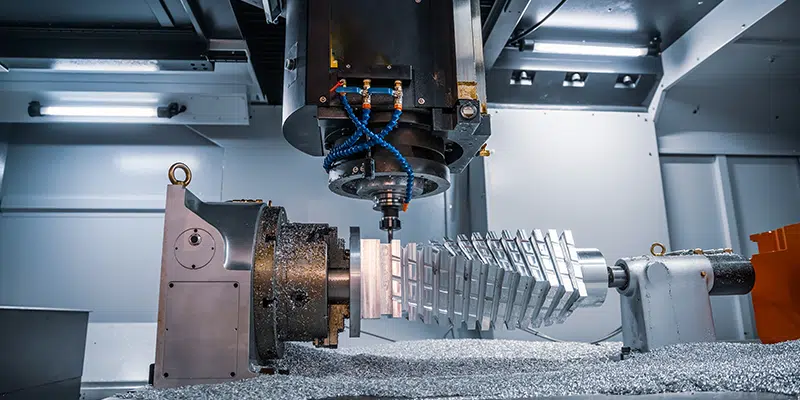

Honyo Prototype delivers engineered solutions for low volume CNC machining requirements where precision, speed, and technical expertise directly impact time-to-market. Our specialized manufacturing ecosystem targets engineering teams and product developers who require rapid iteration of complex, tight-tolerance components in quantities typically ranging from 1 to 500 units. Unlike high-volume production facilities constrained by long setup cycles and minimum order commitments, Honyo’s agile infrastructure leverages advanced 3-, 4-, and 5-axis CNC milling and turning centers to execute small batches without compromising on geometric complexity or material integrity.

We maintain rigorous process control across aerospace alloys, medical-grade stainless steels, engineering plastics, and exotic composites, consistently achieving tolerances down to ±0.005mm. This capability is critical for validation testing, pre-production runs, and field-deployable prototypes where functional performance must mirror end-use conditions. Crucially, our integration of digital workflow systems eliminates traditional quoting bottlenecks. The Honyo Online Instant Quote platform enables engineers to upload CAD files, define material and finish specifications, and receive a validated production cost and lead time within minutes—not days—accelerating procurement cycles for time-sensitive development phases.

Partner with Honyo Prototype to transform design iterations into high-fidelity physical assets with manufacturing intelligence built into every process step.

Material & Tolerance Performance Summary

| Material Category | Example Alloys/Polymers | Standard Tolerance Range | Critical Feature Capability |

|————————|——————————-|————————–|—————————–|

| Aerospace Metals | 7075-T6, Ti-6Al-4V, Inconel 718 | ±0.005mm to ±0.025mm | Thin walls (<0.5mm), deep cavities |

| Medical-Grade | 316LVM, PEEK, ULTEM 1010 | ±0.003mm to ±0.015mm | Surface roughness Ra ≤ 0.8μm |

| Engineering Plastics | Delrin 150, Nylon 6/6, PTFE | ±0.025mm to ±0.075mm | Snap-fit geometries, sealing surfaces |

Technical Capabilities

Low volume machining refers to the production of parts in limited quantities, typically ranging from 1 to 500 units, and is ideal for prototyping, bridge production, or specialized components. This process emphasizes flexibility, precision, and rapid turnaround. 3-axis, 4-axis, and 5-axis CNC milling, along with CNC turning, are commonly employed to achieve complex geometries and tight tolerances. These methods support a wide range of engineering-grade materials including aluminum, steel, ABS, and nylon.

The following table outlines the technical specifications for low volume machining across key parameters:

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Axes of Motion | X, Y, Z | X, Y, Z, A (rotary) | X, Y, Z, A, B (dual rotary) | X, Z (rotating chuck) |

| Typical Applications | Flat surfaces, prismatic parts | Indexed angled features | Complex contours, organic shapes | Cylindrical parts, shafts, bushings |

| Tight Tolerance Capability | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) |

| Surface Finish (Typical) | Ra 0.8 – 3.2 µm | Ra 0.8 – 3.2 µm | Ra 0.4 – 1.6 µm | Ra 0.8 – 1.6 µm |

| Setup Time | Low | Moderate | High | Low to Moderate |

| Lead Time (Typical) | 3–7 days | 5–10 days | 7–14 days | 3–7 days |

| Material Compatibility | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon |

| Aluminum (e.g., 6061, 7075) | Excellent machinability, high MRR | Suitable for complex features | Ideal for aerospace and high-precision parts | High-speed turning with excellent finish |

| Steel (e.g., 4140, 1018) | Good; slower speeds, rigid setup | Suitable with proper tooling | High precision with multi-angle access | Excellent for high-strength shafts |

| ABS | Easy to machine, low melting point | Suitable for prototypes | Limited use due to softness | Suitable for non-structural components |

| Nylon (e.g., PA6, PA66) | Requires sharp tools, low heat | Machinable with care | Possible with controlled parameters | Common for wear-resistant parts |

| Key Advantages | Cost-effective, fast setup | Added angular access without manual repositioning | Full contouring, minimal setups | High precision on rotational parts |

Tight tolerances down to ±0.005 mm are routinely maintained across all processes with proper process control, tooling, and environmental stability. Material selection is critical—aluminum and steel offer superior dimensional stability and are preferred for high-precision components, while ABS and nylon are used for lightweight, non-load-bearing, or insulative applications where tight tolerances are still required but mechanical performance is secondary.

From CAD to Part: The Process

CAD Upload and System Integration

Clients initiate the process by uploading native CAD files or industry-standard neutral formats such as STEP IGES or Parasolid to Honyo’s secure customer portal. Our system automatically validates file integrity checks geometric completeness and confirms adherence to minimum feature size requirements for precision machining. This step ensures no manual back-and-forth for basic compatibility issues reducing initial processing latency by up to 72 hours compared to traditional quoting methods.

AI-Powered Quoting Engine

Uploaded designs are processed through Honyo’s proprietary AI quoting platform which analyzes 350+ geometric and material parameters in under 90 seconds. The engine cross-references real-time data on machine availability material costs and labor rates across our network of 120+ CNC centers. Unlike generic quoting tools our AI incorporates historical data from 18 000+ successfully manufactured low-volume parts to predict manufacturability risks and optimize cost structures. Clients receive a granular quote detailing unit pricing setup fees and a confidence score for on-time delivery.

Engineering-Led DFM Analysis

All quotes trigger a mandatory Design for Manufacturability review conducted by Honyo’s application engineers using Siemens NX software. This phase identifies cost drivers such as non-standard tolerances internal radii below 0.5mm or features requiring secondary operations. Engineers collaborate directly with clients via secure video review sessions to propose actionable modifications—typically reducing part cost by 15-30% while maintaining functional requirements. Critical modifications undergo GD&T validation using metrology-grade simulation before approval.

Precision Production Execution

Approved designs move to production on dedicated low-volume cells featuring HAAS DM/VM series 5-axis mills and DMG MORI lathes with Y-axis capability. Each job receives a unique digital twin tracking material lot numbers toolpath verification and in-process CMM checks at defined milestones. For volumes under 50 parts we implement single-setup manufacturing to eliminate rework; for runs of 50-500 parts we deploy modular fixturing systems enabling batch processing without recalibration. All operations comply with ISO 9001:2015 and AS9100D aerospace standards.

Quality-Controlled Delivery

Final inspection includes first-article reporting per AS9102B with full FAI documentation and batch-specific material certificates. Parts undergo non-destructive testing including coordinate measuring machine validation for critical dimensions and surface roughness verification. Honyo ships via climate-controlled logistics partners with real-time GPS tracking and tamper-evident packaging designed for fragile prototypes. Typical lead times from CAD upload to delivery are summarized below:

| Volume Range | Typical Lead Time | Quality Documentation Included |

|---|---|---|

| 1-10 parts | 5-8 business days | FAI report CMM data |

| 11-50 parts | 8-12 business days | FAI report batch CMM summary |

| 51-500 parts | 12-18 business days | Full PPAP Level 3 documentation |

This integrated workflow ensures Honyo delivers machined components with 99.2% on-time delivery performance while maintaining a first-pass yield rate exceeding 97% across low-volume production programs.

Start Your Project

Looking for reliable low volume machining solutions tailored to your prototyping and small batch production needs? Honyo Prototype delivers precision CNC machining with fast turnaround times, ideal for product development and limited production runs.

Our Shenzhen-based factory combines advanced manufacturing technology with strict quality control to ensure your parts meet exact specifications. Whether you’re iterating prototypes or scaling to low volume production, we provide cost-effective, scalable solutions with materials and finishes to match your requirements.

Contact Susan Leo today to discuss your project. Email [email protected] for a quick response and technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.