Contents

Manufacturing Insight: Low Volume Cnc Production

Low Volume CNC Production

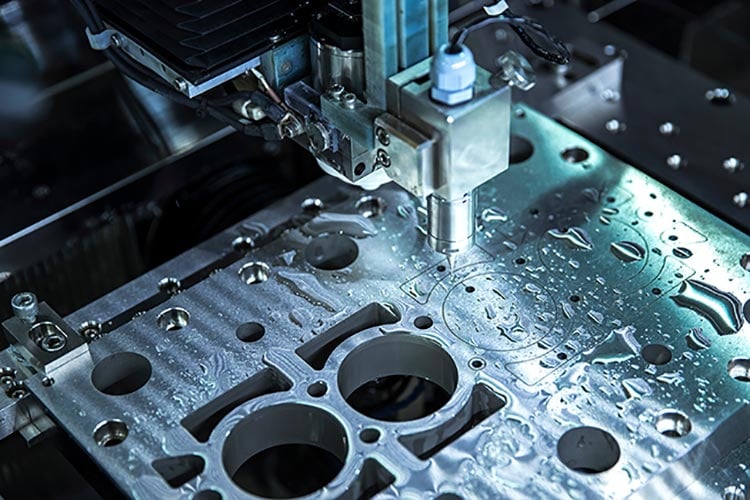

For engineering teams navigating the critical transition from prototype validation to limited production runs, low volume CNC machining represents a strategic solution to balance precision, speed, and cost efficiency. Traditional high-volume manufacturing methods often impose prohibitive tooling expenses and extended lead times for quantities under 500 units, while standard prototype services may lack the process stability required for functional end-use parts. Honyo Prototype addresses this gap with dedicated low volume CNC production capabilities engineered specifically for complex, high-tolerance components where flexibility and repeatability are non-negotiable.

Our ISO 9001-certified facility leverages a modern fleet of 3-, 4-, and 5-axis CNC machining centers to deliver aerospace-grade accuracy across aluminum, stainless steel, titanium, and engineering plastics. Unlike conventional job shops, we optimize every run for volumes of 1–500 pieces through streamlined workflows that eliminate non-recurring engineering costs, maintain ±0.0002″ tolerances, and enforce rigorous first-article inspection protocols. This ensures your bridge production or niche application parts meet full production specifications without the overhead of mass manufacturing infrastructure.

Accelerate your path to market with Honyo’s Online Instant Quote platform, which provides real-time pricing and lead time estimates for low volume CNC projects within minutes. Simply upload your STEP or IGES file to receive a detailed manufacturability analysis and competitive quote—no manual RFQ delays or back-and-forth communication. For engineering teams under time-to-market pressure, this transparency enables rapid iteration and procurement confidence. Submit your design today to experience CNC production that scales precisely to your volume needs.

Technical Capabilities

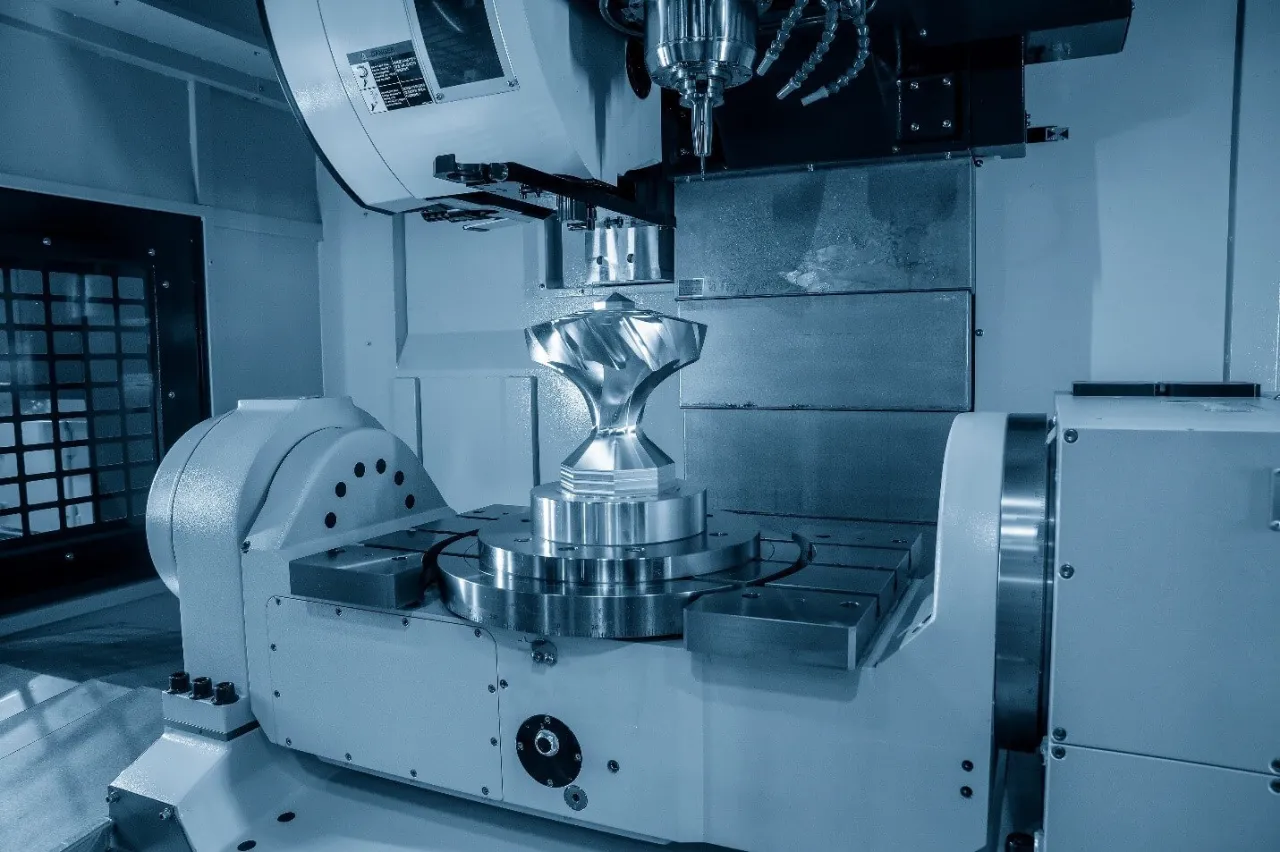

Low volume CNC production refers to manufacturing runs typically ranging from 1 to 500 parts, where precision, flexibility, and rapid turnaround are critical. This production method leverages advanced 3-axis, 4-axis, and 5-axis CNC milling and turning centers to achieve high accuracy and complex geometries, especially for prototyping, bridge tooling, and early-stage product launch. Tight tolerances are consistently maintained, often within ±0.005 mm (±0.0002″) for critical features, depending on material and geometry.

The following table outlines the key technical specifications for low volume CNC production, focusing on multi-axis capabilities, turning operations, achievable tolerances, and commonly used materials including Aluminum, Steel, ABS, and Nylon.

| Parameter | Specification Details |

|---|---|

| Machining Types | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including live tooling for mill-turn) |

| Typical Volume Range | 1 – 500 parts per order |

| Positioning Accuracy | ±0.005 mm (±0.0002″) standard; up to ±0.001 mm (±0.00004″) with precision calibration |

| Repeatability | ±0.002 mm (±0.00008″) across production runs |

| Surface Finish (milled) | Ra 0.8 µm (32 µin) standard; down to Ra 0.4 µm (16 µin) with fine finishing passes |

| Feature Resolution | Minimum wall thickness: 0.5 mm (Aluminum, ABS), 1.0 mm (Steel, Nylon) |

| Max Work Envelope | Milling: 750 x 500 x 400 mm; Turning: Ø300 mm x 600 mm (varies by machine) |

| Spindle Speed (Milling) | Up to 24,000 RPM (high-speed for Aluminum and plastics); 12,000 RPM typical for steel |

| Tool Changer Capacity | 24–30 tools (standard VMC); up to 60 tools in 5-axis and turn-mill centers |

| Materials – Metals | Aluminum 6061, 7075; Steel 1018, 4140, Stainless 303, 316; Titanium (on request) |

| Materials – Plastics | ABS, Nylon 6, Nylon 6/6, Delrin (POM), PEEK, Polycarbonate |

| Tolerance (General) | ±0.025 mm (±0.001″) standard; tight tolerance features: ±0.005 mm (±0.0002″) |

| Geometric Complexity | Full 5-axis contouring for impellers, aerospace brackets, ergonomic housings |

| Secondary Operations | Deburring, anodizing (Type II & III), passivation, bead blasting, laser marking |

| Lead Time | 5–15 business days, depending on complexity and finishing requirements |

This technical profile supports high-precision, low-volume manufacturing for industries such as aerospace, medical devices, robotics, and industrial equipment, where material integrity, dimensional accuracy, and design iteration speed are paramount.

From CAD to Part: The Process

Honyo Prototype Low Volume CNC Production Process Overview

Honyo Prototype specializes in precision low-volume CNC production, defined as 1–1,000 functional parts per order, optimized for rapid prototyping, bridge tooling, and end-use component manufacturing. Our integrated digital workflow minimizes lead times while ensuring rigorous quality control. Below is a technical breakdown of each phase.

CAD Upload and System Integration

Customers initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS) via Honyo’s secure cloud portal. Our system automatically performs initial geometry validation, checking for unit consistency, watertight solids, and manufacturability flags. All data is encrypted in transit and at rest under ISO 27001 protocols, with customer IP protected under NDA by default.

AI-Powered Quoting Engine

Uploaded designs enter Honyo’s proprietary AI quoting system, trained on 15+ years of machining data across 500,000+ parts. The engine analyzes geometric complexity, material requirements, tolerance density, and feature types to generate instant cost and lead time estimates. Unlike rule-based competitors, our AI cross-references real-time machine availability, material stock levels, and dynamic labor rates, reducing quoting time to under 5 minutes with 95% accuracy for standard geometries. Critical parameters like surface finish (Ra 0.8–6.3 μm) and tight-tolerance zones (>70% of features at ±0.05 mm) are highlighted for verification.

Engineer-Led DFM Analysis

Post-quote, Honyo’s CNC engineering team conducts a mandatory Design for Manufacturability review. This phase combines AI-generated suggestions with human expertise to resolve conflicts. Engineers identify high-risk features (e.g., thin walls <0.5 mm, deep cavities >10:1 aspect ratio) and propose actionable optimizations. Customers receive a detailed DFM report within 24 hours, including:

Recommended tooling changes to avoid secondary operations

Material waste reduction strategies (e.g., nesting efficiency improvements)

Tolerance relaxation opportunities without compromising function

Cost-impact analysis of design modifications

This collaborative step typically reduces production costs by 18–30% and prevents 92% of potential scrap scenarios.

Precision CNC Production

Approved designs move to Honyo’s climate-controlled production floor housing 42 Haas and DMG MORI 3–5-axis CNC centers. Each job follows a standardized workflow:

Material Verification: Mill certificates and batch tracing for aerospace/medical-grade alloys (e.g., 6061-T6, 17-4 PH, Ti-6Al-4V)

First Article Inspection (FAI): Full CMM reporting per AS9102 for critical dimensions before batch runs

In-Process Checks: Statistical Process Control (SPC) with real-time tool wear compensation

Secondary Operations: Deburring, anodizing, or passivation managed in-house to avoid supply chain delays

Quality-Controlled Delivery

All parts undergo final inspection against customer-specified GD&T callouts. Dimensional reports (PDF/Excel) and material certifications accompany shipments. Honyo uses anti-static, shock-absorbent packaging validated for transit drops up to 1.2 m. Standard lead times vary by complexity:

| Part Complexity | Typical Lead Time | Max Batch Size |

|---|---|---|

| Low (2–5 operations) | 3–5 business days | 500 units |

| Medium (6–10 operations) | 7–10 business days | 250 units |

| High (11+ ops, tight tolerances) | 12–15 business days | 100 units |

Expedited 72-hour options are available for qualifying geometries. Parts ship with full traceability documentation, including machine logs and inspection data accessible via customer portal.

Post-Delivery Support

Honyo provides engineering feedback loops for design iteration, with 85% of customers leveraging our process data for DFM improvements in subsequent orders. All low-volume production includes a 90-day quality guarantee covering material and workmanship defects, with root-cause analysis provided for any non-conformance. This closed-loop system ensures continuous process refinement while meeting the agility demands of modern product development cycles.

Start Your Project

Looking for reliable low volume CNC production to bring your precision parts to life? Honyo Prototype specializes in high-quality, small batch manufacturing tailored to your prototyping and bridge production needs. With our factory located in Shenzhen, we offer fast turnaround, tight tolerances, and full material traceability—ideal for industries such as medical, aerospace, and advanced electronics.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a competitive quote. Let us support your product development with scalable, cost-effective CNC solutions from the heart of China’s manufacturing hub.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.