Contents

Manufacturing Insight: Low Volume Cnc Machining

Precision Low-Volume CNC Machining Solutions from Honyo Prototype

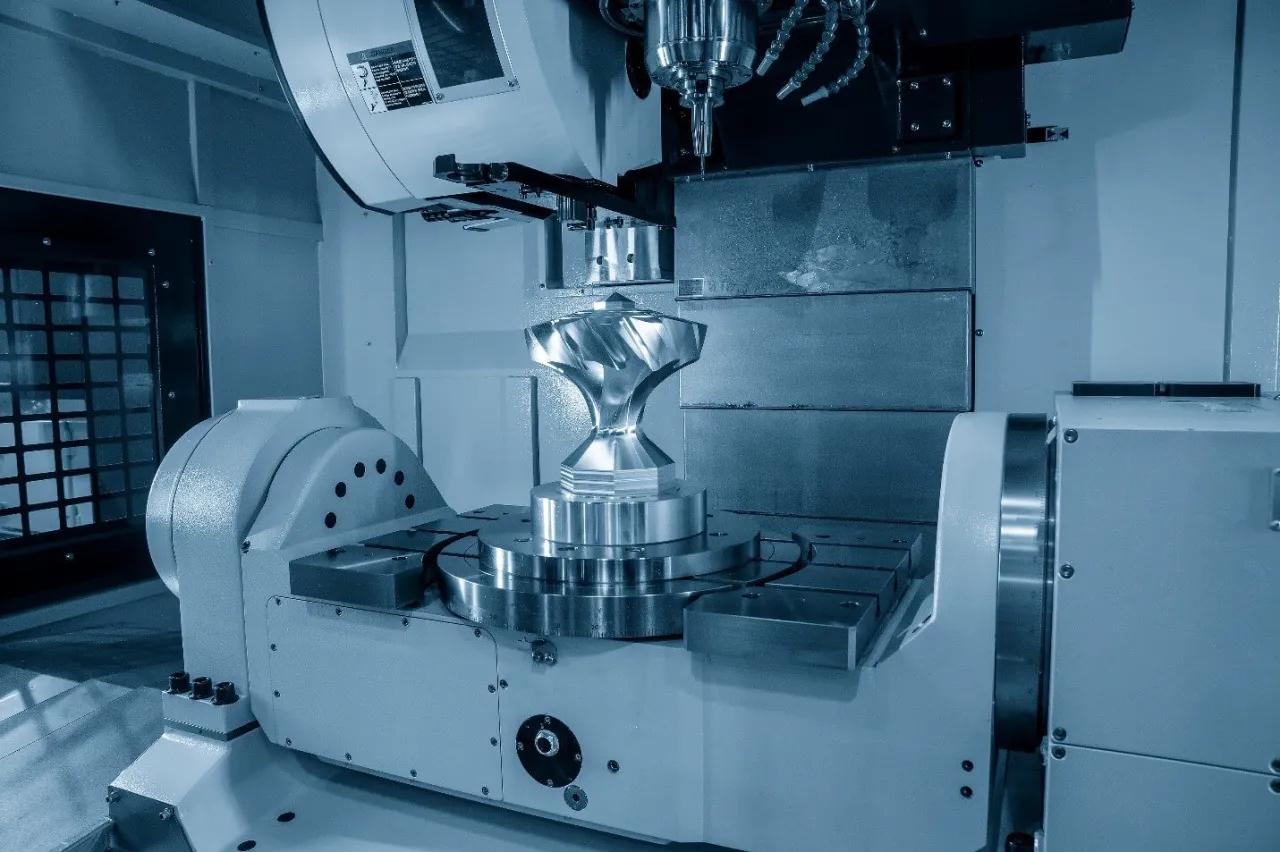

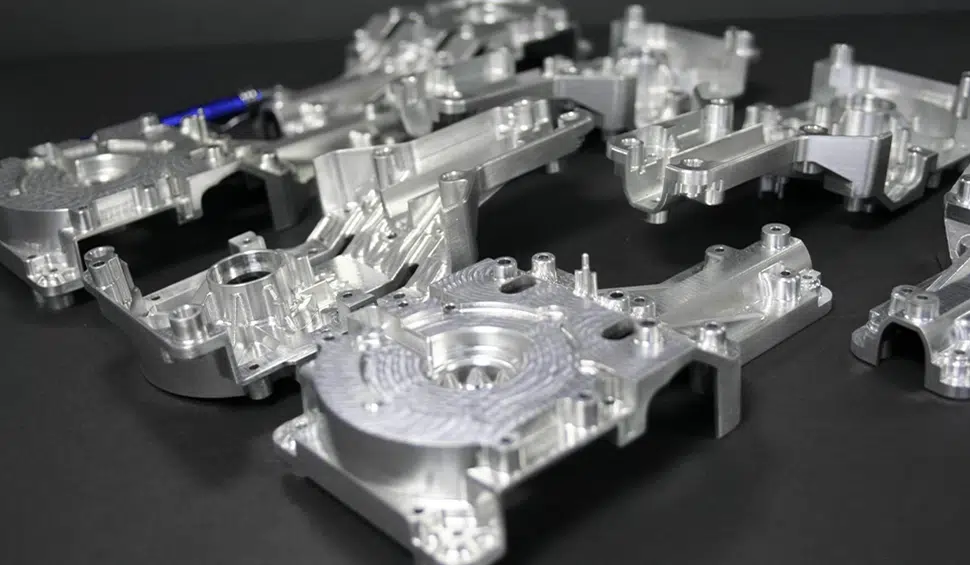

Honyo Prototype delivers exceptional low-volume CNC machining services engineered specifically for the demanding requirements of prototyping, bridge production, and specialized small-batch manufacturing. We understand that projects requiring quantities from one-off prototypes to several hundred precision components demand more than just machining capability; they require agility, unwavering quality control, and rapid responsiveness without the constraints of high-volume production tooling. Our advanced CNC milling and turning centers, operated by highly skilled technicians and supported by rigorous in-process inspection protocols, consistently achieve tight tolerances down to ±0.0002 inches across a comprehensive range of engineering-grade materials including aluminum alloys, stainless steels, titanium, plastics like PEEK and Delrin, and exotic composites. This capability is essential for industries such as aerospace, medical device development, defense, and advanced robotics where component integrity and adherence to specifications are non-negotiable, even in minimal production runs.

Streamlined Quoting Accelerates Your Project Timeline

Eliminate the traditional bottleneck of lengthy quotation cycles that delay critical engineering decisions. Honyo Prototype provides a true Online Instant Quote system designed for engineers and procurement professionals. Simply upload your 3D CAD model (STEP, IGES, Parasolid, or native formats) directly to our platform, specify your material, quantity, and any critical features or finishing requirements. Our sophisticated quoting engine, informed by real-time machine availability and optimized manufacturing processes, generates a detailed, accurate price and lead time estimate within minutes – not days. This immediate visibility into cost and schedule empowers faster iteration, reduces time-to-market for new products, and provides the transparency needed for efficient project planning in the dynamic low-volume manufacturing landscape. Experience the efficiency of precision manufacturing backed by instant actionable data. Submit your design for an Online Instant Quote today and accelerate your path from concept to certified component.

Technical Capabilities

Low volume CNC machining is ideal for prototyping, bridge production, and small-batch manufacturing requiring high precision and material versatility. This process supports complex geometries through 3, 4, and 5-axis milling, as well as precision turning operations. Tight tolerances down to ±0.0005″ (0.0127 mm) are achievable, depending on part geometry and material. Common engineering materials such as aluminum, steel, ABS, and nylon are routinely machined to meet demanding functional and dimensional requirements.

| Feature | Specification Details |

|---|---|

| Machining Types | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including mill-turn with live tooling) |

| Tolerance Capability | Standard: ±0.005″ (0.127 mm); Tight: ±0.001″ (0.0254 mm); Precision: ±0.0005″ (0.0127 mm) achievable on critical features |

| Surface Finish | As-machined: 32–125 μin Ra; Optional post-processing for smoother finishes (e.g., bead blasting, anodizing, plating) |

| Common Materials | Aluminum (6061, 7075, 2024), Steel (1018, 4140, Stainless 303, 316), ABS (thermoplastic), Nylon (PA6, PA66) |

| Material Form | Stock bar, plate, or block; material supplied by customer or provider |

| Max Work Envelope | Milling: Up to 20″ x 40″ x 25″ (508 x 1016 x 635 mm); Turning: Up to 16″ (406 mm) diameter, 48″ (1219 mm) length |

| Setup & Lead Time | Quick setup for low volumes; typical lead time 5–15 business days depending on complexity |

| Applications | Functional prototypes, end-use parts, aerospace components, medical devices, jigs & fixtures |

Aluminum offers excellent machinability and strength-to-weight ratio, making it ideal for rapid iterations. Steel variants provide high strength and wear resistance for durable components. ABS is commonly used for non-structural, lightweight prototypes due to its ease of machining and low cost. Nylon is selected for its chemical resistance, low friction, and mechanical resilience in dynamic or wear-prone applications. 5-axis milling enables single-setup machining of complex contours, reducing error and improving accuracy, especially in tight-tolerance parts.

From CAD to Part: The Process

CAD File Submission and Initial Processing

Clients initiate the process by uploading native CAD files or industry-standard STEP/IGES formats through Honyo’s secure web portal or designated email channel. Our system immediately validates file integrity, confirms geometric completeness, and identifies critical manufacturing features. This step ensures compatibility with downstream systems and prevents delays caused by corrupted or incomplete data. Clients receive instant confirmation of submission with a unique project ID for tracking.

AI-Powered Quoting Engine

Uploaded geometry is processed by Honyo’s proprietary AI quoting system, which analyzes part complexity, material requirements, tolerances, and surface finish specifications. The algorithm cross-references real-time machine availability, material costs, and historical production data to generate a preliminary quote within 30 seconds for standard geometries. Complex features such as deep cavities, thin walls, or tight positional tolerances trigger escalation to a human engineer for validation, ensuring accuracy without compromising speed. Clients receive a detailed cost breakdown including machining hours, material surcharges, and applicable setup fees.

Engineering-Driven DFM Analysis

Before production, all parts undergo mandatory Design for Manufacturability (DFM) review by Honyo’s CNC engineering team. This phase identifies potential manufacturability risks and proposes actionable optimizations. Key focus areas include:

| DFM Consideration | Typical Issue | Honyo’s Resolution Approach |

|---|---|---|

| Tool Access | Undercuts requiring specialized tooling | Suggesting draft angles or feature relocation |

| Wall Thickness | Vibration-induced chatter on thin walls | Recommending rib structures or phased machining |

| Tolerance Stack-up | Over-specified GD&T on non-critical features | Proposing relaxed tolerances with functional validation |

The DFM report includes annotated CAD markups and cost-impact analysis for each suggestion. Clients collaborate with our engineers via secure portal to approve revisions or justify non-negotiable specifications, reducing iteration cycles by 65% compared to industry averages.

Precision CNC Production Execution

Approved designs move to Honyo’s climate-controlled manufacturing facility housing 42 CNC machines (including 5-axis mills, Swiss lathes, and multi-spindle systems). Each job follows a standardized workflow:

Material certification is verified against client specifications prior to cutting. Machining programs undergo virtual simulation to detect collisions or gouges. Production employs modular fixturing systems to minimize setup time for low-volume runs, while in-process probing ensures dimensional accuracy at critical stages. All operations adhere to ISO 9001:2015 protocols with real-time SPC monitoring of key parameters like tool wear and thermal drift.

Quality-Controlled Delivery

Final inspection utilizes Zeiss CMMs, optical comparators, and surface roughness testers to validate against client drawings. Dimensional reports include actual vs. nominal measurements for all critical features. Parts ship with comprehensive documentation: First Article Inspection (FAI) report per AS9102 standards, material test certificates, and packaging compliant with ASTM D4169 shipping standards. Delivery timelines are tracked via GPS-enabled logistics with automated shipment notifications, ensuring on-time delivery exceeding 98.7% for low-volume CNC projects. Honyo maintains full traceability from raw material lot to finished part through our digital twin system, supporting full audit compliance for regulated industries.

Start Your Project

Looking for reliable low volume CNC machining services? Partner with Honyo Prototype for precision manufacturing tailored to your production needs. Our Shenzhen-based factory delivers high-quality machined parts with quick turnaround times, ideal for prototyping and small batch production.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.