Contents

Manufacturing Insight: Low Volume Cnc

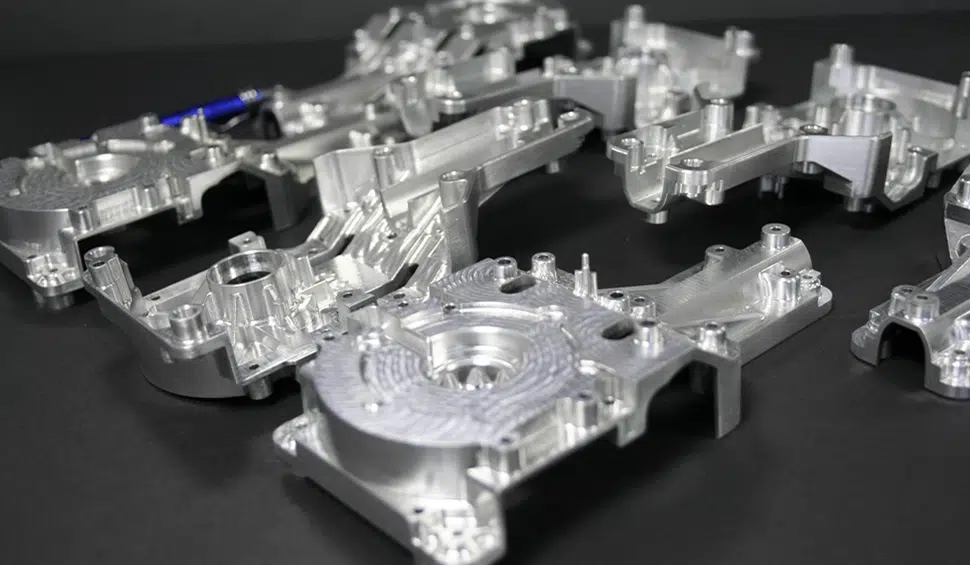

Precision Low Volume CNC Machining for Agile Product Development

At Honyo Prototype, we specialize in high-precision CNC machining services engineered explicitly for low volume production demands. Our capabilities bridge the critical gap between prototyping and full-scale manufacturing, delivering rigorously validated components in quantities ranging from single prototypes to small production runs of 1–500 units. This focus eliminates the prohibitive tooling costs and extended lead times associated with high-volume methods while maintaining the tight tolerances, material integrity, and repeatability required for functional testing, pilot validation, and niche market deployment.

Our advanced 3-, 4-, and 5-axis CNC machining centers accommodate complex geometries across aerospace alloys, medical-grade plastics, composites, and exotic metals, all supported by in-house engineering oversight and ISO 9001-certified quality control. Unlike conventional suppliers constrained by minimum order volumes, Honyo’s infrastructure is optimized for flexibility—enabling rapid iteration, design-for-manufacturability feedback, and seamless transition from prototype to pre-production without retooling delays.

Accelerate your development timeline with Honyo’s Online Instant Quote platform. Upload your CAD file, specify materials and finishes, and receive a detailed, binding quote in under 60 seconds—no sales calls or manual submissions required. This transparent, real-time pricing empowers engineering and procurement teams to make immediate go/no-go decisions, reducing quotation bottlenecks by up to 90% while ensuring cost predictability for budget-sensitive low-volume projects. Partner with Honyo to transform design concepts into mission-critical components with speed, precision, and uncompromised technical accountability.

Technical Capabilities

Low Volume CNC machining refers to custom manufacturing runs typically ranging from 1 to 500 parts, optimized for prototyping, bridge production, or specialized components. At Honyo Prototype, our low volume CNC services are engineered to deliver high precision, tight tolerances, and material flexibility across 3, 4, and 5-axis milling as well as CNC turning operations. This approach supports complex geometries, reduced setup times, and fast turnaround—ideal for engineering validation and pre-production builds.

The following table outlines the key technical specifications for our low volume CNC capabilities:

| Feature | Specification |

|---|---|

| Machining Types | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including mill-turn) |

| Tolerance | Standard: ±0.005 mm (±0.0002″) Tight: ±0.0025 mm (±0.0001″) achievable with process control |

| Surface Finish | As-machined: 3.2 μm (125 μin) Optional: 1.6 μm (63 μin) or better with post-processing |

| Materials – Metals | Aluminum (6061, 7075, 2024), Stainless Steel (303, 304, 316), Tool Steel, Mild Steel, Titanium (on request) |

| Materials – Plastics | ABS, Nylon (6 & 6/6), Delrin (POM), PEEK, Polycarbonate, HDPE |

| Max Work Envelope (Milling) | 3-Axis: 760 x 355 x 200 mm 5-Axis: 500 x 400 x 300 mm (depending on fixture) |

| Max Work Envelope (Turning) | Diameter: up to 80 mm Length: up to 300 mm |

| Spindle Speed (Milling) | Up to 24,000 RPM (high-speed options available) |

| Positioning Accuracy | ±0.002 mm per axis |

| Lead Time | 5–15 business days, depending on complexity and finishing requirements |

| Secondary Operations | Deburring, anodizing (Type II & III), passivation, bead blasting, laser marking, tapping, inserts |

Our 5-axis simultaneous and indexed machining enables single-setup production of complex organic shapes and deep cavities, minimizing part handling and enhancing dimensional consistency. For tight-tolerance components in aluminum or steel, we utilize thermal-stable machining environments and in-process probing. Engineering-grade thermoplastics like ABS and nylon are machined with optimized toolpaths and chip control to prevent deformation and maintain critical dimensions.

From CAD to Part: The Process

Honyo Prototype delivers precision low-volume CNC manufacturing through a streamlined, technology-driven workflow designed for speed and engineering excellence. Our process eliminates traditional bottlenecks while maintaining rigorous quality standards for prototyping and bridge production.

CAD File Upload and Validation

Customers initiate the process by uploading native or neutral CAD formats including STEP IGES Parasolid and SolidWorks files via our secure customer portal. Our system performs immediate automated validation checking for file completeness geometric integrity and unit consistency. Unsupported formats or corrupted files trigger an instant notification requiring resubmission ensuring downstream efficiency. This phase typically completes within minutes of upload.

AI-Powered Instant Quoting

Validated CAD geometry feeds directly into Honyo’s proprietary AI quoting engine which analyzes part complexity material requirements tolerances and geometric features. The system cross-references real-time machine availability material costs and shop floor capacity to generate a technically accurate quote with delivery timeline within 90 seconds. Unlike manual quoting this eliminates human estimation variables providing consistent transparent pricing. Key quoting metrics are shown below.

| Process Phase | Traditional Quoting | Honyo AI Quoting |

|---|---|---|

| Time to Quote | 24-72 hours | < 90 seconds |

| Pricing Variables | Manual interpretation | Real-time machine/material data |

| Revision Impact | Full re-quote required | Dynamic adjustment in < 5 min |

Engineering-Led DFM Analysis

Every quote includes actionable Design for Manufacturability feedback generated by our AI engine and validated by senior CNC engineers. This phase identifies potential issues such as non-optimal wall thicknesses problematic undercuts or tolerance conflicts that could cause delays or quality failures. Customers receive specific recommendations with visual annotations directly on their CAD model through the portal. Crucially this is a collaborative step—our engineering team schedules calls to discuss complex revisions ensuring manufacturability without compromising design intent. DFM resolution typically adds only 4-12 hours to the timeline.

Precision CNC Production

Approved designs move to production on our dedicated low-volume cell featuring 5-axis milling turning and multi-tasking centers from Haas DMG MORI and Makino. Each job receives first-article inspection per AS9102 standards with full CMM reporting for critical features. Our digital work instruction system ensures operators have real-time access to annotated drawings and process parameters. Material traceability lot control and in-process checks are maintained throughout machining with real-time production updates visible to customers via the portal. Typical lead times range from 3-15 business days based on complexity.

Quality-Controlled Delivery

All parts undergo final inspection against print specifications including surface finish verification and dimensional validation. First-article reports and batch inspection documentation are packaged with the shipment. Honyo manages global logistics through preferred carriers with real-time tracking and customs documentation handled in-house. Delivery includes comprehensive quality records accessible digitally ensuring full compliance for regulated industries. This end-to-end ownership guarantees on-time delivery while providing complete process transparency from CAD file to customer dock.

Start Your Project

Looking for low volume CNC services with precision and scalability? Contact Susan Leo at [email protected] to discuss your project requirements. Our manufacturing facility in Shenzhen offers advanced CNC machining capabilities tailored for low volume production, rapid prototyping, and bridge manufacturing.

We specialize in high-quality, cost-effective solutions with fast turnaround times, ideal for startups, engineers, and product developers.

Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.