Contents

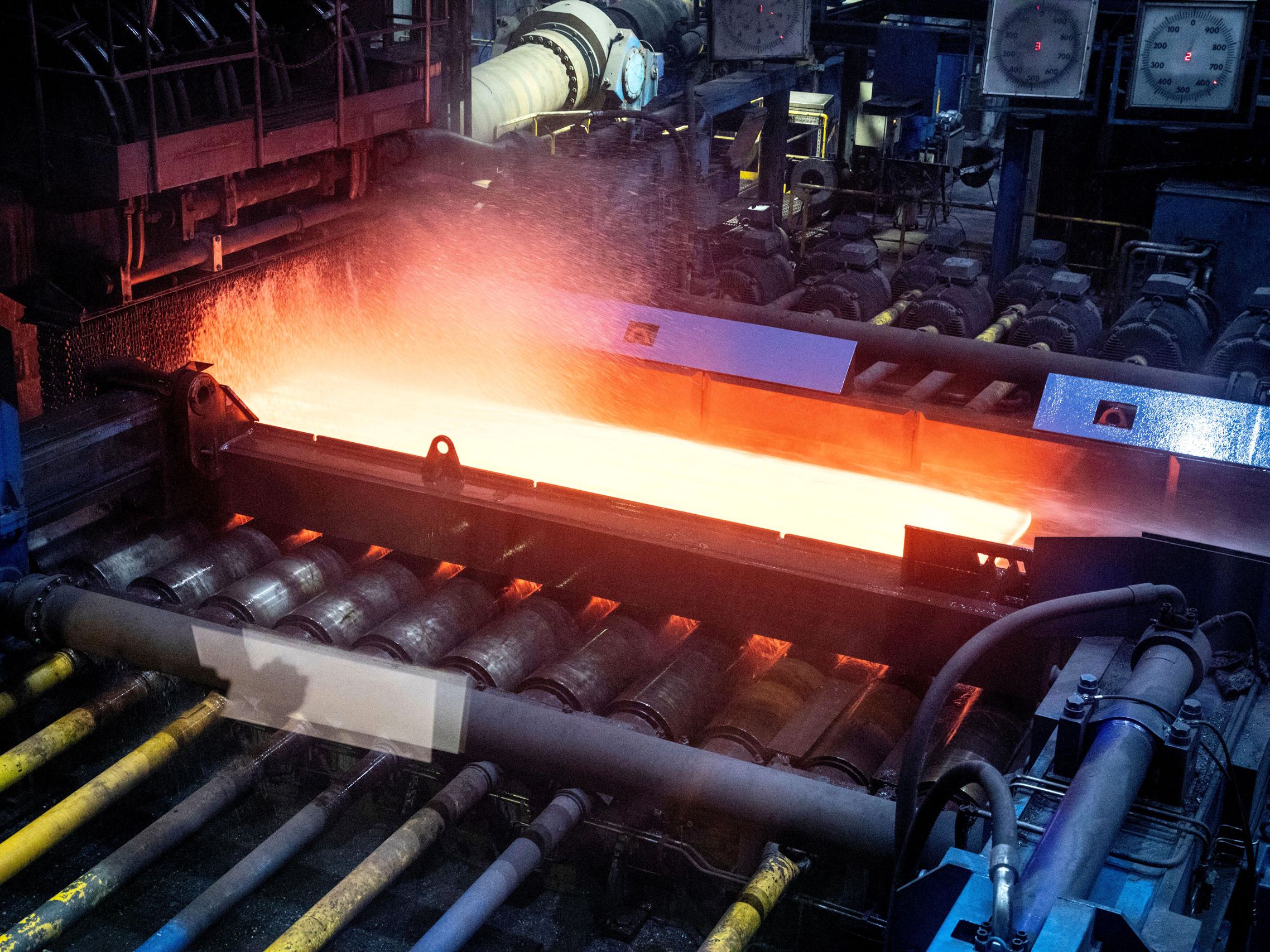

Manufacturing Insight: Low Re Carbon Steel

Precision Low Carbon Steel Machining for Critical Prototypes

Low carbon steel remains a cornerstone material for functional prototypes and low-volume production due to its optimal balance of machinability, weldability, and cost efficiency. At Honyo Prototype, we specialize in CNC machining low carbon steel grades—including 1018, 1020, and 12L14—with rigorously controlled processes to ensure dimensional stability, superior surface finishes, and consistent mechanical properties. Our expertise addresses common challenges such as burr formation, thermal distortion, and material galling through optimized toolpaths, precision coolant management, and in-process metrology.

Engineered for Prototyping Excellence

Honyo’s CNC milling and turning capabilities deliver tight tolerances down to ±0.005 mm on low carbon steel components, critical for applications in automotive, aerospace, and industrial machinery where form, fit, and fatigue resistance are non-negotiable. We implement ISO 2768 medium tolerance standards as a baseline, with optional GD&T compliance for complex geometries. Our facility leverages HAAS and DMG MORI machines with high-speed spindles to minimize cycle times while maintaining repeatability, ensuring your prototype performs identically to final production intent.

Accelerate Your RFQ Cycle with Online Instant Quote

Reduce prototyping lead times from days to hours using Honyo’s Online Instant Quote system. Simply upload your STEP or IGES file, specify low carbon steel requirements, and receive a detailed manufacturing assessment—including DFM feedback, material certification options, and expedited shipping estimates—within minutes. This transparent, real-time quoting engine eliminates procurement bottlenecks while providing actionable insights to refine designs before machining begins.

Partner with Honyo Prototype to transform low carbon steel designs into high-integrity prototypes with engineering-grade precision and seamless scalability. Initiate your project today through our digital platform and experience the convergence of material science and advanced manufacturing.

Technical Capabilities

Low re carbon steel typically refers to low residual carbon steel, which is a classification sometimes used to describe steels with minimal residual elements and tightly controlled carbon content—often aligned with low-carbon steel grades such as AISI 1008–1020. These materials exhibit excellent machinability, weldability, and formability, making them well-suited for precision CNC machining processes including 3-, 4-, and 5-axis milling and turning operations where tight tolerances (±0.0005″ to ±0.005″) are required.

In high-precision applications, low re carbon steel is often compared to other commonly machined materials such as aluminum, steel (various grades), ABS, and nylon. Each material has distinct mechanical and thermal properties that influence tool selection, cutting parameters, surface finish, and achievable tolerances.

Below is a comparative technical specification table focusing on machinability in multi-axis CNC environments:

| Material | Typical Grades | Tensile Strength (psi) | Hardness (Brinell) | Machinability Rating (%) | Thermal Expansion (in/in/°F ×10⁻⁶) | Common Applications in Precision Machining | Max Achievable Tolerance (± inches) | Notes for 3/4/5-Axis Milling & Turning |

|---|---|---|---|---|---|---|---|---|

| Low Re Carbon Steel | AISI 1008, 1010, 1018, 1020 | 50,000 – 70,000 | 120 – 150 | 70 – 85 | 6.7 | Jigs, fixtures, shafts, housings | 0.0005 – 0.001 | Excellent dimensional stability; moderate tool wear; requires coolant for tight tolerance work |

| Aluminum | 6061-T6, 7075-T6 | 45,000 – 83,000 | 95 – 150 | 90 – 100 | 12.8 | Aerospace components, heat sinks, enclosures | 0.0005 – 0.001 | High metal removal rates; low cutting forces; prone to thermal growth; sticky chip formation |

| Alloy Steel | 4140, 4340 | 100,000 – 160,000 | 200 – 300 | 50 – 65 | 6.5 | High-stress mechanical parts, gears | 0.0005 – 0.002 | Higher tool wear; requires rigid setups; slow speeds for tight tolerances |

| ABS (Thermoplastic) | ABS-M30, ABSplus | 4,000 – 6,000 | 80 – 95 | Not applicable (non-metal) | 50 – 60 | Prototypes, housings, non-structural parts | 0.002 – 0.005 | Low melting point; sharp tools required; minimal clamping force to avoid deformation |

| Nylon (Polyamide) | Nylon 6, Nylon 6/6 | 9,000 – 12,000 | 75 – 85 | Not applicable (non-metal) | 45 – 55 | Insulators, bushings, wear components | 0.002 – 0.005 | Hygroscopic; pre-dry before machining; flexible—requires high spindle speeds and sharp tools |

Key Considerations for Tight Tolerance Machining:

Low re carbon steel performs reliably in multi-axis environments due to its consistent microstructure and low internal stress. When held to tight tolerances, stress relief prior to final machining is recommended. In comparison:

Aluminum offers faster cycle times but is more sensitive to thermal drift.

Alloy steels provide higher strength but increase tooling costs and cycle time.

ABS and nylon are suitable for non-metallic prototypes or functional parts but lack dimensional stability at high precision levels.

For 5-axis milling and turning, low re carbon steel supports complex geometries with good surface finish (typically 32–64 μin Ra) when using carbide tooling and proper coolants. It is often selected when a balance of strength, machinability, and cost is required in production or prototype runs.

From CAD to Part: The Process

Honyo Prototype Low Carbon Steel Manufacturing Process Overview

Honyo Prototype utilizes a streamlined digital workflow for low carbon steel components, specifically engineered for grades such as AISI 1008, 1010, and 1018. This process ensures rapid turnaround while maintaining precision and cost efficiency. Below is a technical breakdown of each phase:

CAD Upload and Material Specification

Clients initiate the process by uploading native or neutral-format CAD files (STEP, IGES, Parasolid) via our secure portal. During upload, material selection is explicitly defined as low carbon steel, with options to specify grade, tolerance class (e.g., ISO 2768-mK), and surface finish requirements. Our system validates geometric integrity and flags unsupported formats immediately, reducing pre-processing delays.

AI-Powered Quoting Engine

Uploaded designs undergo automated analysis through Honyo’s proprietary AI quoting system. The engine evaluates key low carbon steel-specific parameters:

Material density and scrap rate optimization

Machinability factors (e.g., chip control challenges in 1008 due to low carbon content)

Secondary operation costs (welding, plating, or stress-relieving for distortion-prone geometries)

Quotes are generated in under 2 hours, including granular cost breakdowns for material, CNC machining, and finishing. Real-time pricing reflects current steel market indices and mill lead times.

DFM Analysis with Material-Specific Optimization

Engineers conduct a dedicated Design for Manufacturability review focused on low carbon steel’s properties:

Machining Adjustments: Recommending reduced feed rates for 1008/1010 to prevent built-up edge and burring

Weldability Assessment: Flagging designs requiring pre/post-weld heat treatment for 1018 to avoid cold cracking

Tolerance Validation: Adjusting ±0.005″ tolerances to ±0.010″ where residual stresses from cold-rolled stock may cause warpage

Cost-Saving Alternatives: Proposing hot-rolled stock for non-cosmetic parts to eliminate machining allowances

Clients receive annotated DFM reports with actionable revisions, typically within 24 business hours.

Production Execution

Approved designs enter our integrated production ecosystem:

Material Sourcing: Direct procurement from certified mills (e.g., AK Steel, Nucor) with full MTR traceability

Machining: Precision CNC milling/turning using carbide tooling optimized for low-carbon alloys (e.g., TiAlN-coated end mills at 600 SFM)

Process Controls: In-process CMM checks for critical dimensions; post-machining stress relief for parts >500mm

Secondary Operations: Deburring via automated brushing, followed by optional zinc plating or powder coating

Delivery and Documentation

All low carbon steel components undergo final inspection per ASME Y14.5 standards. Shipments include:

Dimensional inspection report with actual vs. nominal measurements

Material test report (MTR) verifying chemical composition and mechanical properties

Certificates of compliance (RoHS, REACH)

Standard lead time is 7–10 business days from DFM approval, with expedited options. Logistics partners provide real-time tracking from our Shenzhen facility to global destinations.

Material-Specific Process Metrics

| Parameter | Low Carbon Steel (1008/1010/1018) | Industry Average |

|——————–|———————————–|——————|

| Machining Speed | 450–650 SFM | 300–500 SFM |

| Typical Tolerance | ±0.008″ | ±0.015″ |

| Post-Machining Distortion | <0.003″ per 100mm | 0.008″ per 100mm |

| Lead Time Reduction| 35% vs. manual quoting | 15–20% |

This closed-loop process leverages material science expertise and digital integration to deliver low carbon steel prototypes and bridge-production parts with repeatable accuracy. Clients gain full visibility via our customer portal, with real-time updates at every workflow stage.

Start Your Project

Looking for low carbon steel solutions tailored to your manufacturing needs? Contact Susan Leo today at [email protected] to discuss your project requirements. With our advanced fabrication capabilities and quality control, Honyo Prototype delivers precision components made from low carbon steel, ideal for applications requiring weldability, formability, and consistent mechanical properties.

Our production facility is located in Shenzhen, China, enabling efficient turnaround and scalable production for prototyping and low-to-mid volume manufacturing. Partner with a team that combines engineering expertise with agile manufacturing.

Reach out to Susan Leo at [email protected] for material specifications, lead times, and project quotations. Let’s build your next component—right, and on time.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.