Contents

Manufacturing Insight: Lost Wax Casting Service

Precision Metal Casting Enhanced by Integrated Manufacturing Capabilities

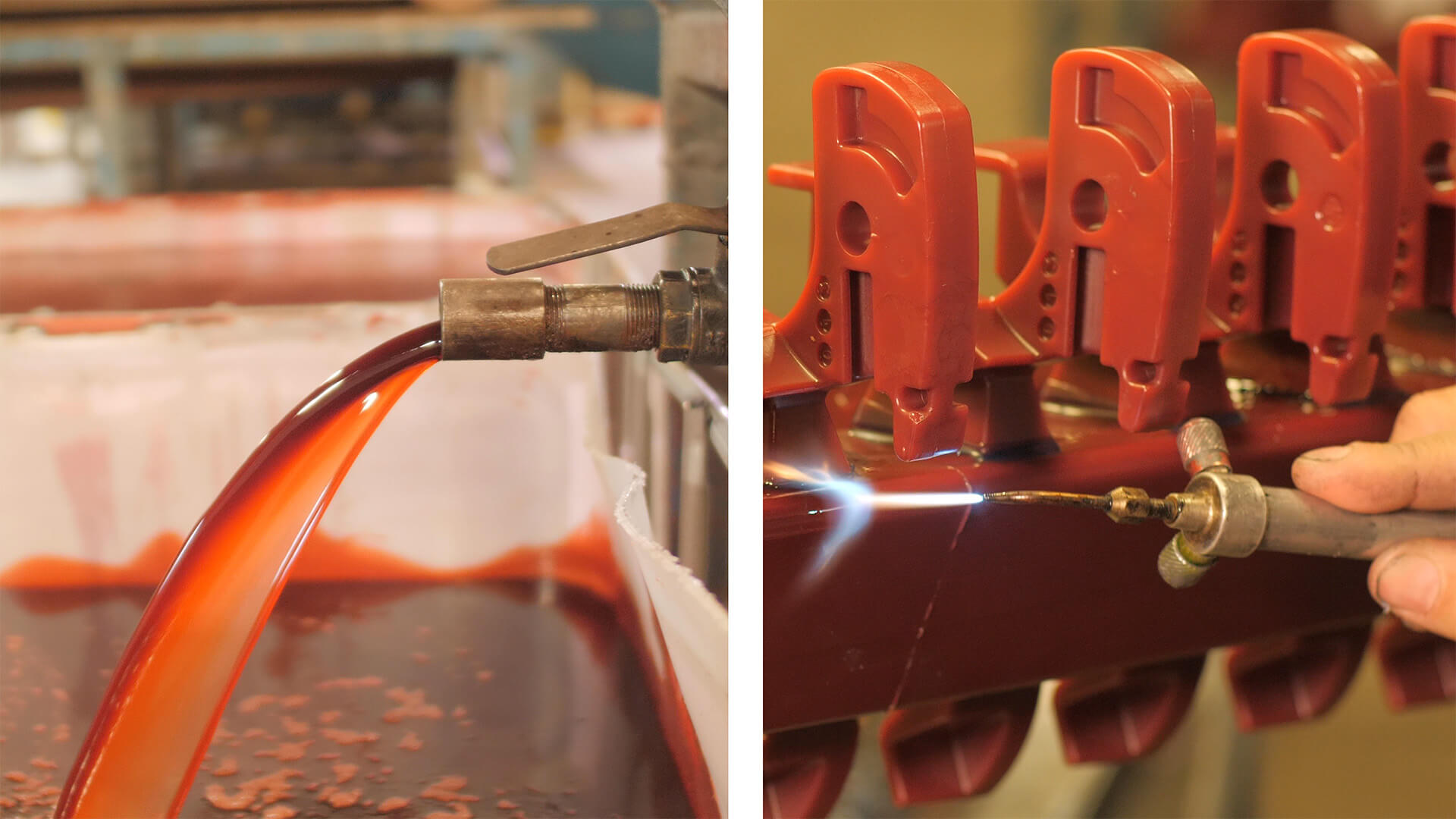

Honyo Prototype delivers industry-leading lost wax casting services for complex, high-integrity metal components across aerospace, medical, and industrial sectors. Our process leverages proprietary ceramic shell formulations and vacuum/inert gas melting techniques to achieve exceptional dimensional accuracy, surface finish, and material properties in alloys ranging from titanium and inconel to stainless steels and aluminum. Crucially, our in-house CNC machining capabilities directly complement and elevate this casting workflow. By integrating five-axis milling, precision turning, and wire EDM operations within the same facility, we ensure seamless secondary operations for critical features, tight-tolerance machining of cast near-net shapes, and rapid pattern or fixture fabrication—eliminating supply chain delays and quality handoffs. This vertically integrated approach guarantees consistent part quality from wax pattern to finished component while optimizing lead times and total cost of ownership.

To accelerate your prototyping or low-volume production timeline, utilize Honyo Prototype’s Online Instant Quote system. Upload your 3D CAD file to receive a detailed manufacturability analysis and competitive pricing for both lost wax casting and CNC machining services within hours—not days. Our platform provides transparent cost drivers, material options, and lead time estimates, empowering faster project initiation without compromising engineering rigor.

Service Integration Performance Metrics

| Capability | Lost Wax Casting | Integrated CNC Machining | Combined Value |

|—————————|——————|————————–|——————————|

| Typical Tolerance Range | ±0.05mm/mm | ±0.005mm | Critical feature precision |

| Lead Time Reduction | — | — | Up to 35% vs. external vendors |

| Secondary Operation Cost | Standard | 15-25% lower | Reduced NRE and unit cost |

| First-Pass Yield | 88% | 95% | 92% for cast+machined parts |

Partner with Honyo Prototype for casting solutions where engineering precision meets manufacturing agility. Initiate your project with confidence through our Online Instant Quote system today.

Technical Capabilities

The lost wax casting service at Honyo Prototype is integrated with advanced post-casting machining capabilities to deliver high-precision metal and polymer components. While lost wax casting (also known as investment casting) forms the base geometry with excellent surface finish and complex shape capability, precision 3/4/5-axis CNC milling, turning, and tight-tolerance finishing operations ensure dimensional accuracy and functional performance. These secondary processes are essential for achieving tight tolerances, critical feature alignment, and interface compatibility in demanding industrial, aerospace, and medical applications.

The following table outlines the technical specifications of our end-to-end lost wax casting and precision machining service:

| Parameter | Specification |

|---|---|

| Casting Method | Investment Casting (Lost Wax) with ceramic shell molding |

| As-Cast Tolerance (Standard) | ±0.5 mm per 25 mm (±0.020″ per inch), depending on geometry and size |

| Post-Machining Tolerance | ±0.01 mm (±0.0004″) for critical features |

| Surface Finish (As-Cast) | Ra 3.2–6.3 µm (125–250 µin) |

| Surface Finish (Machined) | Ra 0.8–1.6 µm (32–63 µin), customizable with polishing or coating options |

| Machining Capabilities | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning; multi-tasking machining |

| Max Part Size (Machined) | 800 mm × 500 mm × 400 mm (31.5″ × 19.7″ × 15.7″) |

| Minimum Feature Size | 0.5 mm (milled); 1.0 mm (cast features) |

| Lead Time (Casting + Machining) | 10–20 business days, depending on complexity and finishing requirements |

| Materials – Metals | Aluminum (e.g., 6061, 7075), Steel (e.g., 4140, 17-4 PH stainless) |

| Materials – Engineering Plastics (Prototype Patterns or Non-Structural Parts) | ABS, Nylon (PA6, PA12) – used for master patterns or functional prototypes |

| Secondary Operations | Heat treatment, passivation, anodizing, powder coating, precision inspection |

| Quality Control | CMM inspection, GD&T reporting, first-article inspection (FAI), X-ray (on request) |

Note: While ABS and Nylon are not cast via lost wax, they are used in the creation of master patterns for the casting process or for non-metal prototypes requiring similar form/fit. Final cast parts in aluminum and steel are machined using 5-axis CNC systems to achieve tight tolerances and complex contours unattainable through casting alone.

From CAD to Part: The Process

Honyo Prototype Lost Wax Casting Service Process Overview

Honyo Prototype delivers precision metal components via an optimized lost wax casting (investment casting) workflow. Our integrated digital-to-physical pipeline ensures technical accuracy, manufacturability, and on-time delivery for aerospace, medical, and industrial clients. The end-to-end process follows five rigorously controlled phases.

CAD Upload and Initial Validation

Clients initiate the process by uploading 3D CAD models (STEP, IGES, or native formats) via our secure portal. Our system performs immediate geometric validation, checking for watertightness, minimum feature resolution (≥0.5mm), and orientation feasibility. Non-conforming files trigger automated feedback with specific correction guidance, reducing rework cycles. All data is encrypted per ISO 27001 standards, with version control maintained throughout the project lifecycle.

AI-Powered Quoting Engine

Upon CAD validation, our proprietary AI quoting system analyzes 120+ parameters—including part volume, surface complexity, material grade, and historical production data—to generate a preliminary cost and lead time estimate within 90 seconds. This AI model is trained on 15,000+ past casting projects, correlating design features with actual shop-floor resource consumption. Crucially, the AI output serves as a technical starting point; final pricing requires DFM validation to address geometric nuances algorithms cannot fully assess.

Engineer-Led Design for Manufacturability (DFM)

A dedicated Honyo manufacturing engineer conducts a formal DFM review within 24 business hours of quote acceptance. This phase identifies critical casting risks:

Wall thickness transitions below 1.5mm requiring reinforcement

Undercuts necessitating soluble cores

Draft angles <1° requiring mold segmentation

Hot-spot zones prone to shrinkage porosity

The engineer provides a marked-up CAD report with actionable redesign recommendations. Clients approve revisions via our collaborative portal before progression, ensuring zero ambiguity in production intent.

Precision Production Execution

Approved designs move to our AS9100D-certified foundry. The casting sequence follows strict protocols:

| Stage | Key Parameters | Quality Control |

|——-|—————-|—————-|

| Wax Pattern | Injection pressure: 0.8–1.2 MPa

Temperature: 65–72°C | CMM verification of 5 critical dimensions per 100 units |

| Ceramic Shell | Slurry viscosity: 25–30 sec (Ford Cup #4)

Dry time: 12–18 hrs per layer | Shell thickness X-ray validation |

| Dewax & Burnout | Ramp rate: 80°C/hr to 900°C

Hold time: 2 hrs at peak temp | Atmosphere O₂ < 50 ppm |

| Pouring & Solidification | Superheat: 30–50°C above liquidus

Cooling rate: 1.5–2.5°C/sec | Infrared thermal mapping |

Post-casting, parts undergo precision cutoff, gate removal, and vibratory finishing. All aerospace/medical components receive 100% dimensional inspection against CAD nominal.

Traceable Delivery and Documentation

Final parts ship with full material traceability (mill test reports), first-article inspection data (FAIR), and process validation records. We provide serialized Certificates of Conformance meeting AMS 2750 for heat treatment and ASTM E505 for porosity grading. Standard lead time is 18–22 days from DFM sign-off; expedited options (12 days) are available for critical-path projects. Every shipment includes real-time logistics tracking and digital quality dossiers accessible via client portal.

This structured approach eliminates traditional casting bottlenecks, reducing time-to-part by 35% versus conventional suppliers while maintaining ≤0.1% defect rates for complex geometries. Contact Honyo engineering to discuss material-specific process parameters for your application.

Start Your Project

Discover precision metal parts with our lost wax casting service, ideal for high-detail prototypes and low-volume production. Our in-house foundry in Shenzhen ensures strict quality control, fast turnaround, and cost-effective solutions for aerospace, medical, and industrial applications.

Contact Susan Leo to request a quote or submit your design for a free assessment. Email us at [email protected] and leverage our expertise in investment casting to bring complex geometries to life with superior surface finish and accuracy.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.