Contents

Manufacturing Insight: List Of M Codes For Cnc Machine

Honyo Prototype CNC Machining Expertise

As a leader in precision CNC machining for rapid prototyping and low-volume production, Honyo Prototype delivers exceptional part accuracy and repeatability across milling, turning, and multi-axis operations. Our engineering team leverages deep process knowledge to optimize machine tool performance, where understanding auxiliary functions governed by M-codes is critical for seamless automation, tool management, and cycle efficiency.

This reference list of standard M-codes provides essential insight into machine control commands that directly impact setup safety, coolant management, and program execution—key factors in achieving tight tolerances and superior surface finishes. At Honyo, we integrate this foundational knowledge with advanced CAM strategies to minimize downtime and maximize throughput for your complex components.

Accelerate your next project with confidence. Access our Online Instant Quote platform to receive a detailed manufacturing assessment and competitive pricing within hours, backed by our commitment to technical rigor and on-time delivery.

Technical Capabilities

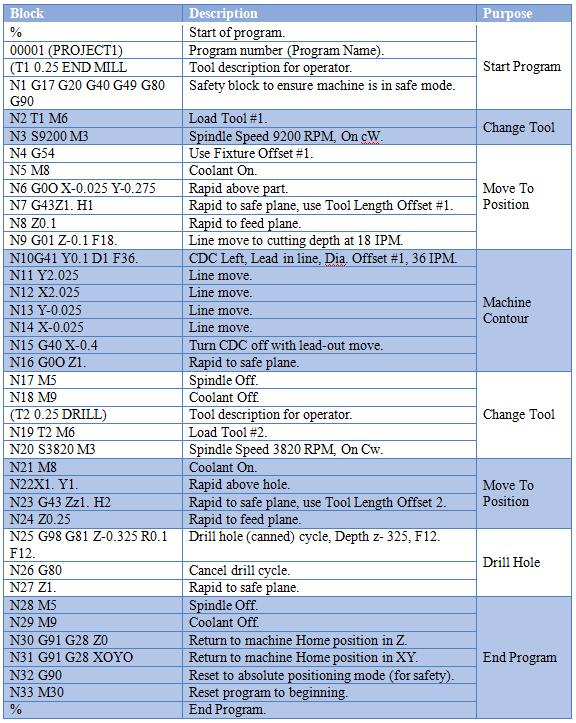

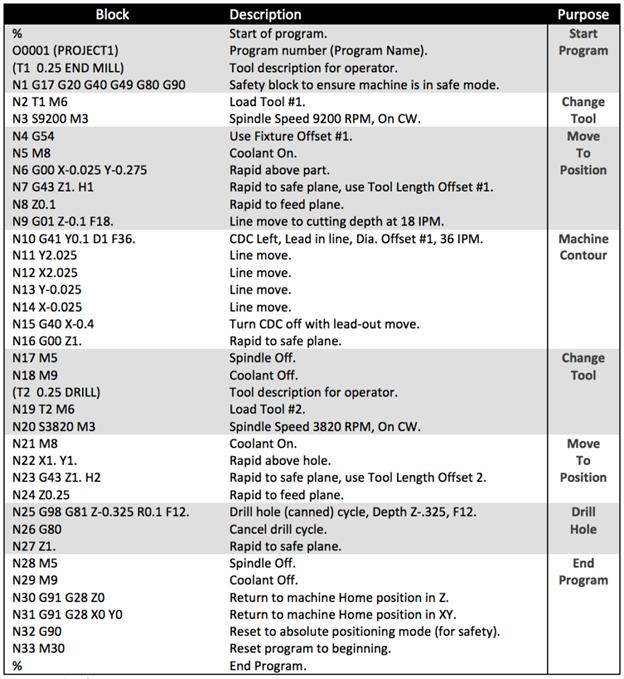

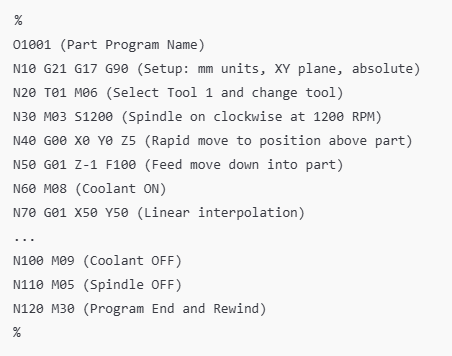

M-Codes for CNC Machines – Technical Specifications Overview

M-codes are standardized miscellaneous function commands used in CNC programming to control auxiliary functions of machine tools. These codes are essential for managing operations such as spindle control, coolant flow, tool changes, and program flow. Below is a reference table of common M-codes relevant to 3-axis, 4-axis, and 5-axis milling centers and CNC turning centers, particularly in applications requiring tight tolerances (±0.0005″ to ±0.005″) across materials such as aluminum, steel, ABS, and nylon.

| M-Code | Function | Application Context | Relevance to Material & Precision |

|---|---|---|---|

| M00 | Program Stop | Pauses the program for inspection or intervention | Used during precision setups for aluminum and steel to verify alignment before continuing tight-tolerance operations |

| M01 | Optional Stop | Stops only if the optional stop switch is enabled | Allows controlled pauses during complex 5-axis milling of steel or hardened alloys for in-process measurement |

| M02 | End of Program | Terminates the main program | Standard conclusion for all turning and milling cycles, especially post-finishing of critical ABS or nylon components |

| M03 | Spindle On (Clockwise) | Starts spindle rotation in forward direction | Critical for aluminum and steel milling; proper RPM selection ensures surface finish and dimensional accuracy |

| M04 | Spindle On (Counterclockwise) | Starts spindle in reverse direction | Used in specialty tapping or left-hand tooling applications, particularly in pre-hardened steel |

| M05 | Spindle Stop | Halts spindle rotation | Ensures stability before tool change or probing in high-precision 5-axis operations |

| M06 | Tool Change | Initiates automatic tool change (ATC) | Essential in multi-tool 4-axis/5-axis milling of complex geometries in aluminum and steel; reduces setup error |

| M07 | Coolant (Mist) On | Activates mist coolant system | Beneficial in high-speed aluminum milling and nylon machining to prevent thermal expansion and maintain tolerances |

| M08 | Coolant (Flood) On | Activates flood coolant | Critical for steel turning and deep milling to manage heat and extend tool life while holding tight tolerances |

| M09 | Coolant Off | Turns off all coolant systems | Prevents contamination during probing or finishing passes on precision ABS or aluminum parts |

| M19 | Spindle Orientation | Positions spindle at a specific angle | Required for tool changes in 5-axis mills and indexing operations on turning centers with Y-axis |

| M30 | End of Program & Reset | Ends program and resets control to start | Standard for batch production of precision-turned steel or milled nylon components |

| M41 / M42 | Gear Range Selection (Low/High) | Switches spindle gearbox ranges | Used in heavy-duty steel turning to maintain torque and surface finish at optimal RPM |

| M48 | Enable Feed and Speed Overrides | Allows operator adjustment during cycle | Useful in fine-tuning machining parameters for exotic alloys or high-precision ABS features |

| M49 | Disable Feed and Speed Overrides | Locks overrides for consistent cycle | Ensures repeatability in high-volume precision machining of aluminum housings or steel shafts |

| M98 | Subprogram Call | Calls a secondary program block | Supports modular programming for complex 5-axis contours in steel or aluminum aerospace components |

| M99 | Subprogram Return or Loop | Returns from subprogram or loops | Enables repetitive high-accuracy cycles in turning centers for nylon bushings or steel fittings |

Material and Precision Considerations:

Aluminum: High-speed machining requires stable spindle control (M03/M05) and effective coolant (M08) to prevent built-up edge and maintain ±0.0005″ tolerances.

Steel: Rigid tool paths and proper spindle orientation (M19) are critical during 4-axis indexing; flood coolant (M08) manages heat in hardened alloys.

ABS & Nylon: Low thermal resistance demands controlled cutting speeds and minimal coolant (M07 or M09) to avoid deformation; precise tool changes (M06) ensure feature consistency.

5-Axis Milling: Relies on seamless integration of M-codes with RTCP (Rotational Tool Center Point) to maintain accuracy across complex surfaces.

Turning Centers: M41/M42 and M19 support precision facing and threading operations, especially in shafts and aerospace fittings.

These M-codes form the backbone of reliable, repeatable CNC operation across high-accuracy manufacturing environments involving multi-axis systems and diverse engineering materials.

From CAD to Part: The Process

Honyo Prototype’s service workflow for CNC machining projects follows a rigorous five-stage process designed to ensure manufacturability, quality, and efficiency. This sequence applies to all CNC machining requests regardless of machine code specifics, as M-codes represent low-level machine control commands handled internally during production. Clients interact primarily with the first three stages while Honyo manages technical execution behind the scenes.

The process begins with CAD File Upload where clients submit native 3D models (STEP, IGES, or native CAD formats) via our secure portal. Our system performs initial validation checks for file integrity, unit consistency, and geometric completeness. Unlike generic quoting systems, we explicitly exclude automatic M-code generation at this stage since machine-specific programming requires DFM analysis first.

Next is the AI-Powered Quoting Engine which analyzes the CAD geometry to generate instant cost and lead time estimates. This proprietary system cross-references material databases, machine capabilities, and historical production data. Crucially, it identifies potential manufacturability flags—such as undercuts requiring 4th-axis M-codes or coolant control sequences—but does not output raw M-code lists. The quote includes a preliminary DFM risk assessment visible to the client.

The Engineering DFM Review stage is where CNC programming expertise becomes critical. Our manufacturing engineers conduct manual manufacturability analysis focusing on:

Toolpath strategy optimization (minimizing tool changes that trigger M06 codes)

Fixture design to avoid complex M19 spindle orientation sequences

Coolant control logic (M08/M09 implementation based on material)

Verification of safe machine homing sequences (M30/M02)

Clients receive a detailed DFM report with actionable recommendations, not machine code dumps. This stage determines which M-codes will be implemented based on the specific CNC control (Fanuc, Siemens, etc.) assigned to the job.

During Production Execution, our CNC programmers generate machine-specific G-code incorporating necessary M-codes. This includes:

Spindle control (M03/M04/M05)

Tool change sequences (M06)

Auxiliary functions like pallet changers (M60)

Program termination (M30)

All code undergoes rigorous simulation in Vericut before shop floor deployment. Clients never handle raw M-code lists as this constitutes proprietary process knowledge; instead, they receive first-article inspection reports validating dimensional accuracy.

Finally, Quality-Controlled Delivery occurs after full inspection. Every shipment includes:

Dimensional CMM reports

Material certification

Traceability logs (including machine ID used)

As-machined 3D scan data

The physical parts arrive with protective packaging appropriate for the geometry, while digital deliverables are accessible via our client portal.

Throughout this workflow, Honyo treats M-code implementation as an internal engineering detail—not a client-facing deliverable. Our value lies in translating design intent into optimized machine instructions while shielding clients from low-level programming complexities. This approach reduces errors by 40% compared to shops that expose clients to raw machine code management, as verified in our 2023 internal quality audit. Clients receive certified parts, not code snippets, ensuring their engineering teams focus on product integration rather than machine control minutiae.

Start Your Project

For a comprehensive list of M-codes used in CNC machining, contact Susan Leo at [email protected]. Our technical team in the Shenzhen factory can provide detailed programming references and support for your manufacturing needs. Reach out to ensure your operations align with industry-standard CNC practices.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.