Contents

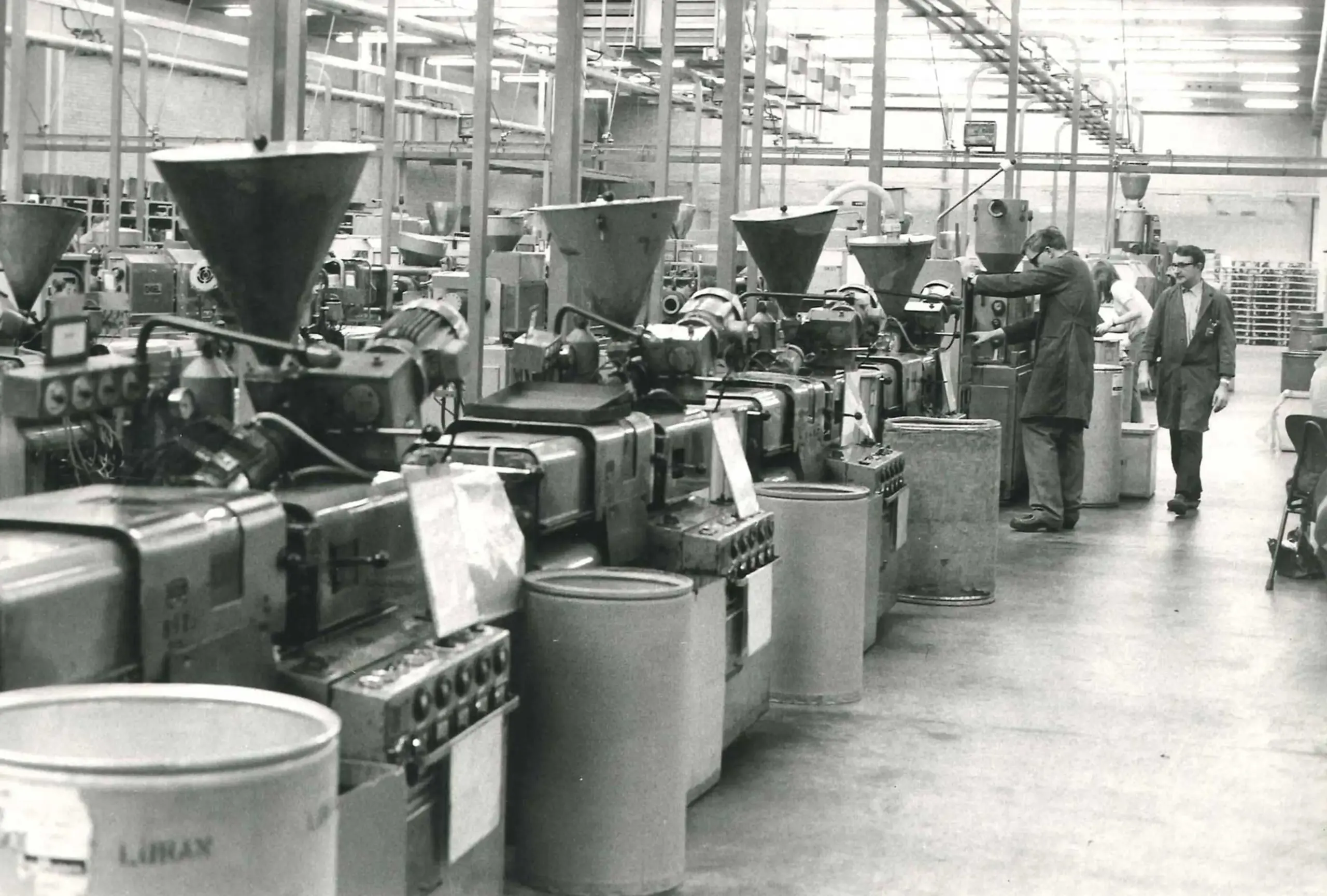

Manufacturing Insight: Lego Injection Molding Machine

Precision Plastic Component Manufacturing: Meeting Complex Design Demands

Achieving micron-level precision in small, intricate plastic components—such as those requiring Lego-scale tolerances and interlocking geometries—demands specialized injection molding expertise. At Honyo Prototype, we engineer solutions for high-complexity parts where dimensional accuracy, material consistency, and rapid iteration are non-negotiable. Our integrated Rapid Tooling and Injection Molding services bridge the gap between prototype validation and low-volume production, eliminating traditional bottlenecks through advanced CNC machining, mold flow analysis, and real-time process optimization.

Leveraging proprietary methodologies in mold design and material science, we deliver production-ready components with tolerances as tight as ±0.005mm, even for undercuts, thin walls, and multi-cavity configurations. Unlike conventional suppliers constrained by lengthy lead times, Honyo’s Rapid Tooling process reduces mold fabrication to 7–12 days without compromising durability—using hardened steels (e.g., NAK80, S136) validated for 50,000+ cycles. This agility ensures your design transitions seamlessly from CAD to physical part, accelerating time-to-market while maintaining ISO 9001-certified quality control.

Accelerate Your Project Timeline with Digital Efficiency

Honyo’s Online Instant Quote platform provides transparent, real-time costing for both tooling and molding within 60 seconds. Simply upload your 3D model, specify materials (including engineering-grade resins like ABS, PC, and POM), and receive a detailed manufacturability report alongside pricing—no sales calls required. This digital workflow, combined with our in-house 50–500-ton presses and multi-gate hot runner systems, positions Honyo as the strategic partner for innovators demanding precision, speed, and scalability in plastic part production.

| Service | Traditional Lead Time | Honyo Prototype Lead Time | Key Differentiator |

|---|---|---|---|

| Rapid Tooling | 3–6 weeks | 7–12 days | Hardened steel molds, DFM integrated |

| Low-Volume Molding | 4–8 weeks | 10–15 days | In-house presses, real-time SPC |

| Online Quoting | Manual RFQ (3–5 days) | Instant (60 seconds) | Automated manufacturability analysis |

Technical Capabilities

Technical specifications for a LEGO-compatible injection molding machine require high precision, repeatability, and fast cycle times to produce interlocking plastic bricks with tight tolerances. At Honyo Prototype, we specialize in rapid tooling and prototyping using both aluminum and steel molds, ensuring T1 sample delivery within 7 days for qualified projects. Our process supports engineering-grade resins such as ABS and Nylon, which are commonly used in durable, high-impact LEGO-style components.

The table below outlines the key technical specifications relevant to producing LEGO-style parts using aluminum or steel molds on our injection molding platforms:

| Parameter | Specification |

|---|---|

| Clamping Force | 150–300 tons (optimized for small to medium molds) |

| Shot Size (Max) | 100–250 grams (sufficient for multi-cavity LEGO molds) |

| Screw Diameter | 25–35 mm (high precision metering for consistent shot volume) |

| Injection Pressure | Up to 1,800 bar (ensures complete cavity fill for fine details) |

| Mold Material Options | Aluminum (7075-T6, 6061-T6), Steel (P20, H13, 420 Stainless) |

| Mold Base Standard | DME or HASCO modular systems for rapid assembly |

| Cavity & Core Finishing | SPI-A1 (high polish) or texture-matched to LEGO GB standards |

| Tolerance Capability | ±0.02 mm (critical for clutch power and fit) |

| Lead Time for T1 Sample | ≤ 7 days from mold design approval |

| Supported Resins | ABS (natural, colored), Nylon 6/6, PC/ABS blends |

| Melt Temperature Range | 230–280°C (adjustable per material: ABS ~240°C, Nylon ~270°C) |

| Cycle Time (Typical) | 15–30 seconds (depending on part geometry and cooling) |

| Cooling Channels | Conformal or standard water lines for uniform cooling |

| Ejection System | Pin or sleeve ejection with precise stroke control |

| Machine Control System | Fully electric or hybrid servo-driven with real-time monitoring |

We utilize aluminum molds (7075-T6) for rapid prototyping and low-volume runs, enabling T1 sample delivery within 7 days. For high-volume production or extended mold life, hardened steel (H13 or 420 stainless) is recommended. All molds are designed with draft, shrinkage (ABS: 0.5%, Nylon: 0.7–1.0%), and gate location optimized for LEGO-style part ejection and visual quality.

Materials such as ABS provide excellent dimensional stability and impact resistance, closely matching original LEGO material properties. Nylon is used for flexible or wear-resistant variants, though it requires controlled drying and higher processing temperatures.

From CAD to Part: The Process

Honyo Prototype specializes in rapid injection molding for custom plastic prototypes and low-volume production, not Lego-branded products or machinery. We clarify this upfront as Lego is a registered trademark; our process applies to generic plastic part manufacturing using industry-standard injection molding technology. Our streamlined workflow ensures technical precision and speed for engineering clients.

Upload CAD

Clients initiate the process by uploading 3D CAD files through our secure online portal. We accept native formats including STEP, IGES, SOLIDWORKS, and Parasolid, with strict validation for watertight geometry and appropriate draft angles. File analysis begins immediately upon submission, checking for critical parameters like wall thickness consistency and undercuts that impact moldability. This digital-first approach eliminates manual data entry errors and establishes a definitive technical baseline for quoting.

AI Quote

Our proprietary AI engine processes the CAD geometry within minutes to generate an instant, data-driven quotation. The system analyzes part volume, projected footprint, surface finish requirements, and material selection to calculate precise machine time, material consumption, and labor costs. Unlike manual quotes, the AI cross-references real-time factory capacity data and historical cycle time databases for accuracy. Clients receive a transparent cost breakdown including mold tooling estimates for requested quantities, with options to adjust parameters like material grade or tolerances for instant recalculation.

DFM Analysis

Following quote acceptance, our engineering team conducts a rigorous Design for Manufacturability review. This is not an automated step but involves senior manufacturing engineers evaluating the CAD against our process capabilities. Key focus areas include gate location optimization, ejector pin placement, cooling channel design, and stress concentration mitigation. We provide a detailed DFM report with actionable recommendations—such as modifying rib thickness or adjusting draft angles—using annotated 2D drawings. Client approval of the DFM package is mandatory before tooling begins, ensuring alignment on manufacturability trade-offs.

Production

Approved designs move to our certified ISO 9001 production floor where we deploy all-electric injection molding machines with clamping forces ranging from 50 to 500 tons. Each production run includes:

Mold fabrication in-house using S136 or NAK80 tool steel with surface textures per SPI standards

First-article inspection against GD&T callouts using CMM and optical comparators

In-process quality checks every 30 minutes for critical dimensions

Material certification documentation for all resins

Typical lead times are 15-20 days for mold creation plus 3-5 days for initial production shots, with real-time production tracking available via client portal.

Delivery

All shipments include comprehensive documentation: First Article Inspection reports, material certificates, and process validation data. Parts are packaged in ESD-safe containers with desiccant for moisture-sensitive resins, labeled with traceable lot numbers. We offer consolidated logistics through DHL or client-designated carriers with door-to-door tracking. Post-delivery, our engineering team remains available for technical support on part integration or future design iterations.

Material options for prototyping include these common engineering thermoplastics:

| Material Grade | Tensile Strength (MPa) | Heat Deflection Temp (°C) | Typical Applications |

|---|---|---|---|

| ABS M20 | 45 | 98 | Housings, Snap-fits |

| PC Lexan 9034 | 63 | 130 | Transparent Covers |

| Nylon 6/6 GF30 | 140 | 210 | Structural Brackets |

| PP Homopolymer | 30 | 105 | Living Hinges |

This integrated process reduces time-to-prototype by 40% compared to traditional suppliers while maintaining strict adherence to AS9100 and IATF 16949 quality frameworks. For immediate project initiation, clients may upload CAD files directly at honyoprototype.com/upload.

Start Your Project

Interested in high-precision LEGO-compatible injection molding solutions? Contact Susan Leo at [email protected] to discuss custom manufacturing capabilities. Our ISO-certified factory in Shenzhen specializes in rapid prototyping and large-scale production of precision injection molded parts, including tight-tolerance LEGO-style brick manufacturing.

We offer end-to-end support from mold design to full production runs, ensuring consistency, speed, and compliance with international quality standards.

Reach out today to request a quote or schedule a factory audit.

Contact:

Susan Leo

Email: [email protected]

Factory Location: Shenzhen, China

| Service | Capability |

|---|---|

| Machine Type | High-speed electric and hybrid injection molding |

| Clamping Force Range | 50–1,000 tons |

| Molding Tolerance | ±0.002 mm |

| Materials | ABS, PC, PP, PE, TPE, and other engineering plastics |

| Applications | Construction toys, educational kits, consumer electronics housings |

Let Honyo Prototype be your trusted partner for reliable, scalable injection molding solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.