Introduction: Navigating the Global Market for lathe services

In the evolving landscape of global manufacturing, sourcing reliable lathe services can present a formidable challenge for B2B buyers, especially those in emerging markets across Africa, South America, the Middle East, and Europe. As companies increasingly seek precision-engineered components, navigating the intricate ecosystem of lathe suppliers, technologies, and pricing options becomes paramount. This guide is crafted to empower international buyers by elucidating the spectrum of lathe services available, including CNC turning, rapid prototyping, and serial production, alongside their varied applications across diverse industries.

Our comprehensive overview delves into vital aspects such as the latest trends in lathe technology, criteria for supplier vetting, and cost considerations, allowing buyers to make informed decisions tailored to their specific needs. With a focus on quality assurance and adherence to international standards, this resource serves as a crucial tool for effectively evaluating potential partners. By emphasizing actionable insights and strategic approaches, our guide equips B2B buyers from regions such as Brazil and Germany to not only enhance their procurement processes but also leverage global opportunities in the expansive lathe services market. Join us in navigating this vital component of modern manufacturing, ensuring your sourcing efforts align with your organization’s goals and operational demands.

Understanding lathe services Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Turning | Automated control, high precision, capable of complex designs | Aerospace, automotive, medical | Pros: High accuracy, rapid production; Cons: Higher initial setup costs. |

| Manual Lathe Services | Operated by skilled technicians, suitable for custom work | Custom prototypes, small runs | Pros: Flexibility in design; Cons: Slower than CNC, potential for human error. |

| Live Tooling | Combines turning with milling, allows for multifaceted components | Complex geometries in machinery | Pros: Reduces part handling; Cons: Increased machine complexity and maintenance. |

| Swiss Turning | Precision machining for small, complex parts, using CMS machining | Electronics, medical devices | Pros: Great for high-volume production; Cons: Limited in larger parts. |

| Vertical Lathe Services | Vertical spindle alignment, effective for large and heavy workpieces | Shipbuilding, large equipment | Pros: Handles weight and size better; Cons: Space and setup requirements. |

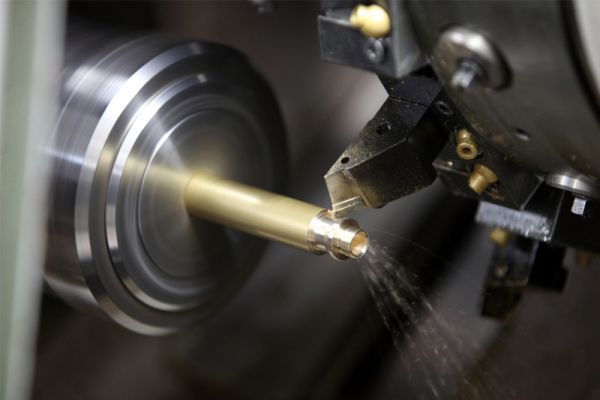

What Are CNC Turning Services and Their Key Characteristics?

CNC turning is characterized by the use of computerized controls to create highly precise components. This technology allows for rapid production and can accommodate complex designs with various materials such as metals and plastics. B2B buyers often seek CNC turning for industries like aerospace and automotive, where accuracy is paramount. Key purchasing considerations include supplier certifications (e.g., ISO standards), production volume requirements, and turnaround times.

How Do Manual Lathe Services Stand Out in Customization?

Manual lathe services are performed by skilled technicians and are ideal for custom work where flexibility and adaptability are required. This method is particularly beneficial for creating prototypes or small production runs that require unique specifications. However, buyers need to factor in longer lead times and the possibility of human error compared to automated processes. Support and expertise from the provider can help optimize designs during the manual lathe service process.

What Advantages Do Live Tooling Solutions Offer?

Live tooling integrates milling capabilities into a lathe, enabling the creation of complex, multifaceted components in a single setup. This reduces the handling time and can lead to cost savings for B2B operations focused on efficiency. Live tooling is particularly useful in industries that demand highly intricate part designs, though buyers should be aware of the increased complexity and maintenance that accompany this technology.

Why Choose Swiss Turning for Small Precision Parts?

Swiss turning specializes in the production of very small yet highly precise components, making it essential for sectors like electronics and medical devices. This technique allows for efficient mass production of intricate designs, often at high volumes. For B2B buyers, the benefits of Swiss turning include enhanced precision and reduced waste, but it’s important to note that this method may not be suitable for larger parts, limiting its application scope.

What Are the Benefits of Vertical Lathe Services?

Vertical lathe services are distinct due to their spindle alignment, which allows them to handle large and heavy workpieces effectively. This method is commonly employed in industries like shipbuilding and heavy machinery manufacturing. B2B buyers attracted to vertical lathe services must consider factors like space requirements for the machinery and specialized handling techniques that may be necessary for larger components. The ability to accommodate weight and size makes it a favored option in specific large-scale projects.

Key Industrial Applications of lathe services

| Industry/Sector | Specific Application of lathe services | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Production of precision components | Ensures high safety standards and regulatory compliance | Emphasis on material certifications and tight tolerances |

| Automotive | Manufacturing of engine components | Improves performance and efficiency of vehicles | Focus on rapid prototyping and low volume production |

| Oil and Gas | Creation of specialized valves and fittings | Enhances operational reliability in harsh environments | Importance of corrosion-resistant materials |

| Medical Devices | Development of custom surgical instruments | Meets stringent hygiene and precision requirements | Need for ISO-certified processes and material sourcing |

| Consumer Electronics | Fabrication of housings and casing parts | Integrated design flexibility and aesthetic appeal | Adaptability to various materials and finishing options |

How Are Lathe Services Utilized in Aerospace Applications?

In the aerospace industry, lathe services are critical for producing precision components that meet rigorous safety standards. Components like rotor shafts, landing gear parts, and engine assemblies require tight tolerances and high-quality finishes, making CNC lathe turning a preferred method for manufacturers. For international buyers, especially in Europe and the Middle East, ensuring that suppliers comply with ISO certifications and possess adequate quality assurance processes is vital for compliance with regulations.

What Role Do Lathe Services Play in Automotive Manufacturing?

Lathe services in the automotive sector focus on creating various engine components, such as pistons, crankshafts, and other critical parts. These components help enhance vehicle performance and safety, directly impacting consumer satisfaction and regulatory compliance. Buyers from regions like South America and Africa should prioritize suppliers that can offer rapid prototyping services and scalability for low-volume production runs, crucial for responding quickly to market demands.

How Are Lathe Services Applied in the Oil and Gas Industry?

In the oil and gas sector, lathe services are employed to manufacture specialized valves and fittings that are critical for pipeline operations. These components often face extreme conditions, requiring high durability and resistance to corrosion. For international B2B buyers, particularly from emerging markets, sourcing materials that meet industry standards is essential for ensuring the reliability and longevity of components in harsh environments.

How Are Lathe Services Essential for Medical Device Production?

Lathe services are integral to the manufacturing of custom surgical instruments, where precision and hygiene are paramount. The medical devices industry necessitates rigorous standards for health safety, meaning that components must be crafted to exact specifications. Buyers should seek suppliers with ISO certifications and experience in medical-grade materials to ensure compliance with global and local regulations, particularly when sourcing from regions with stringent health industry requirements.

How Do Lathe Services Enhance Consumer Electronics Manufacturing?

In consumer electronics, lathe services are utilized for fabricating housings and casings that combine functionality with aesthetic appeal. The demand for sleek, custom designs in smartphones and other devices makes high-quality CNC lathe turning essential. Buyers need to consider suppliers that offer flexibility in materials and surface finishing options to meet unique design specifications while adhering to production timelines, especially in competitive markets like Europe and South America.

3 Common User Pain Points for ‘lathe services’ & Their Solutions

Scenario 1: Delays Due to Unsuitable Material Choices

The Problem: When sourcing lathe services for specific projects, many B2B buyers often encounter delays because of unsuitable material choices. The complexity of material specifications can lead to orders being placed for components that either do not meet the project’s requirements or are not machinable with the chosen lathe service. This issue is exacerbated in international projects, where varying standards and material availabilities may affect the timeline and cost. Such setbacks not only hamper production schedules but can also lead to strained relationships with end clients who are relying on timely deliveries.

The Solution: To mitigate these challenges, B2B buyers should prioritize pre-project consultations with lathe service providers to discuss material specifications in detail. Communicate the project requirements thoroughly—this includes tolerances, mechanical properties, and desired finishes. Engage with suppliers who have diverse inventory options, visible certifications, and an understanding of international material standards. Additionally, leveraging online platforms that provide real-time feedback on material compatibility can drastically reduce misunderstandings and ensure that only suitable materials are quoted and used. Ensure that any material specifications stipulated in contracts are clear and consistent to avoid costly amendments later in the process.

Scenario 2: Quality Control Issues During Production

The Problem: Quality assurance is a significant concern for B2B buyers utilizing lathe services, especially for precision-critical applications such as aerospace or medical devices. Components produced may sometimes exhibit unacceptable tolerance levels or surface finishes that deviate from specified parameters. This not only risks the functionality and safety of the final products but could also result in expensive rework or reordering, negatively affecting the bottom line.

The Solution: To address potential quality control issues, buyers should implement a comprehensive inspection and quality assurance plan right from the outset. This plan should include clearly defined tolerances and acceptance criteria in the specifications provided to the lathe services. Buyers can also insist on third-party inspections or audits to ensure that the lathe service adheres to the required standards throughout the production process. Furthermore, maintaining open lines of communication with manufacturers regarding sample testing and first-run evaluations can identify any quality discrepancies before full production begins. Utilizing real-time monitoring tools, such as CNC machining feedback systems, enables buyers to catch deviations immediately, thus preventing larger-scale production issues.

Scenario 3: Complicated Documentation and Compliance Challenges

The Problem: Navigating documentation requirements and compliance regulations can be daunting when sourcing lathe services for international projects. Buyers often struggle with understanding the varying certifications needed for their specific industry or region. Errors in documentation can lead to project delays, import/export restrictions, and compliance violations, creating barriers to successful procurement that could have been easily avoided.

The Solution: To streamline the documentation and compliance process, buyers must educate themselves on the relevant standards applicable in their industry—such as ISO, AS9100, or IATF—before engaging with lathe service providers. Investing in a reliable compliance consultant can also be beneficial in tailoring documentation needs specific to the product and region, ensuring no detail is overlooked. Moreover, establishing a checklist that includes all required paperwork before procurement begins will simplify the overall process. Engaging with lathe service providers that offer comprehensive documentation packages, including certifications and compliance records, can save time and reduce the likelihood of lapses in regulatory requirements. Ultimately, having a well-organized documentation protocol in place will facilitate smoother communication, compliance, and operational success across borders.

Strategic Material Selection Guide for lathe services

CNC lathe services rely on selecting appropriate materials vital for performance, cost-efficiency, and suitability for specific applications. The selection of materials can significantly impact production timelines, overall costs, and end-product viability, particularly for international B2B transactions across regions like Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Aluminum for Lathe Services?

Aluminum is a widely used metal in lathe services due to its advantageous properties. It has excellent corrosion resistance and is lightweight, making it suitable for applications requiring reduced weight without sacrificing strength. Specific grades, like 6061 and 7075, offer good machinability and mechanical properties, making them suitable for structural parts in aerospace or automotive applications.

Pros:

– Lightweight and high strength-to-weight ratio.

– Excellent corrosion resistance.

– Good machinability, allowing for tight tolerances.

Cons:

– Relatively low temperature resistance compared to steels.

– Professional finishing required to enhance aesthetics and surface integrity.

When considering application impacts, aluminum parts are compatible with a variety of media but may not withstand extreme temperatures. Buyers in regions like Europe may need to consider compliance with standards such as EN or ISO certifications, while those in South America and Africa should ensure availability of material grades locally to minimize shipping costs.

What Are the Properties of Stainless Steel for Lathe Services?

Stainless steel is known for its durability and resistance to corrosion and staining. Common grades used in lathe services, such as 304 and 316, feature excellent mechanical properties and are often used in harsh environments, including chemicals and weather exposure.

Pros:

– High durability and corrosion resistance.

– Suitable for high-strength applications.

– Versatile processing options.

Cons:

– Generally higher material costs.

– More challenging to machine than aluminum, potentially increasing manufacturing time.

The impact on applications is significant; stainless steel parts are preferable in food processing, marine environments, and medical applications where sterilization and corrosion resistance are crucial. International buyers should also ensure that their suppliers adhere to ASTM and JIS standards, particularly in the food and health sectors.

How Does Brass Perform in Lathe Services?

Brass is another material commonly used in CNC lathe services, especially when low friction properties and acoustical performance are needed, typically in plumbing fittings or electrical connectors.

Pros:

– Excellent machinability, allowing for cost-effective production.

– Good corrosion resistance in atmospheric conditions.

– Attractive appearance for aesthetic applications.

Cons:

– Less strength compared to stainless steel and aluminum.

– Susceptible to dezincification in specific environments.

Brass is ideal for media compatibility in plumbing or electrical applications, being resistant to corrosive elements. However, B2B buyers should check for market-specific availability of brass alloys and ensure compliance with local standards, like the EN standards commonly referenced in Europe.

What Advantages Does Titanium Offer for Lathe Services?

Titanium is favored for applications requiring exceptional strength-to-weight ratios and corrosion resistance. With grades like Ti-6Al-4V, it is unsurpassed in aerospace applications.

Pros:

– Outstanding strength-to-weight ratio.

– Excellent corrosion resistance from seawater to extreme environments.

– Biocompatibility makes it desirable in medical applications.

Cons:

– Very high material costs and challenging to machine.

– Longer production times due to the need for specialized tools and processes.

For applications involving extreme conditions or where weight is critical, titanium is often the material of choice. However, international buyers must be aware of additional costs associated with sourcing and processing, particularly in regions with limited access to titanium supplies.

Summary of Material Considerations for CNC Lathe Services

| Material | Typical Use Case for lathe services | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace structural components | Lightweight and excellent corrosion resistance | Low temperature resistance | Medium |

| Stainless Steel | Food processing equipment | High durability and corrosion resistance | Higher costs and challenging machinability | High |

| Brass | Plumbing fittings | Excellent machinability | Less strength, susceptible to dezincification | Low |

| Titanium | Aerospace applications | Exceptional strength-to-weight ratio | Very high cost, difficult to machine | High |

This strategic guide outlines the essential materials considerations when utilizing lathe services. By understanding these factors, international B2B buyers can better navigate material choices to ensure product success while adhering to compliance and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for lathe services

What Are the Main Stages of Manufacturing Processes for Lathe Services?

The manufacturing process for lathe services involves several critical stages that contribute to the efficiency and quality of the final product. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Lathe Services?

Material preparation begins with carefully selecting the appropriate raw materials, which can range from metals like aluminum, brass, and stainless steel to various plastics. The chosen materials must meet the specifications outlined in the engineering design. Quality assurance at this stage is crucial, as the integrity of the material directly impacts the overall performance of the lathe-machined components. Suppliers should provide certifications to prove the material’s compliance with relevant standards, including material traceability documents.

Once the materials are sourced, they undergo inspection (Incoming Quality Control, or IQC) to ensure they meet required specifications. Any discrepancies can result in rework or scrapping of parts, which underscores the importance of stringent material verification.

What Techniques Are Used in the Forming Stage of Lathe Services?

The forming stage primarily involves the use of CNC lathes and turning centers. These advanced machines operate by rotating the material at high speeds while cutting tools shape the component to precise specifications. Key techniques include CNC turning, where the tool follows programmed paths for optimal efficiency and accuracy.

Common turning methods also encompass facing, grooving, and parting off. High-quality CNC lathes equipped with live tooling allow for simultaneous operations, such as drilling or milling, enhancing productivity and reducing lead times.

Additionally, the implementation of automation and robot-assisted techniques can streamline operations, facilitating faster production rates while maintaining consistent quality.

What Are the Finishing Processes Used After Lathe Services?

Finishing is vital for enhancing the aesthetic qualities and functional properties of lathe-turned parts. Various finishing techniques may be employed, such as anodizing, powder coating, or bead blasting to achieve desired surface characteristics. Anodizing, for example, not only improves corrosion resistance but also allows for color customization, which can be crucial for branding in B2B applications.

Furthermore, the choice of finishing technique can also impact the part’s performance, especially in demanding environments. For example, parts exposed to aggressive chemicals may require specific chemical treatments or coatings to prolong their service life.

What International Quality Standards Should B2B Buyers Consider?

Quality assurance in lathe services must adhere to international standards to ensure product reliability and safety. Notably, ISO 9001:2015 is a widely recognized framework that outlines quality management provisions applicable across various industries, including manufacturing.

Additionally, industry-specific certifications, such as CE for products sold in the European Union or API for oil and gas components, often apply. These certifications ensure that the products meet rigorous safety and compliance standards.

B2B buyers should inquire about their supplier’s quality certifications and ensure they have all necessary documentation for verification.

How Are Quality Checkpoints Implemented in Lathe Services?

Quality control checkpoints are essential throughout the manufacturing process to monitor product quality at various stages. Typically, these include:

- Incoming Quality Control (IQC): This initial stage involves assessing raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Conducted during machining operations, this checkpoint evaluates the production process to identify any deviations or defects in real-time.

- Final Quality Control (FQC): Once production is complete, FQC entails a thorough inspection of the final products against specifications to ensure conformance.

Common testing methods include dimensional inspections, mechanical property tests, and functional tests, depending on the application requirements.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verification of a supplier’s quality control processes is paramount. One of the most effective methods is through supplier audits, where buyers can assess the manufacturing environment, quality management systems, and compliance with international standards.

Additionally, requesting Quality Assurance documents, inspection reports, and test results provides transparency. Third-party inspections can also be very useful, offering an unbiased evaluation of the supplier’s capabilities and adherence to quality standards.

What Are the Unique Quality Assurance Challenges for International Buyers?

B2B buyers operating in different regions often face unique challenges in the realm of quality assurance. Variations in regional regulations, cultural attitudes towards quality, and supply chain logistics can complicate the procurement process. Buyers should be aware of how these factors may impact supplier performance and product quality.

It is important for buyers to establish clear communication channels with suppliers, set specific quality expectations, and define deliverables upfront. By maintaining proactive engagement and ongoing assessments, buyers can mitigate risks and ensure the reliability of lathe services on an international scale.

Conclusion

In conclusion, understanding the manufacturing processes and quality assurance practices for lathe services is essential for international B2B buyers looking to source high-quality components. By grasping each stage of the manufacturing process and emphasizing the importance of certifications and quality control checkpoints, buyers can make informed decisions that ensure desired product outcomes. Establishing a strong partnership with suppliers who prioritize quality and compliance will ultimately lead to successful projects and long-term collaborations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lathe services’

Introduction

This sourcing guide provides a comprehensive checklist for B2B buyers seeking lathe services. It aims to streamline the procurement process by outlining key steps to ensure quality, efficiency, and cost-effectiveness when selecting lathe service providers.

Step 1: Define Your Technical Specifications

Clearly outline the dimensions, tolerances, and material requirements for your lathe project. This step is crucial as it helps potential suppliers assess your exact needs and ensures that you receive accurate quotes and services tailored to your specifications. Be specific with regards to requirements such as:

- Material Types: Identify which materials (e.g., metals, plastics) are suitable for your project.

- Tolerances: Specify the level of precision you require (e.g., ±0.005″ for features of size).

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with capabilities tailored to your project needs. Utilize online platforms, industry directories, and trade shows to gather a list of potential vendors. Focus on:

- Capabilities: Ensure suppliers can provide the specific lathe services you require, such as CNC turning or live tooling.

- Location: Consider suppliers who can serve your geographic location effectively, particularly if you value timely delivery.

Step 3: Evaluate Supplier Certifications

Before finalizing your choice, verify that suppliers possess relevant industry certifications. This step is vital to ensure compliance with international standards and regulations. Look for providers with:

- ISO Certifications: Certifications like ISO 9001:2015 or ISO 13485 indicate a commitment to quality management and industry standards.

- Safety Regulations: Suppliers should adhere to local and international safety and environmental guidelines.

Step 4: Request Samples or Prototypes

Once you have narrowed down your choices, ask for samples or prototypes of previously completed work. This step allows you to assess the quality and craftsmanship of the supplier. Pay attention to:

- Quality Assurance Processes: Ask about their inspection methods to ensure they meet tolerances and specifications.

- Timeframes: Inquire about the lead times for producing prototypes to gauge their efficiency.

Step 5: Analyze Pricing and Terms of Service

Review quotes from potential suppliers, paying special attention to the total cost and terms of service. This step helps you ensure you’re getting the best value for your investment. Consider:

- Transparent Pricing: Confirm that quotes account for all costs, including shipping and tariffs for international orders.

- Payment Terms: Understand their payment conditions, such as upfront deposits or payment upon completion.

Step 6: Check Customer References

Ask for references from past clients, preferably from businesses in your industry or region. Speaking with previous customers can provide insights into the supplier’s reliability, communication, and overall satisfaction. Focus on:

- Project Examples: Understanding real-world applications of their services can help you assess their match with your requirements.

- Timeliness: Inquire about whether the supplier consistently meets deadlines and maintains quality.

Step 7: Establish Communication Channels

Effective communication is critical throughout the procurement process. Make sure to establish clear channels of communication with your chosen supplier to ensure a smooth workflow. Look for:

- Responsiveness: Assess their communication speed and clarity during the quote process.

- Project Management Tools: Check whether they utilize tools or platforms that facilitate transparent updates and collaboration throughout the project duration.

Following this checklist will enhance your chances of successfully securing high-quality lathe services that meet your business needs.

Comprehensive Cost and Pricing Analysis for lathe services Sourcing

When sourcing lathe services, understanding the comprehensive cost structure and pricing dynamics is crucial for international buyers, particularly from regions like Africa, South America, the Middle East, and Europe. A thorough grasp of cost components and influencing factors can empower businesses to make informed decisions that optimize their procurement strategy.

What are the Main Cost Components for Lathe Services?

-

Materials: The choice of materials significantly influences the overall cost of lathe services. Common materials include various grades of steel, aluminum, brass, and plastics. Premium materials or specific alloys—often required for specialized applications—can escalate costs. Factors such as market pricing fluctuations and availability variations across regions must also be considered.

-

Labor: Labor costs encompass wages given to machinists and technicians involved in the operation and programming of CNC lathes. In regions with higher labor costs, such as parts of Europe, expect to see a premium on service pricing. Conversely, regions with lower labor costs may offer more competitive pricing options.

-

Manufacturing Overhead: This includes costs related to utilities, machinery maintenance, rental of manufacturing spaces, and other administrative expenses. Well-managed facilities may have lower overhead, allowing for more competitive pricing.

-

Tooling: The costs associated with tooling can vary significantly based on the complexity of the parts being machined. Custom tooling may lead to higher initial costs, but can enhance efficiency and precision in the long term.

-

Quality Control (QC): Ensuring parts meet required specifications involves testing, inspections, and certifications, which add to the cost. Quality certifications (such as ISO) are often crucial for buyers aiming to maintain high quality standards.

-

Logistics: Shipping and handling can also impact pricing, particularly when dealing with international shipments. Factors such as distance, shipping method, and import duties (like tariffs) can influence transportation costs significantly.

-

Margin: Suppliers typically build a profit margin into their prices, which may vary based on market competition, service demand, and specialization in lathe services.

How Do Price Influencers Affect Lathe Services?

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for bulk orders. Understanding your operational needs can help leverage better pricing through higher volume purchases.

-

Specifications and Customization: Highly customized parts typically require more intensive labor and increased production time, resulting in higher costs. Clear and precise specifications can help suppliers eliminate guesswork and reduce potential reworks.

-

Materials and Quality: Selecting standard materials and less stringent quality requirements can lead to cost savings. However, striking a balance between cost and quality is essential to avoid future complications.

-

Supplier Factors: Supplier location, reputation, and manufacturing technology can significantly affect pricing. Suppliers with advanced technologies and efficient processes may charge more but provide better quality and quicker turnaround.

-

Incoterms: Different shipping terms can affect how costs are absorbed or allocated between buyers and sellers. Understanding terms like FOB, CIF, or DDP is essential for comprehensive pricing treatment.

What Buyer Tips Can Enhance Cost-Efficiency in Lathe Services?

-

Negotiation: Buyers should engage suppliers in discussions about pricing. Knowing the market averages and being prepared to negotiate can lead to cost savings.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes initial sourcing price, ongoing operational costs, and potential maintenance or rework fees. This broader understanding can lead to better investment in lathe services.

-

International B2B Pricing Nuances: When sourcing from different international suppliers, be aware of currency fluctuations, import taxes, and regional pricing strategies. Suppliers may adjust prices depending on regional competition, affecting overall sourcing strategy.

-

Establish Long-Term Relationships: Cultivating strong supplier relationships can often translate into more favorable pricing, priority service, and improved collaboration on future projects.

Disclaimer:

Prices for lathe services can vary significantly based on multiple factors discussed above. The prices offered are indicative, and buyers should consult multiple suppliers to obtain precise quotes tailored to their specific requirements.

Alternatives Analysis: Comparing lathe services With Other Solutions

The quest for precision machining often leads B2B buyers to consider various solutions beyond traditional lathe services. As companies aim to streamline production and reduce costs without compromising quality, understanding alternative methods is essential for informed decision-making. Below, we provide a comparative analysis of lathe services against two viable alternatives: CNC milling and additive manufacturing (3D printing).

| Comparison Aspect | Lathe Services | CNC Milling | Additive Manufacturing (3D Printing) |

|---|---|---|---|

| Performance | High precision on symmetrical parts | Excellent for complex geometries | Creative and versatile; supports complex designs |

| Cost | Moderate; varying with materials | Generally higher due to setup time | Cost-effective for low-volume runs; material costs vary |

| Ease of Implementation | Requires skilled operators | Less skilled labor needed | User-friendly software aids design and production |

| Maintenance | Requires regular upkeep | Moderate maintenance | Minimal; primarily software upkeep |

| Best Use Case | Production of cylindrical parts | Complex shapes and high-tolerance parts | Prototyping and small-batch production |

What Are the Advantages and Disadvantages of CNC Milling Compared to Lathe Services?

CNC milling is an advanced solution that excels in producing detailed and complex geometries, making it an attractive alternative to lathe services. Its high versatility allows for the machining of various materials with different thicknesses. However, it typically comes at a higher cost due to longer setup times and equipment intricacies. While the operational skill required may be less than that for lathe services, the overall manufacturing process can be more complex.

In What Situations Does Additive Manufacturing Offer Benefits Over Lathe Services?

Additive manufacturing, or 3D printing, has revolutionized the prototyping landscape with its ability to create intricate designs that would be impractical or impossible with lathe services. This technology allows for rapid production cycles and can significantly lower costs in small volume runs. However, it often struggles with material durability and post-processing requirements compared to the sturdiness of traditional lathe-turned products. Therefore, it’s most beneficial for initial prototyping phases rather than final production.

How Can B2B Buyers Make Informed Decisions About Machining Solutions?

Choosing the right machining solution depends on several factors, including project specifications, volume requirements, and budget constraints. Lathe services are best for high precision and durability, particularly for cylindrical parts, while CNC milling is ideal for projects demanding complex shapes. Additive manufacturing offers flexibility and speed, making it suitable for prototyping or low-volume custom parts. Buyers should evaluate their unique needs, including lead times and material requirements, to determine the best fit among these solutions. Careful assessment will not only save costs but also enhance product quality and manufacturing efficiency.

Essential Technical Properties and Trade Terminology for lathe services

What Key Technical Properties Should You Know About Lathe Services?

When engaging with lathe services, understanding specific technical properties is crucial for ensuring the quality and compatibility of the finished products. Below are some essential specifications to consider:

-

Material Grade

The grade of material used in lathe manufacturing significantly affects the performance and durability of a component. Common materials include various types of aluminum, steel, brass, titanium, and plastics, each with distinct properties. For example, aluminum 6061 is often chosen for its excellent corrosion resistance and weldability, making it ideal for aerospace applications. For B2B buyers, selecting the appropriate material grade ensures the final product meets industry standards and operational requirements. -

Tolerance Levels

Tolerance refers to the permissible limit of variation in a physical dimension of a part. In lathe services, dimensions are often tight, ranging typically from ±0.001″ to ±0.005″ depending on the complexity of the component. Precise tolerances are vital for parts that must fit together accurately, such as in automotive or aerospace engineering. An understanding of tolerances helps purchasing agents evaluate whether a supplier can meet their project specifications. -

Surface Finish

Surface finish describes the quality of the finished surface of a part following machining. It impacts the part’s performance (e.g., friction, wear resistance) and may involve options like anodizing, powder coating, or bead blasting. Different finishes can enhance aesthetic qualities or improve long-term durability. Understanding the implications of particular finishes allows buyers to tailor products to enhance both function and appearance. -

Lead Time

Lead time is the duration required to manufacture and deliver parts after an order is placed. It is an essential factor in supply chain planning and inventory management. Lathe service providers may offer expedited options that impact production costs. Buyers must assess their project timelines to ensure that the supplier can meet deadlines without sacrificing quality. -

Production Volume Options

Lathe services often specify production volume capabilities, ranging from rapid prototyping (producing a small number of parts for testing) to high-volume serial production. This flexibility allows businesses to scale their order sizes according to their specific needs, which is especially useful in markets with fluctuating demands. Grasping production capabilities helps buyers make informed decisions that align with their project scope.

What Are Common Trade Terms in Lathe Services?

Familiarity with industry jargon can facilitate smoother communications and negotiations with service providers. Here are some commonly used terms in the lathe services sector:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts that are incorporated into another company’s end products. Understanding the dynamics of OEM partnerships helps buyers identify reliable sources for high-quality components that integrate seamlessly into their broader manufacturing processes. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of product that a supplier is willing to sell. This term is vital for B2B buyers, as it informs them of the least amount they can order without incurring additional costs or administrative burdens. Knowing MOQ helps in budgeting and planning inventory levels. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotations from suppliers for specific products or services. Sending out an RFQ allows companies to compare multiple bids based on quality, pricing, and lead times, facilitating informed purchasing decisions. -

Incoterms

International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers for the delivery of goods under sales contracts. Understanding these terms is crucial for managing shipment logistics, risk, duties, and fees, especially for international transactions. -

CNC (Computer Numerical Control)

CNC refers to the automated control of machining tools using computers. This advanced technology allows for high precision and efficiency in lathe operations. B2B buyers should be aware of the implications of CNC technology on the manufacturing process, as it often results in improved production quality and repeatability.

These properties and terminologies play a pivotal role in selecting a lathe service provider. Empowered with this knowledge, B2B buyers can confidently navigate the complex landscape of manufacturing and ensure they make sound purchasing decisions.

Navigating Market Dynamics and Sourcing Trends in the lathe services Sector

Navigating the evolving landscape of lathe services requires an understanding of various market dynamics and sourcing trends that are increasingly influencing B2B transactions. Buyers from regions such as Africa, South America, the Middle East, and Europe are faced with unique opportunities and challenges that shape their sourcing strategies.

What Are the Global Drivers and Current Trends in Lathe Services?

The demand for lathe services is propelled by several global drivers, including technological advancements, a focus on precision manufacturing, and the push for rapid prototyping. Innovations in CNC (Computer Numerical Control) technology allow for faster production times and higher accuracy, which directly appeals to B2B buyers seeking cost efficiencies and quick turnaround times. The marketplace is also responding to the trend of customization and on-demand manufacturing, which allows businesses to order tailored solutions that meet specific requirements without incurring the costs associated with large inventory storage.

Emerging technologies such as artificial intelligence and machine learning are enhancing the capabilities within lathe services, providing companies access to streamlined processes and real-time feedback on manufacturability. This not only improves production quality but also aids in minimizing material waste. Additionally, the globalization of supply chains facilitates access to a diverse range of materials and finishes, expanding the options available to buyers.

However, international buyers must remain cognizant of geopolitical factors and trade regulations, particularly as they pertain to tariffs and compliance with industry standards. Adherence to certifications such as ISO and ITAR must be prioritized, especially for sectors like aerospace and medical manufacturing where quality and reliability are non-negotiable.

How Is Sustainability Influencing Sourcing Strategies in Lathe Services?

The significant environmental impact of manufacturing processes has shifted the focus towards sustainability and ethical sourcing in lathe services. B2B buyers increasingly prioritize suppliers who demonstrate a commitment to reducing their ecological footprint through responsible sourcing of materials and efficient manufacturing processes. The adoption of ‘green’ certifications, such as ISO 14001 for environmental management, is becoming more prevalent in supplier evaluations.

Buyers should also look for suppliers that utilize recycled materials or sustainable manufacturing technologies in their lathe operations, contributing to resource conservation. Materials such as recycled aluminum or bioplastics can be advantageous, presenting both sustainability benefits and potential cost savings. Moreover, transparent supply chains that outline the sourcing of materials can enhance a company’s reputation and align with the values of environmentally-conscious consumers.

Engaging with suppliers that share a commitment to ethical practices can foster long-term partnerships and open avenues for collaborative innovation, aligning with the global shift towards a circular economy where waste is minimized, and resources are reused.

What Is the Brief Evolution of Lathe Services in the B2B Context?

Lathe services have evolved significantly over the decades, transitioning from traditional manual operations to advanced automated processes. The introduction of CNC technology in the late 20th century marked a pivotal change, enabling precision machining and programmability in manufacturing. As industries demanded faster and more accurate production, CNC lathes began to incorporate sophisticated software and automated tools that facilitated complex designs and mass production.

The evolution was further propelled by globalization, allowing businesses to outsource lathe services and leverage capabilities in different regions. The rise of e-commerce platforms enables B2B buyers to access services and suppliers globally, enhancing competition and driving innovation in lathe services.

Today’s landscape demonstrates a convergence of technology, sustainability, and customer-centric approaches, making it imperative for businesses to adapt and adopt practices that not only meet their operational needs but also align with broader economic and environmental goals.

Frequently Asked Questions (FAQs) for B2B Buyers of lathe services

1. How do I choose the right lathe service provider for my project?

When selecting a lathe service provider, consider their certifications, experience, and production capabilities. Look for standards such as ISO certifications that reflect quality management systems. Review their portfolio for similar projects to ensure they possess the required expertise. Communication is key; a service provider that effectively understands your specifications will better meet your needs. Additionally, inquire about their turnaround times and minimum order quantities to ensure they align with your project timeline.

2. What materials can be used for CNC lathe turning services?

CNC lathe services can work with a wide range of materials including metals like aluminum, brass, copper, and various steels, as well as plastics such as nylon, acrylic, and PTFE. Your choice of material should be influenced by the application requirements, cost considerations, and mechanical properties needed for your parts. When sourcing services, ensure the provider has access to materials that meet international quality standards, particularly if your project is for specific industries such as aerospace or automotive.

3. What are the typical lead times for CNC lathe services?

Lead times for CNC lathe services can vary significantly based on the complexity of the part, the volume of the order, and the service provider’s capacity. Generally, quick-turn prototypes can be delivered within a few days, while larger production runs may take weeks. Always confirm lead times up front to align with your project schedule. Additionally, international buyers should account for potential delays in shipping and customs processing when planning timelines.

4. How do I manage customs and tariffs when sourcing lathe services internationally?

When sourcing lathe services across borders, you will need to understand the tariffs and customs regulations in both the sending and receiving countries. Collaborate closely with your supplier to ensure they provide detailed documentation that can facilitate the customs process. It’s advisable to consult with a customs expert or freight forwarder to mitigate unexpected costs or delays. Be prepared to pay applicable tariffs upfront, which can often be included in the final pricing provided by your vendor.

5. What are common payment terms offered by lathe service providers?

Payment terms can vary widely among lathe service providers. Most will require a deposit upfront, particularly for larger orders, with the balance due upon completion or delivery. Some may offer credit terms based on your business relationship or prior purchasing history. Ensure you clarify payment methods, such as wire transfer, credit card, or PayPal and confirm whether they accommodate international currency exchanges. This will help you avoid financial surprises and streamline the procurement process.

6. How can I ensure quality assurance for my CNC lathe turned parts?

To ensure quality assurance in CNC lathe turned parts, discuss the provider’s quality control practices up front. Look for details about their testing methods, certifications, and inspection processes. Many providers will utilize techniques such as dimensional tolerances verification and surface finish assessments. Request certifications that demonstrate adherence to industry standards, and where possible, consider a pre-production sample or prototype to validate quality before committing to full production runs.

7. What is the minimum order quantity (MOQ) for lathe services?

Minimum order quantities (MOQ) can vary based on the complexity of the parts and the supplier’s capabilities. Some providers may offer lower MOQs for prototype services, while larger production runs tend to have stricter MOQs. Clarifying these terms upfront with your supplier ensures you align your project budget and timeline accordingly. Always ask if the provider can accommodate lower quantities for critical projects, as flexibility can be an important factor in maintaining a good supplier relationship.

8. How do I communicate my specifications effectively to a lathe service provider?

Effective communication of your specifications is crucial for achieving the desired results. Begin by providing detailed technical drawings or CAD files that illustrate the exact dimensions, tolerances, and finishes required. Clearly outline any unique considerations, such as materials to be used or functional requirements. Establishing a direct dialogue with your supplier to discuss these specifications can also ensure clarity. Regular follow-ups during the production process can help mitigate potential issues before they arise.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Lathe Services Manufacturers & Suppliers List

1. PCBWay – CNC Turning Services

Domain: pcbway.com

Registered: 2012 (13 years)

Introduction: CNC Turning Services include the production of prototypes and parts using CNC turning machines (lathes) for simple cylindrical geometries. Key features include: low cost part production, capability for live tooling for complex geometries, operation using single-point cutting tools, and removal of material from rotating workpieces. Applications include functional prototypes, end-use parts, and part…

2. eMachineShop – CNC Turning Services

Domain: emachineshop.com

Registered: 1999 (26 years)

Introduction: eMachineShop offers CNC Turning Services for precision turned parts, utilizing CNC lathes to produce cost-effective solutions for single parts, prototypes, or production orders. Key offerings include:

– Availability of 50+ materials

– Free shipping in the USA

– 100% quality guaranteed

– High dimensional tolerances and smooth finishes possible

– Suitable for cylindrical parts from round, squar…

3. Proto Labs – CNC Turning Service

Domain: protolabs.com

Registered: 2006 (19 years)

Introduction: CNC Turning Service produces custom prototypes and end-use production parts in as fast as 1 day. It utilizes CNC lathes with live tooling to machine features such as axial and radial holes, flats, grooves, and slots. Common applications include functional prototypes, parts with cylindrical features, and components with specific machining requirements. Certifications include ISO 9001:2015, AS9100D,…

4. Rapid Direct – Custom CNC Turning Services

Domain: rapiddirect.com

Registered: 2010 (15 years)

Introduction: Custom CNC turning services with fast lead times and competitive pricing. Tolerance of 0.005 mm. Lead time as fast as 1 day. Capable of delivering high-quality prototypes and end-use production parts. Works with machine-grade metals and plastics. Offers low and high-volume production. Utilizes precision CNC turning lathes and live tooling for complex geometries. Common materials include: Metals (A…

5. Modern Group – Precision CNC Turning Parts

Domain: moderngroupusa.com

Registered: 2021 (4 years)

Introduction: Precision CNC turned parts manufactured using over 20 precision CNC lathe turning centers. Capable of producing cylindrical parts like gear blanks, fasteners, joint connectors, levels, and rotors. Use of 2-axis and 3-axis lathes for various machining operations; maximum diameters up to 36 inches. Available machine models include Murata MW200, Hwacheon 230B & 230C, Takisawa TCN-2500 L6, Haas SL-40,…

6. Goodwood Bros – Custom Wood Lathe Services

Domain: goodwoodbros.com

Registered: 2019 (6 years)

Introduction: {“service_name”: “Lathe / Turning Service”, “starting_price”: “$100.00”, “free_shipping”: true, “description”: “We turn your woodwork ideas into reality! Our skilled team specializes in custom wood lathe services, creating beautiful and unique pieces just for you.”, “offerings”: {“custom_woodturning”: “From bowls to furniture parts, we make one-of-a-kind items tailored to your needs.”, “material_c…

7. A.R. Machining Inc. – Precision Lathe Machining & CNC Turning Services

Domain: armachining.com

Registered: 1997 (28 years)

Introduction: A.R. Machining Inc. specializes in Precision Lathe Machining and CNC Turning Services. Established in 1979, the company excels in both small volume prototype work and large volume production runs. Their facility spans 38,000 square feet and is equipped with an extensive variety of lathes including models from Okuma and Mazak. A.R. Machining is ISO 9001 certified and ITAR registered, working with i…

8. Salco Global – CNC Lathe Services

Domain: salcoglobal.com

Registered: 2008 (17 years)

Introduction: CNC Lathe Service: Provides state of the art 2- to 9-axis CNC lathe capabilities. Emphasizes precision and quality, capable of producing high-quality parts. Operates 13 specialized CNC lathes that can handle both low and high quantities, from single prototypes to batches of 250,000 parts. Experienced with various materials including aluminum, brass, beryllium copper, stainless steel, titanium, Inc…

Strategic Sourcing Conclusion and Outlook for lathe services

In today’s competitive landscape, strategic sourcing of lathe services plays a pivotal role for international businesses seeking quality and efficiency. Leveraging advanced CNC technology allows companies to access a broad spectrum of materials such as aluminum, brass, and plastics, offering the precision necessary for custom-engineered products. By integrating real-time quoting and rapid prototyping capabilities, suppliers enable buyers to streamline their production processes, reduce lead times, and enhance innovation.

For international buyers, especially in emerging markets across Africa, South America, the Middle East, and established industries in Europe, sourcing reliable lathe services is more crucial than ever. It not only mitigates risks related to production but also positions companies to respond swiftly to market demands and customer needs.

Looking ahead, businesses should prioritize building relationships with trustworthy suppliers who understand global standards and can provide tailored solutions. As you explore lathe services, consider the advancements in machine learning and automation that can further optimize manufacturing efficiency and create substantial cost savings. Embrace this opportunity to enhance your competitiveness and drive your business forward in the global market.