Contents

Manufacturing Insight: Lathe Machining Tools

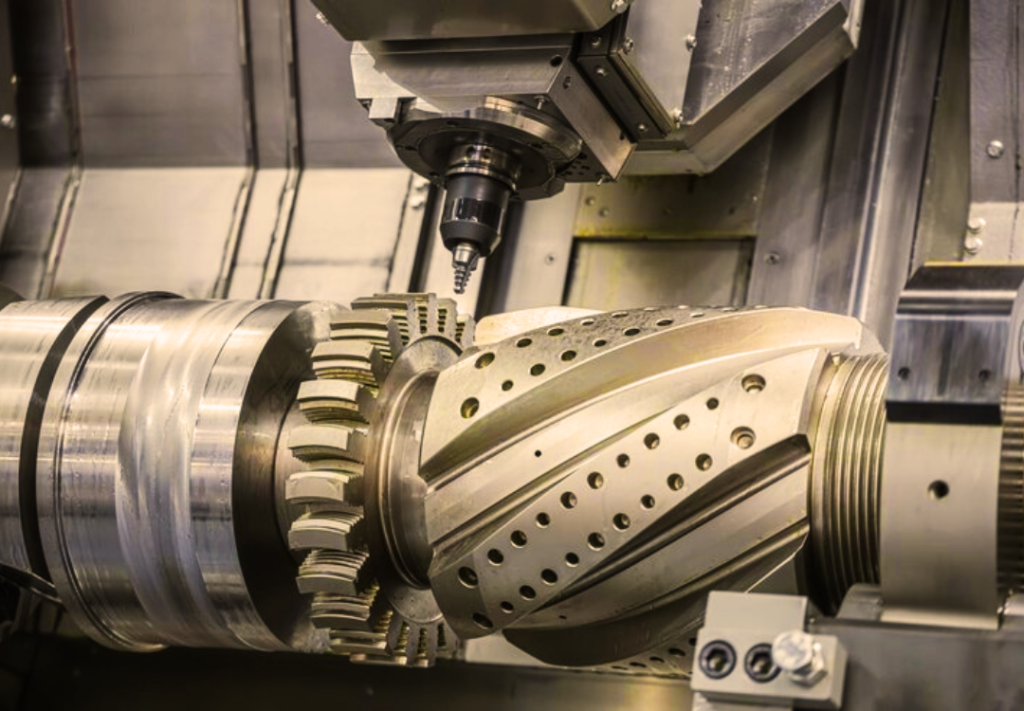

Precision Lathe Machining Solutions Engineered for Zero Compromise

At Honyo Prototype, our CNC lathe machining services deliver uncompromising precision for complex rotational components across aerospace, medical, and industrial sectors. Leveraging state-of-the-art Swiss-type and multi-axis CNC lathes, we achieve tolerances down to ±0.0005 inches while maintaining rigorous ISO 9001:2015 compliance. Our technical expertise spans challenging materials including titanium alloys, Inconel, PEEK, and hardened steels, ensuring optimal surface finishes and geometric accuracy for mission-critical applications.

Every project benefits from our integrated manufacturing ecosystem, where design validation, rapid prototyping, and high-volume production converge under one roof. We eliminate traditional barriers between engineering intent and physical realization through real-time process monitoring and adaptive toolpath optimization. This methodology consistently reduces lead times by 30% compared to industry benchmarks while maintaining 100% first-pass yield for critical features.

Accelerate your development cycle with Honyo’s Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats to receive a detailed manufacturability analysis and competitive pricing within 2 hours—no sales calls required. This transparent, data-driven quoting system provides immediate visibility into cost drivers, material utilization, and timeline projections, empowering informed decision-making from prototype to production.

Partner with Honyo Prototype to transform precision requirements into engineered realities, where advanced lathe capabilities meet seamless digital workflow integration.

Technical Capabilities

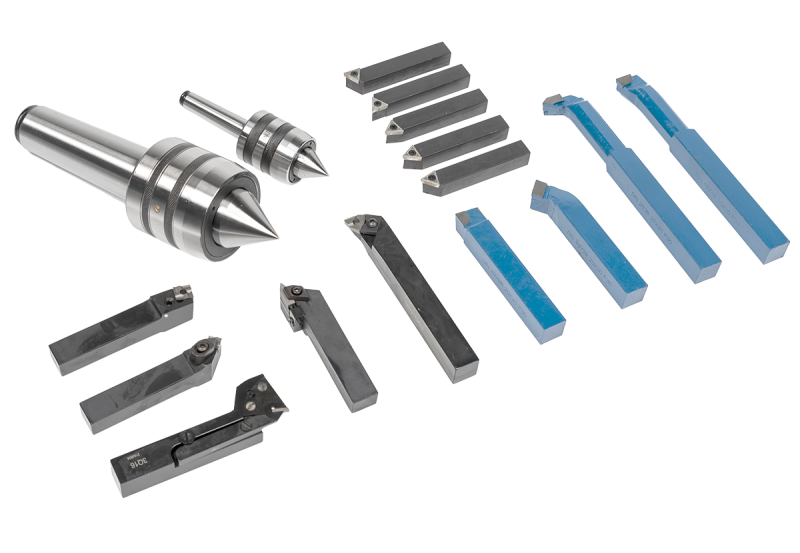

Technical specifications for lathe machining tools used in precision manufacturing—particularly in 3/4/5-axis milling and turning operations—encompass key parameters related to tool geometry, material compatibility, tolerance capabilities, and performance under high-precision demands. These tools are engineered to maintain tight tolerances (±0.005 mm to ±0.025 mm typical) across a range of engineering materials such as aluminum, steel, ABS, and nylon. Below is a summary of typical technical specifications.

| Parameter | Description |

|---|---|

| Axis Configuration | Compatible with 3-axis (X, Y, Z), 4-axis (adds A or B rotary), and 5-axis (dual rotary axes) CNC lathes and mill-turn centers. Enables complex geometries with single-setup efficiency. |

| Spindle Speed Range | 1,000 – 12,000 RPM (dependent on material and tooling); higher speeds used for aluminum and plastics, lower for steel. |

| Tool Material | Carbide inserts, CBN (Cubic Boron Nitride) for hardened steel, PCD (Polycrystalline Diamond) for aluminum and nylon. HSS used for low-speed ABS trimming. |

| Tolerance Capability | ±0.005 mm (±0.0002″) for critical dimensions; surface finishes down to 0.8–1.6 µm Ra achievable with fine-turning and finishing passes. |

| Feed Rates | 0.05 – 0.3 mm/rev (adjustable per material); optimized for chip load control and edge integrity. |

| Cutting Tools | Indexable inserts (e.g., CNMG, DNMG), boring bars, grooving tools, threading inserts, and live tooling for mill-turn operations. |

| Coolant Compatibility | Internal/external coolant delivery; high-pressure coolant recommended for steel and deep turning; mist coolant suitable for ABS/nylon. |

| Workpiece Materials | Aluminum (6061, 7075), Steel (1018, 4140, stainless), ABS (thermoplastic), Nylon (PA6, PA66). Tool coatings (TiAlN, AlCrN) selected per material. |

| Fixturing | Collet chucks, 3- or 4-jaw chucks, hydraulic expansion tool holders for vibration damping in high-speed/5-axis applications. |

| Surface Finish | Achievable Ra values: 0.8 µm (aluminum/steel fine finish), 1.6–3.2 µm (ABS/nylon with sharp polycarbonate-tipped tools). |

| Control System | Fanuc, Siemens, Heidenhain, or Mitsubishi CNC controls with high-resolution feedback for contouring accuracy in multi-axis moves. |

These specifications ensure that lathe machining tools meet the demands of high-precision prototyping and production, particularly when integrating milling and turning on multi-axis platforms. Material-specific tool paths and optimized cutting parameters are essential to achieving tight tolerances and superior surface quality across diverse substrates.

From CAD to Part: The Process

Honyo Prototype Lathe Machining Process Overview

Honyo Prototype employs a streamlined, technology-driven workflow for lathe machining services, designed to accelerate prototyping and low-volume production while ensuring manufacturability and cost efficiency. Our end-to-end process integrates AI validation with engineering expertise to minimize delays and rework. Below is a detailed explanation of each phase.

CAD Upload & Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) or 2D technical drawings via our secure customer portal. Our system immediately performs automated geometry validation, checking for critical issues such as unsupported file formats, unit inconsistencies, or missing datums. Files failing validation trigger instant notification with specific error details, allowing rapid client correction. Validated files proceed directly to the quoting engine, eliminating manual intake delays.

AI-Powered Quoting

Honyo’s proprietary AI engine analyzes the CAD geometry alongside material specifications, quantity, and tolerance requirements provided by the client. The system cross-references real-time machine availability, tooling libraries, and material costs to generate a technically accurate quote within 2 hours. Crucially, the AI performs preliminary manufacturability screening—flagging potential issues like excessive aspect ratios, non-standard thread forms, or geometric complexities requiring secondary operations. Quotes include explicit notes on these findings, enabling informed client decisions before commitment.

Engineering DFM Review

Upon quote acceptance, Honyo’s manufacturing engineering team conducts a rigorous Design for Manufacturability (DFM) analysis. This phase examines feature geometry, tolerance stack-ups, surface finish requirements, and material suitability against lathe capabilities (including Swiss-type and multi-axis turning centers). Engineers collaborate directly with clients via the portal to propose actionable optimizations—such as adjusting radii to reduce tool deflection or modifying chamfers to eliminate secondary operations—without compromising functional intent. Typical DFM resolution occurs within 4 business hours, significantly compressing traditional timelines.

Precision Production Execution

Approved designs move to our climate-controlled machining floor. All lathe operations utilize high-precision CNC equipment (e.g., Citizen Swiss-types, Mori Seiki turning centers) with in-process probing for closed-loop accuracy. Key practices include:

Material verification via certified mill certificates

First-article inspection against AS9102 standards

Real-time SPC monitoring of critical dimensions

Automated deburring and cleaning per client specifications

Complex parts undergo intermediate CMM checks at defined operation stages to ensure conformance before proceeding.

Quality-Controlled Delivery

Final inspection includes full FAI documentation, surface roughness validation, and dimensional reports traceable to NIST standards. Parts are packaged with anti-corrosion protection and serialized labels for full lot traceability. Shipping coordinates integrate with client ERP systems, providing real-time logistics updates. All deliverables include digital quality records accessible via the client portal, supporting audit requirements for regulated industries.

Process Efficiency Comparison

The following table highlights Honyo’s performance metrics against industry averages for lathe machining projects:

| Process Phase | Industry Average Duration | Honyo Prototype Duration | Key Differentiator |

|---|---|---|---|

| CAD to Quote | 24-72 hours | < 2 hours | AI-driven geometry validation |

| DFM Resolution | 24-48 hours | < 4 hours | Collaborative engineering portal |

| Production Lead Time | 7-14 days | 3-7 days | Dedicated lathe cell scheduling |

| First-Time Yield | 82-88% | 96-98% | In-process SPC and probing |

This integrated approach ensures clients receive dimensionally accurate, functionally validated machined components faster while reducing non-conformance risks. By embedding manufacturability insight early and leveraging automation for routine validation, Honyo transforms lathe machining from a potential bottleneck into a strategic asset for rapid product development.

Start Your Project

Explore high-precision lathe machining tools designed for demanding manufacturing applications. Built for performance, durability, and tight-tolerance accuracy, our tooling solutions support rapid prototyping and low-volume production.

Contact Susan Leo for technical specifications, pricing, and lead times.

Email: [email protected]

Factory located in Shenzhen, China – ISO-compliant facility with end-to-end quality control.

Request a quote today to streamline your machining operations with reliable, in-house manufactured tools.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.