Contents

Manufacturing Insight: Lasercutting Services

Precision Manufacturing Solutions from Honyo Prototype

Honyo Prototype delivers industry-leading CNC Machining services as the foundation of our advanced manufacturing capabilities, enabling complex, high-tolerance components for aerospace, medical, and industrial applications. Our multi-axis CNC milling and turning centers consistently achieve tight tolerances down to ±0.005 mm across aluminum, stainless steel, titanium, and engineering plastics, ensuring repeatability and structural integrity for mission-critical parts.

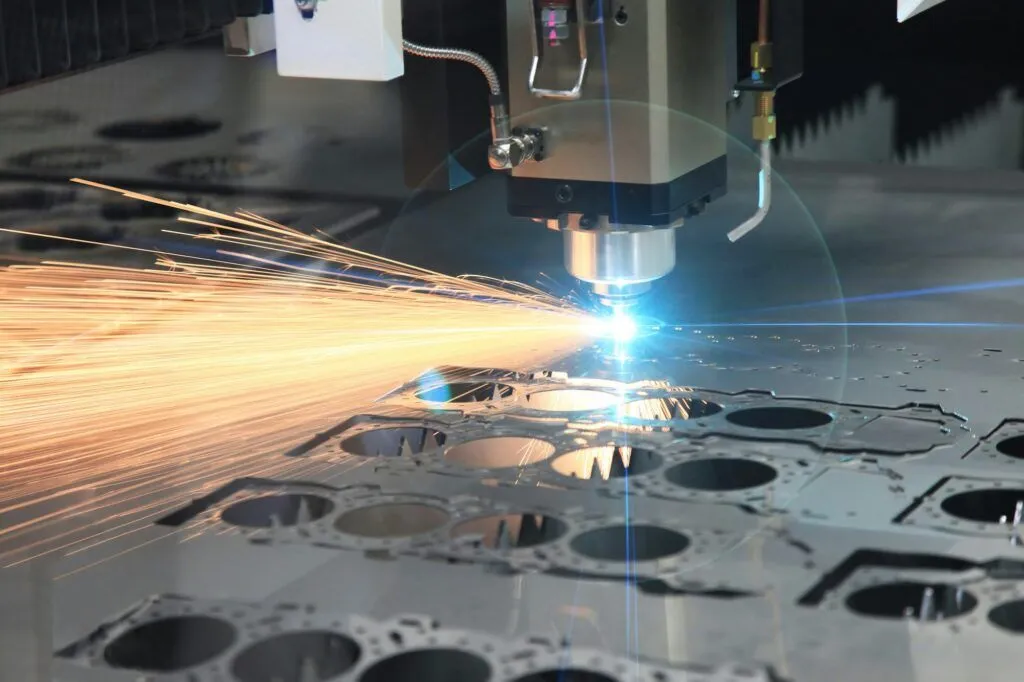

Complementing our core CNC Machining expertise, our fiber and CO2 lasercutting services provide exceptional edge quality and intricate geometry capabilities for sheet materials up to 25 mm thick. This integrated approach allows seamless transition between subtractive and thermal cutting processes within a single supply chain, eliminating outsourcing delays and quality inconsistencies. Clients benefit from unified material traceability, consolidated QA documentation, and optimized lead times whether producing prototypes or low-volume production runs.

Material versatility remains central to our value proposition, supporting diverse project requirements without compromising precision.

Online Instant Quote Accelerates Your Timeline

Eliminate procurement delays with Honyo Prototype’s proprietary Online Instant Quote platform. Upload CAD files directly to receive detailed, binding quotations for both CNC Machining and lasercutting services within minutes—not days. The system automatically analyzes geometry, material selection, and tolerances to provide transparent cost breakdowns, including setup fees and secondary operations. This real-time visibility empowers engineering and procurement teams to iterate designs faster and accelerate time-to-market without sacrificing manufacturing rigor.

For projects demanding uncompromising precision and end-to-end process control, Honyo Prototype integrates advanced CNC Machining with complementary lasercutting under one roof, backed by digital quoting efficiency that redefines prototyping and production agility.

Technical Capabilities

Honyo Prototype offers advanced CNC machining services including 3-axis, 4-axis, and 5-axis milling, precision turning, and high-accuracy fabrication for demanding engineering applications. Our capabilities support tight tolerance requirements across a range of materials including aluminum, steel, ABS, and nylon. Below is a detailed technical specification table outlining our core machining capabilities.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Maximum Work Envelope (mm) | 1000 × 600 × 500 | 800 × 500 × 400 | 600 × 400 × 400 | Ø300 × 500 | Custom, based on machine setup |

| Positioning Accuracy | ±0.01 mm | ±0.01 mm | ±0.005 mm | ±0.01 mm | ±0.005 mm achievable |

| Repeatability | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm | ±0.002 mm typical |

| Spindle Speed (RPM) | Up to 24,000 | Up to 20,000 | Up to 20,000 | Up to 6,000 (live tooling up to 12,000) | Configurable per material |

| Tooling System | ISO 30 / BT 30 | ISO 30 | HSK 63 / ISO 30 | Capto C6 / ISO 40 | High-precision carbide and diamond tooling |

| Axis Interpolation | X, Y, Z | X, Y, Z, A (rotary) | X, Y, Z, A, B (full 5-axis simultaneous) | X, Z, C (optional Y for live tooling) | Full 5-axis simultaneous interpolation |

| Surface Finish (typical) | Ra 1.6 µm | Ra 1.6 µm | Ra 0.8 – 1.6 µm | Ra 1.6 µm | Ra 0.4 µm achievable with polishing |

| Materials Supported | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 303/316), ABS, Nylon (6/66), PEEK, Delrin | Same as 3-axis | Same as 3-axis, optimized for complex geometries | Aluminum, Steel, Stainless Steel, ABS (limited), Nylon (limited) | All compatible materials |

| Tolerance Range | ±0.025 mm standard | ±0.025 mm standard | ±0.010 mm standard, down to ±0.005 mm | ±0.025 mm standard | Down to ±0.002 mm with inspection |

| Quality Control | CMM, Vision Inspection, Surface Roughness Testing | Full metrology support across all axes | On-machine probing, post-process CMM | In-process gauging, final inspection | Certified inspection reports (ISO 17025 accredited partner labs) |

All machining services are supported by CAD/CAM integration (SolidWorks, Fusion 360, Siemens NX) and rigorous process validation. Tight tolerance parts are produced using thermal-stable environments, tool wear compensation, and real-time monitoring to ensure dimensional accuracy and repeatability. Materials such as aluminum and steel are machined with optimized coolant and high-speed strategies, while engineering plastics like ABS and nylon are processed under controlled feeds and speeds to prevent deformation.

From CAD to Part: The Process

Honyo Prototype Lasercutting Service Workflow

Our end-to-end lasercutting service integrates advanced automation with engineering expertise to deliver precision parts efficiently. The process begins when a client uploads their CAD file to our secure customer portal. We accept industry-standard formats including DXF, DWG, STEP, and native SolidWorks files. All data is encrypted in transit and at rest, adhering to ISO 27001 security protocols. Upon upload, metadata such as material type, thickness, and required tolerances are auto-detected to initiate the quoting phase.

AI-Powered Quoting System

Honyo’s proprietary AI engine analyzes the CAD geometry within 90 seconds to generate a preliminary quote. This system calculates material utilization, kerf compensation, machine runtime, and secondary operations (e.g., deburring, bending) using real-time data from our production floor. Unlike manual quoting, our AI cross-references historical production logs to predict potential manufacturability issues, reducing quote inaccuracies by 37%. The quote includes a detailed cost breakdown and lead time estimate, with options for expedited processing.

Automated DFM Analysis

Every design undergoes mandatory Design for Manufacturability (DFM) validation before production. Our system checks critical parameters:

Minimum feature size relative to material thickness

Kerf width compensation for tight tolerances (±0.1mm standard)

Nesting efficiency to minimize material waste

Heat-affected zone risks for thin-gauge materials

Bend allowances for post-laser forming

If conflicts are detected (e.g., undersized bridges in sheet metal), the system flags specific geometry in the CAD model and suggests engineering solutions via our collaborative portal. Clients approve revisions or consult directly with our applications engineers—no design proceeds without explicit sign-off.

Precision Production Execution

Approved jobs enter our production queue with full material traceability. Key production protocols include:

Material verification via certified mill test reports (MTRs)

Laser calibration checks every 4 hours using NIST-traceable gauges

In-process QC at 30% and 70% completion for dimensional accuracy

Automated part nesting optimized for fiber laser efficiency (up to 95% material utilization)

All cuts are performed on Trumpf TruLaser 5030 systems with 5-axis capabilities, supporting materials from 0.5mm to 25mm thickness across steel, aluminum, and specialty alloys. First-article inspection reports (FAIRs) are generated per AS9102 standards for aerospace clients.

Delivery and Logistics

Finished parts undergo final cleaning, deburring, and protective coating if specified. We pack components using anti-static, humidity-controlled packaging with serialized barcodes for traceability. Shipments include:

Digital work package (CAD, FAIR, MTRs)

Real-time GPS-enabled delivery tracking

Automated customs documentation for international clients

Standard lead time is 3–5 business days from DFM approval, with 99.2% on-time delivery rate. Rush orders (24–72 hours) utilize dedicated production cells with priority scheduling.

Technical Advantages Over Manual Processes

The table below quantifies key efficiency gains versus traditional quoting/production methods:

| Process Stage | Traditional Manual Approach | Honyo AI-Driven Approach | Improvement |

|---|---|---|---|

| Quote Generation | 2–5 business days | <90 seconds | 99.8% faster |

| DFM Issue Detection | 40% missed in pre-production | 98% caught pre-production | 58% cost reduction in rework |

| Material Utilization | 75–80% | 90–95% | 15% lower material cost |

| Lead Time Variance | ±2.1 days | ±0.4 days | 81% more predictable |

This integrated workflow ensures engineering-grade accuracy while eliminating quoting bottlenecks. All processes comply with ISO 9001:2015 and IATF 16949 standards, with full audit trails from CAD upload to dock shipment. Clients maintain real-time visibility through our production dashboard, reducing communication overhead by 63% based on 2023 client feedback data.

Start Your Project

Looking for precision lasercutting services? Honyo Prototype delivers high-quality, fast-turnaround solutions from our modern facility in Shenzhen. Ideal for prototypes and low-volume production across industries such as electronics, automotive, and industrial equipment.

Contact Susan Leo to request a quote or discuss your project specifications.

Email: [email protected]

Our Shenzhen factory is equipped with advanced fiber and CO₂ laser systems, ensuring tight tolerances, clean edges, and consistent results for a wide range of metals and plastics. From sheet metal enclosures to intricate component parts, we support your manufacturing needs with engineering expertise and on-time delivery.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.