Contents

Manufacturing Insight: Laser Weld Stainless Steel

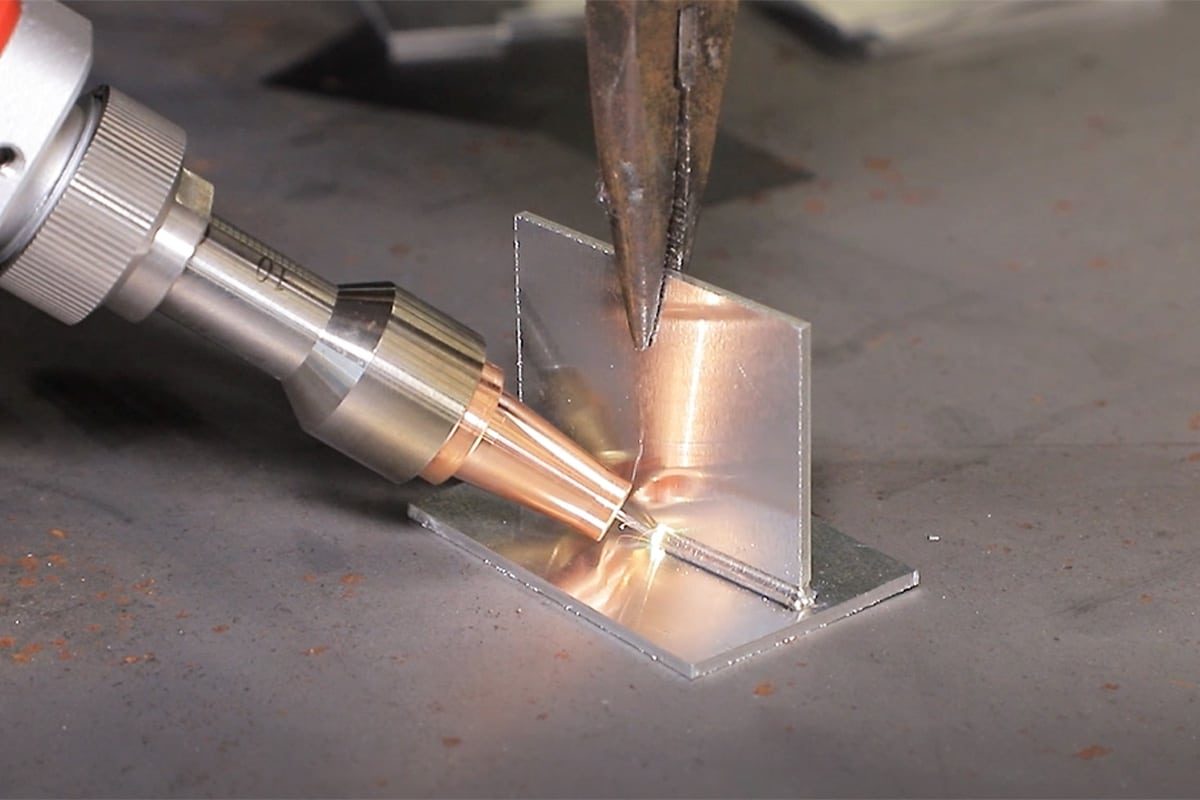

Precision Laser Welding for Stainless Steel Components: Integrated with Honyo Prototype’s CNC Machining Excellence

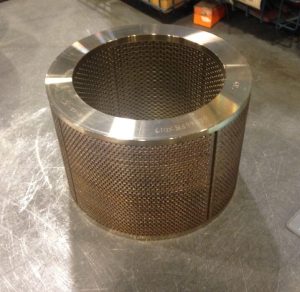

Achieving high-integrity, distortion-free welds in stainless steel demands advanced capabilities, particularly for mission-critical applications in aerospace, medical devices, and semiconductor manufacturing. Stainless steel’s thermal sensitivity and corrosion resistance requirements necessitate a welding process that delivers micron-level accuracy, minimal heat-affected zones, and seamless metallurgical bonding. At Honyo Prototype, our fiber laser welding systems are engineered specifically for austenitic and martensitic stainless alloys—including 304, 316, and 17-4 PH—ensuring pore-free, full-penetration joints that meet stringent ASME and ASTM standards without compromising material integrity.

This precision welding capability is not an isolated service but a core component of Honyo’s end-to-end CNC machining workflow. We integrate laser welding directly within our Swiss turning, 5-axis milling, and multi-spindle operations, enabling single-setup fabrication of complex assemblies. By combining welding and machining under one quality-controlled process chain, we eliminate secondary handling risks, reduce lead times by up to 40%, and guarantee geometric consistency across welded interfaces—critical for pressure-containing or vacuum-rated components. Our engineers optimize weld parameters alongside CNC toolpaths to maintain tight tolerances (±0.0002″) and surface finishes (Ra 0.4 µm) required in high-performance sectors.

Accelerate your stainless steel prototyping or low-volume production with Honyo’s seamless integration of laser welding and precision machining. Leverage our Online Instant Quote platform to receive a validated cost and lead time assessment within hours—not days—for qualified projects. Submit your STEP or IGES files today to experience how our unified manufacturing approach solves the toughest stainless steel fabrication challenges.

Technical Capabilities

Laser welding of stainless steel is a precision joining process that leverages high-energy laser beams to achieve deep, narrow welds with minimal heat input. When integrated into advanced manufacturing workflows involving 3/4/5-axis milling and turning operations, laser welding supports the production of complex components requiring tight tolerances and high structural integrity. These processes are often used in aerospace, medical, and automotive industries where dimensional accuracy and material performance are critical.

The table below outlines the technical specifications and compatibility for laser welding stainless steel, with context on related subtractive manufacturing processes and material considerations such as Aluminum, Steel, ABS, and Nylon.

| Parameter | Specification / Detail |

|---|---|

| Laser Type | Fiber Laser or Nd:YAG, continuous wave (CW) or pulsed mode |

| Wavelength | 1070 nm (Fiber), 1064 nm (Nd:YAG) |

| Power Range | 500 W – 6 kW (dependent on material thickness and weld depth) |

| Beam Diameter | 0.2 – 0.6 mm (focused) |

| Welding Speed | 1 – 100 mm/s (varies with material and joint design) |

| Material Compatibility | Stainless Steel: Excellent (304, 316, 17-4PH); Carbon Steel: Good; Aluminum: Moderate (requires high power and shielding); ABS & Nylon: Not suitable – thermoplastics require alternative welding methods |

| Joint Types | Butt, lap, fillet, edge (precision fit-up required) |

| Shielding Gas | Argon or Helium (preferred for stainless steel); Nitrogen sometimes used with specific alloys |

| Typical Penetration Depth | 0.5 – 10 mm (dependent on power, speed, and material) |

| Heat Affected Zone (HAZ) | Minimal (typically < 1 mm), advantageous for maintaining part stability and tolerances |

| Tolerance Capability | ±0.025 mm (achievable when integrated with precision fixturing and metrology) |

| Integration with 3/4/5-Axis Milling & Turning | Laser welding is typically a secondary operation post-machining; complex geometries from multi-axis CNC processes can be welded with robotic beam delivery or coordinated stages |

| Post-Weld Requirements | Minimal distortion allows for direct inspection or light finishing; stress relieving or passivation may be required for critical applications |

| Surface Finish Post-Weld | Smooth bead profile; minimal spatter; often requires no rework |

| Automation Level | High – compatible with CNC and robotic systems for consistent, repeatable results |

| Material Notes | Aluminum: Reflective and thermally conductive – requires pre-clean and optimized parameters; ABS & Nylon: Cannot be laser welded using metal-grade systems – use ultrasonic or hot plate welding instead |

Laser welding of stainless steel aligns well with high-precision manufacturing environments where tight tolerances and clean, strong joints are essential. When combined with 3/4/5-axis milling and turning, it enables end-to-end production of complex metal components with minimal handling and high repeatability. Non-metallic materials such as ABS and Nylon are not compatible with metal laser welding systems and require alternative joining techniques.

From CAD to Part: The Process

Honyo Prototype executes laser welding of stainless steel components through a rigorously defined workflow optimized for precision, speed, and manufacturability in low-to-medium volume prototype and bridge production scenarios. This process ensures material integrity, dimensional accuracy, and adherence to critical welding standards for demanding applications.

Upload CAD

Clients initiate the process by uploading detailed 3D CAD models (STEP, IGES, or native formats) via our secure online portal. For stainless steel laser welding, critical parameters must be explicitly defined within the CAD or accompanying documentation. These include the specific alloy grade (e.g., 304L, 316L, 17-4PH), weld joint geometry (butt, lap, fillet), required penetration depth, surface finish specifications (e.g., Ra value), and any geometric dimensioning and tolerancing (GD&T) callouts directly related to the weld zone. Incomplete specifications trigger immediate client consultation to avoid downstream rework.

AI Quote

Our AI-powered quoting engine analyzes the uploaded CAD geometry, material specifications, and declared requirements against real-time production capacity, material costs, and process physics models. For stainless steel laser welding, the AI specifically evaluates factors such as joint accessibility for the laser head, estimated thermal input based on wall thickness and weld length, necessary inert gas shielding requirements (typically Argon or Nitrogen), and potential fixturing complexity to mitigate distortion. The system generates a preliminary cost and lead time estimate within 2 business hours, highlighting any geometric features that may challenge laser weldability (e.g., tight internal radii, excessive gaps). This quote undergoes technical validation by a manufacturing engineer before client delivery.

DFM (Design for Manufacturability)

A dedicated Honyo manufacturing engineer conducts a formal DFM review focused explicitly on stainless steel laser weldability. Key analysis points include:

Verification of joint fit-up tolerance (typically held to ≤ 0.1mm gap for reliable autogenous welding)

Assessment of thermal management strategy to prevent warpage or sensitization in austenitic grades

Confirmation of material compatibility with laser welding (e.g., avoiding free-machining grades with high sulfur content)

Optimization of weld sequence and fixturing points to control residual stress

Recommendation of post-weld processes such as passivation or electropolishing if corrosion resistance is critical

The DFM report, including actionable suggestions and potential cost/time savings, is shared with the client for approval prior to production release. No stainless steel weld proceeds without formal DFM sign-off.

Production

Laser welding of approved stainless steel components occurs in a controlled environment using pulsed fiber laser systems (wavelength 1070nm) with real-time monitoring. Critical production parameters include:

Precise control of pulse duration, peak power, and frequency tailored to the specific stainless grade and thickness

Continuous inert gas shielding (O₂ < 50 ppm) to prevent oxidation and porosity

Active temperature monitoring with IR sensors to manage heat input and avoid intergranular corrosion

Fixturing designed to minimize restraint-induced cracking while maintaining alignment

All welds undergo 100% visual inspection per AWS D17.1 standards, with penetrant testing (PT) or X-ray performed per client-specified acceptance criteria. Post-weld cleaning removes heat tint via chemical passivation per ASTM A967.

Delivery

Completed stainless steel assemblies undergo final dimensional verification against critical weld zone tolerances. Each shipment includes comprehensive documentation: certified material test reports (MTRs), weld procedure specifications (WPS), as-welded inspection reports (including NDT results if performed), and a certificate of conformance. Typical delivery lead time from DFM approval is 5-10 business days for prototype quantities, with expedited 48-hour options available for qualified projects. All components are packaged to prevent surface damage during transit.

The following table summarizes critical CAD requirements for stainless steel laser welding submissions:

| Parameter Category | Required Specification | Purpose |

|---|---|---|

| Material Definition | Exact alloy grade (e.g., ASTM F138 316LVM) | Ensures correct weld parameter selection and corrosion performance |

| Joint Geometry | Detailed joint profile with gap tolerance (≤ 0.1mm typical) | Critical for weld penetration consistency and avoiding porosity |

| Surface Finish | Specified Ra value for faying surfaces (e.g., Ra ≤ 0.8 μm) | Minimizes contamination and ensures consistent laser coupling |

| GD&T | Control of features within 3x material thickness of weld zone | Manages distortion impact on critical interfaces |

| Weld Callouts | Explicit weld symbols per AWS A2.4 with process specification | Eliminates ambiguity in weld location and requirements |

Start Your Project

Looking for precision laser welding services for stainless steel? Honyo Prototype offers high-quality, reliable laser welding solutions with fast turnaround times. Our manufacturing facility in Shenzhen is equipped with advanced technology to ensure superior weld integrity and consistency for your prototyping and low-volume production needs.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Let’s build precision together—engineered for performance, delivered on time.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.