Contents

Manufacturing Insight: Laser Vs Plasma Cnc

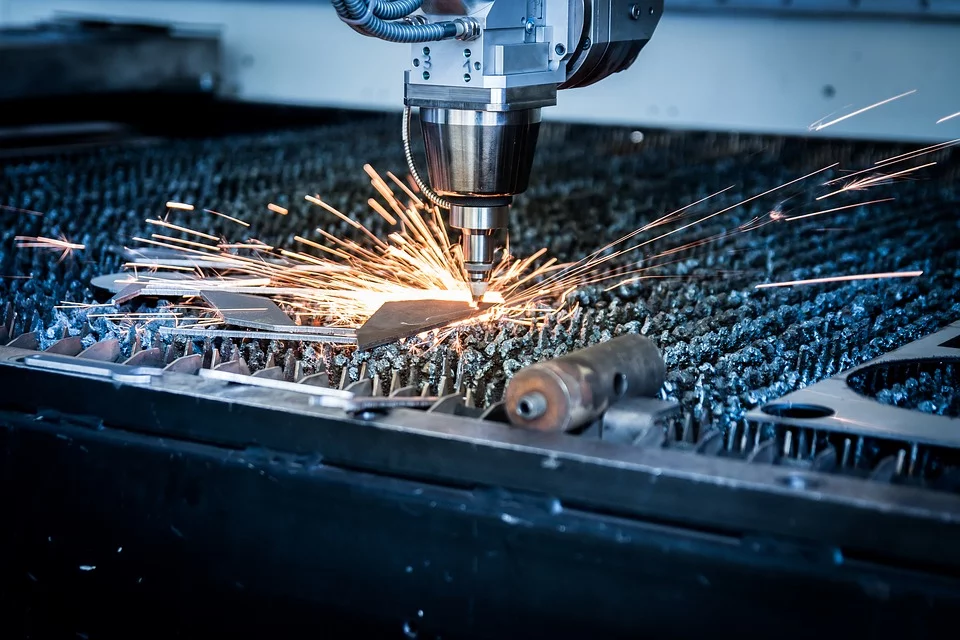

Precision Material Processing: Navigating Laser vs Plasma CNC Cutting for Optimal Manufacturing Outcomes

Selecting between laser and plasma CNC cutting technologies presents a critical decision point for industrial manufacturers seeking precision, efficiency, and cost-effectiveness. Laser cutting excels in delivering intricate geometries and superior edge quality on thin to medium-thickness metals and non-ferrous materials, leveraging focused photonic energy for minimal thermal distortion. Plasma cutting, conversely, dominates in high-speed severing of thicker conductive materials—particularly steel alloys exceeding 25mm—where raw throughput and operational cost per meter outweigh micron-level finish requirements. The optimal choice hinges on specific project parameters: material type, thickness tolerances, production volume, and secondary processing needs.

At Honyo Prototype, we engineer CNC machining solutions that transcend generic fabrication. Our integrated facility houses advanced fiber laser systems (up to 6kW) for sub-0.1mm kerf accuracy on materials up to 30mm, alongside high-definition plasma platforms (100A+) capable of cutting 50mm+ mild steel with precision motion control. We prioritize metallurgical integrity and dimensional repeatability through proprietary nesting algorithms, real-time process monitoring, and AS9100-certified quality protocols. This technical rigor ensures your components meet aerospace, medical, and industrial equipment specifications without costly rework.

For immediate project assessment, leverage our Online Instant Quote platform. Upload CAD files to receive a detailed manufacturability analysis and competitive pricing within hours—not days—factoring in material optimization, technology selection, and secondary operations. This eliminates quoting bottlenecks while providing transparent cost drivers for informed procurement decisions.

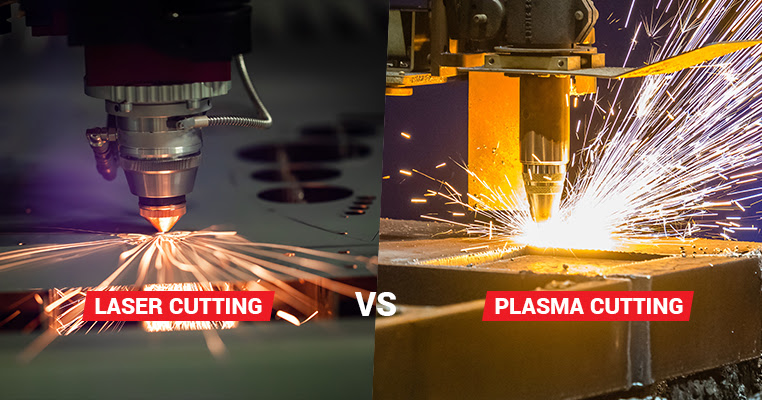

Technology Comparison at a Glance

| Parameter | Laser CNC Cutting | Plasma CNC Cutting |

|——————–|————————-|————————|

| Optimal Thickness | 0.5–25mm | 10–50mm+ |

| Edge Quality | Burr-free, smooth finish| Moderate dross (requires secondary finishing) |

| Material Range | Steel, aluminum, brass, composites | Primarily conductive metals (steel, stainless, copper) |

| Precision Tolerance| ±0.05mm | ±0.25mm |

| Production Speed | High for thin materials | Superior for thick sections |

Honyo Prototype transforms material processing challenges into competitive advantages through technology-agnostic expertise and rapid-turn engineering collaboration. Initiate your precision manufacturing workflow with confidence—where technical insight meets operational agility.

Technical Capabilities

Laser and plasma CNC systems are primarily thermal cutting technologies used for 2D or 2.5D profile cutting of sheet or plate materials. They are not suitable for 3/4/5-axis milling or turning operations, which require subtractive machining methods such as CNC milling or lathe-based tooling. Similarly, achieving tight tolerances (typically ±0.001″ or better) is generally outside the capability of standard laser and plasma processes, especially with plasma, due to heat-affected zones (HAZ), taper, and edge quality limitations.

For high-precision 3/4/5-axis milling and turning with tight tolerances, CNC machining centers and multi-axis lathes using carbide or diamond-tipped cutting tools are the appropriate technologies. These processes can precisely machine complex geometries in materials like aluminum, steel, ABS, and nylon with excellent surface finish and dimensional accuracy.

Below is a comparative table outlining the technical capabilities of laser and plasma CNC systems versus CNC milling/turning systems in the context of multi-axis operations, material compatibility, and tolerance performance.

| Feature | CNC Laser Cutting | CNC Plasma Cutting | CNC 3/4/5-Axis Milling & Turning |

|---|---|---|---|

| Primary Function | 2D/2.5D thermal cutting | 2D/2.5D thermal cutting | 3D contouring, milling, turning, drilling |

| Multi-Axis Capability | Limited to 2D or 3-axis motion for bevel cutting (not full 5-axis) | Typically 2-axis; limited 3-axis for bevels | Full 3, 4, and 5-axis simultaneous motion |

| Typical Tolerance | ±0.005″ – ±0.010″ | ±0.010″ – ±0.020″ | ±0.0005″ – ±0.005″ (tight tolerance capable) |

| Surface Finish | Smooth cut edge, minor dross | Rougher edge, moderate dross | Fine surface finish (Ra < 32 μin achievable) |

| Heat-Affected Zone (HAZ) | Small (especially with fiber laser) | Moderate to large | Minimal (mechanical removal, no thermal input) |

| Materials – Aluminum | Yes (thin to medium thickness) | Yes (conductive only) | Yes (all grades, including 6061, 7075) |

| Materials – Steel | Yes (mild, stainless, up to 1″) | Yes (mild, thicker sections) | Yes (mild, stainless, tool steel, etc.) |

| Materials – ABS | Limited (melts, poor edge) | No (non-conductive, melts) | Yes (excellent machinability) |

| Materials – Nylon | Poor (melts, inconsistent edge) | No (non-conductive, melts) | Yes (good machinability, low friction) |

| Tooling / Consumables | Laser lens, nozzle, assist gas | Electrode, nozzle, shield cap | End mills, drills, inserts, collets |

| Best For | High-speed 2D cutting of metals | Thick-section conductive metals | Complex geometries, tight tolerances, mixed materials |

| Limitations | Reflective materials, thick steel | Poor edge quality, high HAZ | Slower than thermal cutting for simple profiles |

Summary:

For applications requiring 3/4/5-axis capabilities, tight tolerances, and compatibility with both metallic and non-metallic materials such as aluminum, steel, ABS, and nylon, CNC milling and turning are the correct manufacturing solutions. Laser and plasma CNC systems serve a different purpose—efficient, high-speed cutting of conductive sheet or plate materials—but lack the precision, multi-axis motion, and material flexibility needed for advanced machining tasks.

From CAD to Part: The Process

Honyo Prototype Laser vs Plasma CNC Process Workflow

Honyo Prototype integrates material science expertise and precision manufacturing into a streamlined five-stage workflow for laser and plasma CNC cutting projects. The selection between laser and plasma methods is not predetermined but is strategically evaluated during the Design for Manufacturability (DFM) phase based on technical requirements.

Upload CAD

Customers submit CAD files (DXF, DWG, STEP) via our secure portal. Our system immediately analyzes geometric complexity, material type, thickness, and critical tolerances. For instance, geometries requiring ±0.1mm tolerances or materials under 25mm thickness are flagged for potential laser suitability, while thicker sections (e.g., 25–100mm carbon steel) trigger plasma evaluation.

AI Quote

Our AI engine generates a preliminary cost estimate within 2 hours, calculating variables for both laser and plasma methods. The quote explicitly compares:

Estimated cycle time per method

Material waste analysis (kerf width: laser 0.1–0.5mm vs plasma 1.5–3mm)

Projected cost delta (e.g., plasma may show 15–30% cost savings for >30mm mild steel)

This stage provides data-driven options but does not finalize the cutting method.

DFM Engineering Review

Honyo’s manufacturing engineers conduct a rigorous DFM analysis to determine the optimal process. Key decision criteria include:

| Parameter | Laser CNC Selection Criteria | Plasma CNC Selection Criteria |

|---|---|---|

| Material Thickness | ≤25mm (stainless/Al) ≤30mm (mild steel) | >25mm (all conductive metals) |

| Edge Quality | Critical (mirror finish, no dross) | Secondary (dross acceptable) |

| Tolerances | ±0.1mm or tighter | ±0.5mm acceptable |

| Heat-Affected Zone | Must be minimized | Permissible |

Engineers validate cut feasibility, recommend kerf compensation adjustments (plasma requires +15–25% kerf allowance), and confirm assist gas requirements (N₂ for laser stainless, O₂ for plasma carbon steel). Customer approval is required before proceeding.

Production Execution

Upon DFM sign-off:

Laser systems (20kW fiber lasers) deploy for high-precision thin-gauge work with nitrogen assist gas to prevent oxidation.

Plasma systems (400A high-definition plasma) process thick plates using oxygen for exothermic reaction efficiency.

Real-time monitoring tracks cut speed, torch height, and thermal distortion. First-article inspection validates edge squareness (≤0.5° deviation for laser) and dimensional accuracy per ASME Y14.5.

Delivery Assurance

All deliverables include method-specific documentation:

Laser-cut parts: Surface roughness reports (Ra ≤ 3.2μm) and gas purity certificates

Plasma-cut parts: Dross level classification (per ISO 9013) and HAZ measurement logs

Shipments include serialized traceability tags linking to original CAD, DFM notes, and in-process inspection data. Typical lead time from CAD upload to delivery is 3–5 business days for standard orders.

This structured approach ensures technical alignment between customer requirements and process capabilities, eliminating method-related rework through engineering-led validation at the DFM stage. Honyo maintains 99.2% first-pass yield across both cutting modalities by enforcing this protocol.

Start Your Project

Considering the precision and speed of laser cutting versus the robustness and cost-effectiveness of plasma CNC for your next fabrication project? Understand the key differences and find the optimal solution tailored to your material, tolerance, and production requirements.

Contact Susan Leo at [email protected] to discuss your application in detail. With our advanced manufacturing facility located in Shenzhen, we deliver high-quality, scalable metal fabrication services using both laser and plasma CNC technologies—backed by engineering expertise and strict quality control.

| Feature | Laser CNC | Plasma CNC |

|---|---|---|

| Best For | Thin to medium metals, fine detail | Thick conductive metals, heavy-duty cutting |

| Precision | ±0.1 mm | ±0.5 mm |

| Edge Quality | Smooth, minimal dross | Good, may require post-processing |

| Material Thickness | Up to 25 mm (steel) | Up to 50+ mm (steel) |

| Operating Cost | Higher initial cost, lower operating | Lower initial cost, higher consumable use |

Let Susan Leo guide you to the right process for your project. Email [email protected] today.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.