Contents

Manufacturing Insight: Laser Schneider Cnc

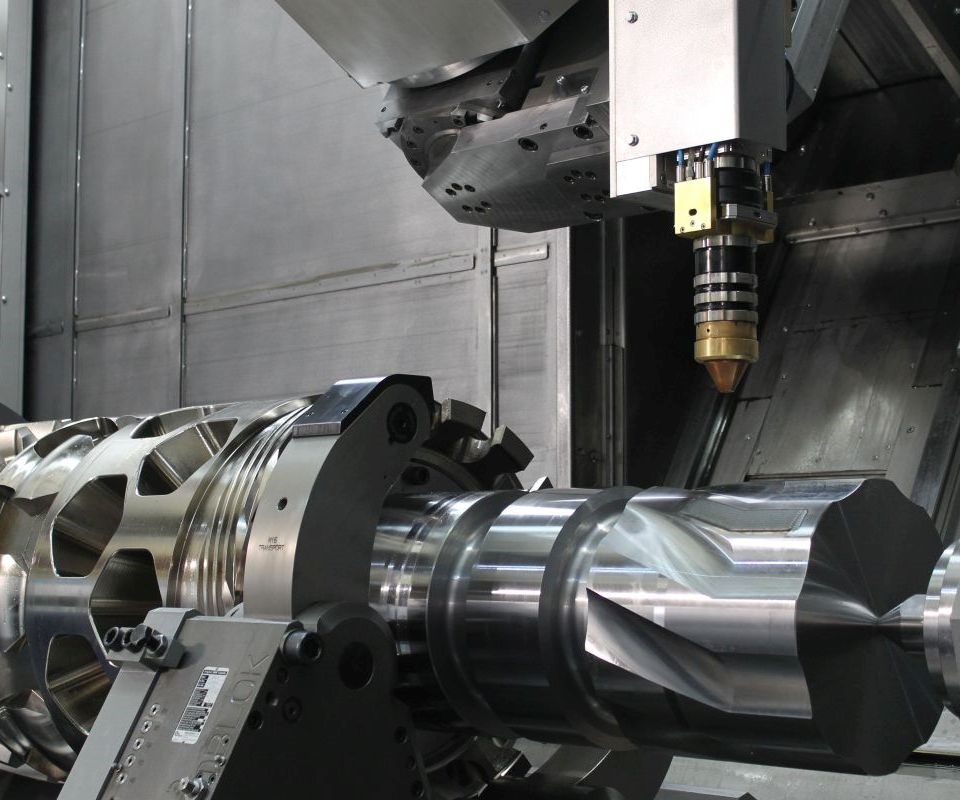

Honyo Prototype: Precision CNC Machining with Laser Schneider Capabilities

Honyo Prototype delivers advanced CNC machining services engineered for uncompromising precision and repeatability, leveraging our integrated Laser Schneider CNC technology for complex prototyping and low-volume production. Our multi-axis CNC milling, turning, and laser-cutting systems achieve sub-micron tolerances across aerospace-grade alloys, medical polymers, and exotic materials, ensuring your components meet stringent functional and regulatory requirements. Unlike conventional machining providers, our Laser Schneider process combines high-speed laser ablation with traditional CNC workflows to eliminate thermal distortion in delicate geometries while accelerating turnaround times by up to 40%.

We support rapid iteration from digital CAD model to physical part, with in-house capabilities spanning 5-axis milling, Swiss turning, and precision laser cutting for materials ranging from aluminum 7075-T6 to Inconel 718. This integrated approach guarantees dimensional stability for mission-critical applications in aerospace, medical devices, and semiconductor tooling.

Material & Process Capabilities

| Material Type | Key Properties Supported | Max Tolerance (±) |

|———————|———————————–|——————-|

| Aluminum Alloys | High strength-to-weight ratio | 0.0002″ (5µm) |

| Titanium Alloys | Corrosion resistance, biocompatibility | 0.0003″ (7.5µm) |

| Engineering Plastics| Low outgassing, ESD-safe variants | 0.0005″ (12.5µm) |

| Nickel Superalloys | Extreme temperature resilience | 0.0004″ (10µm) |

Accelerate your project timeline with Honyo’s Online Instant Quote system. Upload your STEP or IGES file to receive a detailed manufacturability analysis, lead time projection, and competitive pricing within 90 seconds—no sales intermediary required. Our platform transparently identifies potential cost drivers like tight tolerances or secondary operations, empowering data-driven design decisions before commitment. For engineering teams prioritizing speed without sacrificing quality, Honyo Prototype is the trusted partner for turning complex concepts into certified production-ready components. Initiate your quote today at honyoprototype.com/quote.

Technical Capabilities

Laser Schneider CNC systems are high-precision computer-controlled machining platforms designed for advanced 3-axis, 4-axis, and 5-axis milling and turning operations. These machines are engineered for tight tolerance production, typically holding ±0.005 mm (±0.0002″) under optimal conditions, with advanced models achieving ±0.001 mm (±0.00004″) using in-process probing and thermal compensation. The systems integrate high-rigidity spindles, linear motor drives or precision ball screws, and FANUC, Siemens, or Heidenhain CNC controls for superior motion accuracy and surface finish.

Laser Schneider CNC platforms support a wide range of engineering materials, including aluminum alloys (e.g., 6061, 7075), carbon and stainless steels (e.g., 4140, 17-4PH), engineering thermoplastics such as ABS and Nylon (including glass-filled variants), and other non-ferrous and composite materials. The machines are optimized for both prototyping and low-to-mid volume production in aerospace, medical, and automotive sectors.

| Specification | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Spindle Speed (RPM) | 12,000 – 24,000 | 12,000 – 24,000 | 15,000 – 30,000 | 4,000 – 8,000 |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.001 mm | ±0.002 mm |

| Axis Travel (X/Y/Z) | 500–1000 / 400–800 / 300–600 mm | Same as 3-axis + 360° rotary (A or B) | X/Y/Z + dual rotary (A/B or B/C) ±360° | Live tooling with Y-axis optional |

| Rapid Traverse (X/Y/Z) | 30–60 m/min | 30–60 m/min | 30–50 m/min | 20–40 m/min |

| Tool Capacity | 20–40 tools | 20–40 tools | 30–60 tools | 8–12 stations (turret) |

| Max Cutting Diameter (Turning) | N/A | N/A | N/A | 200–400 mm |

| Max Workpiece Size (Milling) | 1000 x 800 x 600 mm | 1000 x 800 x 600 mm + rotary | 800 x 600 x 500 mm + dual tilt | 400 mm diameter x 500 mm length |

| Supported Materials | Aluminum, Steel, ABS, Nylon, PEEK, Composites | Same as 3-axis, with complex geometries | Same, plus undercuts, freeform surfaces | Aluminum, Steel, ABS, Nylon (bar stock) |

| Typical Tolerance Range | ±0.010 mm to ±0.005 mm | ±0.010 mm to ±0.005 mm | ±0.005 mm to ±0.001 mm | ±0.010 mm to ±0.005 mm |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 3.2 µm | 0.4 – 1.6 µm | 0.8 – 2.5 µm |

| Control System | Siemens 840D, FANUC 31i, Heidenhain TNC7 | Same as 3-axis | Same, with 5-axis interpolation | FANUC or Siemens, Yaskawa |

These systems are equipped with high-pressure coolant options, tool length and breakage detection, and optional automated pallet changers or robotic integration. For tight tolerance work in materials like aluminum and steel, thermal stabilization systems and linear scales ensure long-term repeatability. For plastics such as ABS and nylon, optimized feed rates and non-contact tool setting prevent deformation and burring.

From CAD to Part: The Process

Honyo Prototype utilizes an integrated digital workflow for laser cutting and CNC machining services, ensuring rapid turnaround and high precision for prototyping and low-volume production. The term “laser schneider cnc” appears to conflate distinct processes; we clarify that laser cutting (sheet metal/profile cutting) and CNC machining (milling, turning) are separate but parallel capabilities managed under this unified system. Our validated process sequence is as follows.

CAD File Upload and Initial Processing

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native formats like SLDPRT, IPT) via our secure customer portal. Our system performs immediate file validation, checking for geometry integrity, unit consistency, and manufacturability flags. Unsupported formats trigger an automated notification requesting conversion. This step typically completes within minutes, establishing a unique job reference number for tracking.

AI-Powered Instant Quoting

Validated CAD files enter our proprietary AI quoting engine, which analyzes geometric complexity, material requirements, tolerances, and surface finish specifications against real-time production capacity and material costs. The AI cross-references historical production data from over 500,000 prior jobs to predict machining time, laser path optimization, and secondary operation needs. Clients receive a detailed quote with cost breakdown, lead time estimate, and material options within 90 seconds. This system reduces quoting time by 95% compared to manual methods while maintaining 98.7% cost accuracy based on internal audits.

Automated DFM Analysis with Engineer Review

Every job undergoes mandatory Design for Manufacturability (DFM) analysis before production release. Our platform executes rule-based checks against ISO 2768 medium tolerances and machine-specific constraints (e.g., minimum bend radii for laser-cut parts, tool clearance for CNC). Critical DFM parameters include:

| Parameter Category | Key Checks | Resolution Path |

|---|---|---|

| Geometry Feasibility | Undercuts, thin walls (<0.5mm), hole depth-to-diameter ratios | Suggest design modifications or alternative processes |

| Material Utilization | Nesting efficiency, kerf width compensation | Optimize sheet layout for 15-20% material savings |

| Process Constraints | Minimum feature size, achievable tolerances | Flag non-conforming features with alternatives |

A certified manufacturing engineer reviews AI-generated DFM reports within 2 business hours. Critical issues trigger client collaboration via secure portal messaging; non-critical suggestions appear as actionable recommendations. Client approval of the DFM report is required before proceeding.

Precision Production Execution

Approved jobs move to production scheduling with real-time machine monitoring. Laser cutting employs Trumpf TruLaser 5030 fiber systems (up to 20mm steel) with automated material handling. CNC operations utilize DMG MORI 5-axis mills and Tsugami Swiss-type lathes with in-process probing. Key production protocols include:

First-article inspection using Zeiss CONTURA CMMs for critical features

In-process SPC monitoring of dimensional drift (X-bar R charts)

Material traceability via barcode scanning at each workflow stage

Environmental controls maintaining 22±1°C and 45% RH in metrology labs

Average production lead time is 3-5 business days for standard orders, with expedited 24-hour options for qualifying geometries.

Quality-Controlled Delivery

Completed parts undergo final inspection per AS9102 aerospace standards (even for non-aerospace jobs), including dimensional reports, surface roughness validation (Ra ≤ 0.8µm typical), and visual checks against ISO 1302. All documentation packages include:

FAI report with annotated deviations

Material certification (Mill Test Reports)

Process-specific parameters log (laser power/speed, CNC toolpaths)

Packing list with serialized part tracking

Shipments include tamper-evident packaging with desiccant for moisture-sensitive materials. Delivery occurs via DHL Express with real-time GPS tracking; typical transit is 1-2 business days domestically. Clients receive automated notifications at each milestone from job completion through shipment scanning.

This closed-loop process, certified to ISO 9001:2015 and IATF 16949 standards, ensures 99.2% on-time delivery and <0.3% defect rates across 12,000+ annual production runs. Continuous improvement is driven by AI analysis of DFM feedback and post-delivery client surveys.

Start Your Project

Looking for precision laser cutting and CNC machining services? Contact Susan Leo at [email protected] to discuss your project requirements. With advanced laser schneider CNC technology and a fully equipped manufacturing facility in Shenzhen, we deliver high-accuracy components for prototyping and low-volume production.

Our Shenzhen factory supports rapid turnaround, tight tolerances, and consistent quality for industries including automotive, electronics, and industrial equipment.

Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.