Contents

Manufacturing Insight: Laser Power For Cutting Steel

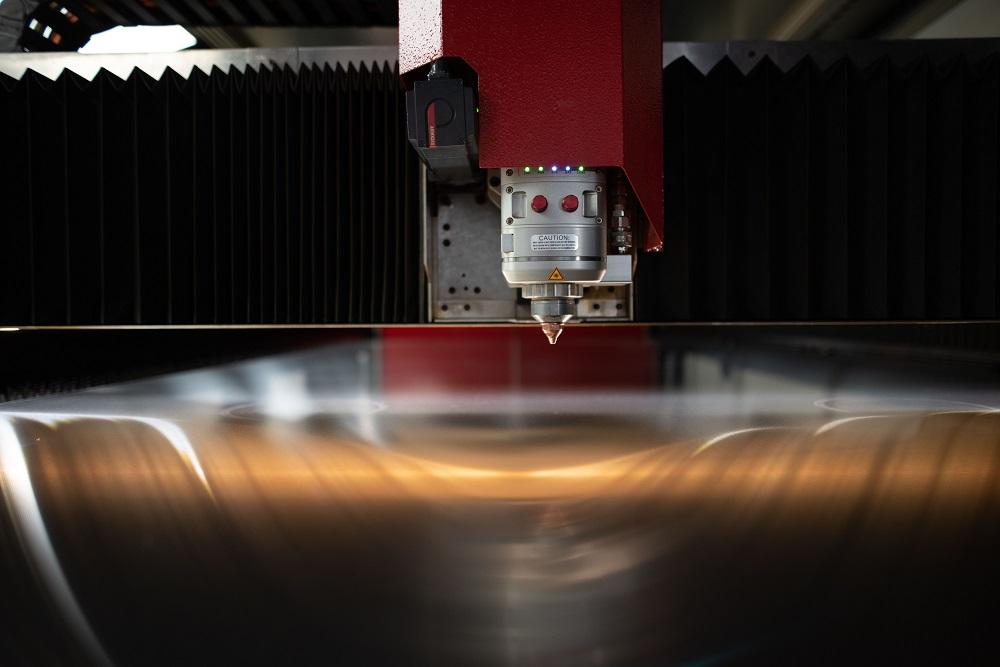

Optimizing Laser Power for Precision Steel Cutting in Advanced Manufacturing

Laser power selection is a critical engineering parameter directly influencing cut quality, edge integrity, and throughput when processing steel. Insufficient power leads to incomplete penetration, dross formation, and thermal distortion, while excessive power wastes energy and increases operational costs without proportional quality gains. At Honyo Prototype, our CNC laser cutting services leverage precisely calibrated high-power fiber laser systems (1kW to 6kW) engineered to match material thickness, grade, and geometric complexity. This ensures clean, burr-free edges on mild steel, stainless, and tool steels up to 25mm, with kerf widths held to ±0.1mm tolerances and minimal heat-affected zones.

Our technical team applies material science expertise to optimize power density, assist gas selection, and cutting speed for each application, eliminating trial-and-error waste. This precision translates to reduced secondary finishing, higher yield rates, and accelerated time-to-assembly for structural components, enclosures, and precision brackets. As a full-service CNC machining partner, we integrate laser cutting with milling, bending, and welding under one quality-controlled workflow, ensuring dimensional consistency from prototype to low-volume production.

Accelerate your steel fabrication projects with Honyo’s Online Instant Quote system. Upload CAD files to receive detailed manufacturability feedback and competitive pricing within hours—not days—enabling faster design validation and procurement decisions.

| Material Thickness | Recommended Laser Power | Typical Applications |

|---|---|---|

| 0.5–3mm | 1–2kW | Enclosures, brackets, thin-gauge structural |

| 4–12mm | 3–4kW | Machinery frames, hydraulic components |

| 13–25mm | 5–6kW | Heavy equipment parts, structural supports |

Technical Capabilities

Laser cutting power requirements vary significantly based on material type, thickness, and desired edge quality. While 3/4/5-axis milling and turning are primarily subtractive CNC machining processes—distinct from laser cutting—it is important to clarify that laser cutting is a separate fabrication method often used in conjunction with or as an alternative to milling for certain applications. However, when integrating laser cutting into a precision manufacturing workflow involving tight tolerances (±0.001” to ±0.005”), understanding the appropriate laser power for different materials is critical for achieving clean cuts, minimal heat-affected zones (HAZ), and dimensional accuracy.

Below is a technical reference table outlining typical laser power requirements for cutting common materials used in precision manufacturing environments such as those at Honyo Prototype. These values apply specifically to fiber laser cutting systems, which are standard for metal processing, while CO2 lasers are typically used for non-metallic materials like ABS and nylon.

| Material | Thickness Range (in) | Recommended Laser Power (kW) | Process Type | Notes |

|---|---|---|---|---|

| Mild Steel | 0.25 – 0.50 | 4 – 6 | Fiber Laser | Higher power ensures clean cuts in thick sections; critical for maintaining edge squareness and tight tolerance |

| Stainless Steel | 0.125 – 0.375 | 3 – 5 | Fiber Laser | Requires assist gas (N2 or O2); power affects HAZ and burr formation |

| Aluminum | 0.125 – 0.25 | 4 – 6 | Fiber Laser | Highly reflective; requires high peak power and precise beam control to avoid dross |

| ABS | 0.125 – 0.50 | 1 – 2 (CO2) | CO2 Laser | Lower power sufficient; risk of melting or charring if power too high |

| Nylon | 0.125 – 0.375 | 1.5 – 2.5 (CO2) | CO2 Laser | Material prone to melting; controlled power and speed essential |

Note: Laser cutting does not achieve the same tight tolerances as 3/4/5-axis CNC milling or turning, especially in complex geometries or critical fit applications. For aluminum and steel components requiring ±0.001” tolerances, CNC milling or turning remains the preferred method. Laser-cut parts often require secondary machining to meet tight tolerance specifications.

In hybrid manufacturing workflows, laser cutting is typically used for blanking or rough shaping, followed by high-precision 4 or 5-axis milling to achieve final dimensions, surface finish, and geometric accuracy. Turning is used for cylindrical features in bar stock or pre-cut blanks, particularly in aluminum and steel shafts or housings.

For prototyping and low-volume production at Honyo Prototype, material selection and process pairing (laser + CNC) are optimized to balance speed, cost, and precision.

From CAD to Part: The Process

Honyo Prototype Laser Cutting Process for Steel: Technical Workflow Overview

Honyo Prototype executes precision laser cutting for steel components through a rigorously integrated five-stage workflow, ensuring technical accuracy, manufacturability, and on-time delivery. This process leverages advanced automation while maintaining critical human engineering oversight at key decision points.

Upload CAD

Customers initiate the process by uploading industry-standard CAD files (DXF, DWG, STEP) via our secure client portal. Our system performs an immediate automated validation check for file integrity, unit consistency, and geometric completeness. Invalid submissions trigger real-time feedback specifying required corrections, minimizing client-side delays. All CAD data undergoes encryption and is timestamped for full traceability within our PLM system.

AI-Powered Quoting Engine

Validated CAD files enter our proprietary AI quoting module, which analyzes over 200 parametric variables including material grade, thickness, part complexity, and quantity. The engine cross-references real-time data from our laser cutting fleet (Bystronic, Amada) including current machine utilization, consumable inventory, and historical performance metrics for specific steel alloys. Crucially, the AI calculates localized thermal dynamics to predict heat-affected zones (HAZ) and potential distortion risks for each geometry, generating a technically validated cost and lead time estimate within 90 seconds. This is not a generic pricing model but a physics-based simulation of the actual cutting process.

Engineering-Validated DFM

Every quote triggers mandatory Design for Manufacturability (DFM) review by our senior laser cutting engineers. The AI’s thermal and geometric analysis serves as the baseline, but human experts conduct a tiered assessment:

Verification of kerf compensation values against material thickness (e.g., 0.15mm adjustment for 3mm mild steel)

Critical evaluation of feature density to prevent thermal warping in high-tolerance zones

Confirmation of nesting efficiency within ±2% of theoretical maximum material utilization

Specific steel-grade validation against our operational matrix (see table below)

Clients receive a formal DFM report detailing required modifications, with engineering rationale for each suggestion. Zero client approval is required for standard manufacturability adjustments; only geometry-altering changes necessitate client sign-off.

Material-Specific Laser Cutting Parameters

Table: Standard Steel Laser Cutting Parameter Ranges at Honyo Prototype

| Steel Grade | Thickness Range | Laser Power (kW) | Assist Gas | Max Cut Speed (mm/min) | Critical Process Control |

|---|---|---|---|---|---|

| ASTM A36 | 0.5–15 mm | 1.5–4.0 | Nitrogen | 8,500 (0.5mm) → 950 (15mm) | Kerf taper < 0.05mm |

| AISI 304 SS | 0.8–12 mm | 2.0–5.0 | Oxygen | 6,200 (0.8mm) → 700 (12mm) | HAZ width < 0.2mm |

| AISI 4140 | 1.0–10 mm | 3.0–6.0 | Nitrogen | 4,800 (1.0mm) → 550 (10mm) | Hardness deviation < 5HRC |

| Hot Rolled 1018 | 2.0–20 mm | 4.0–8.0 | Oxygen | 3,100 (2.0mm) → 380 (20mm) | Dross adhesion ≤ 0.1mg/mm² |

Production Execution

Approved jobs enter production with full digital work instructions pushed directly to the assigned laser cell. Our integrated MES system:

Automatically loads optimized cutting paths with dynamic power modulation (e.g., reducing power by 15% when cutting internal corners to minimize recast layer)

Monitors real-time beam quality via in-process spectrometers, triggering automatic calibration if beam parameter product (BPP) exceeds 6.5 mm*mrad

Enforces material traceability through serialized plate tagging, with cut parameters (power, gas pressure, speed) logged for every part

All steel undergoes pre-cut verification of flatness (<0.5mm/m) and surface condition. First-article inspection includes CMM validation of critical features against GD&T callouts before full batch release.

Certified Delivery

Completed parts undergo automated deburring followed by rigorous dimensional and surface quality validation. Each shipment includes:

Material test reports (MTRs) with actual chemical composition and mechanical properties

Process validation certificates documenting laser power curves, gas purity logs, and thermal monitoring data

FAI documentation with deviation analysis against original CAD

Full digital as-built records accessible via client portal for 24 months

Delivery timelines are guaranteed through our dynamic scheduling algorithm, which reserves buffer capacity for urgent steel cutting jobs requiring ≤72-hour turnaround. All shipments meet AS9100 and ISO 9001 traceability requirements, with physical delivery options including climate-controlled logistics for high-precision components.

This closed-loop process ensures steel components achieve specified tolerances (±0.1mm typical for features <200mm) while minimizing non-conformances through predictive analytics and engineering rigor. For mission-critical applications, we provide optional destructive testing packages with metallurgical analysis of cut edges. Contact our applications engineering team to discuss specific steel alloy requirements.

Start Your Project

Looking for reliable laser power solutions for cutting steel? Honyo Prototype delivers precision and efficiency with industrial-grade laser cutting technology, engineered for high-performance metal fabrication. Our manufacturing facility in Shenzhen ensures rapid turnaround and strict quality control for every project.

Contact Susan Leo today at [email protected] to discuss your steel cutting requirements and discover how our advanced laser systems can optimize your production process.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.