Introduction: Navigating the Global Market for laser pipe cutting machine

In the fast-evolving landscape of manufacturing, sourcing a laser pipe cutting machine poses a significant challenge for international B2B buyers. With diverse applications ranging from automotive to furniture production, the demand for precision and efficiency in cutting processes has never been higher. This comprehensive guide is designed to equip decision-makers with essential insights into the various types of laser pipe cutting machines available, their specific applications, and the key factors to consider when selecting a supplier.

Navigating the complexities of the global market can be daunting, especially for businesses in regions such as Africa, South America, the Middle East, and Europe, including emerging markets like Brazil and Vietnam. This guide will cover critical topics such as supplier vetting, cost analysis, and the technological advancements shaping the industry. By providing a structured approach to understanding the intricacies of laser pipe cutting machinery, we aim to empower buyers to make informed purchasing decisions that align with their operational needs and budget constraints.

Whether you’re seeking to enhance production capabilities or explore new manufacturing opportunities, this guide will serve as a valuable resource, offering actionable insights to help you navigate the global market with confidence. As the industry continues to innovate, being well-informed will be your competitive edge in securing the right solutions for your business.

Understanding laser pipe cutting machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 2D Laser Tube Cutting Machines | Designed for flat 2D profiles; efficient for basic cuts. | Automotive, furniture, HVAC, structural components. | Pros: Cost-effective, easy to operate. Cons: Limited to 2D shapes. |

| 3D Laser Tube Cutting Machines | Capable of complex 3D geometries; versatile cutting options. | Aerospace, industrial machinery, custom fabrication. | Pros: High flexibility, intricate designs. Cons: Higher initial investment. |

| Fiber Laser Tube Cutters | Utilizes fiber laser technology; fast and precise cutting. | High-volume production, precision parts manufacturing. | Pros: Speed and efficiency, low maintenance. Cons: More expensive than CO2 options. |

| CO2 Laser Tube Cutting Machines | Suitable for thicker materials; offers smooth finishes. | Heavy-duty industries, metal fabrication, signage. | Pros: Excellent for thicker metals, good cut quality. Cons: Slower than fiber lasers. |

| Combination Laser Cutters | Integrates tube and sheet cutting capabilities in one machine. | Job shops, custom manufacturers, diverse industries. | Pros: Versatile, space-saving. Cons: Complexity in operation, higher cost. |

What Are the Characteristics of 2D Laser Tube Cutting Machines?

2D laser tube cutting machines are primarily designed for cutting flat, two-dimensional profiles. These machines excel in efficiency and are particularly suitable for industries like automotive and furniture manufacturing, where straightforward cuts are required. When considering a purchase, B2B buyers should evaluate the machine’s cutting speed, ease of operation, and overall cost-effectiveness. While they are cost-efficient, their limitation to 2D shapes can be a drawback for companies seeking more complex designs.

How Do 3D Laser Tube Cutting Machines Stand Out?

3D laser tube cutting machines offer the ability to create intricate three-dimensional geometries, making them ideal for sectors like aerospace and industrial machinery. These machines provide versatility in design, allowing for complex part fabrication that traditional methods cannot achieve. Buyers should consider the initial investment and the potential return on investment due to increased production capabilities. While the upfront cost may be higher, the ability to produce detailed components can lead to significant long-term benefits.

What Are the Benefits of Fiber Laser Tube Cutters?

Fiber laser tube cutters employ advanced fiber laser technology, which results in faster cutting speeds and exceptional precision. They are particularly advantageous for high-volume production settings, where efficiency is paramount. Buyers should assess the machine’s maintenance requirements and operational costs, as fiber lasers generally require less maintenance compared to other types. The initial cost may be higher, but the efficiency gains often justify the investment, especially for precision parts manufacturing.

In What Scenarios Are CO2 Laser Tube Cutting Machines Preferred?

CO2 laser tube cutting machines are well-suited for cutting thicker materials and delivering smooth finishes. They are commonly used in heavy-duty industries, metal fabrication, and signage production. When purchasing, B2B buyers should weigh the machine’s cutting speed against its ability to handle various material thicknesses. Although CO2 lasers may be slower than their fiber counterparts, their effectiveness in cutting thicker metals makes them a reliable choice for specific applications.

Why Choose Combination Laser Cutters for Your Operations?

Combination laser cutters provide the dual functionality of cutting both tubes and sheets, making them a versatile solution for job shops and custom manufacturers. These machines save space and can handle a wide range of applications, from simple to complex cuts. Buyers should consider the complexity of operation and the potential for higher costs due to their multifunctionality. However, the ability to switch between cutting types can lead to increased efficiency and adaptability in production processes.

Key Industrial Applications of laser pipe cutting machine

| Industry/Sector | Specific Application of laser pipe cutting machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Cutting exhaust and structural components for vehicles | Enhanced precision and reduced material waste | Compatibility with various materials, automation capabilities |

| Furniture | Creating intricate designs for metal furniture frames | Improved design flexibility and faster production times | Customization options, support for different tube sizes |

| HVAC | Manufacturing ductwork and piping systems | Streamlined production processes and cost savings | Ability to handle large diameters and various wall thicknesses |

| Construction | Fabricating metal frameworks for buildings and infrastructure | Increased efficiency and reduced labor costs | Durability and reliability of the machine under heavy use |

| Aerospace | Cutting components for aircraft and spacecraft | High precision requirements and lightweight structures | Certification for aerospace materials, speed, and accuracy |

How is the laser pipe cutting machine utilized in the automotive sector, and what are the benefits?

In the automotive industry, laser pipe cutting machines are extensively used for producing exhaust systems and structural components. These machines allow for intricate cuts that enhance the performance and aesthetics of vehicle parts. By utilizing laser cutting, manufacturers can achieve high precision while minimizing material waste, which translates into significant cost savings. For international buyers, it’s crucial to consider the machine’s compatibility with various metals, as well as its automation capabilities to keep up with production demands.

What applications exist for laser pipe cutting machines in the furniture industry?

Laser pipe cutting machines are revolutionizing the furniture sector by enabling the creation of complex and unique designs for metal furniture frames. The precision of laser cutting allows designers to experiment with more intricate patterns without worrying about the limitations of traditional cutting methods. This technology not only improves design flexibility but also accelerates production timelines. Buyers should prioritize machines that offer customization options and can accommodate a variety of tube sizes to meet diverse design needs.

How do laser pipe cutting machines streamline HVAC manufacturing processes?

In the HVAC industry, laser pipe cutting machines are essential for producing ductwork and piping systems with exact specifications. The machines facilitate quick and accurate cuts, which streamline production processes and reduce labor costs. Additionally, the ability to handle large diameters and various wall thicknesses allows manufacturers to cater to different project requirements efficiently. International buyers should assess the machine’s capacity and reliability, particularly in high-volume production scenarios.

What role do laser pipe cutting machines play in construction applications?

Within the construction industry, laser pipe cutting machines are pivotal for fabricating metal frameworks used in buildings and infrastructure. The precision cutting capabilities of lasers lead to improved assembly processes and reduced errors, which ultimately enhances project timelines and cost-effectiveness. For buyers in this sector, sourcing machines that demonstrate durability and reliability under heavy usage is essential, especially for projects that demand consistent performance.

How is the aerospace industry benefiting from laser pipe cutting technology?

The aerospace sector utilizes laser pipe cutting machines for the production of lightweight and high-precision components required in aircraft and spacecraft. The advanced capabilities of these machines ensure that parts meet stringent accuracy and weight specifications, which are critical for flight safety and efficiency. Buyers in this industry must consider machines that have certifications for aerospace-grade materials and can deliver the required speed and accuracy to meet rigorous production schedules.

3 Common User Pain Points for ‘laser pipe cutting machine’ & Their Solutions

Scenario 1: Difficulty in Meeting Production Demands with Laser Pipe Cutting Machines

The Problem: In a competitive manufacturing environment, companies often struggle to keep up with fluctuating production demands. A buyer may invest in a laser pipe cutting machine that initially seems capable, but as orders increase, they find that the machine cannot handle the volume or variety of materials required. This bottleneck not only leads to delays but also risks damaging client relationships and losing contracts, which can significantly impact profitability.

The Solution: To effectively address this issue, buyers should conduct a thorough assessment of their production needs before purchasing a laser pipe cutting machine. This includes evaluating the types of materials they typically work with, the range of thicknesses and diameters required, and expected future growth in demand. Selecting a machine with flexible capabilities—such as the ability to handle a wide range of materials and sizes—can mitigate this problem. Buyers should also consider investing in advanced automation options, which can enhance the throughput of the machine. Collaborating with manufacturers that offer robust after-sales support and training can also ensure that operators are well-equipped to maximize the machine’s capabilities, ultimately leading to improved efficiency and productivity.

Scenario 2: High Operational Costs Due to Inefficient Laser Cutting Processes

The Problem: Many companies face the challenge of escalating operational costs associated with laser pipe cutting, particularly when using older, less efficient machines. These costs can arise from excessive energy consumption, high maintenance needs, and wasted materials due to inaccuracies or slow cutting speeds. For businesses operating on tight margins, these inefficiencies can quickly erode profits.

The Solution: To combat high operational costs, businesses should consider upgrading to newer models of laser pipe cutting machines that utilize advanced fiber laser technology. These machines are known for their energy efficiency and faster cutting speeds, which can significantly reduce operational costs. Buyers should also implement regular maintenance schedules to keep machines in optimal condition, thereby avoiding costly breakdowns and repairs. Additionally, investing in software that optimizes cutting paths can help reduce material waste, further decreasing costs. Engaging with suppliers who provide comprehensive training on best practices for machine operation can also enhance efficiency, leading to lower overall expenditures.

Scenario 3: Challenges in Integrating Laser Pipe Cutting Machines into Existing Workflows

The Problem: As companies adopt new technologies, they often encounter difficulties integrating laser pipe cutting machines into their existing workflows. This can include compatibility issues with other equipment, disruptions to established processes, and the need for staff retraining. Such challenges can lead to downtime and reduced productivity, which are detrimental in a fast-paced manufacturing setting.

The Solution: To ensure a smooth integration of laser pipe cutting machines into current workflows, buyers should prioritize purchasing equipment that is designed with compatibility in mind. Before making a purchase, it’s crucial to consult with suppliers about how their machines can integrate with existing systems. Conducting a pilot program can also help identify potential integration issues before full-scale implementation. Furthermore, investing in comprehensive training programs for operators and staff will ease the transition and ensure that everyone is familiar with the new technology. Leveraging the expertise of the machine manufacturer during the installation phase can provide additional insights and troubleshooting, ensuring that the new equipment is utilized effectively from the outset.

Strategic Material Selection Guide for laser pipe cutting machine

What Are the Key Materials for Laser Pipe Cutting Machines?

When selecting materials for laser pipe cutting machines, it is essential to consider the properties and applications of various metals. The most common materials used in these machines include carbon steel, stainless steel, aluminum, and brass. Each material has unique characteristics that influence performance, cost, and suitability for specific applications.

How Does Carbon Steel Perform in Laser Pipe Cutting?

Key Properties: Carbon steel is known for its high strength and durability, making it ideal for structural applications. It has a temperature rating of up to 400°C and exhibits good machinability.

Pros & Cons: One of the main advantages of carbon steel is its cost-effectiveness; it is generally less expensive than other materials. However, it is prone to rust and corrosion, which can limit its use in environments exposed to moisture. Additionally, the manufacturing complexity can be higher due to the need for protective coatings.

Impact on Application: Carbon steel is suitable for applications requiring high strength, such as in construction and automotive industries. However, its susceptibility to corrosion means it may not be ideal for applications involving exposure to harsh chemicals or moisture.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of local standards for carbon steel, such as ASTM A36. Compliance with these standards ensures quality and performance in applications.

What Are the Advantages of Using Stainless Steel?

Key Properties: Stainless steel is highly resistant to corrosion and can withstand temperatures up to 800°C. Its durability makes it suitable for a wide range of applications.

Pros & Cons: The primary advantage of stainless steel is its corrosion resistance, making it ideal for use in industries like food processing and pharmaceuticals. However, it is more expensive than carbon steel and can be more challenging to machine, which can increase manufacturing costs.

Impact on Application: Stainless steel’s compatibility with various media, including corrosive substances, makes it a preferred choice for applications requiring hygiene and durability.

Considerations for International Buyers: Buyers should consider compliance with standards such as ASTM A304 or A316, which are common in Europe and the Middle East. Understanding these specifications is crucial for ensuring product quality and safety.

Why Choose Aluminum for Laser Pipe Cutting?

Key Properties: Aluminum is lightweight yet strong, with a temperature rating of around 600°C. It has excellent corrosion resistance and is highly malleable.

Pros & Cons: The lightweight nature of aluminum makes it easy to handle and transport, providing a significant advantage in applications where weight is a concern. However, it can be more expensive than carbon steel and may not offer the same strength in high-stress applications.

Impact on Application: Aluminum is widely used in the aerospace and automotive industries due to its strength-to-weight ratio. It is also suitable for applications requiring intricate designs due to its malleability.

Considerations for International Buyers: Buyers should be aware of the relevant standards, such as JIS H 4000 in Japan and EN 573 in Europe, to ensure compliance and quality in their applications.

What Are the Benefits of Using Brass?

Key Properties: Brass is an alloy of copper and zinc, known for its excellent machinability and corrosion resistance. It can withstand temperatures up to 300°C.

Pros & Cons: The primary advantage of brass is its aesthetic appeal and resistance to tarnishing, making it suitable for decorative applications. However, it is generally more expensive than carbon steel and has lower strength, which may limit its use in structural applications.

Impact on Application: Brass is commonly used in plumbing and electrical applications due to its conductivity and resistance to corrosion. However, its cost may be a limiting factor for large-scale applications.

Considerations for International Buyers: Compliance with standards such as ASTM B36 and B453 is essential for ensuring quality and performance, especially in regions like Europe and the Middle East.

Summary Table of Material Selection for Laser Pipe Cutting Machines

| Material | Typical Use Case for laser pipe cutting machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural components in construction | Cost-effective and strong | Prone to corrosion | Low |

| Stainless Steel | Food processing and pharmaceutical applications | Excellent corrosion resistance | Higher cost and difficult to machine | High |

| Aluminum | Aerospace and automotive parts | Lightweight and malleable | More expensive and lower strength | Med |

| Brass | Plumbing and decorative applications | Aesthetic appeal and corrosion resistance | Higher cost and lower structural strength | High |

This analysis provides a comprehensive overview of the materials commonly used in laser pipe cutting machines, aiding international B2B buyers in making informed decisions based on their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for laser pipe cutting machine

What are the Main Manufacturing Processes for Laser Pipe Cutting Machines?

The manufacturing of laser pipe cutting machines involves several critical stages that ensure the final product meets the precise specifications and quality standards required by B2B buyers. Understanding these stages can help buyers assess potential suppliers effectively.

Material Preparation: What Materials are Used in Laser Pipe Cutting Machines?

The initial phase of manufacturing involves selecting appropriate materials, typically high-grade steel or aluminum, that can withstand the intense conditions of laser cutting. These materials are sourced from reputable suppliers to ensure consistency and reliability. Once selected, the materials undergo various treatments such as annealing or surface hardening to enhance durability and performance during the cutting process.

What Forming Techniques Are Employed in the Production of Laser Cutting Machines?

After material preparation, the forming stage begins. This includes processes such as bending, stamping, or machining to create components that will house the laser systems. Advanced CNC machinery is often used to ensure high precision during this stage. Additionally, the integration of robotics in forming processes helps improve efficiency and reduce human error, which is crucial for maintaining quality.

How is the Assembly Process Conducted for Laser Pipe Cutting Machines?

The assembly stage is pivotal in ensuring that all components fit together seamlessly. Skilled technicians or engineers typically handle this process, using specialized tools and fixtures. The assembly of laser pipe cutting machines often involves integrating the laser source, optics, and control systems. It is crucial that this stage is executed with precision, as any misalignment can lead to operational inefficiencies or product defects.

What Finishing Techniques Are Used to Enhance the Quality of Laser Pipe Cutting Machines?

Finishing processes are essential for both aesthetic and functional purposes. Common techniques include powder coating, anodizing, or applying protective films to prevent corrosion and wear. These processes not only enhance the machine’s appearance but also extend its lifespan and reliability. Proper finishing ensures that the machine can perform optimally in various environments, which is particularly important for international buyers who may operate in diverse conditions.

What Quality Assurance Measures Are Essential in Laser Pipe Cutting Machine Manufacturing?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for laser pipe cutting machines. It involves a series of checks and standards that ensure the machines meet specific operational and safety criteria.

Which International Standards Should B2B Buyers Look for in Laser Pipe Cutting Machines?

B2B buyers should be aware of several international quality standards when assessing laser pipe cutting machines. ISO 9001 is a widely recognized standard that outlines the requirements for a quality management system. Compliance with ISO 9001 indicates that a manufacturer consistently meets customer and regulatory requirements. Additionally, certifications such as CE mark for European markets and API standards for oil and gas applications are critical, particularly for buyers in Africa, South America, and the Middle East.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are integral to ensuring that each machine is built to specification. The main checkpoints typically include:

- Incoming Quality Control (IQC): At this stage, raw materials and components are inspected for defects and compliance with specifications before they enter the production line.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, operators perform checks to monitor critical parameters and dimensions. This helps identify issues early, reducing waste and rework.

- Final Quality Control (FQC): Once assembly is complete, the entire machine undergoes rigorous testing to ensure it functions as intended. This includes performance tests, safety checks, and calibration procedures.

What Common Testing Methods Are Used to Ensure Quality?

Several testing methods are employed during the QA process. These include:

- Functional Testing: Verifying that the machine operates correctly under specified conditions.

- Laser Beam Quality Testing: Ensuring the laser output meets required specifications for precision cutting.

- Safety Compliance Testing: Checking that the machine adheres to safety standards, minimizing risks to operators.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, verifying the quality control processes of potential suppliers is crucial to mitigate risks associated with purchasing machinery. Here are some strategies:

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting audits is a practical way to assess a supplier’s manufacturing and quality assurance processes. Buyers can:

- Schedule on-site audits to observe the manufacturing processes and quality control systems in action.

- Review the supplier’s quality management system documentation, including ISO certifications and internal audit reports.

- Evaluate the supplier’s history of compliance with international standards and any previous quality issues.

How Can Buyers Utilize Reports and Third-Party Inspections?

Buyers should request detailed quality reports from suppliers, which outline the results of inspections and tests conducted throughout the manufacturing process. Engaging third-party inspection services can provide an unbiased assessment of the machine’s quality, further ensuring that it meets the necessary standards before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing laser pipe cutting machines internationally, particularly from regions like Africa, South America, and the Middle East, buyers should be aware of several nuances:

- Cultural Differences: Understanding local business practices and communication styles can facilitate better negotiations and clearer expectations regarding quality standards.

- Import Regulations: Buyers must familiarize themselves with the import regulations and quality standards of their respective countries to ensure compliance and avoid delays.

- Supply Chain Reliability: Assessing the supplier’s ability to provide consistent quality over time is crucial, as fluctuations in quality can lead to operational disruptions.

By comprehensively understanding the manufacturing processes and quality assurance measures in place, B2B buyers can make informed decisions when selecting suppliers for laser pipe cutting machines, ensuring they receive reliable, high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘laser pipe cutting machine’

This guide aims to provide international B2B buyers with a practical checklist for sourcing a laser pipe cutting machine. As this technology continues to evolve, understanding the nuances of machine specifications, supplier credibility, and operational requirements will help streamline the procurement process and ensure a successful investment.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for selecting the right laser pipe cutting machine. Consider factors such as cutting capacity (length and diameter), material compatibility (steel, aluminum, etc.), and required precision. Be specific about your production needs to ensure that the machine you choose can meet your operational requirements.

Step 2: Research Market Trends and Innovations

Understanding current market trends and technological advancements will help you make an informed decision. Research the latest innovations in laser cutting technology, such as fiber lasers, which offer higher efficiency and faster processing times. Additionally, consider how emerging trends, like automation and integration with CAD/CAM systems, can enhance your production capabilities.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their experience with laser cutting machines and their ability to provide ongoing support, spare parts, and maintenance services.

- Sub-bullet: Look for suppliers with a solid track record in your target market, particularly in Africa, South America, the Middle East, or Europe.

Step 4: Verify Certifications and Compliance

Ensure that potential suppliers comply with international quality standards and certifications, such as ISO 9001. This step is essential for guaranteeing the machine’s reliability and safety. Additionally, check if the machines meet local regulations and standards specific to your region.

Step 5: Request Demonstrations and Samples

Whenever possible, request live demonstrations or samples of the machine’s cutting capabilities. This will provide you with firsthand insight into the machine’s performance, ease of use, and the quality of the finished product. Seeing the machine in action can also help you gauge its suitability for your specific applications.

Step 6: Assess Total Cost of Ownership (TCO)

Consider not just the initial purchase price but also the total cost of ownership over the machine’s lifespan. This includes maintenance costs, energy consumption, and potential downtime. A machine with a lower upfront cost may incur higher operational costs, so calculate the long-term financial implications before making a decision.

Step 7: Negotiate Terms and Conditions

Once you have identified a suitable machine and supplier, negotiate terms and conditions to ensure a fair deal. Discuss warranty periods, service agreements, and payment terms. Make sure to clarify the support and training that will be provided post-purchase, as these factors can significantly affect your operational efficiency.

By following this step-by-step checklist, B2B buyers can effectively navigate the complexities of sourcing a laser pipe cutting machine, ensuring that they select the best option for their business needs.

Comprehensive Cost and Pricing Analysis for laser pipe cutting machine Sourcing

What are the Key Cost Components for Laser Pipe Cutting Machines?

Understanding the cost structure of laser pipe cutting machines is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts the overall cost. High-quality steel and advanced laser technology can increase initial costs but lead to better performance and lower operational costs over time.

-

Labor: Skilled labor is essential for operating and maintaining laser cutting machines. Depending on the region, labor costs can vary widely, affecting the overall pricing structure.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, facility rent, and equipment maintenance. Efficient manufacturing processes can reduce these overhead costs.

-

Tooling: The initial investment in tooling, such as custom fixtures and cutting heads, is critical. High-quality tooling may result in higher upfront costs but can enhance precision and reduce downtime.

-

Quality Control (QC): Implementing rigorous QC measures ensures that machines meet performance and safety standards. While this may add to the cost, it mitigates the risk of defects and ensures customer satisfaction.

-

Logistics: Shipping and handling costs can vary based on the destination, mode of transport, and Incoterms. For international buyers, understanding these logistics costs is essential for accurate budgeting.

-

Margin: Suppliers typically mark up prices to ensure profitability, which can vary based on market competition and demand. Understanding the market landscape helps in negotiating better deals.

How Do Price Influencers Affect Laser Pipe Cutting Machine Costs?

Several factors influence the pricing of laser pipe cutting machines, and being aware of these can help buyers make informed decisions.

-

Volume/MOQ: Purchasing in larger volumes can lead to significant discounts. Suppliers often have Minimum Order Quantities (MOQ) that, if met, can lower per-unit costs.

-

Specifications/Customization: Customized machines tailored to specific applications may incur additional costs. Buyers should weigh the benefits of customization against the increased expenditure.

-

Materials: The quality and type of materials used in manufacturing the machines directly affect the price. Opting for advanced materials can enhance durability but may also raise costs.

-

Quality/Certifications: Machines that meet international quality standards and certifications may be priced higher but offer reliability and performance assurance, critical for competitive industries.

-

Supplier Factors: The supplier’s reputation, experience, and after-sales support can influence pricing. Established suppliers might charge more but often provide better service and warranty options.

-

Incoterms: Understanding Incoterms is vital for international buyers, as they define who is responsible for shipping, insurance, and tariffs. This knowledge helps avoid unexpected costs.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Laser Pipe Cutting Machines?

International B2B buyers can adopt several strategies to enhance cost-efficiency when sourcing laser pipe cutting machines.

-

Negotiation: Engage in negotiations with multiple suppliers to secure the best deal. Leverage competitive quotes to drive down prices without compromising quality.

-

Total Cost of Ownership: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also operational costs, maintenance, and potential downtime. A higher initial investment might lead to lower operational costs and greater long-term savings.

-

Pricing Nuances for International Buyers: Be aware of regional price variations due to economic conditions, shipping costs, and local competition. For instance, prices may differ significantly between suppliers in Europe and those in Africa or South America.

-

Long-Term Partnerships: Establishing long-term relationships with suppliers can lead to better pricing, priority service, and access to exclusive offers, enhancing overall cost-effectiveness.

-

Research and Benchmarking: Conduct thorough research on market prices and trends. Benchmark against similar products to ensure you are not overpaying and to understand the fair market value.

In conclusion, understanding the comprehensive cost structure, price influencers, and effective negotiation strategies can empower B2B buyers to make informed purchasing decisions regarding laser pipe cutting machines. This approach not only facilitates better budgeting but also optimizes the procurement process, ultimately contributing to a more efficient operation.

Alternatives Analysis: Comparing laser pipe cutting machine With Other Solutions

In the competitive landscape of manufacturing and fabrication, businesses continuously seek the most efficient and cost-effective solutions for their operations. This section will explore viable alternatives to laser pipe cutting machines, allowing B2B buyers to make informed decisions tailored to their specific needs.

Comparison Table

| Comparison Aspect | Laser Pipe Cutting Machine | Plasma Cutting Machine | Waterjet Cutting Machine |

|---|---|---|---|

| Performance | High precision; complex shapes | Good for thick materials; less precision | Excellent for various materials; no heat-affected zone |

| Cost | High initial investment; lower operating costs | Lower initial costs; moderate operating costs | Moderate to high initial investment; high operating costs |

| Ease of Implementation | Requires skilled operators; setup can be complex | Easier to set up; less skilled labor needed | Complex setup; requires skilled labor |

| Maintenance | Low maintenance; occasional calibration | Moderate maintenance; consumables need frequent replacement | High maintenance; parts wear out quickly |

| Best Use Case | High-precision applications in automotive and aerospace | Heavy-duty applications in construction and metal fabrication | Diverse applications including food, aerospace, and artistic designs |

What Are the Pros and Cons of Plasma Cutting Machines?

Plasma cutting machines are a popular alternative to laser pipe cutting technology, particularly for thicker materials. They operate by sending a high-voltage electrical arc through a gas that is blown out of a nozzle, creating plasma.

Pros:

– Lower initial investment compared to laser cutting machines.

– Faster cutting speeds, particularly for thicker sections.

– Simpler operation and less need for skilled labor.

Cons:

– Produces a rougher edge finish, which may require additional machining.

– Less precise than laser cutting, making it unsuitable for intricate designs.

How Do Waterjet Cutting Machines Compare?

Waterjet cutting machines use high-pressure water mixed with abrasive materials to cut through various substances, including metals, plastics, and ceramics.

Pros:

– No heat-affected zone, preserving the integrity of heat-sensitive materials.

– Capable of cutting a wide variety of materials, making them versatile.

– Produces smooth edges, reducing the need for secondary finishing.

Cons:

– Higher operating costs due to the use of abrasives and water.

– Slower cutting speeds compared to laser and plasma cutting.

– More complex setup and operation, requiring skilled technicians.

Conclusion: How to Choose the Right Cutting Solution for Your Business Needs

When selecting the appropriate cutting technology, B2B buyers should consider several factors, including the specific applications required, budget constraints, and operational capabilities. Laser pipe cutting machines excel in high-precision and complex designs, making them ideal for industries such as aerospace and automotive. Plasma cutting machines offer cost-effective solutions for heavy-duty applications, while waterjet cutting machines provide versatility across various materials without thermal distortion. By assessing these aspects, businesses can choose the cutting technology that aligns with their operational goals and market demands, ensuring optimal productivity and profitability.

Essential Technical Properties and Trade Terminology for laser pipe cutting machine

What Are the Essential Technical Properties of Laser Pipe Cutting Machines?

When evaluating laser pipe cutting machines, several technical specifications are crucial for ensuring optimal performance and suitability for specific applications. Understanding these properties can aid B2B buyers in making informed purchasing decisions.

1. Material Grade

Laser pipe cutting machines can process various materials, including steel, stainless steel, aluminum, and brass. The material grade determines the machine’s cutting capabilities, including speed and quality. Higher-grade materials may require more powerful lasers and advanced cutting techniques, impacting the overall cost and efficiency of production.

2. Cutting Tolerance

Tolerance refers to the permissible limit of variation in the dimensions of the cut parts. In laser cutting, tolerances can be as tight as ±0.1 mm, enabling precise and intricate designs. High tolerance levels are essential for industries such as automotive and aerospace, where precision is non-negotiable. Poor tolerance can lead to increased waste and rework costs.

3. Maximum Pipe Diameter and Length

The maximum diameter and length of pipes that a laser cutting machine can handle are vital specifications. Machines may accommodate pipes ranging from small diameters (e.g., 0.4 inches) to large ones (e.g., up to 24 inches), and lengths can vary significantly (e.g., up to 60 feet). Understanding these dimensions helps buyers select equipment that fits their production needs and space constraints.

4. Laser Power

The laser power, typically measured in watts (e.g., 1kW to 6kW), directly affects cutting speed and material thickness capability. Higher wattage allows for faster cutting speeds and the ability to work with thicker materials. For businesses aiming for high-volume production, selecting a machine with sufficient laser power is crucial to maintaining efficiency and competitiveness.

5. Cutting Speed

Cutting speed, expressed in meters per minute (m/min), indicates how quickly the machine can cut through materials. Faster cutting speeds can enhance productivity, but they must be balanced against the quality of the cut. Industries with high throughput requirements should prioritize machines that offer a good balance of speed and precision.

What Are the Common Trade Terms Associated with Laser Pipe Cutting Machines?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B landscape. Here are some common terms relevant to laser pipe cutting machines:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of laser cutting machines, buyers may source components from OEMs to ensure compatibility and reliability. Understanding OEM relationships can impact warranty and service considerations.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For laser pipe cutting machines, MOQs can affect purchasing decisions, especially for smaller companies or those testing new products. Buyers should clarify MOQ policies to avoid overcommitting capital.

3. RFQ (Request for Quotation)

An RFQ is a formal document used by buyers to solicit price quotes from suppliers for specific products or services. In the laser cutting industry, an RFQ helps standardize requests and ensures that suppliers provide comparable pricing and terms, facilitating better decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for determining shipping costs, liability, and delivery timelines. For B2B buyers, clarity on Incoterms can prevent misunderstandings and additional costs.

5. Lead Time

Lead time refers to the duration from the placement of an order until the delivery of the product. In laser cutting, longer lead times may indicate a backlog or custom manufacturing requirements. Buyers should consider lead time when planning production schedules to ensure timely delivery of materials.

Understanding these technical properties and trade terms empowers B2B buyers to make strategic decisions regarding laser pipe cutting machines, ultimately enhancing operational efficiency and competitiveness in their respective markets.

Navigating Market Dynamics and Sourcing Trends in the laser pipe cutting machine Sector

What Are the Key Trends and Market Dynamics in the Laser Pipe Cutting Machine Sector?

The laser pipe cutting machine sector is experiencing significant growth driven by advancements in technology, increasing demand for precision manufacturing, and the need for cost-effective production solutions. Globally, industries such as automotive, aerospace, and furniture manufacturing are integrating laser cutting technology to enhance their operational efficiency. For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial.

Emerging trends include the adoption of fiber laser technology, which offers higher efficiency and lower operational costs compared to traditional CO2 lasers. Additionally, automation and smart manufacturing practices are reshaping the sector, allowing for faster production times and reduced labor costs. Machines are increasingly designed for versatility, capable of handling various tube sizes and materials, thus catering to diverse market needs.

Moreover, manufacturers are focusing on developing machines with integrated software solutions that streamline the design-to-production process. This capability is particularly appealing to buyers looking to optimize their supply chains and reduce lead times. As the market evolves, buyers should also be aware of the competitive landscape, with numerous players offering a range of products that can meet specific industry requirements.

How Does Sustainability Influence Sourcing Decisions in the Laser Pipe Cutting Machine Market?

Sustainability is becoming a focal point in the sourcing of laser pipe cutting machines, driven by both regulatory pressures and consumer demand for environmentally friendly practices. The production and operation of laser machines can have significant environmental impacts, including energy consumption and waste generation. Consequently, B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable manufacturing processes.

Ethical sourcing practices are also gaining traction, with companies seeking to ensure that their supply chains are transparent and that materials are sourced responsibly. This includes opting for suppliers that utilize ‘green’ certifications, such as ISO 14001 for environmental management, and those that offer machines built from recyclable or sustainable materials.

Furthermore, many manufacturers are investing in energy-efficient technologies that reduce the carbon footprint of their machines. For international buyers, aligning purchasing decisions with sustainability goals not only enhances brand reputation but can also lead to long-term cost savings through reduced energy consumption and waste management costs.

What is the Historical Context of Laser Pipe Cutting Technology?

The evolution of laser pipe cutting technology dates back to the 1960s when lasers were first introduced in industrial applications. Initially, these machines were costly and primarily used for specialized tasks. However, as technology advanced and manufacturing processes evolved, laser cutting became more accessible and cost-effective.

The introduction of fiber laser technology in the late 2000s marked a significant turning point, offering improved efficiency, speed, and precision. This innovation enabled manufacturers to produce complex geometries and intricate designs with minimal material waste. Over the years, the sector has continued to evolve, with the integration of automation and smart technologies shaping the future landscape of laser pipe cutting machines.

For B2B buyers, understanding this historical context can provide valuable insights into current product offerings and the potential for future innovations in the sector. As the industry progresses, staying informed about technological advancements will be essential for making strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of laser pipe cutting machine

-

How do I choose the right laser pipe cutting machine for my business needs?

Choosing the right laser pipe cutting machine involves assessing your specific production requirements, including the types of materials you will cut, the thickness and diameter of pipes, and the desired cutting speed and precision. Evaluate whether you need a standalone tube cutter or a combined tube and sheet cutter. Additionally, consider the machine’s automation features, ease of operation, and maintenance requirements. Engage with suppliers to discuss your needs and request demonstrations to see the machines in action. -

What are the key features to look for in a laser pipe cutting machine?

Key features to consider include cutting capacity (diameter and length), laser type (fiber or CO2), automation level, and software compatibility for design integration. Look for machines that offer high precision and speed, as well as the ability to handle various materials and thicknesses. Additional features such as bevel cutting capabilities and integrated loading/unloading systems can enhance productivity. Ensure that the machine can be easily maintained and serviced, with access to spare parts and technical support. -

What is the typical lead time for ordering and receiving a laser pipe cutting machine?

The lead time for a laser pipe cutting machine can vary significantly depending on the manufacturer, model, and customization options. Generally, it ranges from a few weeks to several months. If you require custom features or specific configurations, this may extend the delivery timeline. It is advisable to discuss timelines with suppliers upfront and factor in potential delays caused by international shipping or customs clearance, especially when sourcing from overseas. -

How can I vet potential suppliers of laser pipe cutting machines?

To vet suppliers, start by researching their reputation in the industry through customer reviews, testimonials, and case studies. Verify their experience and expertise in manufacturing laser cutting machines, and check if they comply with international quality standards. Request references from previous clients and inquire about their after-sales support and service agreements. Consider visiting their facility if possible, or attending industry trade shows to see their products firsthand. -

What are the minimum order quantities (MOQs) when purchasing a laser pipe cutting machine?

MOQs for laser pipe cutting machines can vary by supplier and model. Typically, for large machinery, the MOQ is one unit, but some suppliers may offer discounts for bulk orders or additional equipment. Discuss your purchasing plans with suppliers to understand their policies on MOQs and whether they can accommodate your needs. Additionally, inquire about the possibility of leasing or financing options if purchasing outright is not feasible for your budget. -

What payment terms should I expect when sourcing a laser pipe cutting machine?

Payment terms can vary widely among suppliers, but common practices include a deposit upfront (typically 30-50%) with the balance due upon delivery or installation. Some suppliers may offer financing options, allowing for installment payments over a specified period. Always clarify the payment methods accepted (e.g., wire transfer, credit card) and ensure that all terms are documented in the purchase agreement to avoid misunderstandings. -

How do I ensure quality assurance when buying a laser pipe cutting machine?

To ensure quality assurance, request detailed product specifications and certifications from the supplier, such as ISO or CE certifications. Ask about the quality control processes they employ during manufacturing and whether they provide warranties or guarantees for their machines. It’s beneficial to see the machine in operation before purchase, if possible, and to inquire about post-purchase support, including training for your staff and access to spare parts. -

What logistics considerations should I keep in mind when importing a laser pipe cutting machine?

When importing a laser pipe cutting machine, consider shipping methods, customs duties, and taxes that may apply. Engage with a logistics provider experienced in handling heavy machinery to ensure proper packaging and transportation. Understand the import regulations in your country, including any necessary permits or inspections. Plan for the installation process and ensure that you have the necessary infrastructure and skilled personnel to set up and operate the machine effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Laser Pipe Cutting Machine Manufacturers & Suppliers List

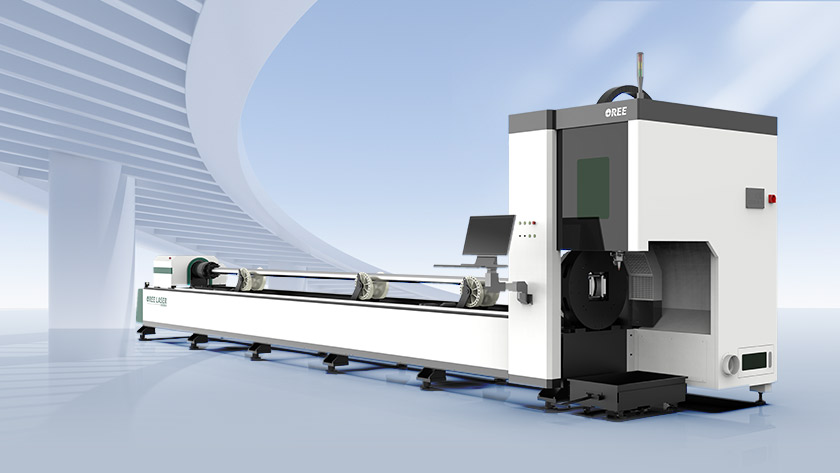

1. Senfeng – Laser Metal Tube Cutter

Domain: senfenglaserusa.com

Registered: 2016 (9 years)

Introduction: Laser Metal Tube Cutter details: 1. Cutting lengths: 19.6 to 39.3 ft 2. Cutting diameters: 0.4 to 22 in 3. Models available: 20′ * φ 0.7″-8.66″ | 1kW-6kW, 20′ * φ 0.6″-8.66″ | 3kW-6kW, 30′ * φ 0.8″-13.77″ | 3kW-6kW, 40′ * φ 7.08″-14.96″ | 4kW-12kW 4. Specific models: SF6035GT (Beveling Tube Laser Cutting Machine), SF1500CH (Large H-shaped Steel Laser Cutting Production Line), ST Series (Three-chuc…

2. BLM Group – Lasertube Systems

Domain: blmgroup.com

Registered: 2000 (25 years)

Introduction: Lasertube systems are 2D and 3D laser cutting systems for tubes, bars, and profiles, with diameters ranging from 12 mm to 610 mm (0.5″ to 24″) and lengths up to 18 m (60′). Key models include: LT5.10 (tubes up to ∅ 4.72″ / 120 mm, 2D cut, fiber laser), LTX (tubes up to ∅ 6″ / 152 mm, 2D cutting mode, fiber laser), LT6 (tubes up to ∅ 6″ / 152 mm, 3D cutting mode, fiber laser), LT7 (tube ∅ range min…

3. BES Cutter – TUBE MASTER 3000W – 4000W Fiber Laser Tube Cutting Machine

Domain: bescutter.com

Registered: 2018 (7 years)

Introduction: {“product_name”: “TUBE MASTER 3000W – 4000W Fiber Laser Tube Cutting Machine”, “price_range”: “17000000 – 20000000”, “laser_generator_options”: [“BC Power 3KW”, “BC Power 4KW”, “IPG 3KW”], “loading_option”: [“No Loader”, “Magazine Style”, “Auto Loader”], “specifications”: {“optional_diameter”: “Ø10mm-Ø120mm (0.39″ – 4.7″)”, “tube_range_length”: “295” (7500 mm)”, “standard_tube_diameter”: “0.78”- 8…

4. STYLECNC – CNC Metal Pipe Laser Cutter

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: CNC Metal Pipe Laser Cutter with Automatic Feeding System

– Brand: STYLECNC

– Model: ST-FC6012K

– Laser Source: MAX, Raycus, IPG

– Power Options: 1500W, 3000W, 6000W

– Price Range: $25,000 – $66,800

– Features:

– Automatic feeder for loading/unloading tubes

– Chuck for rotating pipes

– Cuts round, square, rectangular, flat pipes, flanges, channel beams, U-tubes, and special-shaped metal tub…

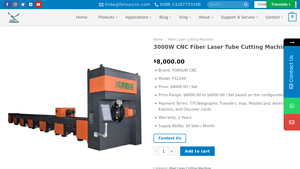

5. FORSUN CNC – 3000W Fiber Laser Tube Cutting Machine

Domain: forsuncnc.com

Registered: 2020 (5 years)

Introduction: Product Name: 3000W CNC Fiber Laser Tube Cutting Machine

Brand: FORSUN CNC

Model: FS1240

Price: $8000.00 / Set

Price Range: $8000.00 to $9000.00 / Set based on configuration

Payment Terms: T/T, Visa, Mastercard, American Express, Discover cards

Warranty: 2 Years (Laser source 1 year)

Supply Ability: 30 Sets / Month

Cutting Range: 0.1-16mm carbon steel, 0.1-6mm stainless steel, 0.1-4mm aluminum, 0….

6. Accurl – Tube Laser Cutting Machine

Domain: accurl.com

Registered: 2012 (13 years)

Introduction: Tube Laser Cutting Machine – High-quality tube cutting. Features automatic loading and unloading.

Strategic Sourcing Conclusion and Outlook for laser pipe cutting machine

In conclusion, the strategic sourcing of laser pipe cutting machines presents significant advantages for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. By investing in advanced laser cutting technology, companies can enhance operational efficiency, reduce production costs, and streamline their manufacturing processes. The ability to cut various materials with precision not only improves product quality but also opens avenues for innovation in design and application.

As global industries increasingly adopt laser technology, suppliers are offering diverse models tailored to specific needs, including automated systems that address labor shortages and maximize productivity. Understanding the technical specifications and capabilities of these machines is crucial for making informed purchasing decisions that align with your business objectives.

Looking ahead, the demand for laser pipe cutting machines is expected to grow, driven by trends in automation and customization across sectors such as automotive, aerospace, and construction. As a proactive buyer, consider evaluating your current capabilities and exploring partnerships with reputable manufacturers. Embrace this opportunity to position your business at the forefront of technological advancement and gain a competitive edge in the marketplace.