Contents

Manufacturing Insight: Laser Milling

Precision Laser Micromachining and CNC Machining Services at Honyo Prototype

At Honyo Prototype, we specialize in advanced subtractive manufacturing processes engineered for the most demanding precision applications. While the term “laser milling” is occasionally used colloquially, it is critical to distinguish true laser ablation—where focused photonic energy vaporizes material at micron-scale resolutions—from traditional mechanical CNC milling. Honyo integrates both methodologies under one roof, delivering unmatched versatility for prototyping and low-volume production. Our multi-axis CNC machining centers achieve tolerances down to ±0.0002″ in metals, engineering plastics, and composites, while our pulsed fiber laser systems enable non-contact micro-structuring of hard-to-machine materials like ceramics, carbides, and thin-film coatings without mechanical stress or tooling costs.

This dual-process capability ensures optimal solution selection for your project’s unique requirements. CNC machining remains ideal for high-speed bulk material removal and complex 3D geometries in production volumes, whereas laser ablation excels in creating micro-channels, surface textures, or fragile component features where mechanical force would compromise integrity. Both services are backed by our rigorous AS9100-certified quality system, ensuring repeatability and traceability from prototype to pilot run.

Accelerate your development timeline with Honyo’s Online Instant Quote platform. Upload your CAD file, specify materials and finish requirements, and receive a detailed manufacturability analysis with pricing in under 60 seconds—no sales calls required. This seamless integration of engineering expertise and digital efficiency allows you to iterate faster while maintaining the precision standards demanded by aerospace, medical device, and semiconductor industries.

Material and Process Capabilities Overview

| Process Type | Tolerance Range | Max Work Envelope | Key Material Applications | Lead Time (Prototype) |

|---|---|---|---|---|

| CNC Milling/Turning | ±0.0002″ (±5 µm) | 24″ x 18″ x 12″ | Titanium, Inconel, PEEK, Aluminum | 3-5 business days |

| Laser Ablation | ±0.00004″ (±1 µm) | 10″ x 10″ x 4″ | Alumina, Silicon, Sapphire, Gold | 2-4 business days |

Leverage Honyo Prototype’s combined laser and CNC machining expertise to solve your most complex micro-manufacturing challenges—with speed, accuracy, and engineering rigor that drives your innovation forward. Initiate your project instantly at honyoprototype.com/quote.

Technical Capabilities

Laser milling is not a conventional machining process and may be confused with laser ablation, laser engraving, or laser cutting. However, in advanced manufacturing contexts, “laser milling” typically refers to a non-contact material removal technique using high-intensity laser pulses to ablate material with precision. It is not equivalent to traditional 3/4/5-axis CNC milling or turning, which are mechanical processes involving rotating cutting tools.

For clarity and technical accuracy, the following table compares traditional CNC milling (3/4/5-axis) and CNC turning—processes commonly associated with tight-tolerance machining of materials like Aluminum, Steel, ABS, and Nylon—with key specifications. Laser-based processes are noted separately where applicable.

| Parameter | 3/4/5-Axis CNC Milling | CNC Turning | Laser Milling (Ablation) |

|---|---|---|---|

| Process Type | Mechanical cutting with rotating end mills | Rotational cutting of cylindrical parts | Non-contact thermal ablation using pulsed lasers |

| Axes of Motion | 3-axis (X, Y, Z); 4-axis (+A or B); 5-axis (X, Y, Z, A, B/C) | Typically 2-axis (X, Z); multi-axis variants available | Typically 2D or 3D galvo-scanned (X, Y, Z via stage or optics) |

| Tight Tolerance Capability | ±0.005 mm (±0.0002″) typical; up to ±0.001 mm with precision systems | ±0.01 mm (±0.0004″) typical; tighter with finishing | ±0.025 mm (±0.001″) typical; highly dependent on material and laser focus |

| Surface Finish (Typical) | 0.8 – 3.2 μm Ra (machined); <0.4 μm Ra (polished) | 0.4 – 1.6 μm Ra | 3.2 – 12.5 μm Ra (as-ablated); may require post-processing |

| Materials – Aluminum | Excellent machinability; high-speed cutting | Excellent; common for shafts, housings | Possible but limited; risk of melting, recast layer |

| Materials – Steel | Good; varies by alloy (e.g., 4140, 17-4PH) | Excellent; widely used in precision shafts | Challenging; requires high-power lasers; slow removal rate |

| Materials – ABS | Good; low melting point requires cooling | Usable for prototypes | Feasible; high removal rate but risk of charring |

| Materials – Nylon | Moderate; prone to deformation without fixturing | Usable; requires sharp tools | Limited; absorbs moisture, inconsistent ablation |

| Material Removal Rate | High (cm³/min) | High (for cylindrical geometries) | Very low (mm³/min) |

| Typical Applications | Complex geometries, molds, aerospace components | Shafts, pins, rotational parts | Micro-features, surface texturing, thin-film removal |

| Setup Complexity | High (especially 5-axis); requires skilled programming | Moderate to high for multi-tasking lathes | Moderate; requires beam path calibration and fixturing |

| Tool Wear | Yes (end mills, inserts) | Yes (cutting inserts) | No mechanical wear; optical degradation possible |

Notes:

CNC Milling and Turning are standard for achieving tight tolerances in production and prototyping environments, particularly for metals and engineering plastics.

Laser milling (ablation) is niche and used when mechanical contact is undesirable or for micro-scale features. It does not replace multi-axis milling for structural or high-precision mechanical components.

For materials like Aluminum and Steel, CNC processes remain superior in dimensional accuracy, surface quality, and throughput.

ABS and Nylon are more commonly machined using CNC methods; laser ablation risks thermal damage and inconsistent edge quality.

Honyo Prototype utilizes advanced 5-axis CNC milling and precision turning for tight-tolerance components in Aluminum, Steel, ABS, and Nylon, ensuring repeatability and conformance to ISO 2768 or customer-specific GD&T requirements. Laser-based processes are selectively applied for marking or surface modification, not primary material removal.

From CAD to Part: The Process

Honyo Prototype Laser Milling Process Overview

Honyo Prototype employs a streamlined, technology-driven workflow for laser milling services, designed to ensure precision, efficiency, and seamless client collaboration from initial design to final delivery. Our process eliminates traditional bottlenecks while maintaining rigorous quality standards for rapid prototyping and low-volume production.

CAD Upload and Initial Processing

Clients initiate the process by uploading native CAD files (STEP, IGES, or native formats like SOLIDWORKS) via our secure online portal. Our system automatically performs initial geometry validation, checking for file integrity, unit consistency, and basic manufacturability flags. This step ensures the design aligns with laser milling capabilities before advancing to quoting.

AI-Powered Quoting Engine

Uploaded designs are processed through our proprietary AI quoting system, which analyzes geometric complexity, material selection, feature density, and tolerance requirements. The AI cross-references real-time data on machine availability, material costs, and historical production metrics to generate an instant, accurate quote within minutes. For highly complex geometries or non-standard materials, a senior engineer conducts manual validation to refine the estimate, ensuring transparency and eliminating quote inaccuracies common in purely automated systems.

Engineering-Led DFM Analysis

Every project undergoes mandatory Design for Manufacturability (DFM) review by our in-house manufacturing engineering team. This phase focuses on optimizing the design for laser milling constraints, including:

Verifying minimum feature sizes and aspect ratios against material properties

Assessing thermal management strategies to prevent warpage in thin-walled features

Recommending adjustments to kerf widths, corner radii, or nesting efficiency

Identifying opportunities to reduce cycle time without compromising accuracy

Clients receive a detailed DFM report with actionable feedback and alternative solutions. Approval of the DFM report is required before production commences, ensuring alignment on feasibility and cost.

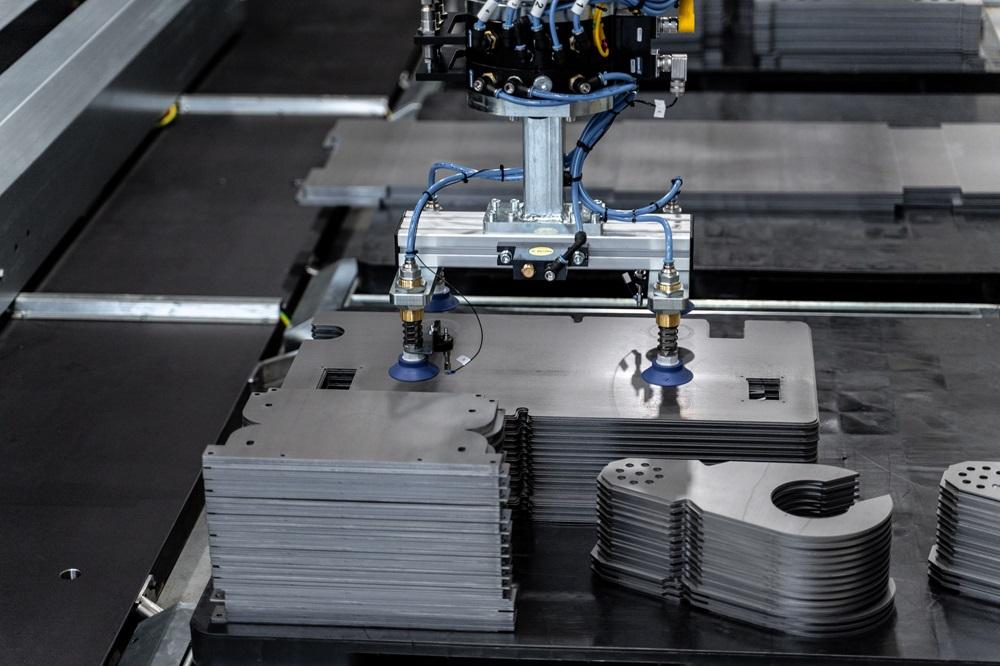

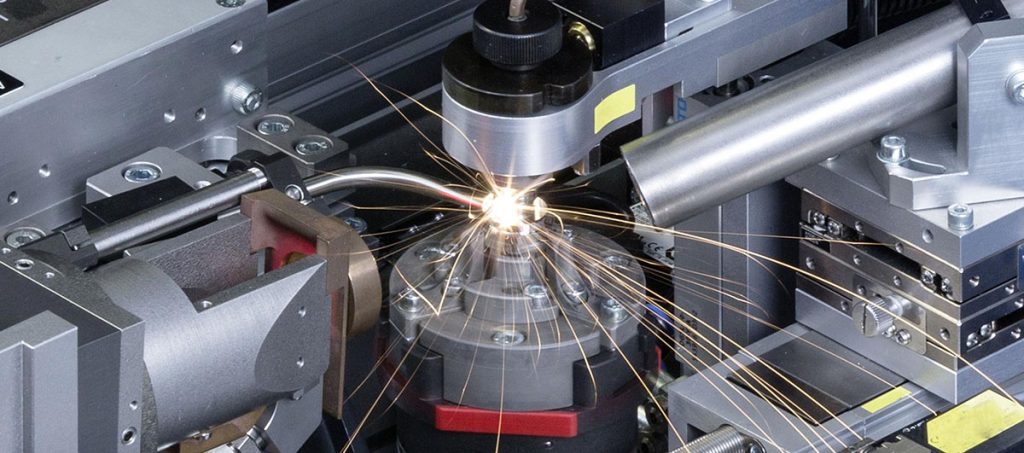

Precision Production Execution

Approved designs move to our laser milling production floor, utilizing state-of-the-art fiber and CO₂ laser systems with 5-axis capabilities. Key production protocols include:

Material verification against certified mill test reports

In-process metrology with non-contact laser scanners for critical dimensions

Real-time power and focus calibration to maintain ±0.025 mm tolerances

Environmental controls to minimize thermal drift during extended runs

Our closed-loop monitoring system logs all process parameters, enabling full traceability and rapid root-cause analysis if deviations occur.

Quality-Controlled Delivery

All parts undergo final inspection per AS9102 or client-specified standards, including first-article inspection reports (FAIR) with dimensional data. Components are packaged with anti-static and moisture protection, accompanied by material certifications and process documentation. Standard lead time is 3–7 business days from DFM approval, with expedited options available. Real-time shipment tracking is provided via the client portal, ensuring end-to-end visibility.

Material and Tolerance Capabilities

The following table summarizes key performance metrics for our laser milling process:

| Material Category | Thickness Range | Typical Tolerance | Max Feature Complexity |

|---|---|---|---|

| Metals (Stainless, Aluminum, Titanium) | 0.1–6.0 mm | ±0.025 mm | High (micro-features <0.1 mm) |

| Polymers (PEEK, Polycarbonate) | 0.2–10.0 mm | ±0.05 mm | Medium-High |

| Ceramics (Alumina, Zirconia) | 0.3–4.0 mm | ±0.03 mm | Medium |

This integrated approach ensures Honyo Prototype delivers laser-milled components with exceptional precision while minimizing time-to-part. Our emphasis on proactive DFM collaboration and data-driven production reduces iteration cycles by up to 40% compared to conventional prototyping vendors, establishing a reliable partnership for engineering teams requiring high-fidelity functional prototypes.

Start Your Project

Interested in high-precision laser milling for your next project? Contact Susan Leo at [email protected] to discuss your requirements. Our advanced manufacturing facility is located in Shenzhen, ensuring fast turnaround and strict quality control for prototypes and low-volume production.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.